Pipe Static Mixers used in the Desalination Process

With the growing demand for water, desalination is seen as one of the answers to meet the shortage of water. The desalination process includes chemical dosing as part of the pre and post treatment processes. Static mixers play an important part in ensuring thorough mixing of these chemicals and Statiflo has an extensive list of references in this industry having supplied Static Mixers to some of the world’s largest desalination plants.

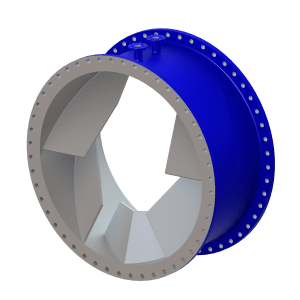

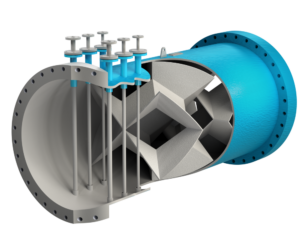

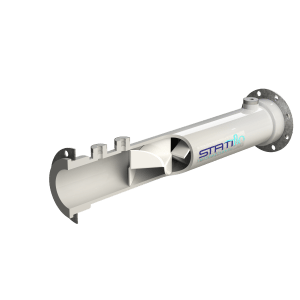

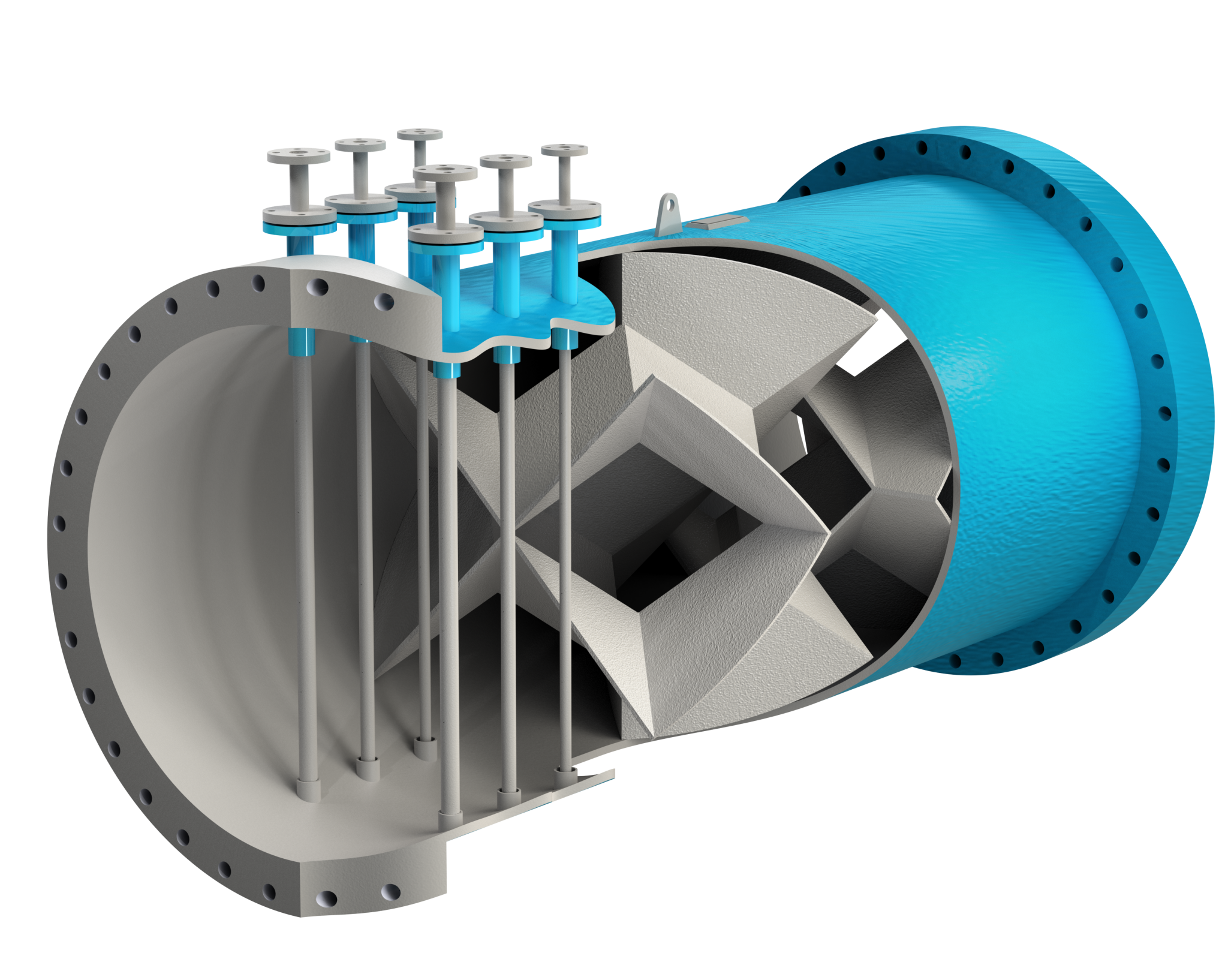

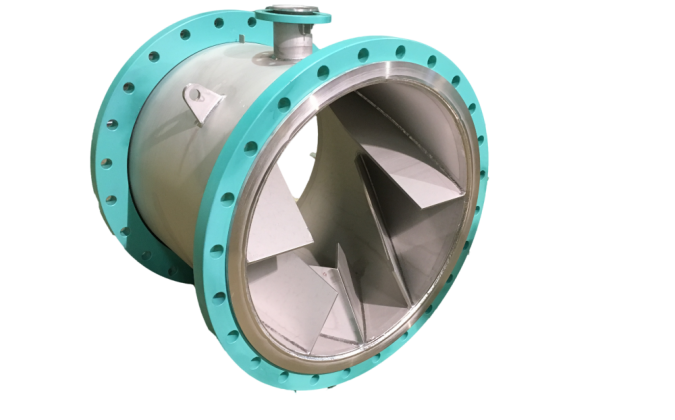

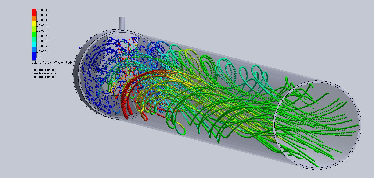

Along with our world-renowned ‘classic’ static mixing element designs, Statiflo have used the latest design and modelling techniques to develop the short-length DesalMixer for turbulent flow dosing and blending applications in the pretreatment and post treatment stages of water treatment in the desalination process.

- No moving parts, no spare parts, virtually zero maintenance

- Very low energy consumption, often 90% less than dynamic mixers

- Low head loss, Can be designed for both gravity and pumped systems.

- Predictable mixing. Chemical savings possible

- Eliminates tanks and dynamic mixers

- No electrical connections.

- Extremely compact design, installation is simple and quick

- Improves sampling and measurement control

- Low Capital cost

- Self cleaning

Like all of our mixer designs, the Statiflo DesalMixer has been independently wet tested for pressure drop and mixing quality (measured by coefficient of variation – CoV) by the BHR group who are world leaders in fluid engineering, research and consultancy. In accordance with Statiflo’s design policy the unit has been tested at industry realistic velocities and additive ratios. The DesalMixer has consistently demonstrated its ability to exceed mixing industry standards.

Below you can find some breif details of applications which we have supplied static mixers for but to find out more about your application, contact us today.

