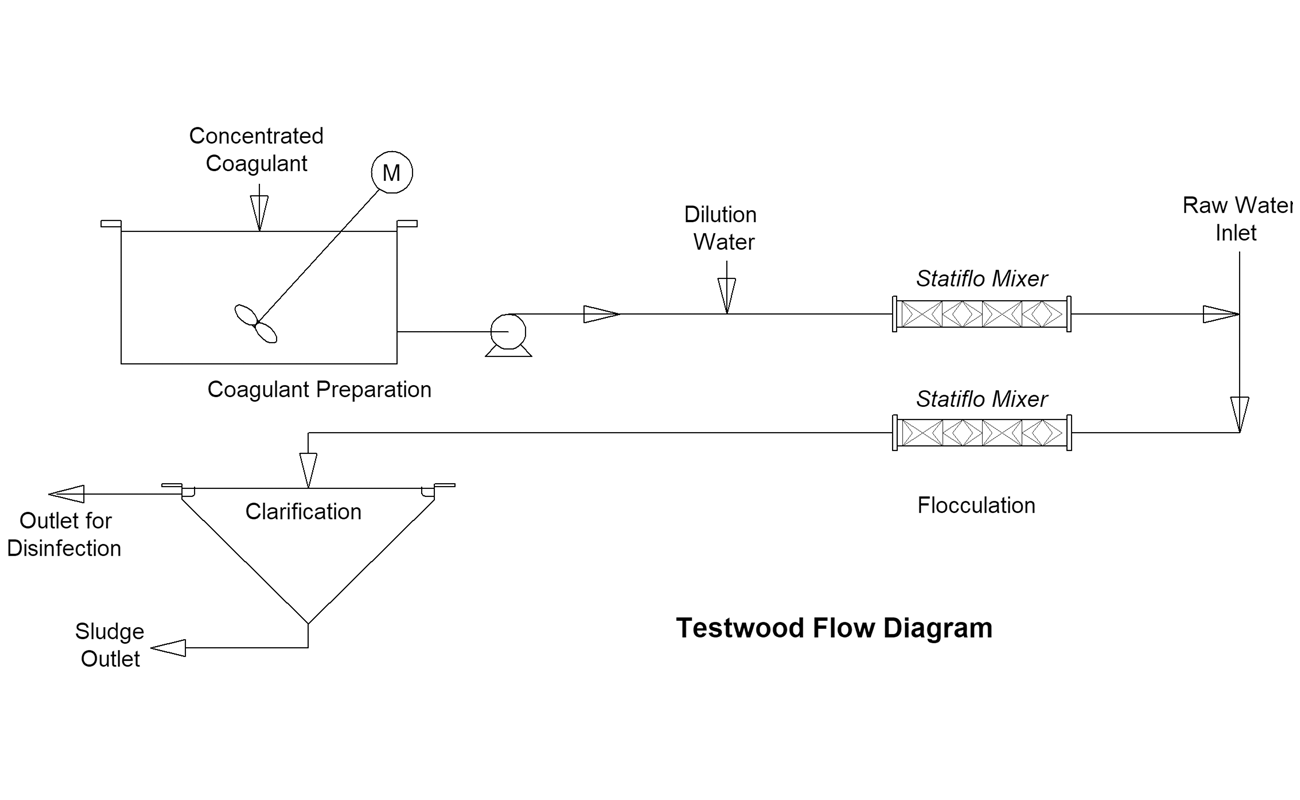

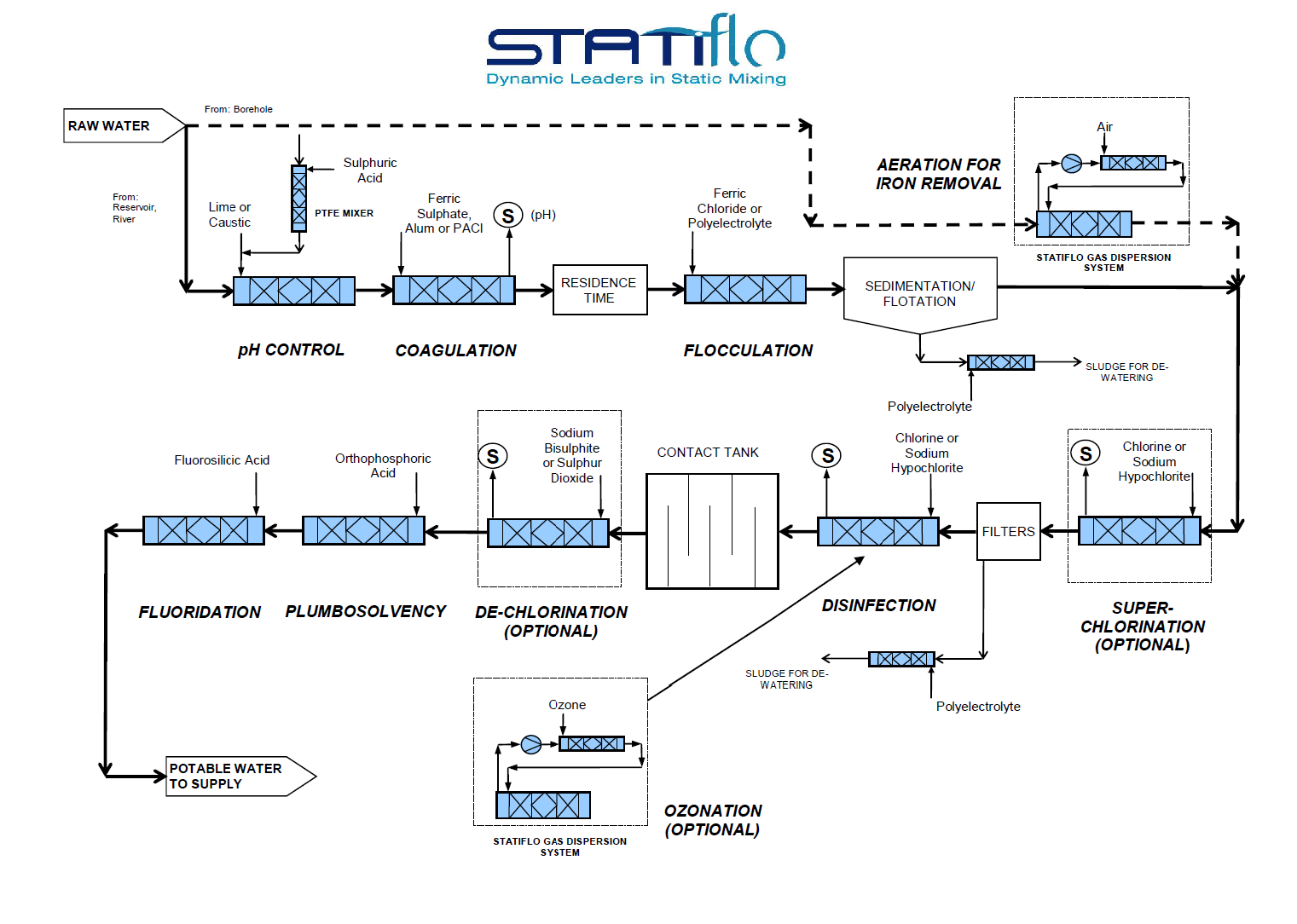

Inline Static Mixers are used in the Municipal and Industrial Water Treatment Process

Inline Static Mixers & Inline Mixing: The demands for precise and responsive chemical dosing in the treatment of drinking water is growing. Applications such as disinfection, flocculation, fluoridation, plumbosolvency, control of taste and odour, ph correction, turbidity, ozonation to name but a few require precise metering of chemicals.

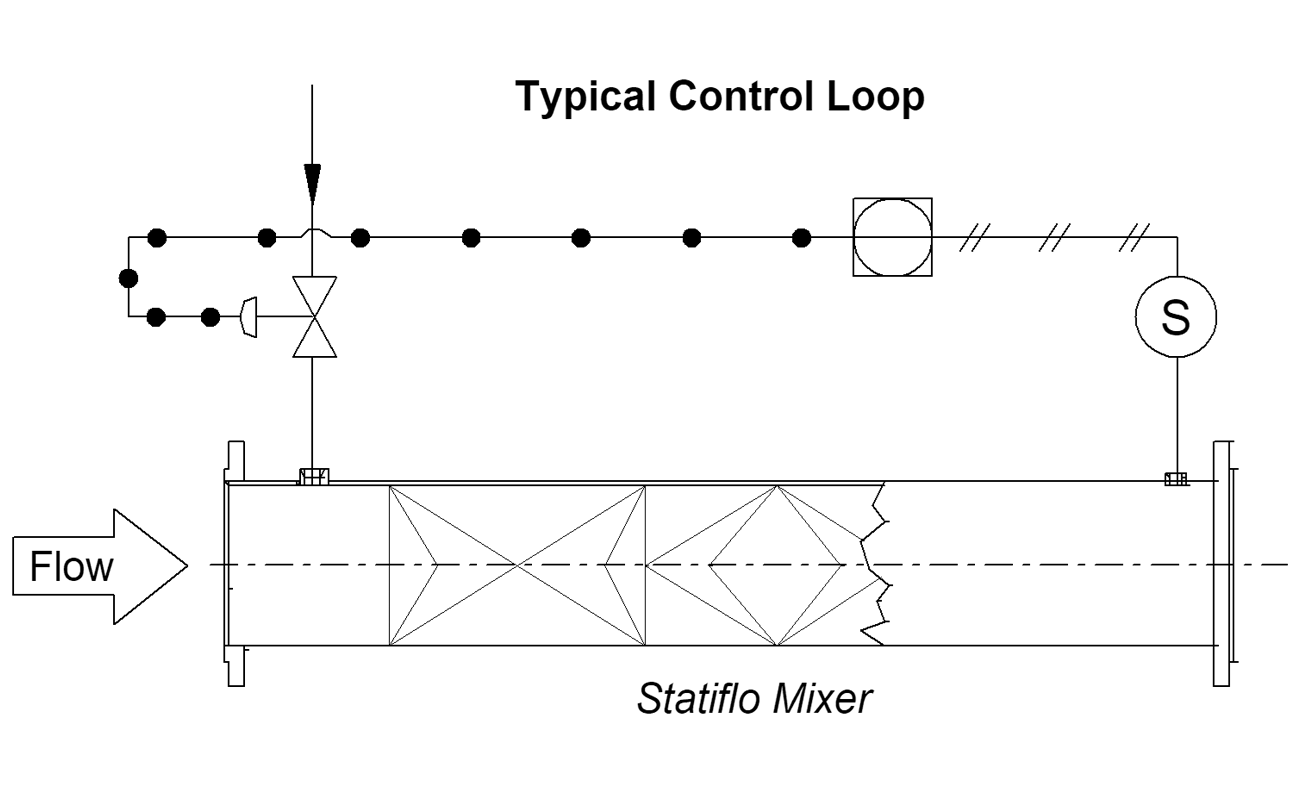

Not only does this require the precise metering of chemicals to meet process demands, stringent levels of residuals, but also to perform when operating in a variety of flow conditions. Therefore there is a need to shorten process times and to ensure that any analysers/sample probes are measuring a representative sample after chemical dosing.

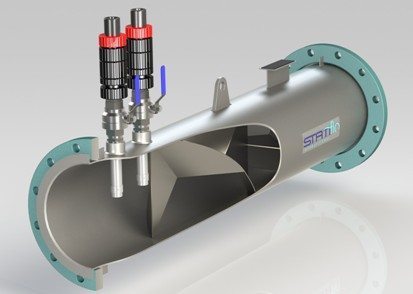

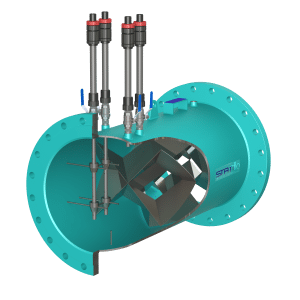

To assist in this process Statiflo inline mixers for water treatment can be supplied complete with chemical injection lances which direct the chemical into the heart of the mixer for optimum performance of the mixer.

The inline mixing and correct dosage of these chemicals has a fundamental influence on each stage of the treatment process and ultimately the complete process itself. So often site conditions do not provide the high level of mixing and process times to meet the prerequisite conditions. The use of in pipe or channel static mixers provides the required level of mixing so that optimum chemical dosing is achieved. Thereby saving chemical, improving the performance of the treatment process as well being able to operate in a variety of conditions and flows encountered in todays treatment processes.

In assessing the benefits of Statiflo Inline Static Mixers it is important to remember:

- Overall length can be varied to suit space limitations.

- Element geometry can be designed for both high and low head loss systems.

- Large diameter – no theoretical upper limits.

- Elements for rectangular or other unusually shaped ducts and open channels

- Special designs for incorporating in bends, offer space saving and minimal disturbance to piping systems.

- Guaranteed highly efficient mixing.

- No moving parts provide a maintenance free operation.

- Reduction in operational energy costs, as no direct power is required.

- Ease of installation.

- Minimal space requirements with no upstream or downstream pipe lengths required. Providing short control process times in applications where quick process response control is critical.

- Short process chemical dosing control loops provide optimum performance in response to rapidly changing process conditions, as well as reducing chemical costs.

- Available in a wide ranges of sizes and material to suit most applications.

- Each unit is custom designed benefiting from Statiflo’s long term experience in designing and manufacturing static mixers to the highest of standards.

- Total support is provided by highly trained engineers situated in Statiflo regional country offices and a world wide representative network.

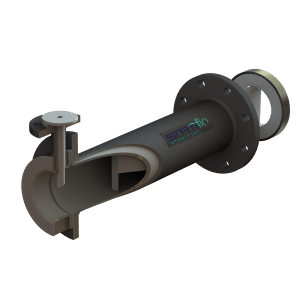

With modern advances in water treatment the use of powerful oxidants such as ozone and AOP processes (Advanced Oxidation Process) are not uncommon. Ozone is a strong oxidising compound which rapidly oxidises organic materials, iron, manganese and other substances when it is added to drinking water. In addition, it is an extremely effective disinfectant against bacteria and viruses. Ozone is very unstable and therefore has a short life. It is therefore essential that the ozone is mixed and dispersed into the water as soon as possible. Statiflo static mixers and gas dispersion systems are ideally suited for this application and there are many installations worldwide.

Static mixers have gained in popularity, as unlike stirred tanks the complete water flow and chemicals are subject to complete and thorough mixing in a relatively short period of time. The required energy for mixing is taken from the main water flow. The resulting headloss is very low and will depend upon the operating conditions and the design of the chosen mixer. Statiflo have considerable experience in designing and selecting the right mixers for the acceptable and calculated head loss.

