- Offer Profile

-

INDEVA Cobotics: process automation with collaborative robots

True to its vocation of offering technologically advanced products to relieve human fatigue, improve ergonomics and work safety, while increasing productivity with a quick return on investment, Scaglia Indeva has added COBOTs to its product range. Manufacturers since 1975 of industrial manipulators at the forefront of technology and later of self-driving vehicles, today Scaglia Indeva offers complete solutions for the internal handling of components along the production and assembly line and in warehouses.

INDEVA Cobotics: Turn-Key Solutions

PalFlex

Collaborative Palletizing Island

Modular and ready-to-use solution for any palletizing need of boxes, cans or other objects up to 16 kg (after checking the applied tool).

Speed up to 14 pieces/min(guaranteed rate with box weight of max 8 kg and with non-collaborative working mode and multiple gripping head).

The large color panel mounted on the machine assists the user in a clear and fast way, allowing him to optimize the palletizing process automatically without the need of additional programs.

Possibility of managing interlayers, thanks to the special warehouse module and the creation of particularly high pallets by means of a telescopic column.

PalFlex Advantages

- Easily transportable with a simple pallet truck

- Motorized telescopic column for Cobot to reach different heights

- Plug & Play: just a standard 220V and AC outlet to get started

- Ballasted base, possibility of working without having to anchor it to the floor and flexibility in positioning

- Secure: Immediate lockout upon obstacle detection, safety level Cat.3 PL d, guaranteed by the CE marking in accordance with the Machinery Directive 2006/42/EC

- Versatile: gripping hand can be customized according to the customer’s specific needs. Realizable in different shapes depending on what is to be handled (16-20 kg after verification of the cobot payload)

- Quick and easy task configuration using dedicated palletizing software, with just a few steps, allows the creation and optimization of palletizing configurations.

LoadFlex

-

Loaders and Automatic Warehouses

Islands prepared to interface with the company management system, industry 4.0 compliant.

They have an integrated system that stores data on quantities and processing times.

They are compatible with most CNC control models. It moves easily, allowing you to automate multiple machines with one cobot.

They make it possible to speed up production processes, especially repetitive and monotonous ones, eliminating downtime and fully exploiting the potential of operators and machines.

CS automated loader

CS is an automated loader , adaptable to different series productions, with different types and quantities of pieces to be processed. Supplied with n°2/4 base grids with customizable hole dimensions.

Optional:

- Inclinable table with excursion 0° – 15°, in order to have rapidity and precision in the positioning of the pieces.

- Industrial PC with Industry 4.0 readiness.

ASW Warehouse

Compact automatic warehouse that represents the solution for any production and process requirement. The load-bearing structure acts as housing and support for 14 drawers, which are managed by a motorized lateral shuttle that brings them to the cobot’s picking bay. More than 5 sqm of storage area. Industrial PC supplied as standard. The grids that can be used in drawers have holes with dimensions: 30 x 30 mm, 50 x 50 mm and 80 x 80 mm.

FP Series Warehouse

Warehouse for the processing of small and large series. Thanks to the rotating table it can work continuously: on one side the operator loads the blanks and unloads the finished products, while on the other side the Cobot picks them up and positions them in the machine. When the series is finished, the table rotates so as to serve the Cobot again. Possibility of handling parts from Ø 20 up to Ø 175 mm, with heights up to 400 mm. The capacity of the grids varies according to the size of the workpiece: for example, if you are machining workpieces with Ø 45 mm (or 45 x 45 mm) you can load 80 pcs/ grid. No. 4 base grids with customizable hole sizes aresupplied.

FPJ Series Warehouse

It allows the machining of small and medium series with a wide range of machining times. The capacity of the grids varies according to the size of the part: for example, if you are machining parts with Ø 40 mm (or 40 x 40 mm) you can load 157 pcs/grid. 2 grids are suppliedwith customizable hole dimensions.

GTO Revolving Pallet Warehouse

Allows palletizing of rings, flanges, gears and any other stackable item. On one side the operator loads, while on the other side the cobot loads and unloads the machine. When the stack is finished, the 14 pallets rotate to serve the robot again. Designed for stacking items with diameters from 60 to 250 mm, for a maximum height of 500 mm.

MyWelder

Available Welding Trajectories

MyWelder Set

-

The set includes:

MyWelder Software:- Doosan cobot – payload 9 kg – reach 1200 mm o Doosan cobot – payload 6 kg – reach 1700 mm.

- Esab welding machine.

Does not include:

- Welding bench

- Final application certification

MyWelder Single

All-inclusive solution including:

- MyWelder software.

- Doosan cobot – payload 9 kg – reach 1200 mm.

- Esab. welding machine welding table 1200×1200 mm.

- Safety barriers.

- Application certification.

MyWelder Double

All-inclusive solution including:

- MyWelder software.

- Doosan cobot – payload 7 kg – reach 1700 mm.

- Esab. welding machine welding table 2400×1200 mm.

- Safety barriers.

- Application certification.