Application Examples and Case Studies

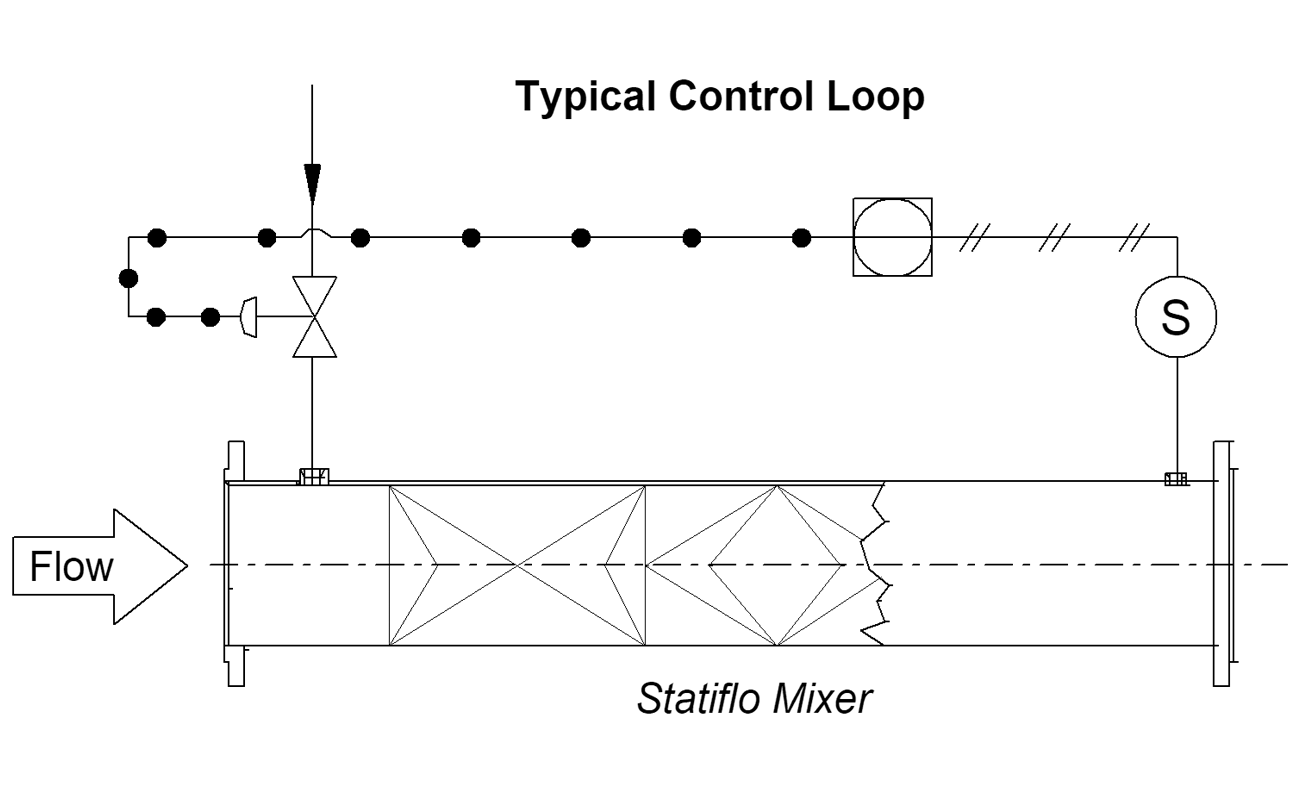

The Statiflo Motionless Mixer is a vital component of any inline mixing/control system. Even the most sophisticated control systems will not perform completely effectively if the measuring equipment fails to see a representative sample. Process control systems are usually very expensive, and despite the mixer being only a small fraction of the total cost, its role as an essential component, vital to plant performance, is often overlooked.

Installing a Statiflo Motionless Mixer allows sampling immediately downstream within very few diameters of the injection point. This allows the system to rapidly adjust to monitored process changes with negligible time lag and minimum use of dosing chemicals.

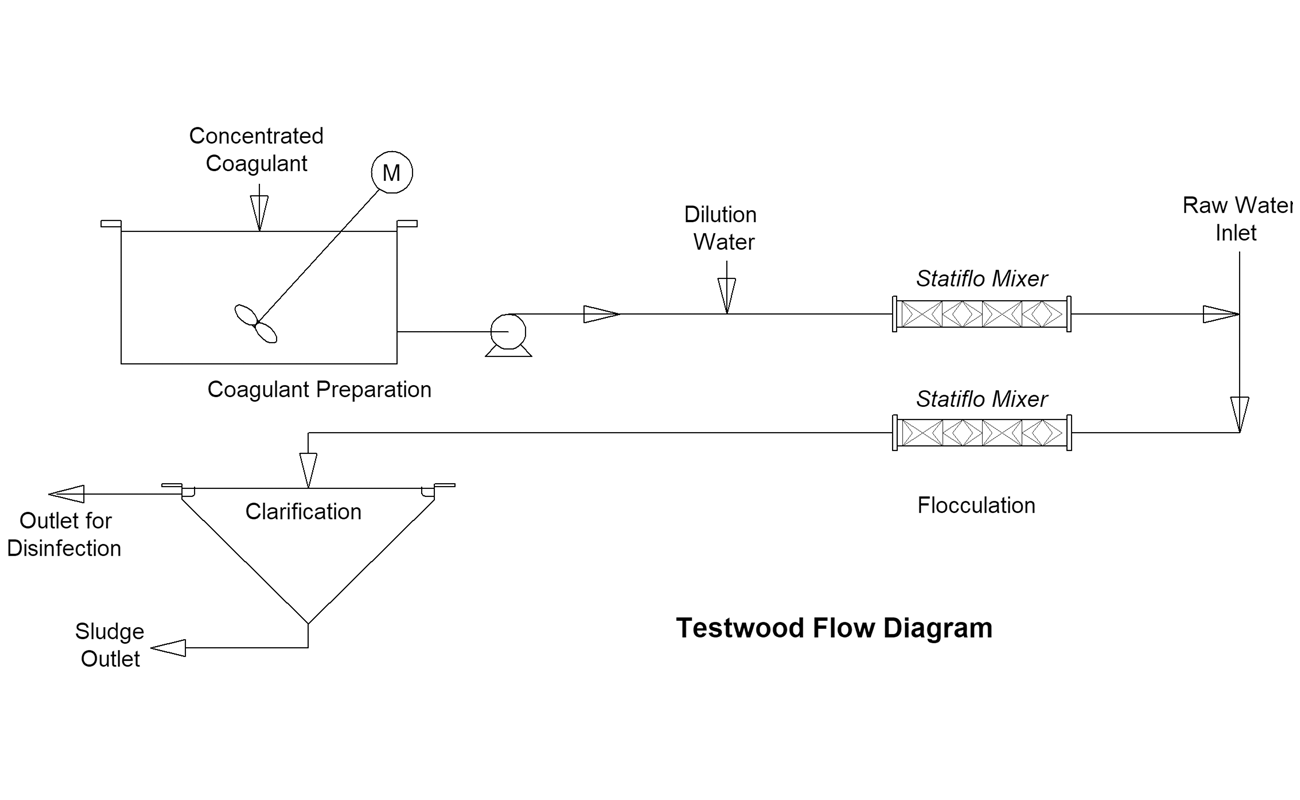

Raw sea water is first course filtered and then treated with coagulant/floculant before secondary fine filtration. The coagulation stage has a vital role to ensure efficient performance of the fine filtration equipment, particularly during periods of algal bloom. Inadequate coagulation can result in:-

Rapid build-up of sand filter pressure drop

Excessive sand filter backwash

Premature blocking of cartridge filters

Algae breakthrough from the fine filters to the membrane section.

Statiflo motionless mixers are frequently used in the coagulation process to avoid these problems. Initially, the mixer distributes injected coagulant into the water stream using a gentle low shear rolling action, promoting floc growth and re-contacting. This mechanism does not rely on relatively high shear rates, commonly associated with agitators, which would increase the risk of floc degradation.

Complete and predictable mixing avoids the need to overdose. Not only are chemical savings possible, but the intact polyelectrolyte molecules have maximum effect on the floc growth and improved filtration rates.

A retrofit Statiflo Motionless Mixer was installed on Jeddah ll SWRO plant were it was reported to have transformed the coagulation/Flocculation process, vastly improving plant performance and capacity.

In areas where salt concentration are particularly high, membrane efficiency is improved by diluting fresh feed with recycled desalinated water. Desalination can then process at lower osmotic pressure, which has the knock on effect of reducing the design pressure of the complete system.

The use of Statiflo Motionless mixers ensure complete blending to allow high efficiency membrane performance.

It is often necessary to adjust the pH before chlorination to maximise the effectiveness of disinfection. There are several common applications.:-

The first is the continuous dilution of concentrated sulphuric acid or sodium hydroxide to manageable levels. The Statiflo Series 300 Mixer has all wetted parts in PTFE construction to withstand corrosion and heat dilution.

The diluted pH correcting chemicals are then dosed upstream of larger Statiflo Series 500/550 or DSM Motionless Mixers, usually in GRP construction, to uniformly mix throughout the treated water prior to representative sampling of the pH.

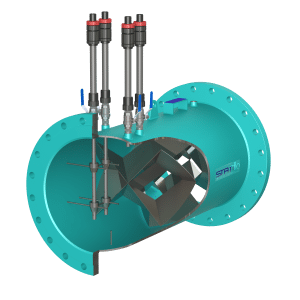

Systems can be incorporated with pH probes, controllers and microprocessors for effective automatic control with both feedback and feed forward control loops.

Representative sampling is vital to ensure effective control and to minimize the risk of under and over chlorination, especially at plant start up and low flow conditions. Statiflo Motionless Mixers can be provided with both injectors and sampling points as integral parts of the equipment, for short time lag and rapid response to system changes.

Desalinated water produced in both SWRO and MSF processes has low soluble carbonate salt levels and is recarbonated before distribution. Two methods are available:-

Primary recarbonation involves the injection of large volumes of carbon dioxide gas into water to raise its pH and ensure that adequate levels of carbonate concentrations are maintained. The Industry has traditionally used large diameter contact towers, but more recently Statiflo Motionless Mixers have been adopted to provide a cost effective inline method of mass transfer. This approach ensure rapid dispersion of of gas and very efficient mass transfer the Statiflo Gas Dispersion System offers extremely high efficiencies where water flow rates vary.

Secondary recarbonation, in the final treatment stages, involves dosing saturated lime solution or milk of lime suspension into the desalinated water to simultaneously increase pH and carbonate concentration before consumption. This process is referred to as ‘potabilisation’, particularly on MSF plants. Lime solution/suspension is injected at the inlet of a Statiflo Motionless Mixer for complete mixing for the pH and recarbonation reactions. Under some circumstances, chlorine is also injected at this location.

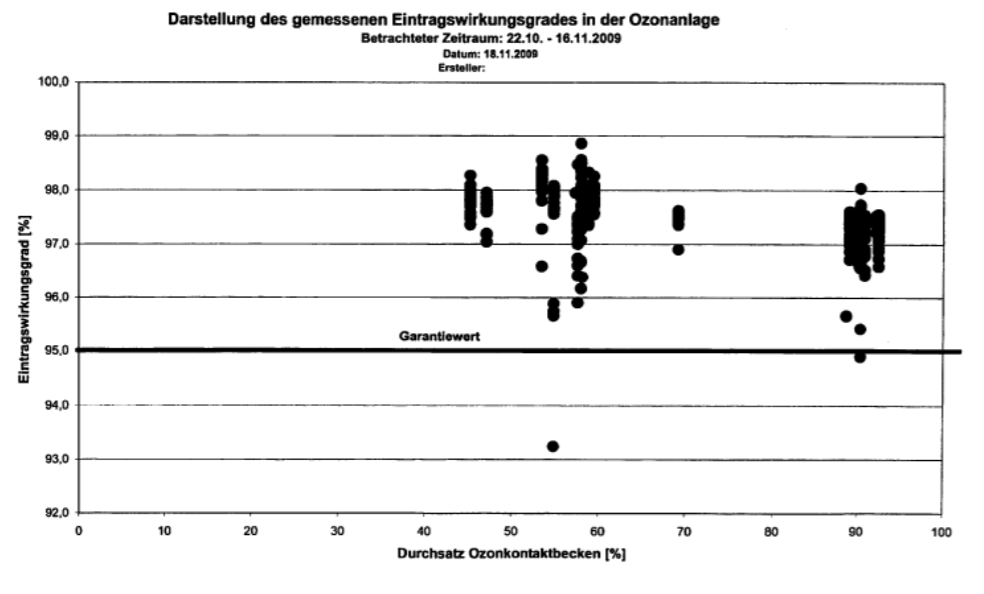

Gas dispersion system for the ozonation of drinking water

Gas Dispersion System: The inline dispersion of a gas in a large volume of liquid very often requires relatively expensive equipment. A classic example is the ozonation of drinking water.…

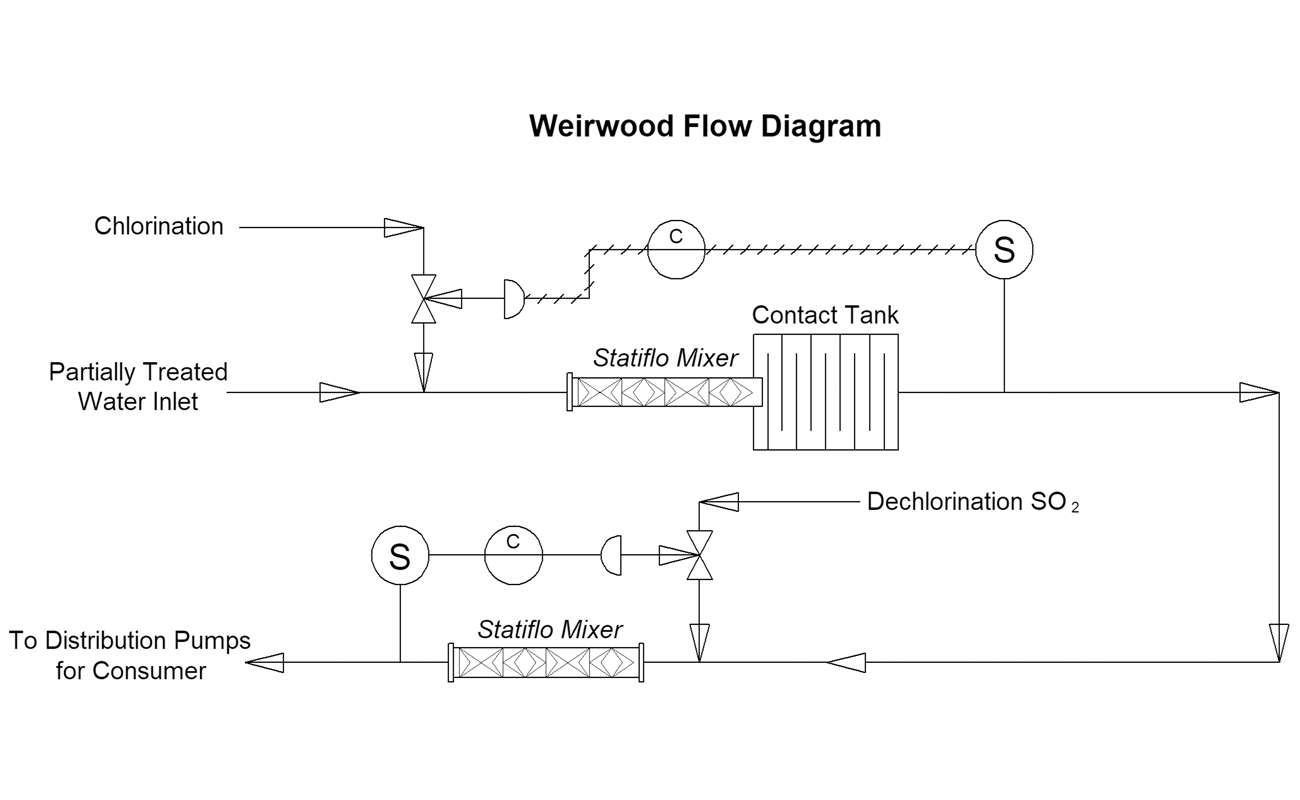

Dechlorination & pH Trim

Problem Dechlorination & pH Trim: Public water treatment plant required highly effective control to dechlorinate and pH trim in difficult access situation. Southern Water’s Weirwood Treatment Works supplies direct to…

Disinfection of Drinking Water

Problem Effective disinfection of drinking water supplies is essential for safe operation. Relying on natural turbulence alone in a pipeline will not guarantee complete mixing of injected sidestream at all…

Replacing Inefficient Dynamic Mixer

Problem As part of their policy of constant improvement and updating, Southern Water had identified that an opportunity existed to improve consistency of performance, energy consumption and maintenance costs at…

Related Products

Compact Static Mixers

A range of Inline Compact (sometimes called Wafer-Style) Static Mixers originally developed to meet the special requirements of the global…

GRP/FRP Static Mixer (Series 500/550)

Corrosion resistant GRP/FRP, large diameter (+250mm) mixers with fixed elements for corrosive applications in the water, wastewater, desalination and pulp…

Plastic Static Mixer (Series 400)

Statiflo Series 400 Pipe Mixers: Plastic construction for cost effective general purpose and corrosion resistant duties. (Sometimes known as a…

Water Treatment Static Mixer (Series 600/650)

Statiflo Inline Static Mixers suitable for the water and wastewater treatment industries supplied with fixed mixing elements. Flanged or plain…