|

#L

|

|

| #POS |

|

|

Germany |

Eaton Industries |

|

|

|

|

|

|

|

|

|

|

|

|

| Navigation |

|

|

|

|

Offer Profile

Moeller is Eaton

The traditional Moeller brand is part of Eaton since April 2008. Both brands

have a lot in common. Key technologies have been complemented by the

integration of Moeller and the global market coverage has been rounded off

with products to UL/CSA and IEC standards. We work together as a team

ensuring the success of our customers. With a larger product portfolio, with

more innovations and a global reach. And all this in just one company –

One Eaton.

Eaton's Moeller Business,

based in Bonn, Germany, is one of

the leading, globally active suppliers of systems and components concerned

with power distribution and automation in industrial,

infrastructure and

residential building applications.

Our components are

specially matched to the particular requirements of different industries.

You will find helpful suggestions, solutions and applications in our

industry portal.

|

|

|

|

|

|

Solutions

|

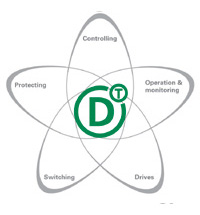

SmartWire-DT

SmartWire-DT.

Innovations merge,

technologies grow together.

Evolution in the control panel.

Manufacturers of machines and systems strive to achieve a balance between

the maximum level of functionality and cost optimization.

SmartWire-DT is a communication system for industrial switchgear based on

the concept of continued development in the control panel and in the

peripherals: from control through to protection and switching, and extending

to driving, operation and monitoring. A technology that benefits you, both

now, and in the future.

SmartWire-DT won the Automation Award 2009!

|

|

SmartWire-DT. Evolution in the

control cabinetGenerally used automation technology has over

the years offered the most varied solutions with different networking

architecture configurations, ranging from the classical central

configurations to distributed solutions. Further potential exists,

particularly in the area of control circuit wiring.

Switchgear is still wired individually and connected to the inputs and

outputs of the control. Wiring faults, complex wiring and function tests,

extended diagnostic times during malfunction trouble-shooting are still the

result irrespective of the sophisticated automation features. SmartWire-DT

transforms standard switchgear to communicationenabled devices. The

conventional control wiring between I/O assemblies and switchgear is reduced

significantly.

|

|

|

|

Yesterday

In the past, the classic control panel consisted of a

central control with switchgear, sensors and actuators, which all had to be

wired individually.

Conclusion: extensive wiring effort, large and expensive control

panels, time-intensive commissioning, complex trouble-shooting, limited

diagnostic features.

|

|

Today

Switchgear is connected directly to SmartWire-DT and

coupled via a gateway to the control. The control circuit wiring is reduced

to a minimum.

Conclusion: drastic reduction in the wiring, clear and compact

control panels, short commissioning times and comprehensive diagnostic

features reduce the standstill times and thus increase the availability.

|

|

Tomorrow

New SmartWire-DT components extend the portfolio. The

next additions for connection to SmartWire-DT are the circuit-breakers of

the NZM series and the new electronic motor-protective circuit-breakers PKE.

Conclusion: Eaton offers a modern and forward-looking interconnection

system for industrial automation with SmartWire-DT.

|

|

|

|

Safety Technology

For the operator of the machine a safely equipped

machine on the one hand means compliance to legal standards, and on the

other hand it means possible savings in costs through:

- Lower insurance premiums

- Shorter standstill times and

- Fewer interruptions in production.

Our products are characterised by exceptional reliability, long life

spans, high levels of serviceability and compliance to required national and

international standards. |

|

|

|

Emergency-Stop Button

Emergency-Stop is now state-of-the-art, providing safety

for Man and the machine. Moeller offers a wide range of Safety Components

for the protection of Man, machines and production goods in emergency

situations.

- Emergency-Stop button from the RMQ-Titan or RMQ-16 ranges

- Foot and palm switches FAK

- Emergency-Stop buttons and Position switches LS-Titan

- AS-Interface Emergency-Stop button

|

|

Emergency-Stop Switch

- Rotary switches T and switch-disconnectors P with Emergency-Stop

function

- Main switches with overload and short-circuit protection, as well as

Emergency-Stop function, using the motorprotective circuit-breaker PKZ

- Circuit-breakers NZM and switch-disconnectors N, the Emergency-Stop

switches for high currents

|

|

Door Safety Switch

The safety of all personnel working in production halls

must be ensured at all times. Protective doors and hinged flaps keep people

out of hazardous areas.

