cmm gantry | mct starlight

CMM gantry | mct starlight

The MCT SL series offers medium to large Gantry CMMs that are notable for their excellent structural stability and adaptability.

They can be configured according to the requirements of any measurement application and are available in a wide range of sizes.

The MCT StarLight is also available in NT configuration , that is, a CMM equipped with a light aluminum alloy Z spindle and x-axis "Single Read" system.

mct starlight

- Generous pad spacing sizing for optimal mechanical rigidity

- High-rigidity Y main crossbar with unique tubular steel design

- Z spindle made of extruded aluminum alloy provides rigidity and minimizes the moment of inertia.

- X-beams with large cross-sectional area made of stabilized steel and equipped with support system that allow linear expansion without induced deformation

- High-strength epoxy resin X/Y axis slideways ground (roughness 0.4 mm)

- Measuring system with high-resolution (0.1µm) linear transducers with "Dual Reader" system on longitudinal X axis

- "Dual Drive" system on longitudinal X axis (optional, standard for Y=3000 stroke)

- Multi-sensor system for automatic compensation of errors due to thermal expansion of structural components.

- Temperature range for metrological specifications:

Ambient temperature: 18 ÷ 22 °C

Maximum hourly gradient: 1.0 °K/h

Maximum daily gradient: 2.0 °K/24h

Maximum gradient in volume: 0.5 °K/m (SL NT) - 1.0 °K (SL) - Operating temperature: 15 to 35 °C

- Relative humidity for operation: 40 to 80 % (non-condensing)

- Allowable vibration: (Peak/peak acceleration)

30 mm/s2 between 1 and 10 Hz

15 mm/s2 between 10 and 20 Hz

50 mm/s2 between 20 and 100 Hz

- Pressure: 6 Bar

- Air consumption: maximum 300 Nl/min

- Power supply:

230 V ± 10%; 50 Hz ± 2% (single-phase)

115 V ±10%; 60 Hz ± 2% (single-phase)

- Manual Heads: MIH, MH20, MH20i

- Motorized Heads: PH10M, PH10MQ

- Indexable Motorized Heads: PH20, REVO

- Point-to-point touchers: TP2, TP20, TP200

- Analog keyers: SP600, SP25M, SP80

- Probe and tip changing systems: Automatic changing stations

Each COORD3 CMM is tested according to UNI EN ISO 10360-2 standards.

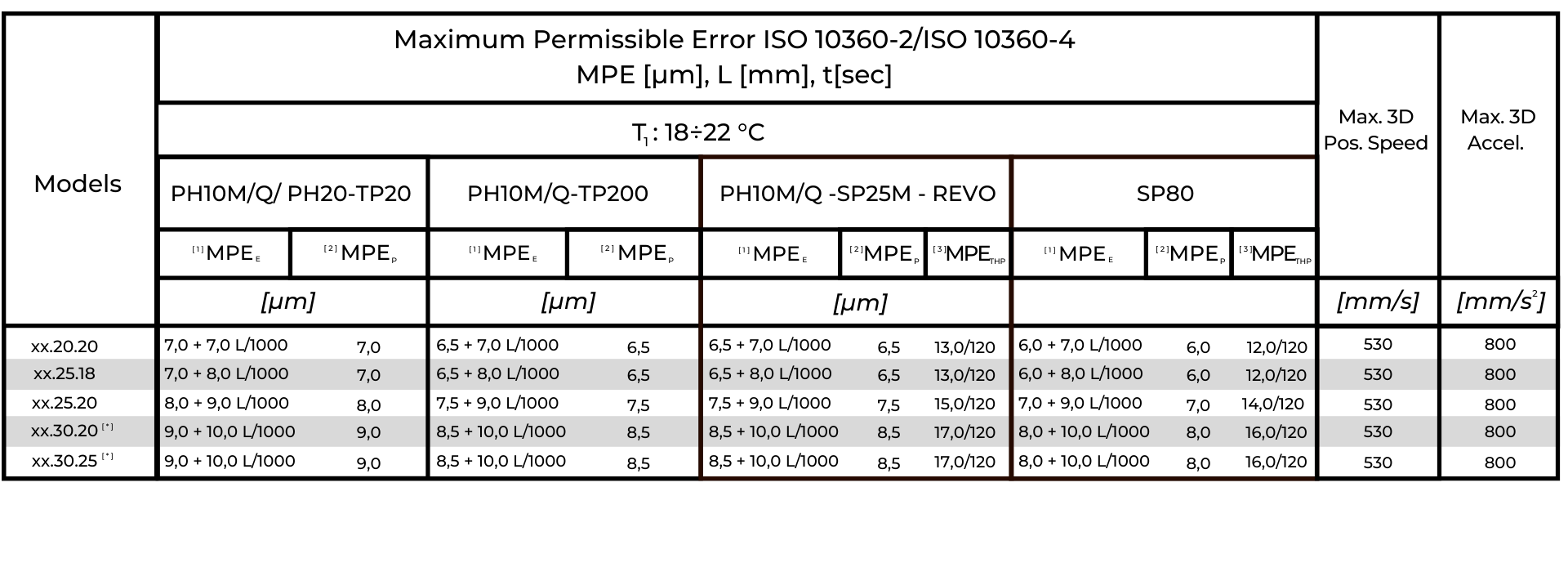

MCT STARLIGHT

The indicated performance is valid under the following conditions:

- TP2/TP20-5W/TP200: Ø4mm x stylus length 10mm

- SP25: SM1, stylus length 50mm Ø5mm

- REVO: RSP2/RSH175 - RSP3-1/SH25-1, stylus length 20mm

- SP80: Ø 5mm stylus length 50mm

- L= measurement length in mm

- Ambient temperature conditions:

T: 18÷22 °C; Gradients max: 1.0 °C/h - 2.0 °C/24h - 1.0 °C/m

[1] Maximum Permissible Error on length measurements according to ISO 10360-2

[2] Maximum Permissible Error on Point Grip according to ISO 10360-2

[3] Maximum Permissible Error of Point Grip on scanning according to ISO 10360-4 for SP25M/SP80/REVO probes.

