- Offer Profile

- Renishaw is a global company

with core skills in measurement, motion control, spectroscopy and precision

machining. We develop innovative products that significantly advance our

customers' operational performance - from improving manufacturing

efficiencies and raising product quality, to maximising research

capabilities and improving the efficacy of medical procedures.

Our products are used for applications as diverse as machine tool automation, co-ordinate measurement, additive manufacturing, gauging, Raman spectroscopy, machine calibration, position feedback, CAD/CAM dentistry and stereotactic neurosurgery.

Industrial metrology

CMM probes, software and retrofits

- Precision sensors for fast, accurate acquisition of

component dimensions and surface data.

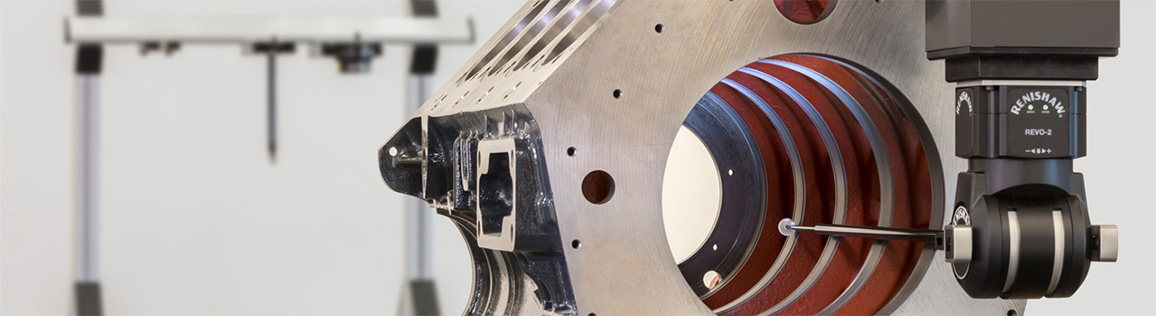

The world's leading range of measurement systems for CMMs

For more than 40 years, Renishaw has delivered innovations that have been milestones in industrial metrology. From the original touch-trigger probe and motorised indexing head, repeatable stylus changing and modular scanning systems, Renishaw sensors for co-ordinate measuring machines (CMMs) are an industry standard.

The 5-axis measurement product range represents the biggest step-change in measurement capability ever introduced, delivering unprecedented speed and measurement flexibility, whilst avoiding the speed versus accuracy compromises inherent in conventional techniques. Whether the REVO scanning or the PH20 touch-trigger, Renishaw's 5-axis systems boost measurement throughput, minimise lead times and give manufacturers a more comprehensive appreciation of the quality of their products.

5-axis technology

- Unlike conventional CMM measurement methods, Renishaw's 5-axis technology uses synchronised motion of CMM and head axes to minimise the machine's dynamic errors at ultra-high measuring speeds.

3-axis systems

- Renishaw probe systems are available in a wide variety of types to enable a best match for a particular application.

Manual systems

- A range of fixed and manually adjustable heads that connect a touch-trigger probe to the machine quill, allowing flexible inspection of complex components.

Machine tool probes and software

-

Renishaw probe solutions can help reduce set-up times by up to 90% and improve your process control.

Renishaw provides solutions for tool setting, broken tool detection, component set-up, in-cycle gauging and first-off component inspection, with automatic offset updates.

Machine tool probes for component setting and inspection

-

Renishaw probing systems provide an innovative solution to improve the efficiency of your machine tools.

Probing systems on CNC machining centres and lathes can be used to identify and set-up parts, measure features in-cycle for adaptive machining, monitor workpiece surface condition and verify finished component dimensions.

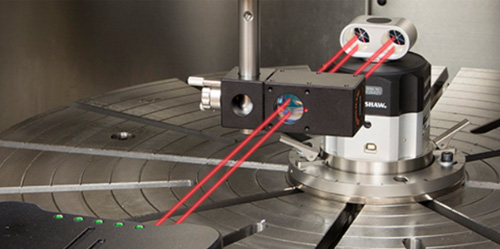

Machine tool probes for tool setting and broken tool detection

-

Renishaw probe systems provide an innovative solution to improve the efficiency of your machine tools.

Tool setting can measure the size of tools before cutting starts, and check for tool damage or breakage during the machining operation.

Powerful, easy-to-use machine tool probe software

-

A range of machine-resident and PC-based probing software solutions.

Solutions

Make the most of your probing hardware with a choice of flexible macro and PC-based probing software for a wide range of applications and machine tool controllers.

More industrial metrology products

Styli for touch probes

-

Renishaw offers a comprehensive range of precision-engineered styli and stylus accessories.

