- Offer Profile

- the expert company for the

supply of tube/hose quick-disconnect couplings and process dosing pumps.

Since 1976 GATHER Industrie GmbH has been providing excellently manufactured high-quality products in the form of magnetic-drive gear pumps and quick-disconnect couplings for piping and hoselines. The products offered by GATHER Industrie GmbH are used for pharmaceutical, chemical applications, in the medical field, plant construction and food processing industry.

Pumps

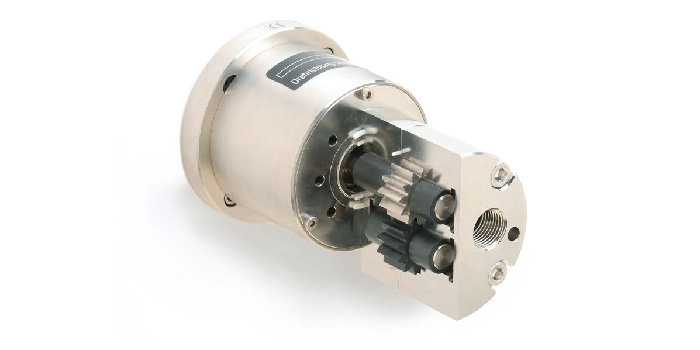

GATHER Gear pump

-

Precise pump technology for non-lubricating liquids

The magnetically coupled GATHER Gear pump is a hermetically sealed dosing and process pump. In numerous industrial sectors (chemicals, pharmaceuticals, food, medicine, cosmetics, etc.) it is mainly used for the pulsation-free delivery or dosing of non-lubricating liquids (e.g. water, salt solutions, acids, alkalis, solvents, etc.).

Features

- Magnetic coupling hermetically sealed

- Pulsation-free delivery & dosing

- Non-lubricating liquids

- Cooling magnetic system & slide bearings

- Robust design and long service life

- CIP- and SIP capable, if desired

GATHER Multi-Purpose laboratory pump

-

Compact, robust and versatile

As already explained under Magnetically coupled gear pump, the GATHER gear pump is a hermetically sealed pump. This pump was designed multifunctionally in its materials in order to be able to pump many different liquids used in the laboratory.

In addition, a drive with integrated speed control is used which is a plug and play solution ready for conncetion and available from stock.

General operating data for laboratory pumps

- Your operating data: Laboratory application

- Temperature: 0 up to +85°C

- Ambient temperature: 0 up to +40°C

- Viscosity: 1,0 up to 500 mPa s

- Maximum possible differential pressure: 10 bar

- Maximum permissible system pressure: 16 bar abs

- The pressure at the suction port must be at least o.1 bar above the vapour pressure of the liquid.

- The pump requires inlet, i.e. the maximum flow rate must be fed to the pump without suction

- Differential pressure, flow rate and delivery speed according to characteristic curve (for 1.0 mPa s)

- Due to manufacturing tolerances, the characteristic curve of the pump head may deviate from the averaged characteristic curve. Therefore we recommend calibrating the pump head individually.

GATHER Centrifugal pump

-

The magnetically coupled process pump

GATHER Industrie GmbHs magnetically coupled mini centrifugal pump is a modern process pump for the pulsation-free metering, conveying and circulating of water, salt solutions, acids, alkalis and solvents, amongst other things.

With three different geometrical variants, flow rates ranging from 20 l up to 3600 l per hour can be attained at differential pressures up to 5 bar (see also operating data and flow rate characteristic diagram). Similar to the gear pump, it has internal wash borings and channels for efficient cooling and fluid circulation.

The magnetic coupling ensures a contactless torque transmission from the drive to the pump shaft. It is not subject to wear and tear and is absolutely maintenance-free. Together with its established slide bearings technology and simple design, the GATHER centrifugal pump represents a cost-effective, robust multi-purpose pump which is extremely quiet in operation.

Characteristics

- Magnetic coupling hermetically sealed

- Pulsation-free delivery & dosing

- Non-lubricating liquids

- Cooling magnetic system & slide bearings

- Robust design and long service-life

- Low-noise operation

Accessories

Inline filter Mini - GATHER Accessories

-

The GATHER filter with drain plug is a universal filter designed even for extreme process conditions. Operating temperatures of up to 350°C at system pressures of up to 500 bar are possible. The stainless steel and Hastelloy® versions qualify this filter for use with aggressive media. Through using pleated filter elements, a compact design with a large filter surface is created, which causes only low pressure losses. The filter is optimally suited for use as a pre-filter in suction lines.

