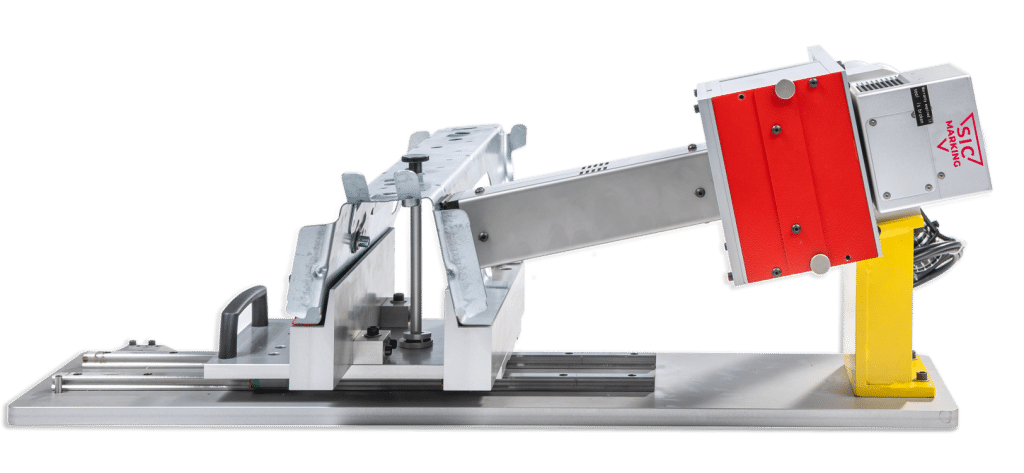

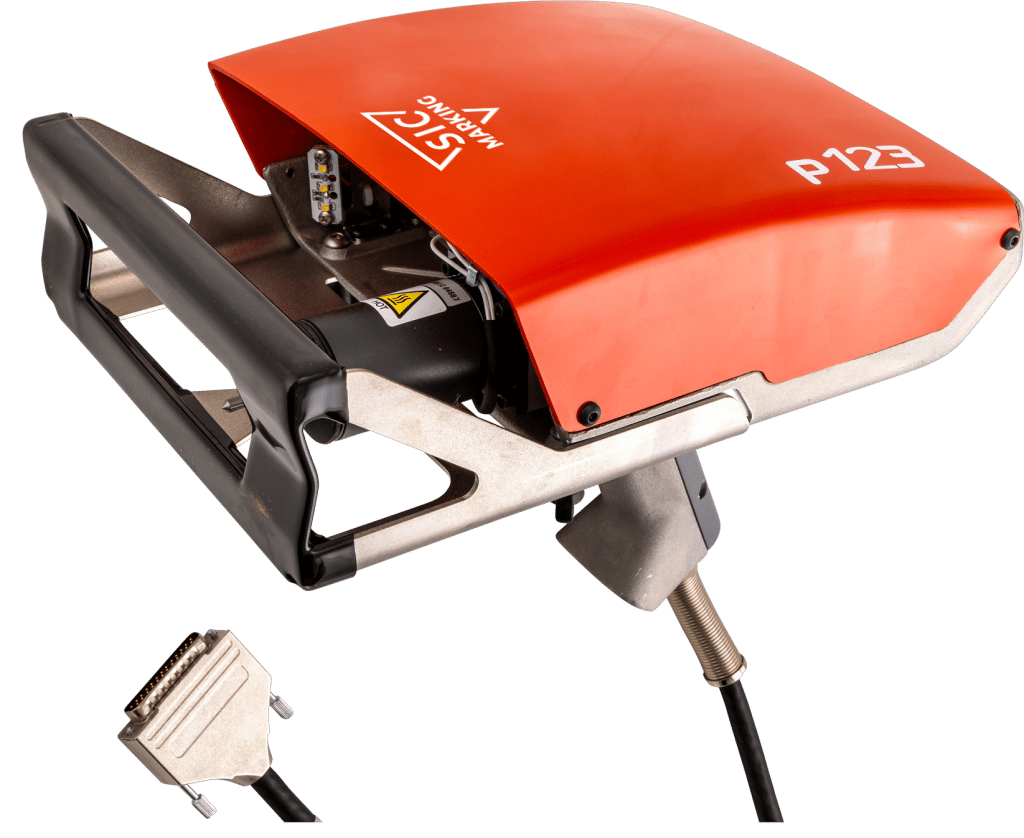

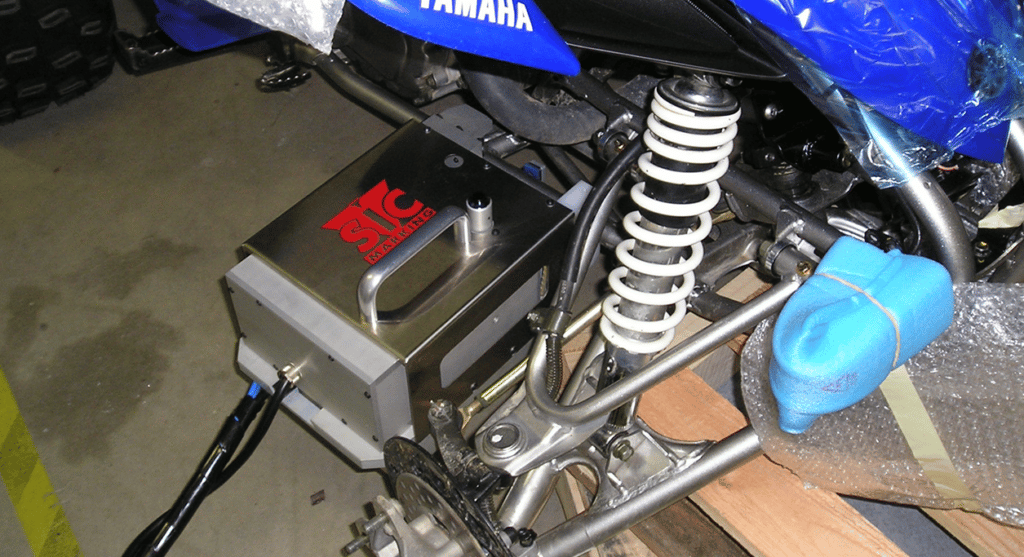

The I 83 is a DOT PEEN MARKING MACHINE designed for easy integration on automated lines in an industrial environment.

The precision of its electro-magnetic control and its crossed table make it THE BEST FOR MARKING VERY HIGH QUALITY 2D CODES (Datamatrix, QR codes, etc.)

This integrable machine can be used in a production line IRRESPECTIVE OF THE DESIRED POSITION. The I 83 connector can also be positioned on the side face, if necessary for production line considerations.

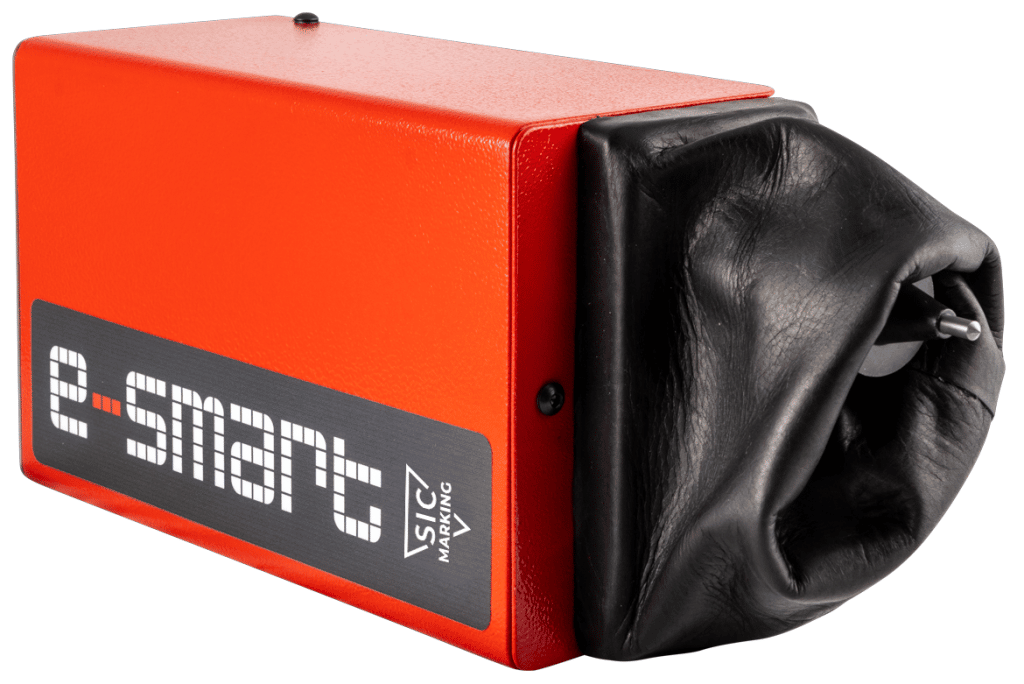

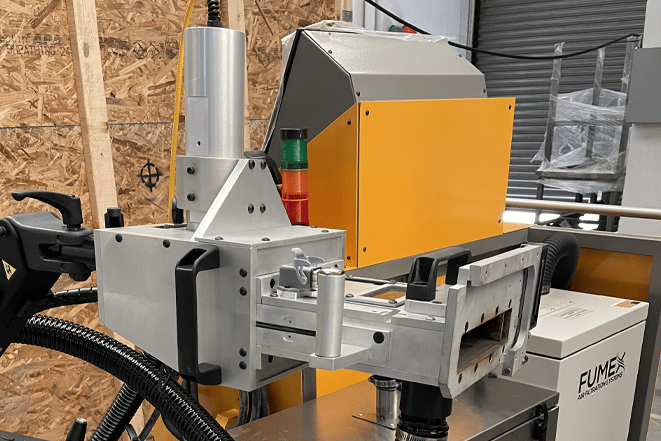

Its robust structure is protected from oil or dust projections by bellows, which also give simpler utilisation in an industrial environment.

The i83 has two specific options.

The first one is the I 83V, an INTEGRAL VIEWING SYSTEM that allows the codes marked to be read at the end of each marking cycle.

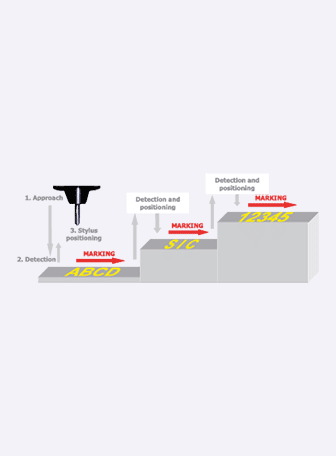

The second one is the I 83A, with an AUTO-SENSING SYSTEM that automatically positions the machine at the correct distance from the piece being marked, through an integral sensor.

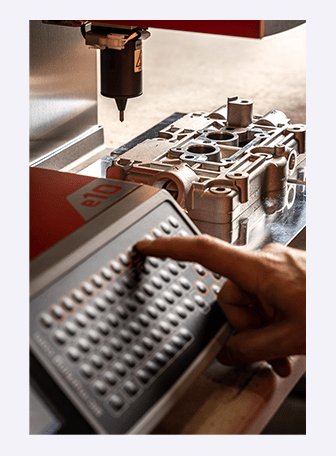

I 83 marking may be alphanumeric text, a logo, a 2D Datamatrix code or a QR Code.

Dot peen technology provides reliable and permanent marking directly in the material, through a tungsten carbide stylus that strikes a series of dots at a very high rate.

Dot peen marking technology with electromagnetic control enables parts with various shapes and surface finishes to be marked: plane, concave, convex, circular, raw and machined surfaces.

It only needs an electrical power supply.