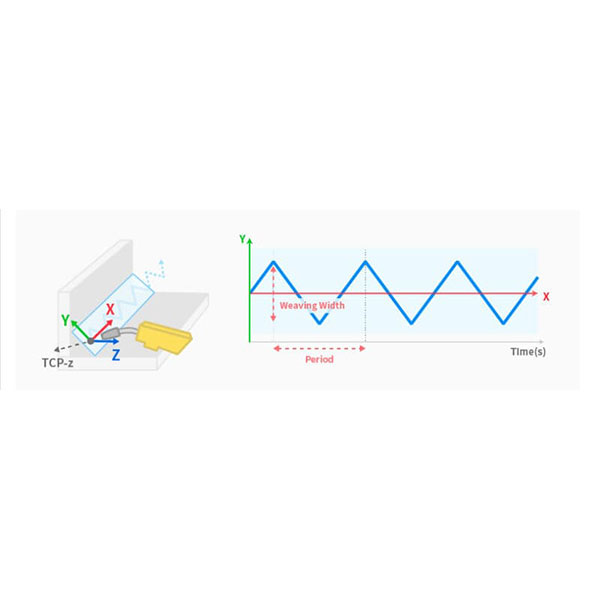

ZIG-ZAG

- Ability to control the wave amplitude and path speed of a period.

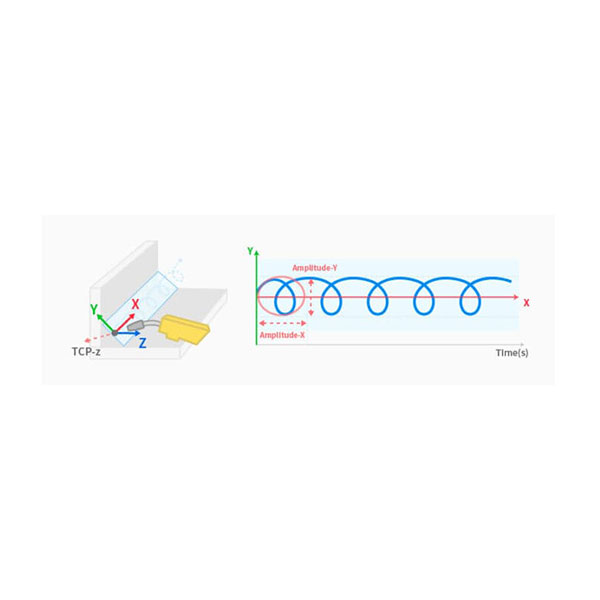

CIRCULAR

- Possibility of modifying the two amplitudes and their respective speeds separately.

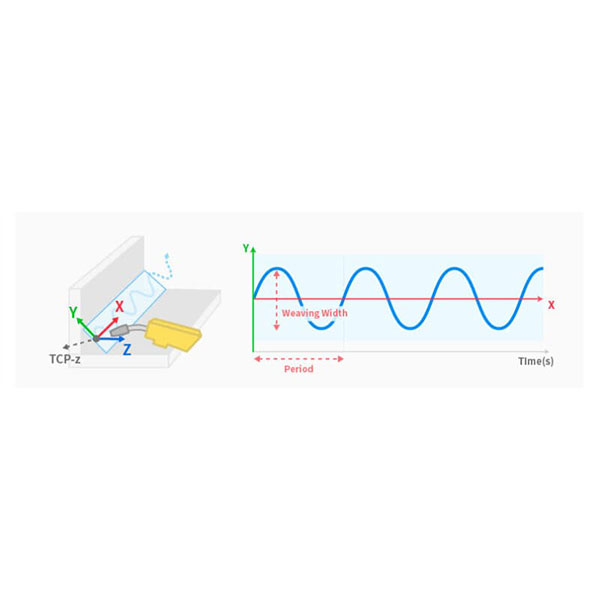

SINUOSOIDAL

- Possibility of changing the amplitude and period.

TRAPEZOIDAL

- It is possible to set a welding time from P1 to P2 and a different one for going from P2 to P1, as well as for accelerations, and it is possible to set a rest time after reaching the points.

MoveFlex

Mobile Collaborative Island

Solution consisting of the integration of a Doosan Cobot with an Automated Guided Vehicle (AGV). This integration allows the handling of components over long distances, making the cobot’s range unlimited.

It is also possible to configure the robot to perform different operations along the way.

The use of a vision system eliminates positioning problems and gives the system maximum flexibility.

Cobots, AGVs and DC controllers are battery powered.

Smart Assembler

Collaborative Assembly Island

Solution composed of Doosan Cobots and Smart Robots that enables interaction between Cobot and human operator.

Smart Robots is a 3D intelligent vision device that supports the human operator in manual tasks through perception and artificial intelligence in order to eliminate errors and improve efficiency and productivity.

The basic solution consists of: Doosan Cobot, 3D Smart Robots intelligent vision system and the MES (manufacturing execution system software).

Accessories available: Monitor, signal turret, scale and other devices, INDEVA Lean System modular bench.

How it works:

- It divides and schedules tasks between humans and cobots:

-Tasks that cannot be automated and are of high value to the human operator.

-Automatable and repetitive subtasks for the cobot. - Recognizes real-time operator actions and objects in assembly and mounting operations

- Verifies proper completion of predefined sequences.

- It alerts the operator in real time of any errors and guides him in correcting them.

Benefits:

- Reduces errors.

- Reduces costs

- Verifies proper completion of predefined sequences.

- Standardize the process.

- Increases the quality of the finished product.

- Double your productivity.

- Avoid collisions.

- Increases quality and ergonimy.

- Flexible and low cost automation.

- It divides and schedules tasks between humans and cobots: