Refrigerant Monitoring

The first synthetic refrigerants hit the market in the 1950s. Unlike their predecessors, they were non-flammable and non-toxic, which made them much more popular to use.

This is to prevent parasites from entering the country. However, these gases are often harmful not only to microorganisms or insects, but also to humans. When the containers are unloaded at their destination, these gases come into contact with people. Many of these gases can hardly or not at all be smelled. Especially when these gases are present in workplaces, there is often a long-lasting exposure. This can lead to illness or organ damage - even decades later. In order to counteract this invisible danger, personal measuring devices are indispensable for occupational safety. Besides measurement techniques based on infrared spectroscopy, other techniques such as electrochemical sensors are also used for this purpose. These devices need frequent maintenance or replacement due to a changing detection limit based on physical reasons. NDIR technology, equipped with long-life infrared sources such as those from Axetris, is often more reliable and requires significantly less maintenance.

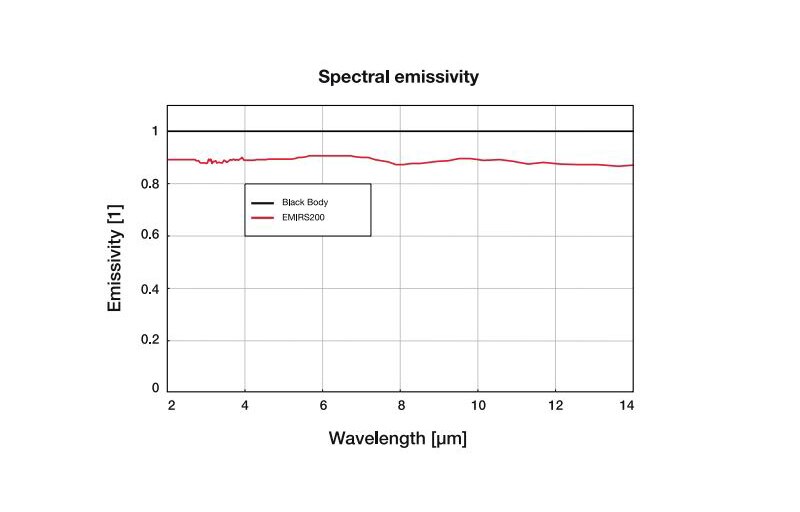

Both principles are significantly higher in their acquisition costs than conventional sensor solutions. They redeem themselves through a long service life of over 7 years and longer calibration and maintenance cycles. HFO, a refrigerant forced by the new regulations, can only be measured with semiconductor sensors (MOS) in addition to IR measurement technology. However, MOS as an inexpensive alternative measurement technology looks at shortcomings with a limited service life and short calibration cycles which don't manage to outweigh the cost-of-ownership comparison.