- Safety for persons and processes: door safety switch

LSR-... /T(KG,S)

- Securing and locking with the safety switch LS...-ZBZ for protective

doors

|

|

|

|

Safety-/ Position Switches

- Monitoring

safe positions with LS-Titan

From material handling systems to plastic injection moulding; from car washes to doors on trams: the position switches LS-Titan

are used wherever there is exact positioning requirement.

- World innovation – the electronic position switch LSE-Titan®

The electronic position switch LSE has an operating point that can be

set variably. Two fast and bounce-free PNP switch outputs enable high

switching frequencies. They are protected against short-circuit and

overload and are equipped with an abrupt switching behaviour. This

guarantees a defined and reproducible operating point.

- Switch off the danger – safety position switches LS...ZB

Safety position switches LS-ZB and LS 4-ZB are used on centrifuges,

motor and gearbox covers, presses, etc..

|

|

Safety Relay

Safety relay ESR5 for monitoring of the safety

circuits

The electronic safety relays ESR5... are an important component of the

safety equipment.

In fault-free operation, the safety-relevant circuits are monitored by the

electronics after the switch on command and the enable paths are enabled via

the relay.

You can choose between the following safety relays:

- Emergency-Stop

- Protective door

- Light barrier

- Two-hand control

- Off delay and

- Contact extension.

|

|

easySafety Control Relay

The new easySafety control relay is used for monitoring

safety devices at the machine.

In this way, applications can be implemented with easySafety that comply

with the most stringent international safety standards such as category 4 in

accordance with EN 954-1, PL e in accordance with EN ISO 13849-1, SILCL 3 in

accordance with EN IEC 62061 and SIL 3 in accordance with EN IEC 61508.

Product features:

- All in one: a host of safety and standard functions in one device

- Small and compact design with integrated display

- Multi-level safety and security concept prevents manipulation and

protects know-how

- Configuration by means of simple assignment of ready-to-use and

tested safety function blocks.

|

|

|

|

Contactors

Reliable monitoring of contactors with mirror contacts

Operational switching of motors, heating etc. is the typical task of the

contactor DIL M.

In hazardous situations the contactor DIL M is used to switch off the motor

which drives the hazardous motion. The state of the contactor contacts are

monitored here via mirror contacts.

|

|

Contactor Relays

Positively driven auxiliary contacts for

safety-relevant controls

Small control tasks – which require the duplication of contacts and the

connection of large contactors to electronic outputs – are typical tasks for

contactor relays.

As soon as safety-relevant circuits are affected the NO and NC auxiliary

contacts may not be closed simultaneously.

Contactor relays DIL A features positively drives contacts conform to IEC EN

60947-5-1 Annex L. They can be used to safely implement control functions in

safety-relevant system sections.

|

|

CMD Contactor Monitoring Relay

Redundant

connection of contactors no longer necessary

The contactor monitoring relay CMD monitors the contactor´s main contacts

for welding. In the case of welding the relay switches off the upstream

circuit-breaker. Because of this circuits in safety catergory 3 no longer

need to have a second contactor that redundantly switches off.

Using the CMD, circuitry can be designed that corresponds to Performance

Level d according to ISO EN 13489.

|

|

|

|

Signal Tower and Acoustic Indicators

A clear picture at a glance

Signal towers SL provide visual and audible signals of machine states,

easily identifiable even at a distance.

