- Offer Profile

-

Lowpad is a high-growth technology provider which arranges automation solutions for intralogistics based on intelligent autonomous mobile robots, intuitive software, custom-made vision, and handling applications. As experts in robotics technology, we are committed to engineering solutions that meet today’s evolving complex demands.

FLEET OF AUTONOMOUS MOBILE ROBOTS (AMR/AGV)

-

Exploit the possibilities of robotics within your business.

Transform your current process by automating your internal transport. Keep your existing building and load carriers and improve your flow and efficiency. Lowpad is committed to providing safe, collaborative solutions that will help you revolutionize your intralogistics with out-of-the-box technology.

Why Lowpad?

- Lowpad is the lowest autonomous mobile robot available on the market with a minimum height of only 13 cm (5”).

- Productivity increase through automating transport tasks.

- Our fleet manager Lowpad Supervisor can manage a fleet of more than a few hundred Lowpads.

Lowpad S

-

The Lowpad S is the perfect automation solution for (food) distribution centers and post and parcel companies—robust and safe AMRs to transport roll cages. Our Lowpads enable you to optimize your performance through increased insights, accuracy, and utilization of scarce human resources.

- Improved efficiency: Able to boost your productivity

- Smart integrations: Easy to integrate and able to exchange data with existing systems such as ERP or WMS.

- Ultra-low: The Lowpad S fits underneath existing roll cages

- Omnidirectional driving: Small turning radius for small pathways

Technical specs:

- DIMENSIONS L x W x H: 1194 x 700 x 657 mm / 47 x 27.6 x 25.9"

- DIMENSTIONS LIFTING TABLE L x W x H 843 x 446 x 110 mm / 31.5 x 17.6 x 4.3"

- LIFTING CAPACITY 450 kg

- LIFTING HEIGHT 225 mm 8.9"

