MAIN CHARACTERISTICS OF THE ifollow AMR ROBOTS

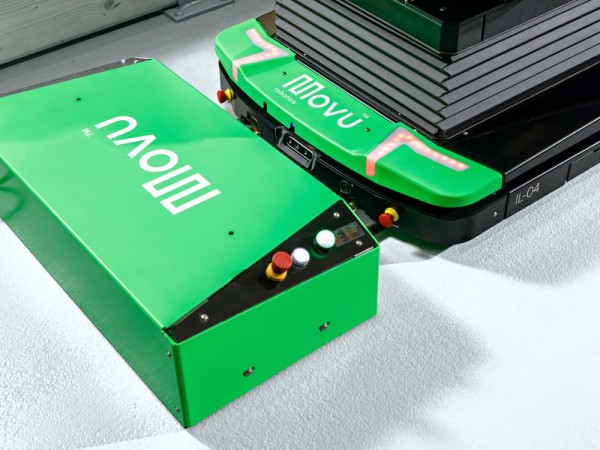

The new compact and ergonomic iFollow robots are capable of autonomously transporting loads ranging from 300 to 1200 kg, making them the perfect solution for automating internal transportation in your warehouse and distribution centers. These systems drastically reduce the need for manual operations and material handling machines. Ifollow AMR robots are already widely used for warehouse automation in the automotive industry, pharmaceutical companies, retail, aviation, warehouses for automotive components, and fast-moving goods. The solution is surprisingly affordable, and integration may be done step by step;

THE SMART MOVEMENT OF THE iFollow AMR ROBOTS

iFollow robots are capable of eluding obstacles while smoothly and quietly transporting your warehouse units. This AMR system autonomously connects storage, picking, packing, and shipping zones in the warehouse. Ifollow robots can move on existing floor surfaces without requiring additional changes to the structure or the architecture;

HOW DOES iFollow AMR ROBOTS WORK?

This innovative technology doesn’t require complex magnetic tapes, reflectors, or QR codes, making its deployment relatively fast. For navigation, each autonomous AMR robot uses wide-angle stereoscopic front and rear cameras, combined with a long-range LIDAR scanner, providing the iFollow robot with a 360° field of vision.

iFollow is powered by intelligent, plug-in software. The experts at STAMH Solutions can assist you in getting the system up and running in a very short period of time. Up to 200 ifollow AMR robots can be integrated with your new or existing WMS - Warehouse Management System and You can plan their paths, change the tasks on the go, and get real-time data and stats;

AUTONOMOUS iFollow AMR SOLUTIONS - THE NEW AIDE IN PICKING AND ORDERS ASSEMBLY

If picking items and ordering assembly are Your main tasks in the warehouse, iFollow is the best choice. One iFollow AMR robot can carry two picking cassettes, and one warehouse or distribution center operator can work on four order lines simultaneously, accompanied by the intelligent ifollow robot;

KEY ADVANTAGES OF THE iFollow AMR SYSTEM AND REASONS TO INTEGRATE IT

- 100% autonomous - no complex navigation systems required;

- Scalability - the number of robots depends on your specific needs and parameters;

- Ability to be integrated in cold storage and working environments at low temperatures, below -25°C;

- No need for expensive navigation infrastructure;

- Easy training and relatively quick integration;

- Safety, reliability, and reduced risk;

- Unparalleled higher productivity immediately after the integration;

- Fast return on investment;

| Technical specifications of ifollow AMR robots | ||||||

| MODEL | ifollow COLD | il300 | il600 | il1000 | il1200 | |

| Length | 1340 mm | 1340 mm | 1340 mm | 1340 mm | 1340 mm | |

| Width | 760 mm | 760 mm | 760 mm | 760 mm | 760 mm | |

| Height | 170 mm | 170 mm | 170 mm | 170 mm | 170 mm | |

| Weight (without loads) | 205 kg | 205 kg | 205 kg | 205 kg | 205 kg | |

| Load surface | 900 x 760 mm | 900 x 760 mm | 900 x 760 mm | 900 x 760 mm | 900 x 760 mm | |

| Payload capacity | 1000 kg | 300 kg | 600 kg | 1000 kg | 1200 kg | |

| Battery run time | 12 to 18 hours | 12 to 18 hours | 12 to 18 hours | 12 to 18 hours | 12 to 18 hours | |

| Maximum Speed | 2m/sec (7 km/h) | 2m/sec (7 km/h) | 2m/sec (7 km/h) | 2m/sec (7 km/h) | 2m/sec (7 km/h) | |

| Ramps and inclines |

5% incline of 10 meters with 0.7 m/s |

5% incline of 10 meters with 0.7 m/s | 5% incline of 10 meters with 0.7 m/s | 5% incline of 10 meters with 0.7 m/s | 5% incline of 10 meters with 0.7 m/s | |

| Battery | Li-ion 48V, 60Ah | Li-ion 48V, 60Ah | Li-ion 48V, 60Ah | Li-ion 48V, 60Ah | Li-ion 48V, 60Ah | |

| Charging time | 2 hours | 2 hours | 2 hours | 2 hours | 2 hours | |

| Battery charging cycle | Minimum 700 cycles | Minimum 700 cycles | Minimum 700 cycles | Minimum 700 cycles | Minimum 700 cycles | |

|

External Charger - Cable or Dock |

Input: 100-230 V AC, 50-60 Hz / Output: 48V DC, max 32A |

Input: 100-230 V AC, 50-60 Hz / Output: 48V DC, max 32A |

Input: 100-230 V AC, 50-60 Hz / Output: 48V DC, max 32A |

Input: 100-230 V AC, 50-60 Hz / Output: 48V DC, max 32A |

Input: 100-230 V AC, 50-60 Hz / Output: 48V DC, max 32A |

|

| Envorinmental temperature | -25°C to 40°C (With a special anti-condensation system) |

up to 40°C | up to 40°C | up to 40°C | up to 40°C | |

| Certifications | Compliant with ISO/EN 13849, NF/ EN 3691-4 CE Certification |

Compliant with ISO/EN 13849, NF/ EN 3691-4 CE Certification |

Compliant with ISO/EN 13849, NF/ EN 3691-4 CE Certification |

Compliant with ISO/EN 13849, NF/ EN 3691-4 CE Certification |

Compliant with ISO/EN 13849, NF/ EN 3691-4 CE Certification |

|

| Communication | WiFi | Dual-band wireless 2,45 / 5 Ghz | Dual-band wireless 2,45 / 5 Ghz | Dual-band wireless 2,45 / 5 Ghz | Dual-band wireless 2,45 / 5 Ghz | Dual-band wireless 2,45 / 5 Ghz |

| I/Os | Ethernet connection - LORA USB connection - Plug access |

Ethernet connection - LORA USB connection - Plug access |

Ethernet connection - LORA USB connection - Plug access |

Ethernet connection - LORA USB connection - Plug access |

Ethernet connection - LORA USB connection - Plug access |

|

| Remote controller |

For manual control according to EN 3691-4 |

For manual control according to EN 3691-4 |

For manual control according to EN 3691-4 |

For manual control according to EN 3691-4 |

For manual control according to EN 3691-4 |

|

| Nanoscan Certified Safety Lidar | 360° visual protection around the robot | 360° visual protection around the robot | 360° visual protection around the robot | 360° visual protection around the robot | 360° visual protection around the robot | |