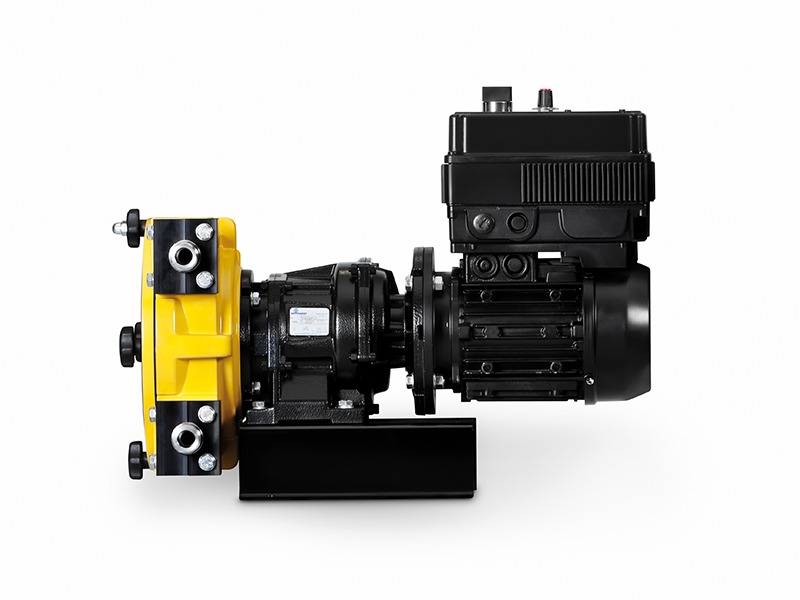

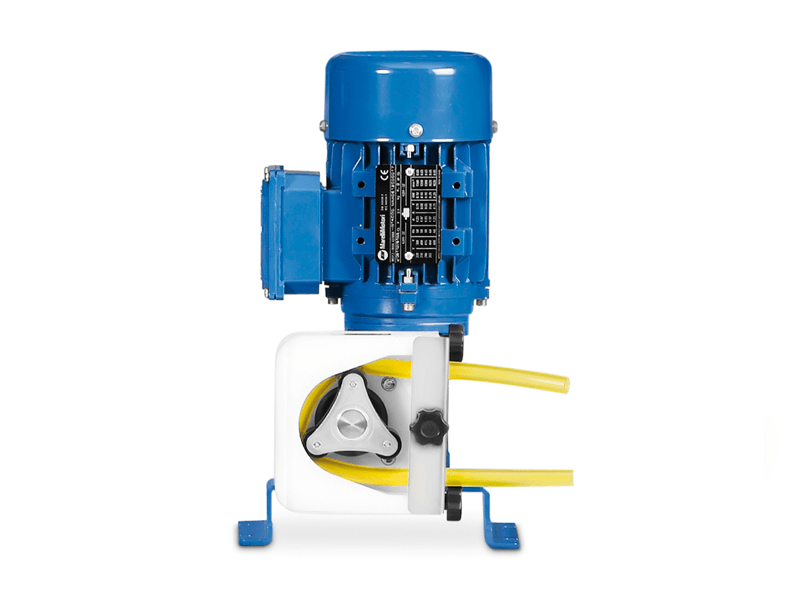

The AMP series peristaltic pumps are industrial pumps for transferring and dosing of fluids.

Available in 4 different sizes, they feature a compact design and offer different drive options depending on whether a continuous or intermittent flow rate is needed.

They are available with a wide range of connections and hoses depending on the type of media to be pumped and the characteristics of the installation, with specific versions for food or corrosive products among other options.

They are available in both continuous flow or regulable flow versions with frequency converters as well as special designs with pneumatic motors, hydraulic motors or DC motors. They are also available in “Skid” version with all the necessary installation and accessories to handle any vital operation in any industrial or sanitation process. They are specially useful for dosing or transferring abrasive products, products with suspended solids, corrosive or viscous products, as well as liquids in general.

MISCELLANEOUS

DO YOU WANT MORE INFORMATION?

AMP SERIES PERISTALTIC PUMP APPLICATIONS

FOOD

Dosing of additives in breads and pastries, beverages, juices, sauces, colorants, lactic ferments, enzymes, syrup, etc.

CHEMICALS

Dosing of all kinds of liquids in the process such as colorants, pigments, resins, latex, acids, dyes, defoamers, glues, oils, etc.

WATER TREATMENT

Sampling, feeding of filtering membranes, dosing of chemical products: ferric chloride, sodium hypochlorite, ferric sulphate, etc. Dosing of media with suspended solids: lime slurry, potassium permanganate, activated carbon, etc. Dosing of polymers, etc.

OTHER INDUSTRIES

Laboratories, paper industry, printing and packaging, ceramics, agriculture, mining, pharmaceuticals, engineering, etc.

PRODUCT DETAILS

Operation

The principle of operation behind a peristaltic pumps convinces for its simplicity and the advantages it offers. A tubing with very precise dimensions and made of different types of elastomer or thermoplastic is housed in the pump body.