- SPEEDRANGE 1.2 m/s

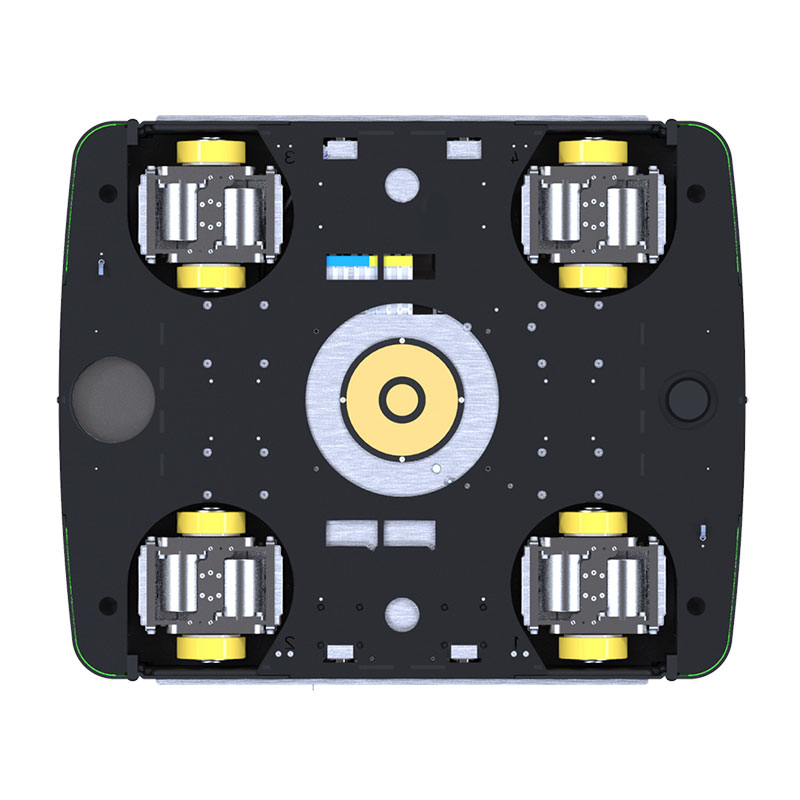

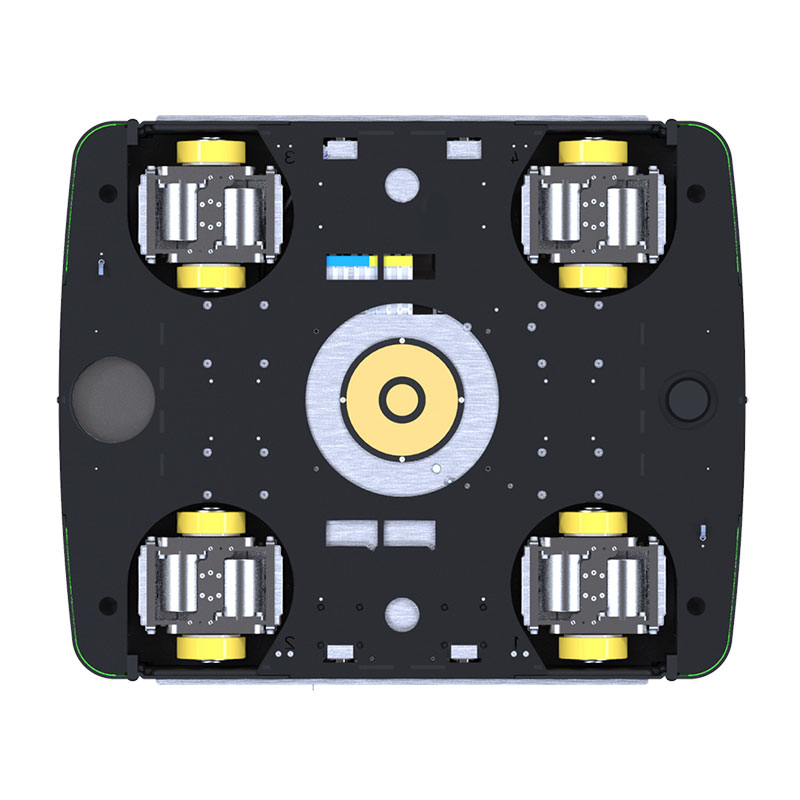

LOWPAD M

-

The Lowpad M is the ultimate mobile robot for pick carts and Danish CC trolleys. The Lowpad M is ultralow, only 128 mm high, and therefore suitable for load carriers with a minimum height between the cart and floor. Looking for an around the clock workforce?

The Lowpad M ensures gentle and safe transport of goods. Due to its unique characteristics, the Lowpad is versatile and can automate various logistical processes.

Improve your productivity and lower your operating costs in your intralogistics. Through high technology, we offer the best quality solution in collaboration with your wishes.

- Powerful lifting capacity: Able to lift 450 kilograms

- Accuracy: Accuracy through decreased human error

- Insights: Real-time data for optimization and decision making

- Smart integrations: Easy to integrate and able to exchange data with existing systems such as ERP or WMS systems.

Technical specs:

- DIMENSIONS L x W x H: 665 x 800 x 125 mm / 26.2 x 31.5 x 5”"

- DIMENSTIONS LIFTING TABLE L x W x H 843 x 446 x 110 mm / 31.5 x 17.6 x 4.3"

- LIFTING CAPACITY 450 kg

- LIFTING HEIGHT 40 mm 1.57”

- SPEEDRANGE 1.2 m/snbsp;

The ultimate solution for the autonomous movement of pick carts and Danish CC trolleys. The Lowpad M can carry heavy loads ensuring improved ergonomics on your work floor. Lowpads can withstand all environments, providing a robust backbone for your entire logistic process.