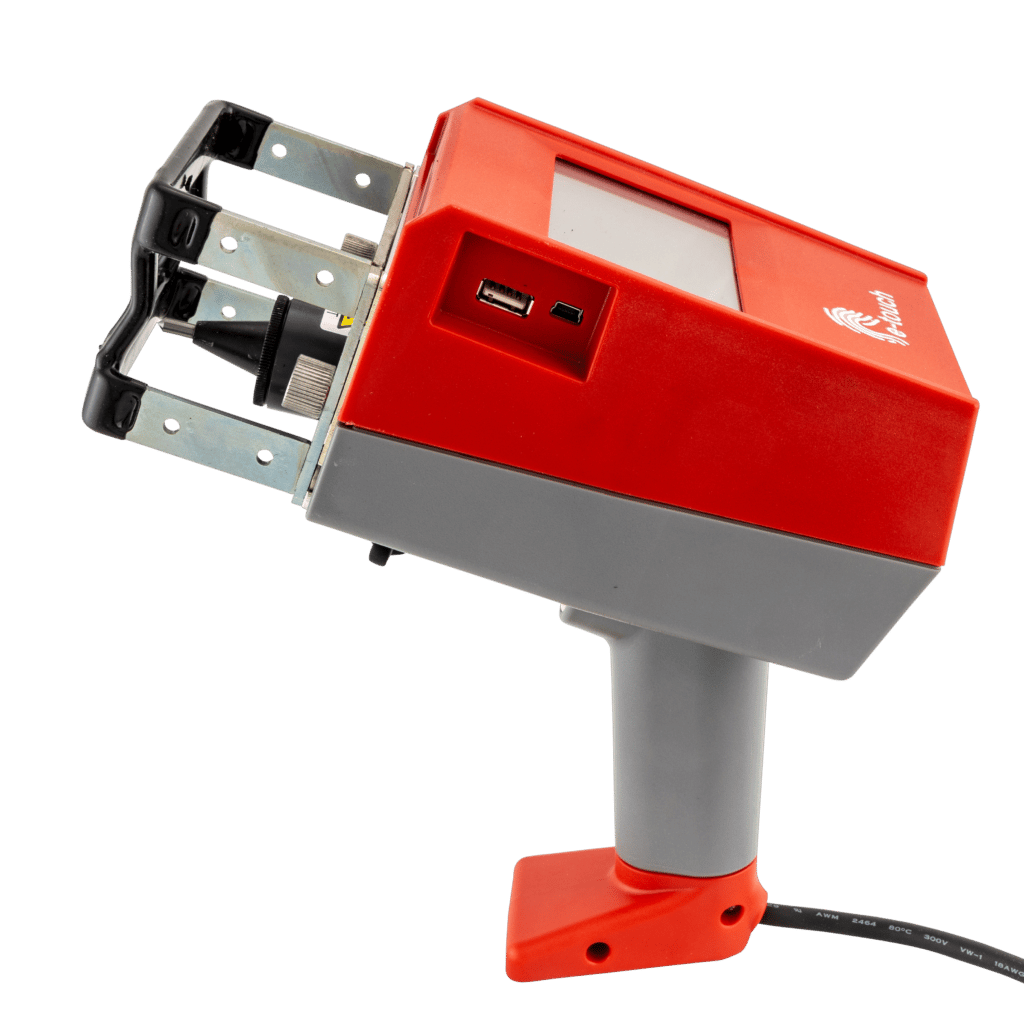

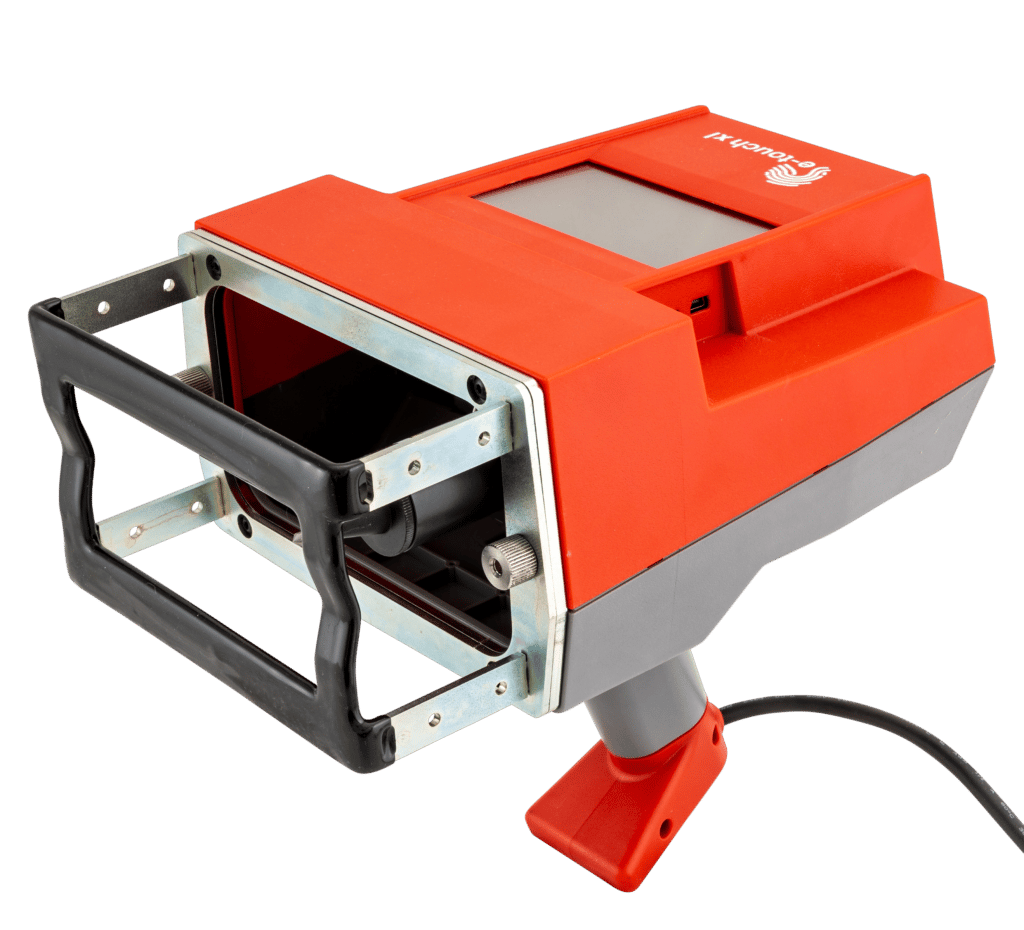

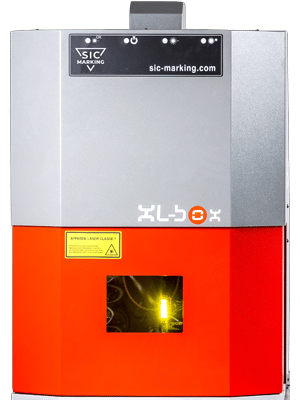

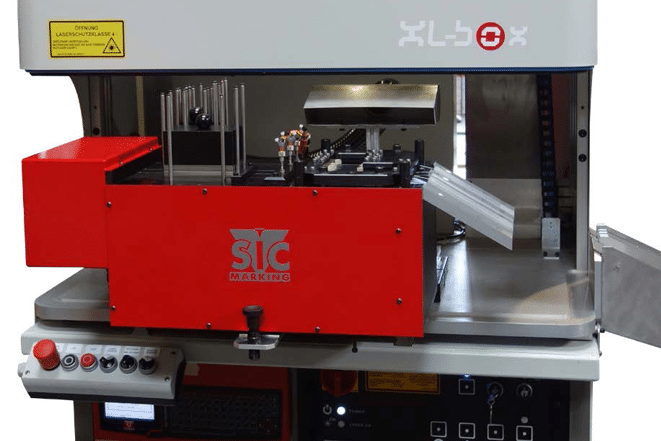

The E 10 is complete and powerful, and can be enhanced with optional supplementary boards, such as Profinet, Profibus or Ethernet IP communication boards

or axis control boards (translation or rotation)

The E 10 R variant is ideal for the integrable range, due to its small size and vertical mounting, which allow it to be installed in a standard electrical cabinet.