etifix

- Offer Profile

- We have been developing and

producing high-grade labels for the cosmetics, pharmaceuticals, high-tech,

food, beverages and tobacco, security and logistics industries for forty

years. Working with our subsidiary etiroll and a highly efficient mechanical

engineering department, we offer complete label printing, labelling and

software application solutions to the entire industrial sector.

Product Portfolio

System

Labellers

Fully automatic labelling systems

- etifix supplies the right answer to every labelling

problem – from standardized through to individually bespoke solutions.

Possible labelling techniques include roll-on/wipe-on methods, no-contact

blow-on application and temp blow labelling – a technology permitting label

application on a minimum of space. It goes without saying that all our

labellers are designed for maximum durability and clarity of operation in

compliance with CE standards.

Fully automatic labelling systems- In-line (within a production line ) and off-line application possible

- Communication capability via an SBS interface with upstream and downstream machines

- Capacity for up to 72,000 labels/hour

- Precise labelling with optimum reproduction accuracy

- Modular design offers scope to address present and future labelling requirements whenever this is needed

- Labelling possible on cylindrical, angular and oval shapes made of a wide range of materials

- Facility for upgrading to include a print module (e.g. for batch numbers or use-by dates)

Fully automatic labelling system etifix 3114

Fully automatic labelling system etifix 9000

Fully automatic labelling system etifix 4138

Semi automatic labellers

- etifix supplies the right answer to every labelling

problem – from standardized through to individually bespoke solutions.

Possible labelling techniques include roll-on/wipe-on methods, no-contact

blow-on application and temp blow labelling – a technology permitting label

application on a minimum of space. It goes without saying that all our

labellers are designed for maximum durability and clarity of operation in

compliance with CE standards.

Semi-automatic labellers- Generally table-top devices

- Application possible as part of a partially automated production line (manual feed and removal of labelled product)

- Throughput of up to 1,500 labels/hour

- Precise labelling with optimum reproduction accuracy

- Modular design offers scope to address present and future labelling requirements whenever needed

- In some cases offering facility for combination with label printers for real-time printing / application

- Labelling possible on cylindrical, angular and oval shapes made of a wide range of materials

- Facility for upgrading to include a print module (e.g. for batch numbers or use-by dates)

Semi-automatic labeller

Semi-automatic labeller

Semi-automatic labeller

Print and apply systems

- etifix supplies the right answer to every labelling

problem – from standardized through to individually bespoke solutions.

Possible labelling techniques include roll-on/wipe-on methods, no-contact

blow-on application and temp blow labelling – a technology permitting label

application on a minimum of space. It goes without saying that all our

labellers are designed for maximum durability and clarity of operation in

compliance with CE standards.

Print and apply systems- For real-time printing and real-time application of labels (to permit retracing production time / batch in compliance with product liability legislation)

- Integration into any production line possible at short notice without preliminary assembly

- Throughput up to 35,000 labels per hour

- Precise labelling with optimum reproduction accuracy (in the micron range)

- Modular design offers scope to address present and future labelling requirements whenever needed

- Labelling in any position possible on cylindrical, angular and oval shapes made of a wide range of materials

Print and apply system etifix 3138 DAT

Print and apply system etifix 3138

etimat

- Etifix has developed for the labelling of cylindrical

objects the new etimat Vario series.

Our easily manageable labelling system is available for fully-automatic and semi-automatic operation.

The advantages of the etimat series are exact and dimensionally accurate labelling, a simple and intuitive handling, lower required space and the diversity of applied labelling goods.

The first etimat Vario system has found its application in the labelling of cheese packets. The specially developed self adhesive label is applied accurate to dimension on the cheese packet. The self adhesive label has a perforation for a later date opening.

The etifix etimat Vario series can also be used as a space saving table top labelling machine. Slightly modified the etifix etimat system can be used for the labelling of pots, tubes and ampullae.

You can also receive the suitable labels for pots/jars, tubes and ampullae from us – etifix your partner for self adhesive labels and innovative labelling solutions.

Details:

The etimat labelling system is a modular construction system with following combinable assemblies:- labelling system with a labelling roll

- Roadbed and pressing unit with electromagnetic and pneumatic lifting cylinder

- mandrel to support unstable tubes

- a specific component transport system for automatic loading and

unloading of the labelling goods

- labelling system with a labelling roll

- Roadbed and pressing unit with electromagnetic and pneumatic lifting cylinder

- mandrel to support unstable tubes

- a specific component transport system for automatic loading and unloading of the labelling goods

etimat vario EH

etimat vario EH

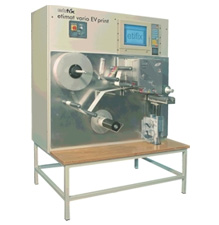

etimat vario EV tube

etimat vario EV print

Printers

- Print your own individual etifix labels with our

optimized printing systems.

There are two printing methods to choose from:

Thermal transfer printers

The ink pigment (black) is transferred from a polyester liner coated with an ink layer onto the label using a thermal print head. This method produces a 100 per cent bond between the ink and the label surface. The result: an imprint that is scratch, abrasion and wipe-proof. etifix guarantees individual coordination between your label and the thermal transfer ribbon and printer.

Thermal direct printers

This technology eliminates the need for a ribbon. Instead, thermo-sensitive material is activated by the print head. This printing method is ideally suited for mass labelling if there are no stringent demands on quality, for example for price labels. Suitable for one-colour label printing.

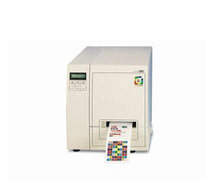

Label printer

Label printer

Label printer

Label printer

accessories

- We offer a wide selection of accessories to supplement the performance of our labellers and label printers. Blank labels and thermal transfer ribbons are naturally also available direct from us in the accustomed etifix standard of quality.

thermal transfer ribbons

auto splice unwinder

software

software

- Standard software

Our software solutions permit you to design your own labels and produce them in-house using etifix printers.

Individual software

We will be pleased to offer you individual software solutions tailored to your specific application requirements. We do this by using our software to integrate our labelling technology into the processes you use, thus ensuring an efficient work flow.

RFID & Auto-ID

- RFID stands for radio frequency identification. This is a technology which

permits the no-contact transmission of data using radio waves. It is ideal

for use in applications such as:

- Libraries

- Ski passes

- Admission tickets and many more

The benefits offered by RFID technology include:- Surveillance, optimization and acceleration of logistic processes

- Enhanced product availability

- Improved quality assurance (e.g. by monitoring sell-by dates)

- No optical detection required

- Information can be written on information carriers

Auto ID is an automatic identification facility using printed data carriers available in the form of a one-dimensional (optionally two-dimensional) printout. Once printed, the resulting code information can no longer be changed but only scanned to the maximum diagonal by optical reading devices.

Applications:- EAN/UPC

- Price labelling

- Batch identification

- Traceability

- Part identification

RFID

RFID

RFID

Auto-ID

Labels

Design ideas Cosmetics

Embossed effects

Shimmer effects, holograms

Metallic/Iriodin

Lamination

Varnishing

No-label-look

Tube/bag labels

Combination printing

Labels for hair dyes

Security / Resealable labels

Wet-wipe labels

Triface

Design ideas pharmaceuticals

Luminescent print

Braille labels

Wraparound labels

Ampoule/syringe labels

Hanger labels

Security labels

Triface-labels

Design ideas beverages

Wine labels and thermal inks

- Description

Beer labels

- Description

Fassfix

- Description

Wash-off

- Description

Scented varnishes

- Description

No-label-look

- Description

Promotion labels

- Description