- Danish CC trolleys

- Pick carts

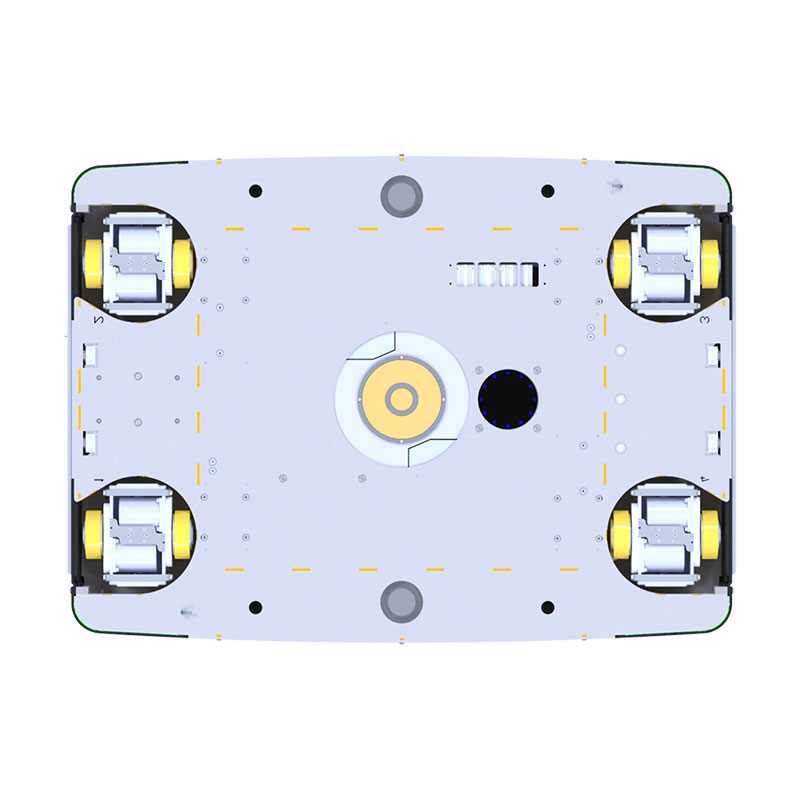

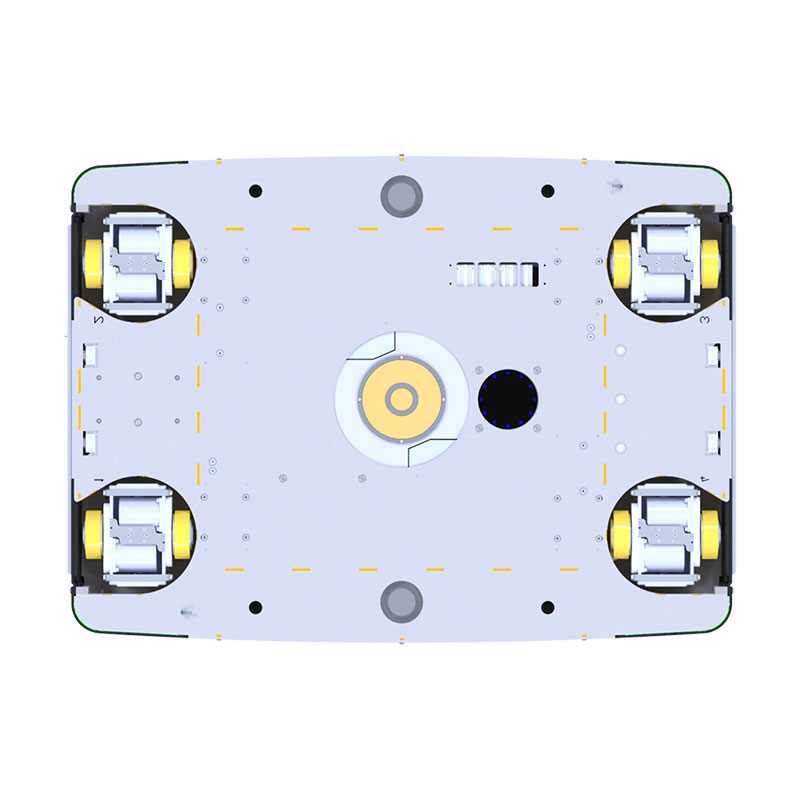

Lowpad L

-

The Lowpad L is the perfect automation solution for moveable racks and trolleys. Reliable and safe AMRs to enable you to keep pace with the dynamic e-commerce and parcel market.

- Decreased human labour: Reduction in labour costs and dependency

- Smart integrations: Easy to integrate and able to exchange data with existing systems such as ERP or WMS systems.

- Powerful lifting capacity: Able to lift a few hundred kilograms

- Scalability: Able to scale up depending on your capacity

Technical specs:

- DIMENSIONS L x W x H: 800 x 1075 x 128 mm / 31.5 x 42.3 x 5”

- LIFTING CAPACITY 450 kg

- LIFTING HEIGHT 40 mm 1.57”

- SPEEDRANGE 1.2 m/s

Looking for ways to automate your transport of racks or trolleys?

Because of its height and maneuverability, the Lowpad L is a flexible, effortlessly implementable solution. Moreover, the Lowpad is easily maintainable service-wise and can be operated by anyone due to its ease of use.