Application Examples

Case Studies

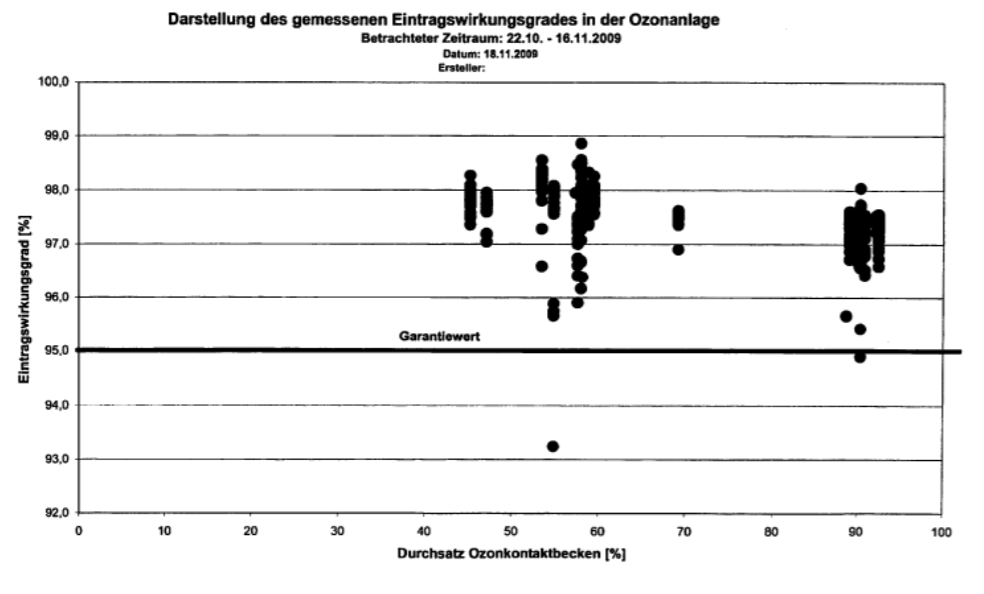

Gas dispersion system for the ozonation of drinking water

Gas Dispersion System: The inline dispersion of a gas in a large volume of liquid very often requires relatively expensive equipment. A classic example is the ozonation of drinking water.…

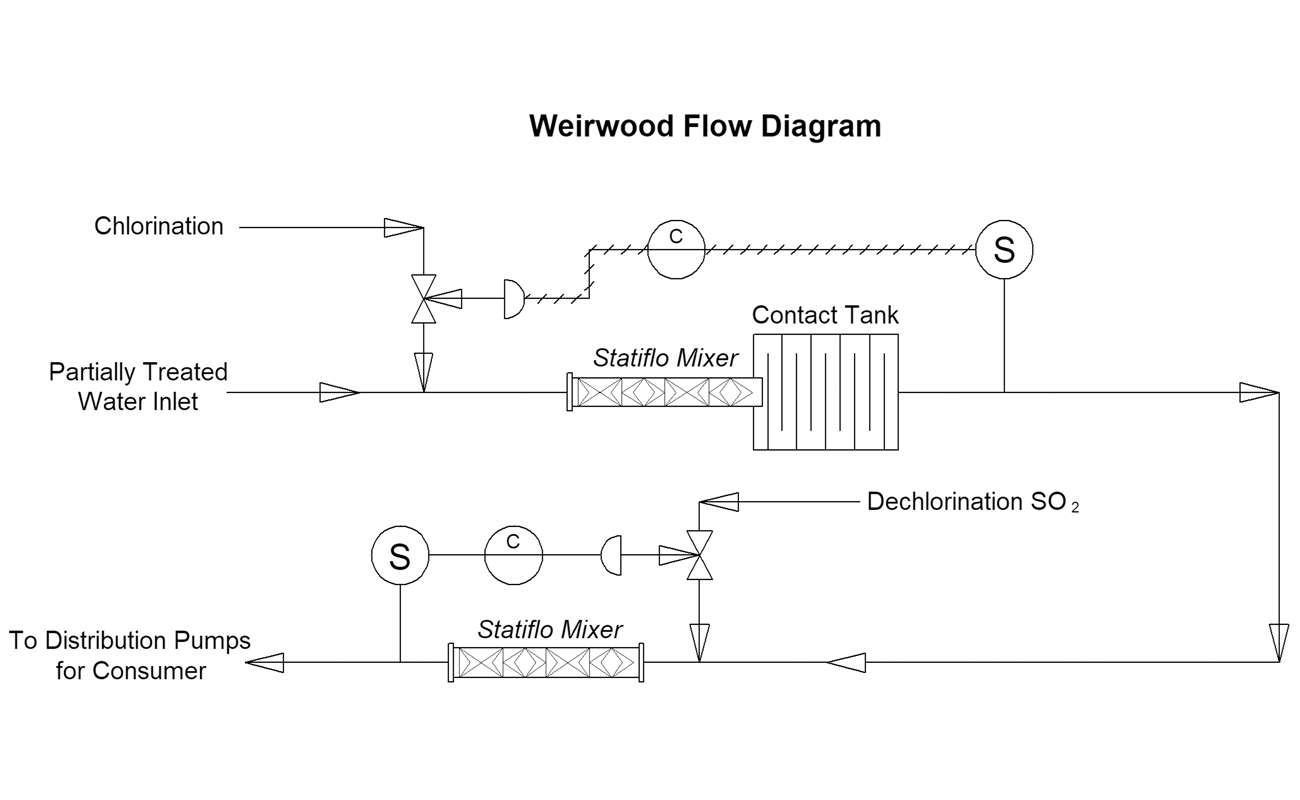

Dechlorination & pH Trim

Problem Dechlorination & pH Trim: Public water treatment plant required highly effective control to dechlorinate and pH trim in difficult access situation. Southern Water’s Weirwood Treatment Works supplies direct to…

Disinfection of Drinking Water

Problem Effective disinfection of drinking water supplies is essential for safe operation. Relying on natural turbulence alone in a pipeline will not guarantee complete mixing of injected sidestream at all…

Replacing Inefficient Dynamic Mixer

Problem As part of their policy of constant improvement and updating, Southern Water had identified that an opportunity existed to improve consistency of performance, energy consumption and maintenance costs at…

Related Products

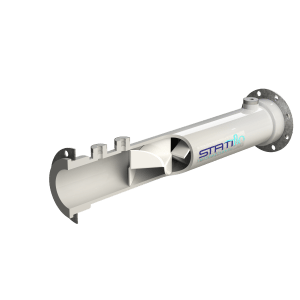

Water Treatment Static Mixer (Series 600/650)

Statiflo Inline Static Mixers suitable for the water and wastewater treatment industries supplied with fixed mixing elements. Flanged or plain…

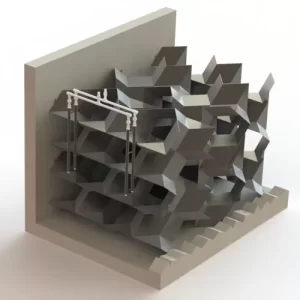

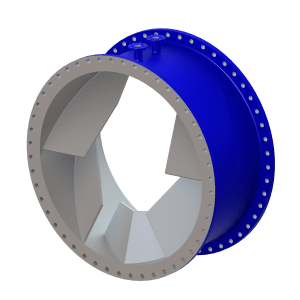

Channel and Duct Static Mixers

Statiflo’s Channel and Duct Static Mixers are revolutionising the design and operation of water and wastewater treatment plants. They are…

Gas Dispersion Systems

The Statiflo Gas Dispersion System (GDS) is a new concept for simultaneous mixing and mass transfer. The Statiflo GDS is…

PTFE Corrosion Resistant Static Mixer (Series 300)

Static Inline Mixers with solid PTFE removable mixing elements and PTFE lined carbon steel housing for corrosive duties in all…

Plastic Static Mixer (Series 400)

Statiflo Series 400 Pipe Mixers: Plastic construction for cost effective general purpose and corrosion resistant duties. (Sometimes known as a…

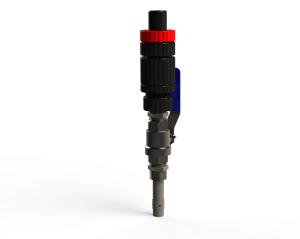

Chemical Dosing / Injection Lances

Statiflo Chemical Dosing Lances / Injection Lances are specifically designed to meet the needs of industry and maximise the mixing…

Compact Static Mixers

A range of Inline Compact (sometimes called Wafer-Style) Static Mixers originally developed to meet the special requirements of the global…

S-Type Static Mixer (Available in stock)

Statiflo Inline Static Mixers suitable for all process industries. Pre-fabricated and packed - meaning you can have rapid delivery of…

Customers Include