Signals are distinguishable as continuous light, flashing light, strobe

light or acoustic indication, enabling their level of importance to be

correctly evaluated without delay.

|

|

|

|

|

Motor Applications

|

Control and Indication

|

|

|

|

Control Circuit Devices RMQ-Titan, RMQ16

|

|

Signal Towers SL

|

|

Electronic Position Switches LS

|

|

Mechanical Position Switches LS

|

|

Electronic Sensors

|

|

|

|

Pressure Switches MCS

|

|

Safety Position Switches

|

|

Rotary Switches, Switch Disconnectors

|

|

Small Enclosures CI-K

|

|

|

|

|

|

Control and Visualisation

|

|

|

|

Timing Relays ETR

|

|

Safety Relays ESR5

|

|

Measuring and Monitoring Relays EMR

|

|

easyControl Relays

|

|

easySafety

|

|

|

|

easyControl Compact Control

|

|

Multi-function display MFD-Titan

|

|

HMI/PLC

|

|

Modular PLC

|

|

Remote I/Os

XI/ON and WINbloc

|

|

|

|

Automation Software Download

|

|

Software GALILEO and MXpro

|

|

Switched-Mode Power Supplies SN3

|

|

|

|

|

|

|

|

Switching, Protecting and Driving Motors

|

|

|

|

x-Start - The New Generation

|

|

Contactors 3-pole

|

|

Contactors 4-pole

|

|

Contactor Monitoring Relays

|

|

Mini Contactor Relays

|

|

|

|

Contactor Relays

|

|

Motor-Protective Relays

|

|

Motor-Protective Circuit-Breaker PKZ

Solar switch up to 63 A

|

|

Motor Starters MSC

|

|

Compact Starters, High-Capacity

Starters PKZ

|

|

|

|

Busbar system SASY 60i

|

|

Soft Starter

|

|

Frequency Inverters

|

|

Distributed, Electronic Drive System Rapid Link

|

|

|

|

|

|

Matching Voltage and Current

|

|

|

|

Customised coiled and wound

Products

|

|

Transformers

|

|

Power Supply Unit

|

|

|

|

|

Power Distribution

|

Switching and Protecting Power Distribution

|

|

|

|

Compact Circuit-Breakers, Switch-Disconnectors

up to 1600 A

|

|

Open Circuit-Breakers and Switch-Disconnectors

from 630 A to 6300 A

|

|

Arc Fault Protection System ARCON

|

|

Curve Select:

Characteristics Program

|

|

BreakerVisu: Visualisation

for Circuit-Breaker

|

|

|

|

Metering & communication module

NZM-XMC

|

|

Miniature & Residual Circuit-Breaker

|

|

Eaton Configurator Circuit Breaker

|

|

|

|

|

|

|

|

Switchgear Systems

|

|

|

|

xEnergy Switchboard Systems

|

|

MODAN Power Distribution Systems

|

|

Insulated Distribution Boards

|

|

Accessories

|

|

Moeller Engineering Tools

|

|

|

|

Buildings

|

|

|

|

Xclever Home

|

|

Xcomfort Building Automation

|

|

Xpatch Network Technology

|

|

Xpole Installation Products

|

|

Xboard Distribution Boards

|

EATON Solar

|

Safe and sustainable exploitation of solar energy

|

|

|

Eaton provides you with the complete package for safe

operation of photovoltaic installations in single-family houses. Here you

can find an overview of the most important components.

Power inverters

Efficient and reliable power inverters secure the yield

DC switch disconnectors

Compact switch-disconnectors for power inverters in switchgear systems or in

separate enclosures with IP65 degree of protection

DC fireman’s switch

In hazardous situations, the house is remotely disconnected from the

electrical supply to ensure that the fire services can offer assistance in

safety

DC string circuit-breakers

– Fuse switch-disconnector with integrated short-circuit protection

– String circuit-breaker immediately ready for reactivation after a short

circuit

DC overvoltage protection

The overvoltage protection prevents damage to the power inverter from

overvoltages and protects the yield of your installation.

|

|

|

|

Safe solutions for solar parks

|

|

|

In photovoltaic power stations, the energy is

switched, protected and distributed from the string right up to

medium-voltage. Eaton provides solutions for every task.

DC string circuit-breakers

DC string circuit-breakers with remote switching are immediately ready for

reactivation after a short circuit

DC fireman’s switch

In hazardous situations, the installation is remotely disconnected from

the electrical supply to ensure that the fire services can offer assistance

in safety.

DC switch disconnectors

Special switch-disconnector versions for up to 1000 V DC comply with the

isolation properties even for earthed IT networks.