Improve your productivity and lower your operating costs in your intralogistics. Through high technology, we offer the best quality solution in collaboration with your wishes.

The Lowpad L is the ideal solution for the autonomous movement of movable racks and trolleys. The Lowpad L can carry heavy loads increasing your throughput. Lowpads can withstand all environments, providing a robust backbone for your entire logistic process.

- Moveable racks

- Trolleys

CASES

GXO

-

Complete marshalling solution at GXO with Lowpads, intuitive software and high-tech process equipment.

GXO was faced with the challenge of optimizing the outbound process at its state-of-the-art facility in Nieuwegein for a leading Dutch food retailer. The temperature-controlled site, which operates 24/7, needed a solution to place orders in the right unloading sequence for the truck driver in front of the docks. The automation of the high volume of rolly movements means that there is 100% elimination of manual walking in operation. Additionally, there are no more mistakes and apart from the Lowpad operator, it has become a completely crewless operation.

DHL

-

A to B transport of heavy printers at Ricoh/DHL configuration center.

Following a successful proof of concept, DHL was convinced of Lowpad AMRs for redesigning their logistics process. Lowpad’s safety feature was crucial in this location due to the crowded area with almost 60 workstations and narrow aisles measuring only 1.6 meters wide. DHL was able to get the operation up and running by making only minor adjustments to the area.

Royal Lemkes

-

Zone picking automation solution with a large fleet of Lowpad AMRs.

Together, Royal Lemkes’ 300 operational employees covered about 5,000 kilometers daily. The company now has a new and more efficient way of registering and distributing plants. By automating the process with Lowpads, the right trolleys with incoming and outgoing plants are presented to employees at the right moment. Staff no longer have to walk 16 kilometres daily or move heavy Danish trolleys.

Monta

-

E-commerce Goods to Person order fulfillment solution with Lowpads.

Where previously, order pickers walked at least 15 km per day, products are now brought to the order pickers with Lowpads. This results in substantial savings in terms of labor deployment and efficiency improvement. Lowpad fulfills a key role in Monta’s logistic process and allows hybrid order picking, where order pickers and Lowpads operate in the same environment.

KWS

-

A to B transport of heavy containers in KWS's glasshouse in Einbeck.

KWS selected Lowpad because of its unique features. Especially the low height of the Lowpad M was a deciding factor. The Lowpads at KWS’ glasshouse facility take over transport tasks that humans were doing before. The result: containers can be moved automatically, faster, and safer and the available space within the glasshouse is allocated much more efficiently.

Double R Trading

-

Goods to Person solution with Lowpad as backbone.

Presenting the racks to the pickers and moving racks through the warehouse by Lowpads prevents much walking and reduces the risk of errors. Double-R implemented a total solution based on pick-to-light and sort-to-light technology, Lowpad AMRs, and an Actemium Logistics Automation WMS/WCS system.

SOFTWARE

-

Intuitive fleet manager software for a fleet of hundreds of AMRs

Optimize your internal transportation with a fleet of Lowpads and intuitive software.

Eliminate bottlenecks and downtime with 24/7 mobile robot operation throughout your facility. Whether you’re just getting started to delve into mobile robots or an enterprise challenged with managing a fleet of AMRs, Lowpad has the operations platform to support your needs now and in the future. Contact us to discuss your project and get a demo of our software.

How it works:

- Configure vehicle's parameters

- Create the Lowpad map

- Define routes and points-of-interest

- Activate Supervisor

- Connect Organiser

- Test the project

INDUSTRIES

Logistics / 3PL

-

A range of solutions to automate your intralogistics.

High customer expectations, rising labour costs, complex multi-product orders and high peaks are challenging the business growth of logistics service providers. At Lowpad, we understand these challenges. We have created a range of solutions for each logistic process to help logistic service providers to beat these challenges and drive their business forward.

Suitable Lowpads for Logistics / 3PL:

- Lowpad S

- Lowpad M

- Lowpad L

Grocery Retail

-

Innovative solutions to revolutionize your logistics.

