CMM gantry | mct nt

The MCT NT series is characterized by an innovative mechanical design, which ensures long-term metrological accuracy while reducing periodic calibration costs.

cmm mct nt

MCT NT is also available in the NT LIGHT configuration, which features a Z ram in light aluminum alloy and a "Single Read" system on the X-axis.

- Y main carriage in advanced alloy: ensures high rigidity combined with low weight to reduce inertia effects

- Z ram in silicon carbide: the use of this material ensures outstanding performance levels in terms of both rigidity and thermal stability

- Automatic, multi-sensor system for compensating errors due to the thermal elongation of structural elements

- "Dual Read" system on both X beams to ensure excellent metrological performance levels up to cross sections of 2500 x 1800 mm

- Machine beams are free to expand (no constraints) on their main axis (machine X axis)

- Optical scales free to expand lengthwise. Resolution: 0.1 microns

- It may be equipped with a full fairing and bellows system on the main mobile structure (X and Y axes)

Temperature range for metrological specification:

- Ambient temperature: 18 ÷ 22 °C

- Maximum hourly gradient: 1.0 °C/h

- Maximum daily gradient: 2.0 °C/24h

- Maximum volume gradient: 1.0 °C/m

- Operating temperature: 15 to 35 °C

- Operating relative humidity: 40 to 80 % (non-condensing)

- Allowed vibrations: (acceleration between peaks)

30 mm/s2 between 1 and 10 Hz

15 mm/s2 between 10 and 20 Hz

50 mm/s2 between 20 and 100 Hz

- Minimum air supply: 5.5 bar

- Air consumption: 150Nl/min

- Power supply voltage:

230 V ± 10%

50 Hz ± 2% (single-phase) 115 V ± 10%

60 Hz ± 2% (single-phase)

- Manual probe heads: MIH, MH20, MH20i

- Motorised indexable probe heads: PH10T, PH10M, PH10MQ, PH20, REVO

- Point to point trigger probes: TP2, TP20, TP200

- Analogue contact probes: SP25M

- Laser probes: Perceptron Laser Scanner

- Stylus and probe changers: Fully automatic changing stations

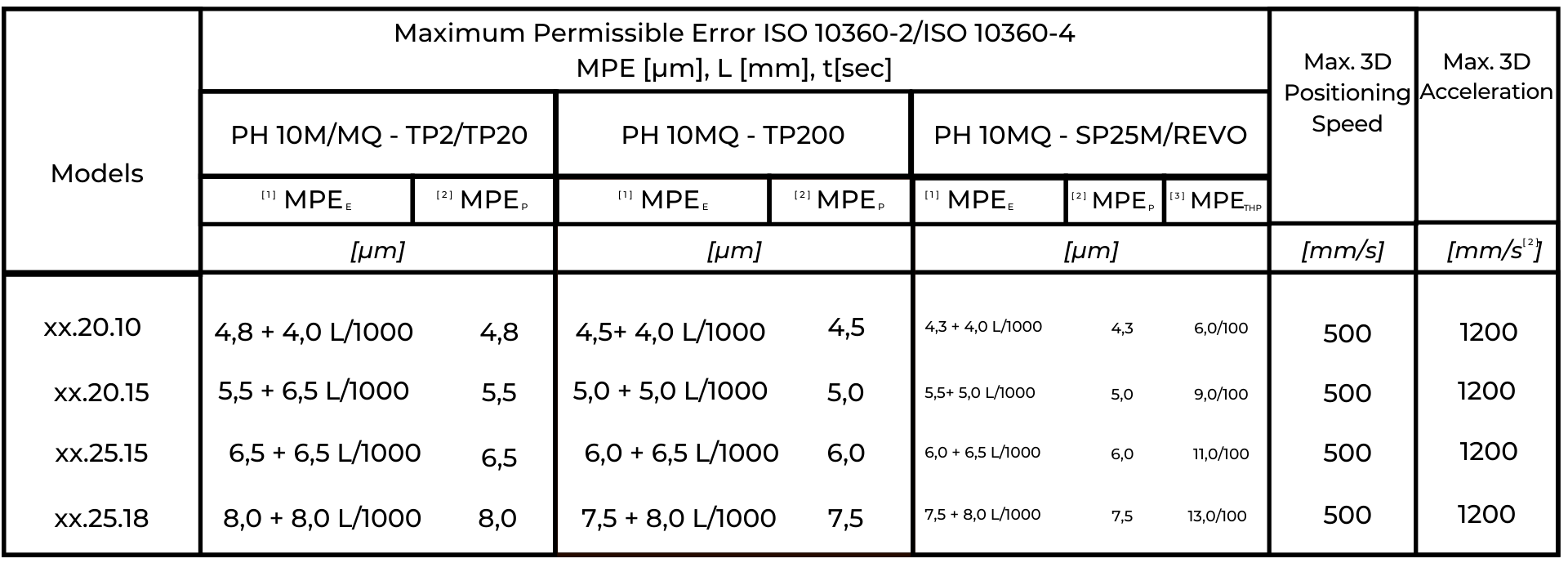

All Coord3 CMM products are factory-tested for accuracy according to the UNI EN ISO 10360 - 2 standard