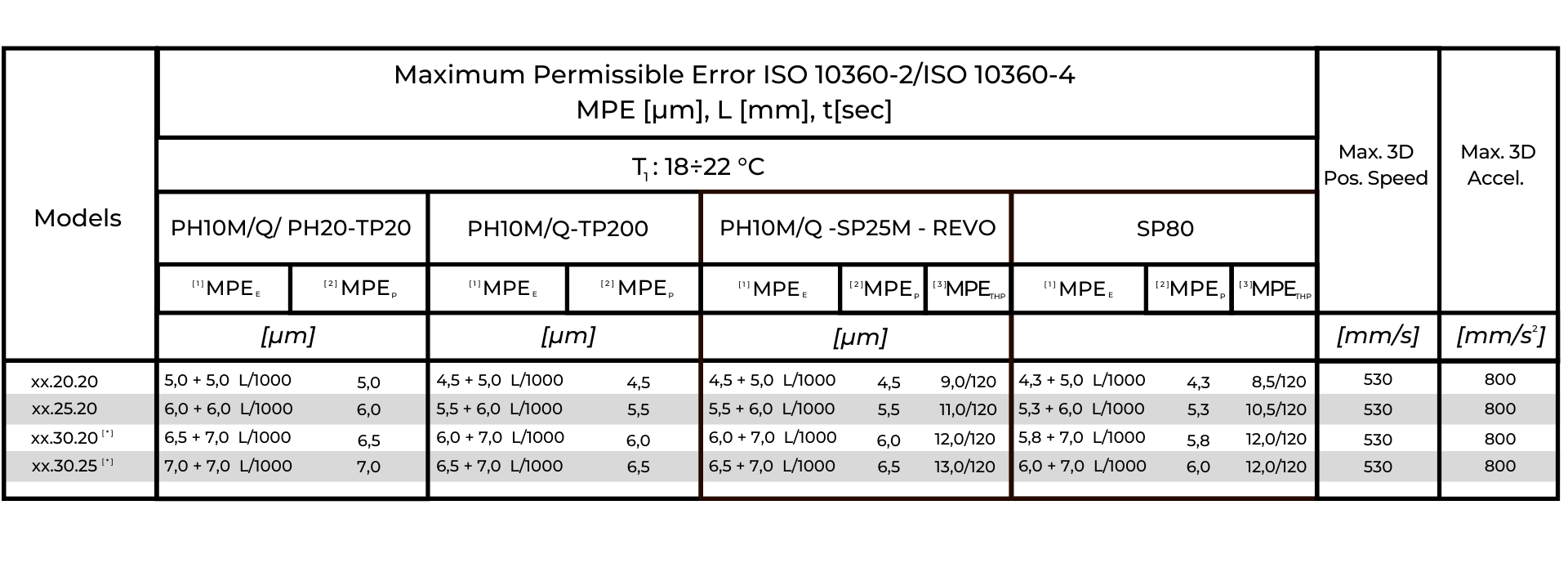

MCT STARLIGHT NT

The indicated performance is valid under the following conditions:

- TP2/TP20-5W/TP200: Ø4mm x stylus length 10mm

- SP25: SM1, stylus length 50mm Ø5mm

- REVO: RSP2/RSH175 - RSP3-1/SH25-1, stylus length 20mm

- SP80: SM1, Ø 5mm stylus length 50mm

- L= measurement length in mm

- Ambient temperature conditions:

T: 18÷22 °C; Gradients max: 1.0 °C/h - 2.0 °C/24h - 0.5 °C/m

[1] Maximum Permissible Error on length measurements according to ISO 10360-2

[2] Maximum Permissible Error on Point Grip according to ISO 10360-2

[3] Maximum Permissible Error of Point Grip on scanning according to ISO 10360-4 for SP25M/SP80/REVO probes.

- Multi-wire wiring

- Models and dimensions:

COORD3 MCT STARLIGHT CMMs are available with the following measuring strokes (Y.Z mm):

20.20/25.18/25.20/30.20/30.25

request a visit from one of our agents

Strada Statale 25, No. 3 - 10050 - Bruzolo (TO) - Italy

TELEPHONE

+39 011 963 5511

TECHNICAL ASSISTANCE

service@coord3.com

SALES

info@coord3.com

ADMINISTRATION

finance@coord3.com

PURCHASING

acquisti@coord3.com

© 2023 COORD 3 S.R.L. | Via XX Settembre, 26 - 00187 Roma (RM) - Italy | REA C.C.I.A.A. No. 1667509 Rome - Paid-up share capital: Euro 50,000.00 | P.IVA\C.F: 11287420019 | SDI ZBGTBLC | ISO 9001 Certified | Privacy Policy | Cookie Policy