DC overvoltage protection

The overvoltage protection protects the power inverter against damage from

overvoltages and protects the yield of the installation.

Contactors DILH

Contactors DILH switch the power inverter safely onto the grid.

Circuit-breakers NZM and IZM

Circuit-breakers NZM: A comprehensive range for energy distribution

applications in the photovoltaic field up to 6300 A.

|

Industries

|

Power Distribution and Automation in Industry and Buildings

|

|

|

|

Renewable Energies

Rising energy prices and limited fossil fuel resources

make the requirement for alternative solutions in the field of electric

power generation world-wide essential. At the same time, demand is

increasing for energy, particularly in regions with high levels of

industrial growth. The industrialised countries are also seeking to lessen

their dependence on imports of oil, gas, coal and uranium.

Renewable Energies

These are the reasons why renewable energies are increasing in significance

on the electricity market. They already contribute in many ways to the

supply of energy and also make a significant contribution to climate

protection. In particular, the diversity of useable raw materials guarantees

the supply and contributes to the independence of states from fossil fuels.

A further benefit: the plants and systems can be simply dismantled at the

end of their service life and recycled.

Renewable energies are primarily native energy sources. An increase in their

use boosts the regional contribution to value generation – an aspect which

should not be neglected. These forms of energy contribute significantly to

countries with underdeveloped infrastructure: large segments of the

population are supplied with energy for example, by rural electrification.

Electricity generation from renewable energy sources – these are small,

compact units which contrast with the large conventional power stations.

This compact method of power generation is based on low-voltage technology.

Wind energy – Solar energy – Bioenergy – Photovoltaic

Moeller is ideally placed for renewable energies as a leading supplier of

components and systems for energy distribution and automation. Our

automation products already control and safely monitor many functions in

systems and plants: For example, programmable logic controllers regulate

photovoltaic power plants world-wide. In the field of power generation, such

as wind energy plants, Moeller switchgear safely and reliably switches and

protects the electrical power generation systems. Moeller contactors are

also a guarantor for malfunction-free connection to the power grid.

Manufacturers, suppliers and installers of these systems already

successfully use our products and put their trust in the proven and tested

quality of Moeller products.

|

|

Photovoltaic switchgear – From small houses to

large-scale systems

Actively shape the future with safe photovoltaic

systems

Photovoltaic power plants convert sunlight directly into electrical energy.

Photovoltaic cells are used for this purpose. Photovoltaic power is a

renewable energy source which is used primarily in domestic and public

buildings as well as open spaces. A differentiation is made between

grid-independent systems and systems coupled to the power grid. Power grid

coupled photovoltaic systems feed the generated power directly into the

electrical grid. There is no need for sophisticated intermediate storage. A

system of this type consists of photovoltaic cells, one or more inverters

and switchgear for operation, maintenance and protection in the event of a

fault. This is why photovoltaic systems coupled to the grid require very

reliable and safe individual components.

Reliable grid disconnection devices

Inverters convert the DC current from the photovoltaic cells to AC current.

The frequency and voltage characteristics are adapted to those of the public

power grid. Reliable protection and main switches ensure safe operation.

Moeller offers the right solutions here: For integrated or external mains

switches, for manual or automated operation on the DC current as well as on

the AC current levels.

|

|

|

|

Automotive

The automotive industry is repeatedly faced by new

challenges based on the increasing level of globalisation of the markets. It

is essential to quickly and flexibly respond to individual demands and

requests from customers with innovative and reliable vehicle models. The

automobile manufacturers concentrate on core components such as the chassis

and powertrains with a low in-house production depth.

The vehicles are manufactured using system components supplied by the

suppliers with the assistance of a sophisticated logistical system. As a

partner of the automotive industry, we provide high-quality components and

products – whether they are used for electrical systems or for the

automation of manufacturing processes and machines. These are decisively

influenced by the respective vehicle model, and nevertheless must guarantee

a high level of flexibility for the most diverse range of variants and

equipment features.

A very high quality and durability are fundamental prerequisites for electro

technical equipment used in production lines. Even the shortest standstill

times entail very high costs for automobile manufacturers. In order to avoid

such a situation, the individual components are tested and standardised.