Our styli can be used on Renishaw's CMM, machine tool, scanning probes and Equator gauging systems, as well as for sensors from other manufacturers, to ensure maximum measurement accuracy.

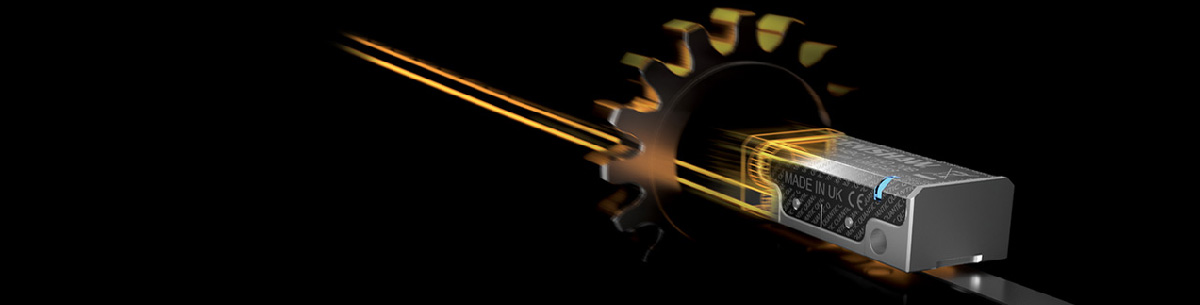

Machine calibration and optimisation

-

Machine performance measurement and diagnosis is essential to establish a known and repeatable level of process capability.

Renishaw's laser interferometer and ballbar measurement systems assess, monitor and improve the static and dynamic performance of machine tools, co-ordinate measuring machines (CMMs) and other position-critical motion systems.

Our products should, therefore, be considered as the first step in process improvement and are complementary to the on-machine and off-machine probing systems.

Equator gauging system

-

The Equator gauging system enables process control by delivering highly repeatable, thermally insensitive, versatile and reprogrammable gauging to the shop floor.

To control manufacturing processes on the shop floor, gauges have been used for decades, for example sets of callipers, go / no-go gauges or bore gauges. With advances in manufacturing, the need for new process control methods is increasing.

The Equator system is a flexible gauge, designed to provide speed, repeatability and ease of use for manual or automated applications, which is why hundreds of manufacturers worldwide are replacing their current gauging method with Equator systems.

Position and motion control

- Higher accuracy. Easier installation. Superior reliability. High quality optical, magnetic and laser encoders from Renishaw.

Magnetic encoders

- Through our associate company RLS d.o.o., we produce a range of robust magnetic rotary and linear motion sensors to meet growing global market demands.

Optical incremental rotary encoders

- High accuracy, superior metrology, easy integration.

Renishaw’s range of optical angle encoders include absolute and incremental versions, with accuracy to ±1 arc second, resolution to 0.00075 arc seconds and speeds up to 36000 rev/min.

RESOLUTE absolute encoder system with REXA30 rotary (angle) ring

- RESOLUTE is a true absolute, fine pitch optical encoder system that has excellent dirt immunity, and an impressive specification that breaks new ground in position feedback. It is the world's first absolute encoder capable of 32-bit resolution at 36 000 rev/min. Ultra low SDE and jitter result in a rotary encoder system that outperforms any other encoder in its class.

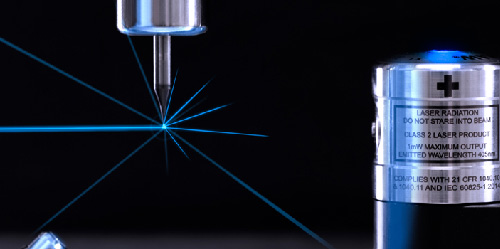

Interferometric laser encoders

-

Laser interferometer encoders provide the ultimate accuracy in linear position feedback.

Renishaw has almost 25 years of experience in providing interferometry based laser encoder solutions to OEM machine builders, ranging from large aerospace centres through to the high precision semiconductor industry.

Metal 3D printing

-

Renishaw is a systems manufacturer and solutions provider for additive manufacturing (AM).

Additive manufacturing with Renishaw

Renishaw is a leading manufacturer of advanced metal additive manufacturing systems and expert provider of customer-tailored solutions.

Renishaw's expertise

We design and manufacture additive manufacturing systems for manufacturing components in a variety of metals using a process called metal powder bed fusion (or laser melting). Our expertise in process development and our experience in using the technology in our own manufacturing operations enable us to provide turn-key and optimised additive manufacturing solutions for a broad range of applications in the industrial and healthcare sectors. Find out more about additive manufacturing systems and services for your industry...

What is metal AM?

