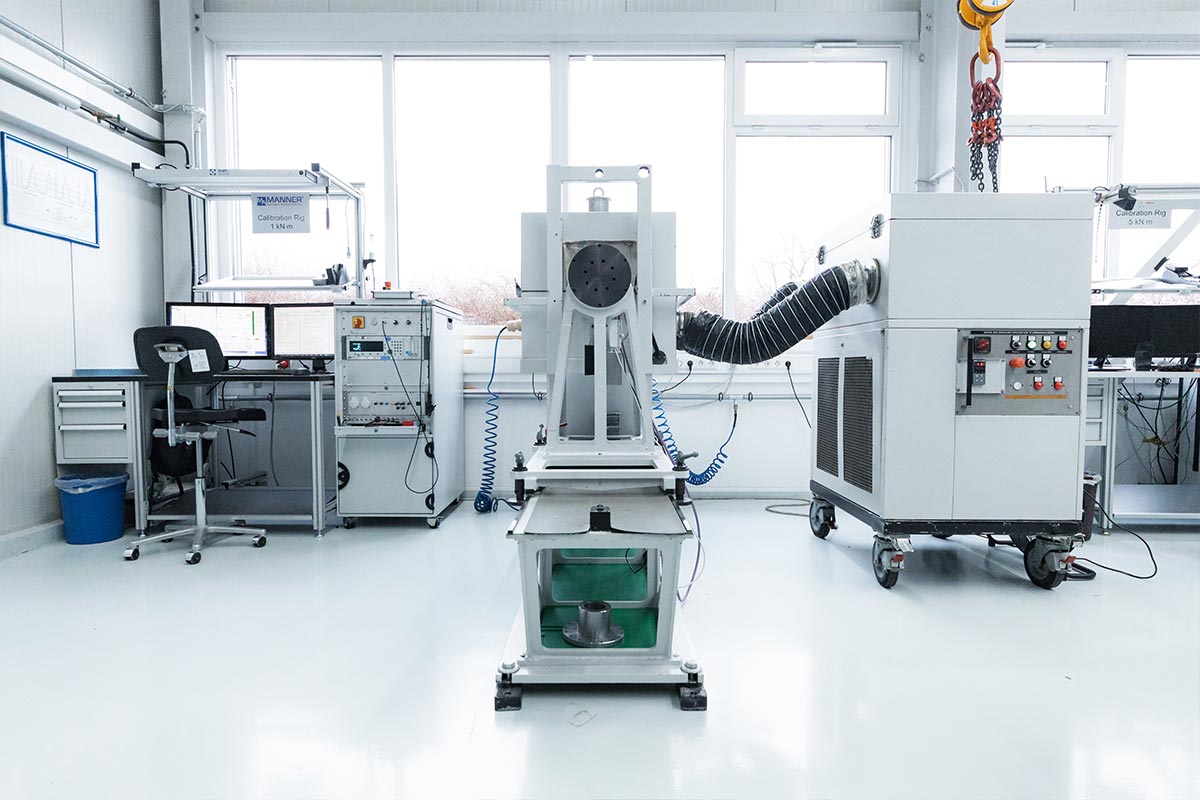

MANNER Sensortelemetrie has established a state-of-the-art calibration laboratory that offers a wide range of torque calibrations. The calibration laboratory is accredited according to DIN EN ISO/IEC 17025:2018 and offers DAkkS calibrations according to DIN 51309 and factory calibrations based on DIN EN ISO 10012. This is the logical step in the expansion of the torque division.

From miniature transducers to 500 kN·m ship flanges, all customer requirements can be covered directly at the company headquarters. A crane runway with a load capacity of up to 4 tons enables professional and efficient handling of large transducers.

Due to increasing regulations for climate protection and the problem of the diesel gate, more and more accurate and traceable calibrations of measuring sensors are required.