Processing and handling simplicity of the products which are used is crucial

for installation and commissioning. During operation a comprehensive range

of diagnostic features and quick replacement are essential.

Our product range includes switchgear such as circuit-breakers and

contactors, as well as automation solutions with a PLC and visualisation. We

provide tried-and-tested and innovative products ranging from the energy

supply, to main switches, to the control of manufacturing processes.

Our close co-operation with the automobile manufacturers on the one hand,

and machine and system suppliers on the other hand, has established us as a

reliable partner in the automotive industry.

|

|

Airport

The continually increasing volume of passengers, luggage

and freight represents a growing challenge for airports, airport operators

and airlines. Airports have to continually adapt their baggage and freight

handling capacities to the astonishing pace of development.

The airport operators have to fully rely on the technical equipment to

master these demands. Airports are some of the largest and most complex

systems where automation components are used. This also includes the power

distribution and systems for conveying persons and luggage. High levels of

availability, longevity and additional functions developed especially

airport operations are of particular importance. We at Moeller are

established as one of the leading providers for many airport operators in

this segment.

Power Distribution and Building services

The energy supply is the umbilical cord of every airport. A power failure

represents a considerable interruption of the operation and endangers the

safety of passengers in every area. Redundant and networked systems are

therefore used in order to ensure optimum availability and reliability.

XEnergy provides the ideal platform here.

Reliability, safety, and protection of passengers are the primary concerns

of the airport operators with regard to the electrical installations in

airport buildings. The demand is for a high level of availability of the

building infrastructure, an increasing level of remote monitoring and remote

operation of the systems, a high level of service availability and

transparency as well as use of standardised modules. We at Moeller, as a

long-standing partner for various airport operators have developed a series

of devices in building services, which ensure a smooth supply of power from

the distribution board to the socket.

Motor Applications

The availability of electrical drives for luggage and cargo handling plays

an increasingly important role due to the continued decrease in stopover and

turnaround times. The highest levels of system availability as well as fast

troubleshooting and problem rectification are essential. With Rapid Link the

decentralised drive control, we provide a reliable and proven solution.

|

|

|

|

Heating - Ventilation - Air Conditioning

Heating – ventilation – air conditioning (HVAC) is a

branch (also referred to as a sector ) of technical building installations

and can therefore be categorized under overall building equipment. This is

comprised mainly of the following:

- HVAC systems

- Sanitary facilities

- Material handling systems

- Electrical systems

(power distribution, communication systems, security systems)

- Building automation.

HVAC is a collective term for all air conditioning technology. Its task

is to reliably maintain the required values of temperature, air-humidity and

air quality – irrespective of fluctuations in the surroundings (adjacent

areas, outdoors).

For this purpose, machines (equipment) are required that dissipate (cool

down) or introduce (heat up) heat to the areas concerned, which increase

(humidify) or reduce (dehumidify) the level of humidity and transport the

media that is used (air, water).

The following functions are vital in HVAC systems:

- Heating of rooms and warm water

- Chilling

- Ventilation

- Air conditioning

We will also be examining this in conjunction with:

- Energy distribution and

- Building automation.

The price increases over the last number of years as well as the more

stringent statutory requirements, relating to minimum energy consumption

requirement for building heating and air conditioning systems, has seen the

introduction of comprehensive demands. Thus, the requirements for improved

HVAC machines, sophisticated building automation and open higher-performance

fieldbus systems enabling inter-communication of the machines/appliances

with one another and the control station are steadily increasing in their

level of sophistication.

Eaton's Moeller Business is a supplier of a range of electrical components

in this sector. |

|

Logistics

It is of vital importance for many customers to speed up

the internal logistical process, due to the persistent cost pressures and

the demand for continuous increases in productivity. Optimisation of the

handling process, transport and the storage of material flows are necessary.

Here solutions such as automated production processes, optimised assembly

lines, and efficient storage and consignment systems are in demand.

Whether it involves the movement of more goods at the main turnaround time

or to turnaround goods more quickly and effectively, our products smooth the

way for optimised operations and processes.

Horizontal material handling

The world is on the move and its starting to speed up. Transportation – swap

in and swap out – consignment, raising, lowering, tilting – and positioning.