-

Renishaw's metal powder bed fusion is an advanced additive manufacturing process that builds complex metal parts direct from 3D CAD data in a variety of metals.

Discover additive manufacturing

Additive manufacturing is a process of creating a three-dimensional object from a digital file. It is called additive because it generally involves building up thin layers of material, one by one. The technology can produce complex shapes that are not possible with traditional casting and machining methods, or subtractive techniques.

Benefits

- Multiple part consolidation - the number of items in an assembly can be reduced by designing as a single complex component.

- Reduce tooling costs - parts can be manufactured directly without the need for tooling.

- Access to complex geometries - internal channels for conformal cooling, hidden features, thin walls and fine meshes.

- Freedom from restrictions associated with traditional subtractive and casting manufacturing methods - when combined with applying new design rules.

- Lightweighting - only build material where it is required for optimum weight reduction

- Bespoke or customised items.

- Rapid design iterations right up to manufacture.

- Complementary tool the additive manufacturing process can be integrated into current manufacturing processes to reduce steps, time to market and cost.

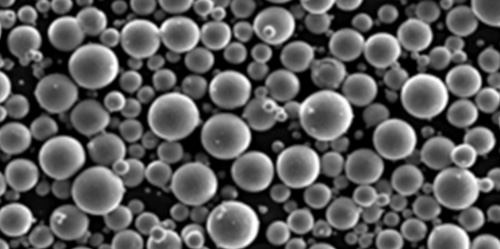

Metal powders for AM

-

Renishaw's powder bed fusion technology uses a range of metal powders including titanium alloy Ti6Al4V, nickel alloys inconel 625 and 718, cobalt chromium, and aluminium alloy AlSi10Mg.

Powder metallurgy (PM) is the general term for the consolidation of metal powders into solid components using heat and pressure to fuse the particles together, it is alternatively referred to as press and sinter. There are various technologies that fall under the PM umbrella such as hot isostatic pressing (HIP), metal injection moulding (MIM) and spark plasma sintering (SPS). All of these technologies can be used to manufacture near net shape components, reducing the requirement for subtractive machining which can create high levels of waste material.

Renishaw's additive manufacturing technology also uses metal powders as the feed material, however rather than using pressure and heat to fuse the particles together in a die, the powder particles are melted using a high power laser in sequential ultra-thin layers approximately the thickness of a human hair. The technique of using fine powders and very thin layers to build up metal components means that highly complex geometries are possible. The capability to include fine meshes, internal channels and to only place material where it is needed means that the technology can be used to reduce the material usage, increase functionality, consolidate multiple parts and manufacture geometries that are practically impossible by alternative methods.

Inert atmosphere generation

-

Renishaw's unique inert atmosphere generation ensures a high quality build environment.

The term inert means 'chemically inactive', so an inert atmosphere is an environment in which powder bed fusion can take place without the risk of contamination from reactive gases that exist in the air, such as oxygen and carbon dioxide. Renishaw use argon gas for the build environment of its additive manufacturing systems due to the fact that it is both inert and plentiful - the third most abundant gas in the earth's atmosphere.

An inert atmosphere is essential for the powder bed fusion process, in order to ensure that the metal parts being built do not become contaminated by air molecules that can change the chemical and physical properties of the final components.

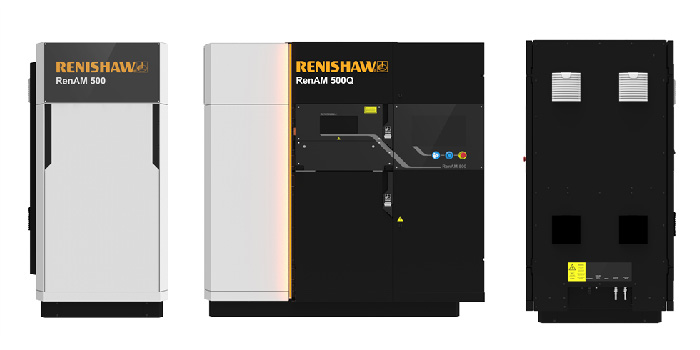

RenAM 500Q

-

Ultra high productivity multi-laser AM system

RenAM 500Q is Renishaw's multi-laser AM system. It features four high-power 500 W lasers, each able to access the whole powder bed surface simultaneously. RenAM 500Q achieves significantly higher build rates, vastly improving productivity and lowering cost per part. The RenAM 500Q features automated powder and waste handling systems that enable consistent process quality, reduce operator intervention time and ensure high standards of system safety.