Lowpad offers a range of solutions for all types of internal transport to automate and optimize your logistics. Flexible, robust and scalable solutions to enable you to stay competitive while meeting changing market demands.Suitable Lowpads for Grocery/ Retail:

- Lowpad S

- Lowpad M

Post & Parcel

-

Automation solutions to improve performance

In the post and parcel industry, the bar for meeting consumer demands is high. Short lead times, smaller orders, greater diversity of all product shapes and sizes and late cut off times must all be balanced against a cost-effective operation.

Suitable Lowpads for Post and Parcell:

- Lowpad S

- Lowpad L

Horticulture

-

Grow your productivity

Reduce labour requirements through Lowpads. By implementing Lowpads into your processes, simple transport jobs can be automated enabling you to utilize your labour force more efficiently.Suitable Lowpads for Horticulture:

- Lowpad M

E-Commerce

-

Cutting-edge technology to achieve customer satisfaction

With the rise of e-commerce, the role of setting standards has shifted from seller to consumer. The market is competitive, and the demands are more challenging. Lowpad offers a range of solutions for all types of logistical processes. Transform your warehouse management with

Lowpads and increase the operational efficiency of your processes. Decrease costs, increase efficiency, and empower your organization with a future-proof flexible system.

Suitable Lowpads for Horticulture:

- Lowpad L

- Lowpad S

APPLICATIONS

Inbound

-

Automate your inbound process with the Lowpad

Inbound logistics entails the transportation and storage of incoming goods. By automating this process with the Lowpad, inbound logistics can be managed more efficiently.By automating repetitive, mundane tasks, productivity gains are compounded across thousands of transactions, enabling greater capacity and agility. If you are considering taking advantage of our automation solution, you are probably wondering the ways that optimizing your supply chain will affect you and your customers. Automizing inbound logistics with effective mobile robot solutions means that you will be poised to take greater control of your supply chain. Stay in control and apprised of all incoming goods, providing ease of information and empowering better analytics overall.

Cross docking

-

Efficient cross docking automation solution

Cross docking is all about the fast moving of inbound shipments to outbound docks. Efficient cross-docking helps delivering your products to customers much faster while saving you a lot of money.The Lowpad cross docking solution, consisting of AMRs and intuitive software, ensure that right shipments are put on the right trailer in the right order – making sure last out is first in – so drivers don’t experience delays while making deliveries. Save on labor and improve your daily operation by implementing autonomous mobile robots who takes care of your internal logistics.

Marshalling

-

Solutions to upgrade your marshalling process

In a hypercompetitive market where cost, availability of labour, and flexibility must be balanced, Lowpad helps you achieve productivity and functionality.Looking for a flexible and easily scalable automation solution for your marshalling process? Take your marshalling to a whole new level. Embrace flexibility, speed, accuracy, safety and reduce deployment of hard-to-find personnel and related costs. We offer a fully automated process where Lowpads moves your load carriers to the outbound area just before they are needed to be shipped. How we do it? We combine all input data, cut off times and bay scheduling and convert it into tasks for your fleet of Lowpads. It results in more efficient use of available loading docks, a dynamic dock schedule and trucks that can be loaded faster and more efficiently.

A to B transport

-

Solutions to upgrade your A to B transport

The Lowpads are very versatile meaning that they can implemented in numerous types movements. As the Lowpad can drive without any infrastructural changes required, they can automate simple transport jobs where goods have to be transported from point to point.

Goods to Person

-

Increase order picking efficiency with Lowpad’s Goods to Person orderpicking solution.

The Goods to Person method with the Lowpad entails that Lowpads are used to retrieve inventory and bring it to the picking station.Through eliminating the simple tasks like walking of the picker, the productivity as well as the picking accuracy per picker is improved while labour intensity is reduced.

Dynamic Zone Picking

-

Looking for ways to improve your order picking process?

With Dynamic Zone Picking with the Lowpad, order pickers are assigned to specific locations or zones and Lowpads move load carriers between these zones.Each load carrier is connected to a specific order. To retrieve an SKU, the load carrier goes to that SKU’s area where we calculate the most efficient pick for the order picker. The order picker then places the required items on the load carrier that travels to the next location and delivers it to the assigned position. This way the pick run is cut from the picker resulting in often an increase of 100% in productivity per picker.

The main advantages of order picking solutions with the Lowpad:

- Increased productivity per picker

- Increased accuracy

- Less manual labor and minimized walking

- Lower operational costs