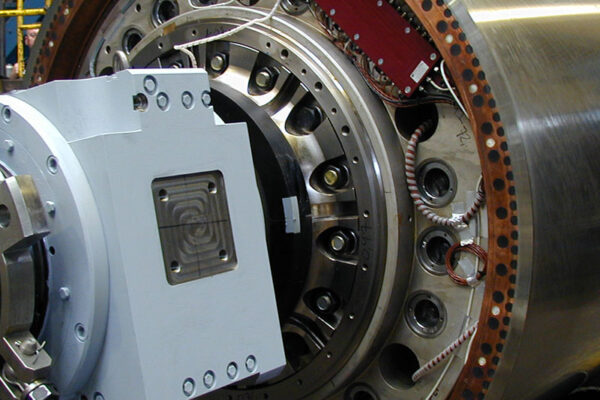

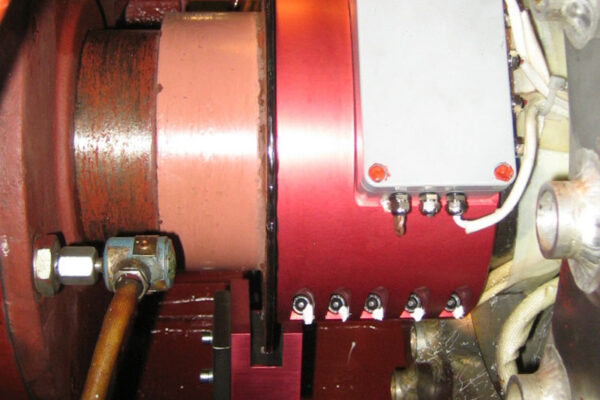

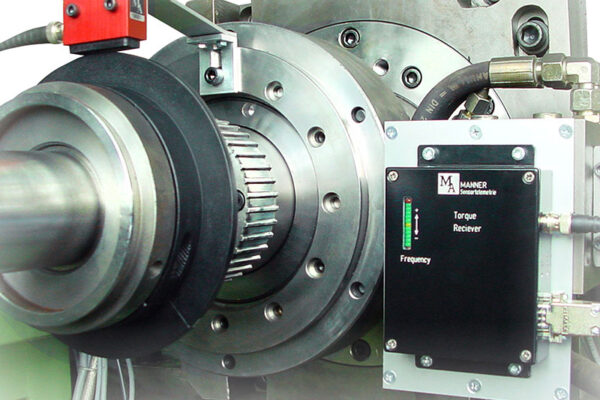

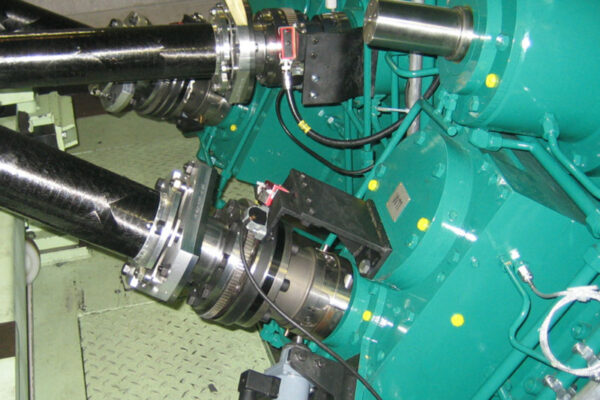

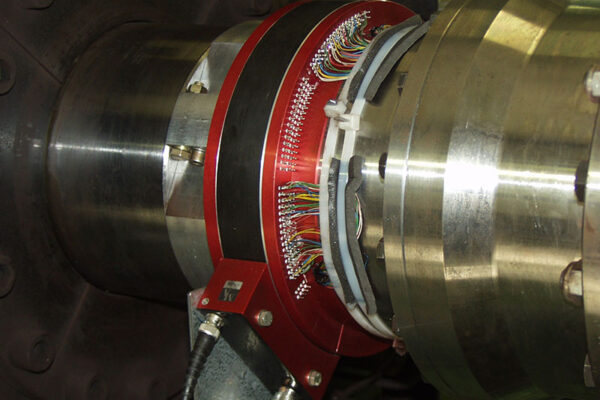

Mechanical and plant engineering is considered one of the leading export and innovation sectors in Germany. It is not surprising that measurement technology plays a particularly important role here. For several years we have been accompanying leading machine manufacturers on their way from the test field to series production. In this way, we support our customers worldwide in measuring torques, speeds, efficiencies, temperatures as well as compressive, tensile and bending forces.