When the tubing is pressed by the rotary motion of the rotor and its rollers, it then recovers its original shape, creating a vacuum and drawing in fluid behind it.

The fluid enters in the cavity formed by the rollers that compress the tube and is gently pushed towards the outlet by the next roller.

So we are in front of a positive displacement pump with exceptional features.

In the case of the AMP series pumps, they are industrial peristaltic pumps with a cast aluminium body and a compression system with ball-bearing rollers.

Pulsation dampenerIn-line pulsation dampeners for all types of volumetric pumps with pulsating flows.

Hose leakage detectorTo avoid all kinds of damage due to the product’s contact with the inner metal parts of the pump body, using a hose leakage detector that detects the increase in level and gives an electrical signal to stop the pump is recommended.

DO YOU WANT MORE INFORMATION?

OTHER PERISTALTIC PUMPS

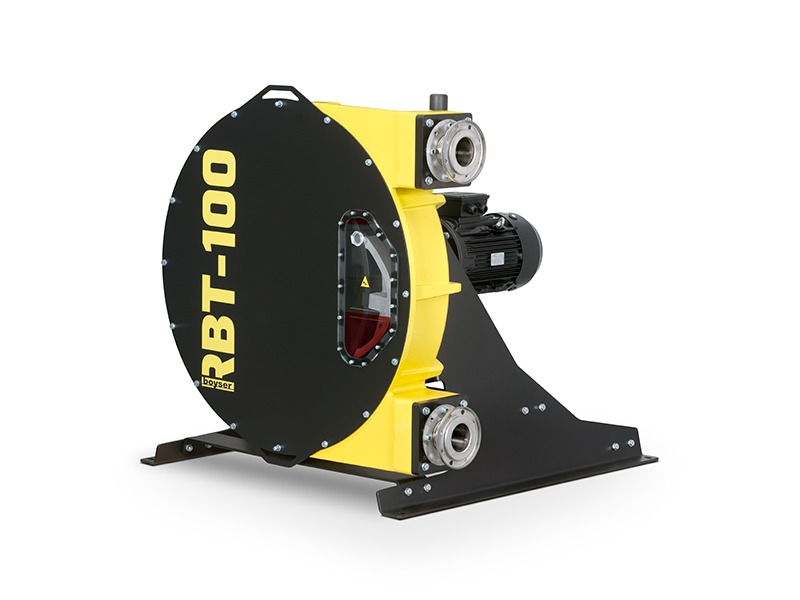

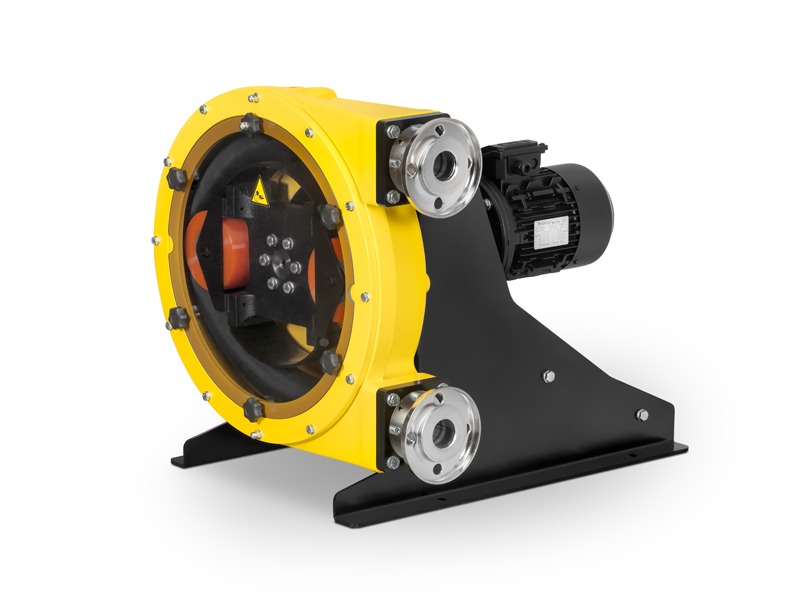

RBT SERIES PERISTALTIC PUMP

Self-priming industrial peristaltic pumps with unlimited dry-running capacity characterised by a high resistance to abrasion for operating pressures of up to 15 bar.

DS-M SERIES PERISTALTIC PUMP

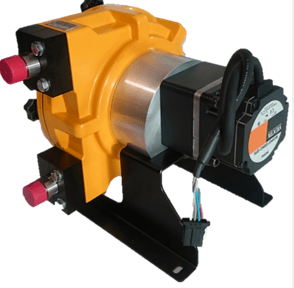

The DS-M series peristaltic pumps are peristaltic pumps for metering or transferring fluids at low flow rates and operating pressures of up to 2 bar.

FMP SERIES PERISTALTIC PUMP

Industrial pumps for the transfer or metering of fluids, available in 6 different sizes boasting a very robust design.