Key benefits

- RenAM 500Q allows you to address a broader range of components with AM

- Up to 150 cm3/hour deposition rate* significantly improves productivity

- Intelligent gas flow ensures the efficient removal of process emissions and extends filter life

- Single additively manufactured galvo mounting built in AlSi10Mg with internal conformal cooling fluid channels enables excellent thermal stability of the optical system

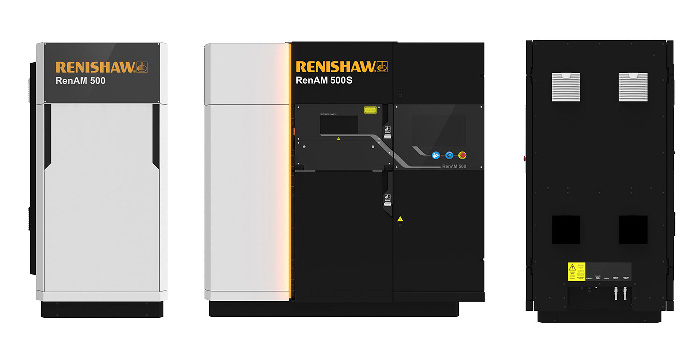

RenAM 500S

-

Advanced single laser AM system with the ability to upgrade to a four laser AM system

RenAM 500S is part of Renishaw's RenAM 500 series additive manufacturing machines. It is specifically designed for building metal components in a production environment. RenAM 500S can easily be upgraded to become a four-laser system to further benefit from higher build rates, whilst maintaining finished part quality, increased productivity and lowering cost per part.

RenAM 500S features automated powder and waste handling systems that enable consistent process quality, reduce operator intervention time and ensure high standards of system safety.

Key benefits

- Intelligent gas flow ensures the efficient removal of process emissions and extends filter life

- Single additively manufactured galvo mounting built in AlSi10Mg with internal conformal cooling fluid channels enables excellent thermal stability of the optical system

Raman spectroscopy

-

Renishaw is a recognised leader in Raman spectroscopy, producing high performance Raman systems for a range of applications.

Next generation Raman imaging

Renishaw has decades of experience developing flexible Raman systems that give reliable results, even for the most challenging measurements.

inVia confocal Raman microscope

-

The new inVia Qontor is Renishaw's most advanced Raman microscope. With the addition of Renishaw's latest innovation, LiveTrack focus tracking technology, the inVia Qontor enables users to analyse samples with uneven, curved or rough surfaces. Optimum focus is maintained in real time during data collection and white light video viewing. This removes the need for time consuming manual focusing, pre-scanning or sample preparation.

The inVia Qontor Raman microscope's cutting-edge technology reduces overall experiment times and makes analysing even the most complex samples easy.

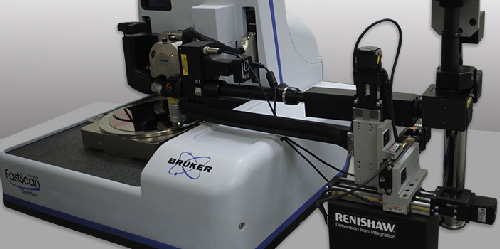

Raman-SPM/AFM combined systems

-

You can combine the power of inVia with scanning probe microscopes (SPMs and AFMs) to investigate the composition, structure and properties of materials at nanometre scales.

TERS: tip-enhanced Raman scattering

Selected inVia-AFM systems can perform tip enhanced Raman scattering (TERS). This exciting technique uses a sharp plasmonic tip to obtain chemical information at the nanometre scale.

TERS mapping complements StreamLine and StreamHR, giving you the flexibility to study your samples at whichever resolution you like.

SEM-Raman system

- The Renishaw structural and chemical analyser (SCA) unites two well-established technologies, scanning electron microscopy (SEM) and Raman spectroscopy, resulting in a powerful and unique technique which allows morphological, elemental, chemical, physical, and electronic analysis without moving the sample between instruments.

Dental / Neurology

Dental products

-

Our dental systems offer the highest levels of flexibility and performance built on precision engineering.

With its expanding list of high-precision measurement and manufacturing technologies, including the latest in 3D printing technologies, Renishaw is a major dental framework and equipment supplier, bringing over 40 years' worth of knowledge to the industry.

Software, scanners, frameworks and 3D printing

With many elements researched, designed and manufactured in-house, including scanners, software and 3D printing machines, Renishaw fully controls its dental manufacturing process, aiming for precision products at competitive prices.

Neurosurgical products and systems

-

Renishaw is applying precision engineering technology to the challenges of functional neurosurgery.

Advancing engineering solutions for stereotactic neurosurgery

Our range of products is designed to enable surgeons to deliver devices with great confidence and accuracy.

Investigating convection enhanced delivery (CED)

We are working with medical technology and biotech companies on the optimisation of next-generation drug delivery systems for the treatment of serious central nervous system (CNS) diseases.