Stauff Connect tube connectors awarded DVGW type test certification

Photo by Walter Stauffenberg GmbH & Co. KG

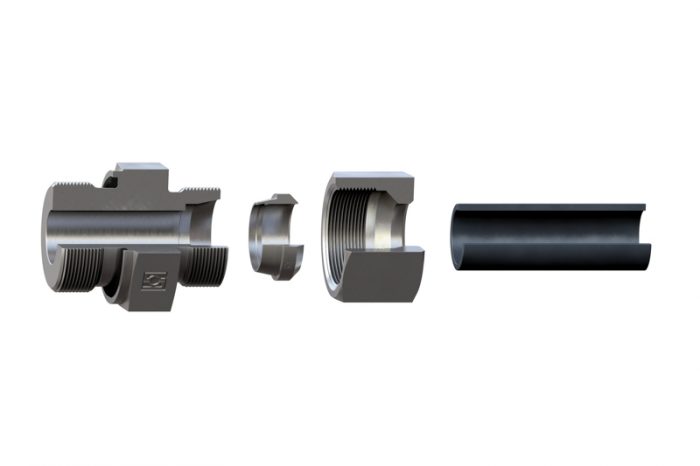

Well-known manufacturers of mobile homes and caravans are using Stauff Connect tube connectors in their gas supply lines. There is now a DVGW type test certificate for a number of different connection and joining components with type FI-DS double-edged cutting rings, which confirms their successful testing and approval for gas applications up to 16 bar.

Camper vans need gas to provide heating, cooking and cooling in their mobile holiday accommodation. The feed line from the safety gas pressure control system to the distributor or to the individual consumers needs to be designed as a fixed tube. It goes without saying that extremely stringent requirements govern the safety and reliability of these components.

Welded precision 8 or 10 mm diameter steel tubes with a 1 mm wall thickness are generally used for this. Well-known manufacturers use components from the STAUFF Connect range to connect these tubes. The range complies with the relevant requirements, such as DIN EN 1949 (“Specification for the installation of LPG systems for habitation purposes in leisure accommodation vehicles and accommodation purposes in other vehicles”) and DVGW code of practice G 607 (“LPG systems in leisure vehicles and residential units”).

The suitability of the Light Series Stauff Connect range for this application, particularly the type FI-DS double-edged cutting rings, is now confirmed by certification by the German Association for Gas and Water (DVGW). Various tests conducted in compliance with DIN 3387-1 (“Separable unthreaded pipe connections for metal gas pipes – Part 1: Connections for pipes with smooth ends”) form the basis of this. The leak-tightness, internal stress resistance (pressure test), axial strength (tensile strength) and resistance to vibrations were tested, among other things.

The result: The tested components fully passed the test requirements of DIN 3387-1 and are therefore awarded a DVGW type test certification for gas applications up to 16 bar.

Apart from safety and reliability, there are other reasons why manufacturers are using these separable connecting elements: STAUFF is a one-stop supplier for the cutting rings and all other components required as well as relevant assembly machines. The range also includes a machine developed specifically for assembly on tubes with extremely narrow bending radii, a property called for especially in mobile homes and caravans where space is very tight. In addition, premium manufacturers, in particular, also appreciate the high-quality look and excellent corrosion resistance of the zinc/nickel finish of these components, which require no further surface post-treatment work.

For more information, please visit http://www.stauff.com.

News Categories

- » NEWS HOME

- » Automation & Robotics

- » Industry 4.0

- » Material Handling

- » Sensors

- » Quality & Testing

- » Machine Vision

- » Laser & Optics

- » Metalworking

- » Motion Control & Drives

- » Hydraulics & Pneumatics

- » Process Industry

- » Renewable Energy

- » Agriculture

- » Home & Office Furniture

- » Environmental Tech