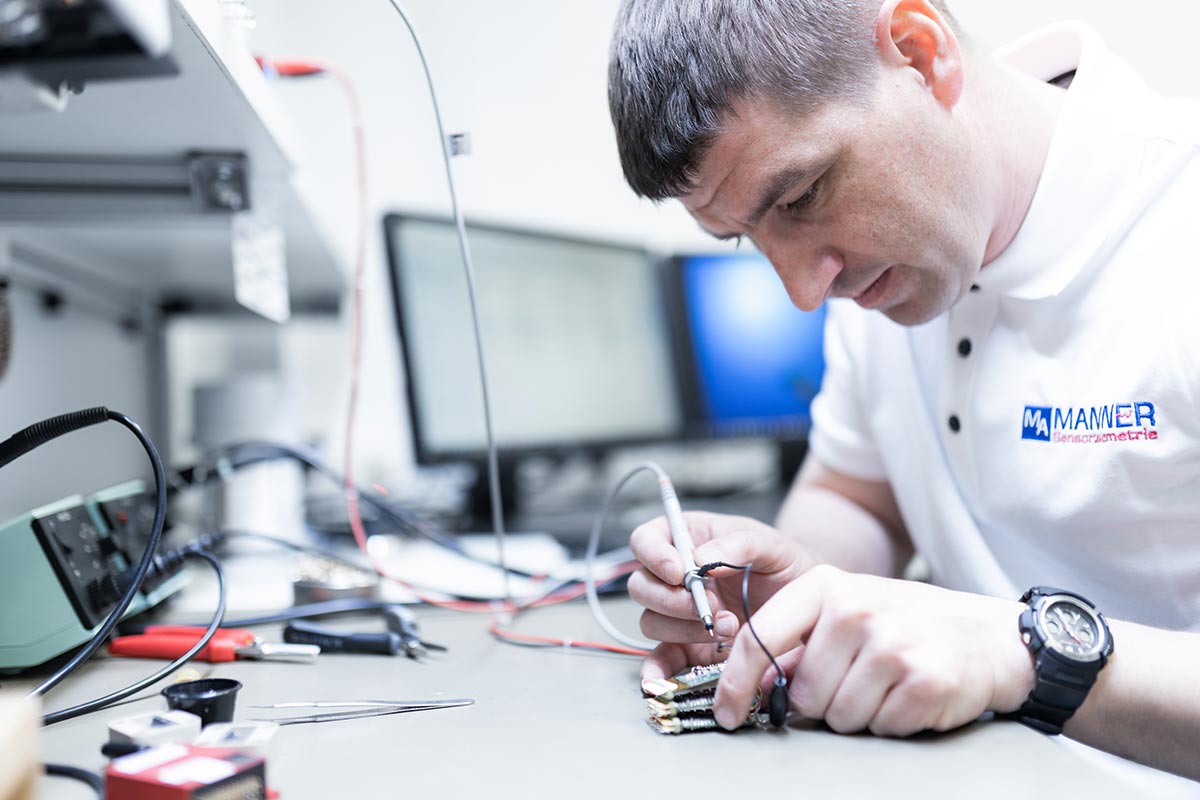

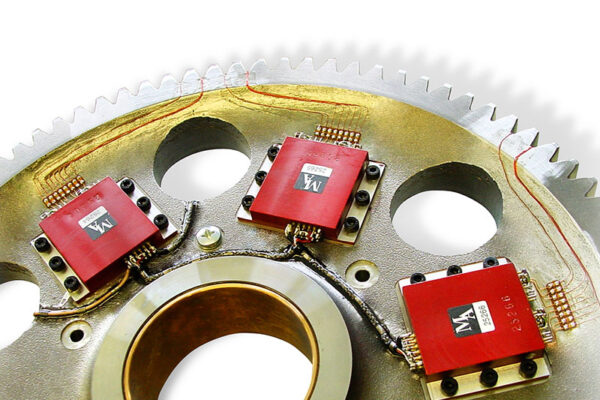

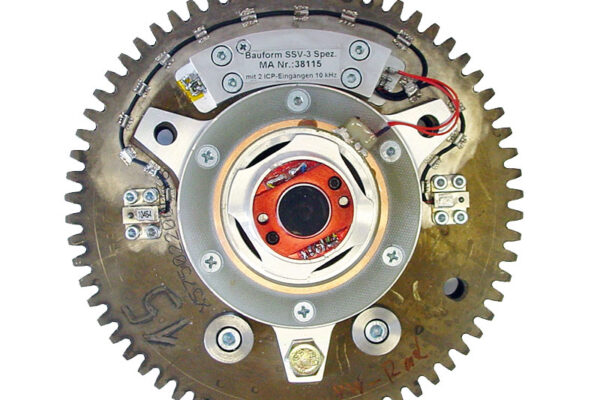

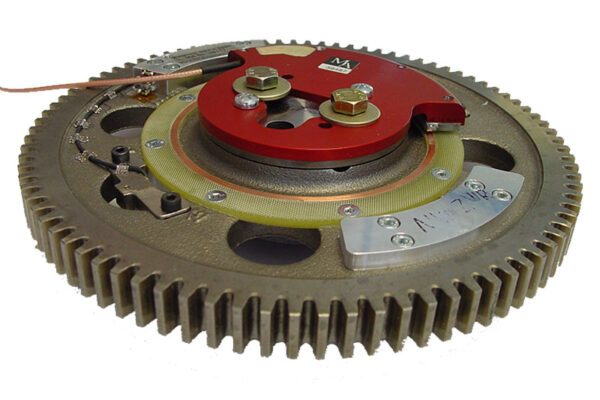

The requirements of today’s machine designs are high, and this naturally also applies to their measurement applications. Not least because of the untiring commitment of our energetic and hard-working design team, which constantly strives for space-saving and maintenance-free assembly, we are able to meet the immense demands.