Technical data

- Max system pressure: 500 bar

- Max temperature: +350°C

- Standard fineness: 10 µm

- Housing

- Stainless steel: Nitronic® 60 / 1.4404

- Alternative: Hastelloy® C-276

- Filter

- Stainless steel: 1.4401

- Alternative: Hastelloy® C-22®

- Connection: G 3/8 Female thread

Overflow valves - GATHER Accessories

-

Overflow valves for liquids, gases and vapours

The GATHER overflow valves are simply designed and compact pressure limiters which offer accurate inlet pressure adjustment with easy installation and maintenance. In operation, the inlet pressure is in balance with the spring-loaded valve as soon as the preset opening pressure (in the pipeline) is reached and exceeded. The preload of the valve spring and thus the opening pressure can easily be adjusted from the outside. As connections, standard pipe fittings or individual connections according to customer specifications are available.

Technical data

- Material: Stainless steel (1.4571)

- Temperature range: T = -15 up to +300°C

- Seals: FFKM (FDA-compliant)

Advantages

- TÜV-certified

- Compliant with the German Clean Air Act

- FDA compliant

- ATEX compliant

- Compact straight-line construction

- Freely selectable optimal installation location

- Low pressure loss (adjustment range 1:35)

Non-return valves - GATHER Accessories

-

Non-return valves for liquids, gases and vapours

Technical Data

- Material: Stainless steel (1.4404)

- Seals

- FKM (Viton®) (-20°C up to +200°C)

- EPDM (-40°C up to +150°C)

- Response pressure: 1,0 barg (± 10%)

Heating jacket - GATHER Accessories

-

Heating jacket use in the high temperature range

The GATHER heating jacket system ensures an even heating of the pump head by the flow of a heating medium. The heating jacket can be easily plugged and installed onto the pump head. Due to the appropriate design and material selection especially in the area of the magnetic pot and the seals the stainless steel pump can be used up to a system pressure of 300 bar and at a simultaneous temperature of +450°C. The heat transfer to the drive is reduced by special connecting parts.

Technichal data

- Material: Stainless steel (1.4571)

- Temperature range: T = -15 up to +450°C

- Seals: FFKM (FDA-compliant)

Specification

- Heating connections G1/4

- Housing stainless steel 1.4571

- Pressure in the heating jacket up to 20 bar

- Heating / cooling medium: brine, steam, thermal oil, etc.

- Heating temperature up to +450°C

Couplings

DBG Standard - GATHER SERIES DBG

-

Flat-face quick disconnect coupling

GATHERs flat-face quick disconnect couplings of the DBG series shut off on both sides and can be operated with one hand. They are designed in such a way that no liquids escape when disconnected and no air pockets enter the pipe system when connected. The design of their internal structure allows inline cleaning CIP (Cleaning in Place).

All components are sufficiently washed around, product adhesions are completely removed. The pressure drop in the quick disconnect coupling is very low, as the flushability is achieved by its inner contour which ensures a favourable flow. All seals are located on the inside, which means increased operational safety.

- Dry-break, robust and safe for every application

- DBG series, DN 4 to DN 65

- Over 500,000 coupling cycles

- The price cutter made of simple, alloyed steel

DBG-CSP - GATHER SERIES DBG

-

Flat-face sterile coupling

Principle: First seal, then release the flow! During the coupling process, the ring valve of the socket and the flat valve of the nipple push against each other. Before the valves release the flow, the interior is shut-off against the environment. The dead space-free design prevents air inclusions when connecting and drip losses when disconnecting.

The robust DBG series represents the top model in its market with over ½ million coupling cycles.

- Dry-break, robust and safe for every application

- Especially in the pharmaceutical industry, Ra <= 0,8 µm

- Special product line within the DBG series, DN 6 to 40

- Unique in its class

DBG-SV - GATHER SERIES DBG

-

Flat-face tank coupling

Shut-off design in both sides, dry-break and capable of connecting under residual pressure

The hose couplings of the DBG SV series have self-closing shut-off valves. When disconnecting, there are no liquid leakages from the hose and container, no air or dirt enters the line system when connecting. These dry-break hose couplings offer a high degree of safety during refuelling, filling and decanting, because despite frequent coupling, environmental damage or hazards to persons due to leaking liquids are excluded. The liquids do not come into contact with the ambient air. Coupling and uncoupling is very easy and smooth, even if the lines are under residual pressure.