The services indicated are valid under the following conditions:

- PH10M/PH10MQ/PH20/TP20/TP200: Ø4mm x stylus length 20mm

- PH10MQ/SP25: SM1, stylus Ø 5mm x 50mm

- L= measuring length in mm

- Ambient temperature conditions:

T: 18÷22 °C; Degrees max: 1.0 °C/h - 2.0 °C/24h - 0.5 °C/m

[1] Maximum Permissible Error on length measurements according to ISO 10360-2

[2] Maximum Permissible point gripping error according to ISO 10360-2

[3] Maximum Permissible Error of scanning point gripping according to ISO 10360-4 standard for SP25M / SP80 probes

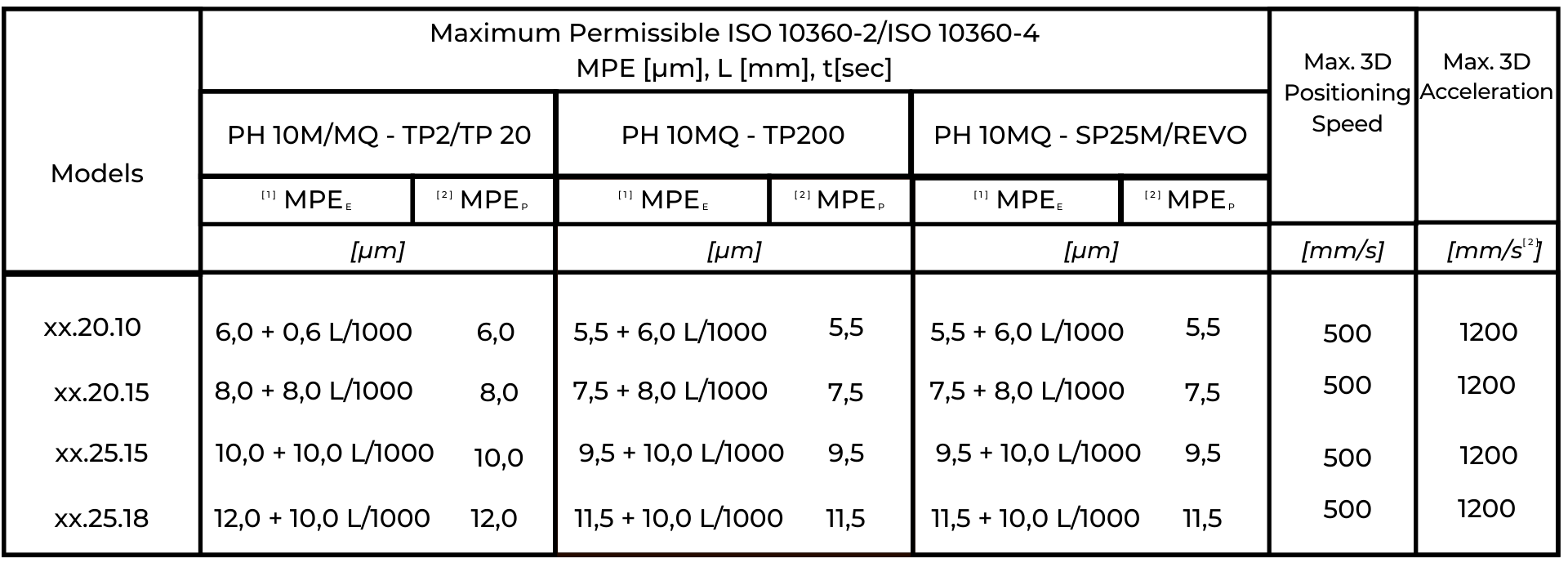

MCT NT LIGHT

The services indicated are valid under the following conditions:

- PH10M/PH10MQ/PH20/TP20/TP200: Ø4mm x stylus length 20mm

- L= measuring length in mm

- Ambient temperature conditions:

T: 18÷22 °C; Degrees max: 1.0 °C/h - 2.0 °C/24h - 0.5 °C/m

[1] Maximum Permissible Error on length measurements according to ISO 10360-2

[2] Maximum permissible point gripping error according to ISO 10360-2

- Multi-wire cables

- Pallet loading/unloading system, manual or automatic

- PC and printer

- Training c/o Coord3 Centres or resellers

- Installation by Coord3 personnel or resellers

- Models and sizes:

COORD3 MCT NT CMMs are available with the following measuring strokes (Y.Z mm):

20.10/20.15/25.18

request a visit from one of our agents

Strada Statale 25, No. 3 - 10050 - Bruzolo (TO) - Italy

PHONE

+39 011 963 5511

TECHNICAL ASSISTANCE

service@coord3.com

COMMERCIAL SUPPORT

info@coord3.com

ADMINISTRATION

finance@coord3.com

PURCHASING OFFICE

acquisti@coord3.com

© 2023 COORD 3 S.R.L. | Via XX Settembre, 26 - 00187 Roma (RM) - Italy | REA C.C.I.A.A. No. 1667509 Rome - Paid-up share capital: Euro 50,000.00 | P.IVA\C.F: 11287420019 | SDI ZBGTBLC | ISO 9001 Certified | Privacy Policy | Cookie Policy