SF6 Monitoring

Carbon dioxide (CO2) and methane (CH4) immediately come to mind when we think of greenhouse gases- after all, they are the talk of the town. Sulfur hexafluoride (SF6) and its harmful effect on the climate, on the other hand, is rather unknown to many.

Naturally, leaks can occur in these plants and systems and release SF6 into the atmosphere. As a preventative measure plants should be continuously monitored. At the Institute for Environmental Physics at the University of Heidelberg, the content of various greenhouse gases in the atmosphere is measured regularly. It was noticed that especially the content of SF6 in the atmosphere is inexplicably high. According to the Kyoto Protocol, all member countries must report their emissions. Interestingly, the reported data do not match the measured data; leakages could be a reason for the indiscrepancy. With the help of optical spectroscopy, especially non-dispersive infrared spectroscopy (NDIR), such measurement tasks could be solved easily and reliably. The infrared sources from Axetris guarantee a continuously high emissivity in the entire mid-infrared spectrum, which is necessary to detect the smallest leaks of harmful SF6 through NDIR technique.

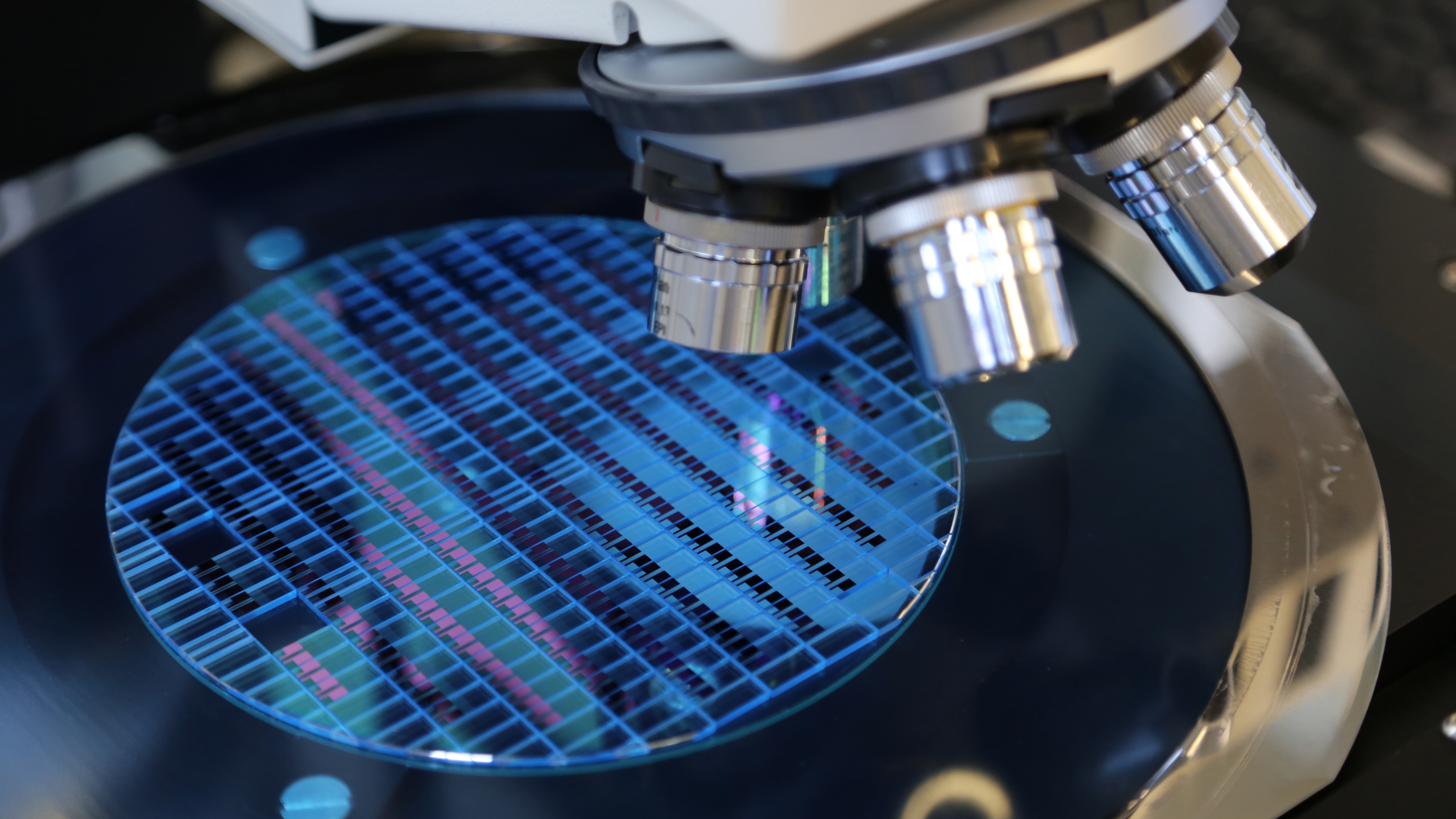

One important step is etching, which is used to produce microstructures. These microstructures are realized during etching by means of material removal. The various etching techniques distinguish between dry etching and wet chemical etching. SF6 is used as an etching gas in dry etching processes. Since even the smallest amounts of particles or foreign gases can damage the sensitive semiconductors, the purity of the gases used is extremely important. Non-dispersive infrared spectroscopy can be used for continuous monitoring of gas purity.