Technical data

- Materials: Stainless steel (1.4404, 1.4021), Hastelloy®, Titanium

- Seals*: FKM, EPDM, FFKM, FVMQ, NBR, CR et al. (also FDA-compliant)

- Temperature range: -55 up to +300°C (according to seal type)

DBG-CUP - GATHER SERIES DBG

-

Dry-break coupling under pressure

The special feature of the DBG-CUP is its possibility to connect a pipe with a hose without pressure relief, whereas both of them can be under pressure. The series owes this property to the unique CUP SYSTEM®. The CUP valve is designed in such a way that the system pressure has hardly any influence on the coupling force.

- Special series DBG-CUP, DN 12 to 25

- Dry-break, robust and safe for every application

- CUP SYSTEM® connection under pressure

- Unique in its class

Series HK - HANSEN ORIGINAL

-

Original Hansen double shut-off hydraulic coupling

Double shut-off design (single shut-off or in both halves possible)

The quick disconnect couplings of the HK series are single shut-off, double shut-off or straight-through. The double shut-off version is to be earmarked for hazardous media such as acids, alkalis, hot water or steam. Single shut-off couplings can be equipped with a non-return valve in the socket or nipple, depending on the application.

During connecting the valves do not push against each other until the coupling is shut off to the outside. Conversely, they are only separated when the valves are closed. This type of quick disconnect coupling works splash-free.

Series ST - HANSEN ORIGINAL

-

Original Hansen coupling with straight-through design

Straight-through hydraulic and pharmaceutical coupling

The ST coupling series is characterized by its extremely robust design. It is particularly eligible for applications where the flow must be guaranteed even with highly viscous media such as greases and a shut-off can be dispensed with.

Special solutions - Multicoupling

-

The ideal interface

A multicoupling system which can be put together individually and combines different operating media in a single interface. The product is robust, durable and easy to use.

Thanks to the perfectly matched adaptive inserts, you can flexibly integrate different diameters, connection types and media in a multiple coupling. The multicoupling system offers many advantages such as increased productivity, space optimization, operator and plant safety. The risk of faulty connections is excluded.

GATHER develops customer-oriented solutions according to your specifications.

- maximum efficiency

- several connections in one coupling

- connecting and disconnecting even under pressure

- shorter machine set-up times

- tool-free installation

- robust and durable

- individual combination of connections

- ideal for machine plant and prototype construction

Applications:

Engine test benches, reactors, temperature control of injection moulding tools, rolling mills, cooling of electronic components, etc.

Accessories

-

Accessories for emergency release couplings

Double shut-off, release by traction rope

Description

A hose line which is used to convey hazardous media must have a predetermined breaking point. The latter prevents the escape of hazardous liquids or flammable gases in the event of unexpectedly occurring tensile forces. Usually, flange couplings screwed together with a tear-off bolt are used for this purpose. If this coupling has come off in an emergency, more effort will be required to reasssemble the connection; the manufacturers customer service must re-bolt the coupling.

Emergency separation function

Our double shut-off quick coupling with its de-coupling by traction rope offers a more cost-effective solution: A wire rope attached to the sliding sleeve of the coupling socket pulls it in the opening direction when pulling forces on the hose occur. The nipple located in the socket is unlocked, the valves of both coupling parts close. Only then does the nipple slide out of the sealing ring of the socket. After unlocking, both ends can be connected again by simply plugging them into each other; the coupling is immediately ready for use again. The wire rope length is so selected that the sliding sleeve of the socket moves in the opening direction before the hose tightens.

Advantages

- No shear pins or shear bolts need to be replaced after an emergency separation; simply plugging them into each other is sufficient to restore the connection.

- Emergency release coupling and quick coupling are combined in one system.

- The coupling does not have to be in the middle of the hose to function properly, but is attached directly to the engine: In an emergency, the vehicle will not drive off with a disconnected hose piece, but the entire hose will remain at the loading station! Zubehör für Nottrennkupplungen