The technology must function with precision and absolute reliability during

the main goods turnover within a logistics centre. Every additional minute

that the trucks or aircraft must wait costs hard cash. Our reliable and easy

to handle systems offer an excellent basis for optimised logistical

processes.

Safety energy distribution and load peak coverage

The quality of power distribution components becomes evident, particularly

in times of peaks or overloads. Overload problems in an area of the

logistics centre may not affect operations in another part of the centre.

Our energy distribution products are optimally matched to one another – from

the distribution board to the miniature circuit-breaker.

Stock control

There are many control and monitoring tasks in a warehouse. It is essential

to control and document stock movements. Safety-relevant areas that exist

may need to be protected.

The control relays of our easy series are the ideal platform for the

assumption of control tasks in the warehouse. Using the control relay

easySafety, it is also easily and reliably possible to protect

safety-relevant areas.

|

|

|

|

Food/Packaging

Processes in the food industry

In the food industry, the level of process automation continues to increase,

and this trend sets new demands – particularly in terms of the suitability

of the technologies used with the stringent hygiene requirements. This is

also true in the multifaceted area of industrial baked goods. This sector in

Germany ranges from the Pizza (about 130 different varieties), to bread

(about 300 varieties), and extends to pastries and cookies (about 1,200

varieties).

The example for the manufacture of baked goods also makes it clear that the

production of food can always be classified into continually recurring

process stages. These are:

- Weighing/Metering

- Mixing/Kneading

- Baking/Drying

- Cooling/Freezing

- Packaging

- Transportation

- Energy distribution and

- Documentation.

As is the case with every production process, the food manufacturing

processes must be supplied first with (electrical) energy. Particularly

energy-intensive are the electrical ovens required for baking and drying, as

they are applied, for example, in the industrial manufacture of Pizzas.

The food industry places particularly high demands on the degree of

protection and design of the electrical control elements: On the one hand,

this facilitates cleaning operations, and on the other hand prevents

bacterial contamination. At the same time, the production data must be

recorded and monitored at all times. The European (EFSA) and the American

(FDA) guidelines stipulate extensive process documentation.

As a leading component manufacturer for electrical machine equipment, we

offer our customers from the food and packaging industries a

high-performance product range for operation (RMQ), display (XV), switching

(DIL) and protection (PKZ/NZM), right up to the control (easyControl/XC) of

the machines.

|

|

Shipbuilding

More than 95 percent of long-distance transport of goods

in world trade are handled by shipping according to information provided by

industrial and trade federations. The increasing demand in transport

capacity on the high seas shapes the entire sector. Shipping companies and

shipyards develop and implement increasingly more efficient, more

environmentally-friendly and safe concepts to fulfil these demands.

As a direct result, the electric drives and the supplies of these components

are becoming increasingly more significant, as the interaction of the

developed measures in the shipping industry is one of the main tasks of the

ancillary partner industries as a lifecycle partner of the shipping company.

Clean engines, optimised ventilation systems, more efficient power supply,

and intelligent course planning are just some examples from companies active

as ancillary industries in shipbuilding and offshore industries on the

German market. In these areas both reliable and high-performance

electro-technical components, controls and monitoring are required. Our

switchgear and automation components have fulfilled these maritime

requirements for decades.

The electro-technical equipment of today's ships is characterised by the

high power density. Whether it is a container ship with a power supply for

cooling refeer containers, or on a passenger cruise liner offering the

highest levels of comfort and exclusivity, compliance to standards,

directives and approvals is essential to guarantee the safety of ships,

persons and cargo. The entire system is just as reliable as each individual

component. We provide shipbuilders flexible and certified solutions for

energy supply and power distribution as well as for control of the ocean

going vessels.

Our product range includes switchgear such as circuit-breakers and

contactors, as well as automation solutions with a PLC and visualisation.

Furthermore, we offer solutions for safe operation of the system with the

arc-fault protection system.

Our products comply with all standards and guidelines for maritime

applications because of our close co-operation with the classification

societies. Our international presence allows us to serve the manufacturing

facilities as well as the after-sales services for shipowners wherever we

are needed.

|

|

|

|

|

|

|

|

|

#R

|

|