- Offer Profile

- DWFritz Automation designs and manufactures brilliant, custom automation systems for advanced manufacturing. Our clients partner with us to develop unique, high-precision automation solutions that ensure superior product quality and high throughput. We do our best work when projects demand tolerances measured in microns, not inches, and throughput is counted in parts per second, not parts per hour.

-

Capabilities

From high-speed metrology and inspection to process automation and material handling, we excel in precision manufacturing solutions. -

Solutions

Whether you need an automated, high-speed assembly or inspection solution, or a contract manufacturing partner, we’ve got you covered. -

Products & Platforms

Explore our expanding product line of industry-leading, high-speed, non-contact metrology and precision inspection solutions. -

Support and Service

We provide support services for every machine shipped worldwide, whenever and wherever our clients need us. -

Resources

Download product briefs, solution sheets, and supplier purchasing and shipping guidelines, or read the latest news on our industry blog.

-

Capabilities

Industry-Leading, Non-Contact Inspection Solutions

Explore our expanding product line of high-speed, non-contact metrology and inspection solutions.

We specialize in high-speed, non-contact inspection and metrology solutions characterized by high repeatability and reproducibility through the integration of custom software, machine vision, multispectral lighting, state-of-the-art sensors, advanced robots, and precision motion control.

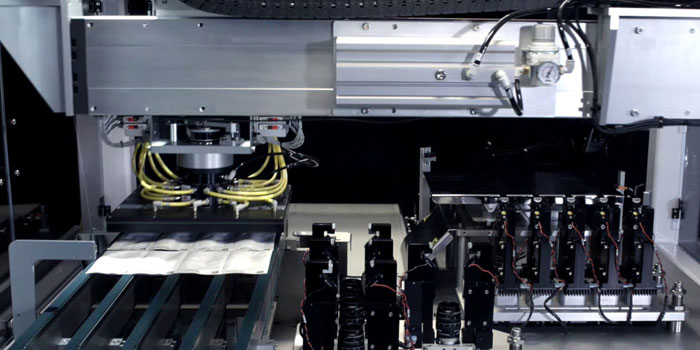

AMP 3100

-

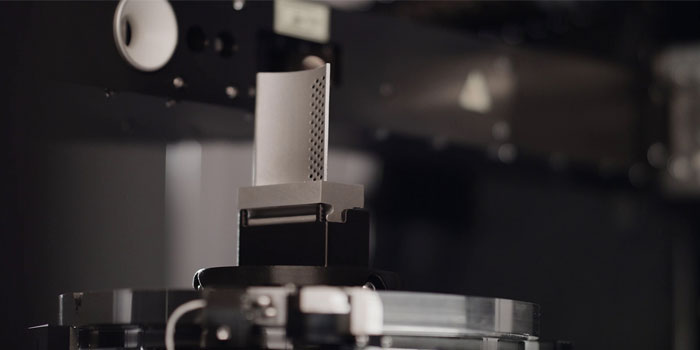

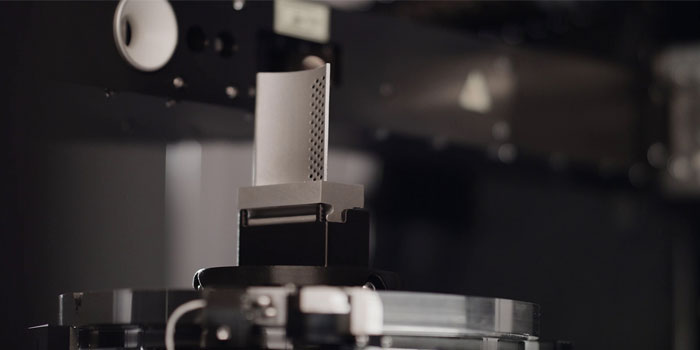

High-Speed Multisensor System for Metrology and Inspection

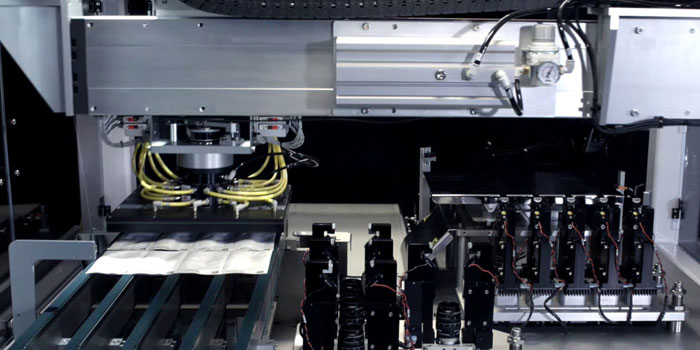

Designed for 100% inspection in high-volume manufacturing, the AMP 3100 non-contact metrology platform features a cutting-edge machine vision system, lasers, custom lighting, advanced robotics, defect detection capabilities, and flexible part-loading options.

With processing speeds exceeding four parts per second, the AMP 3100 metrology platform is a repeatable, high-speed solution offering consistent measurements equal to, or better than, gauge capabilities of Coordinate Measuring Machines (CMMs) and Optical Measuring Machines (OMMs), but with increased throughput to enable 100% measurement of your high-volume parts.- Optimized Optics and Lighting

Non-contact sensors use application-specific, multispectral lighting to scan 3D part profiles at high speed, precisely measuring the most intricate parts at micron levels and with low GRR. - Efficient Design

Using a dual-carriage system, two component-handling robots process parts through the metrology zone, maximizing sensor utilization for high-speed output, while a custom nest ensures precise placement, increasing gauge capability without marring the part surface. - Data Driven Efficiency Insights

Manufacturers can analyze real-time data and perform effective root-cause analyses to adjust and improve upstream and downstream processes. Statistical process control data can drive warning to reduce variablity and scrap.

Specifications

- Work Volume

200 x 20 x 10 mm (L x W x H) - Coordinate System

X-axis: 0.7 to 1.0 m active (±1μm repeatability)

Y-axis: Per requirements (±1μm repeatability)

Z-axis: Per requirements (±1μm repeatability) - System Dimensions

236 x 99 x 204 cm (W x D x H) - System Weight

2,187 kg (4,820 lbs)

- Advanced Metrology Platform for High Volume Inspection

- Automated, high-speed inspection system ideal for small parts manufacturing.

- Optimized Optics and Lighting

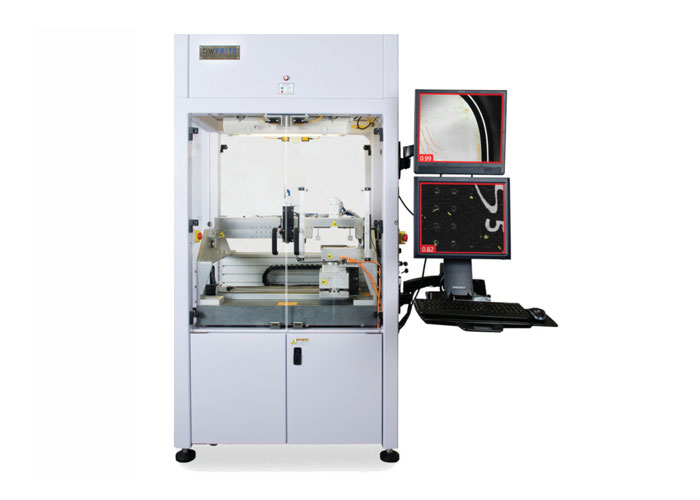

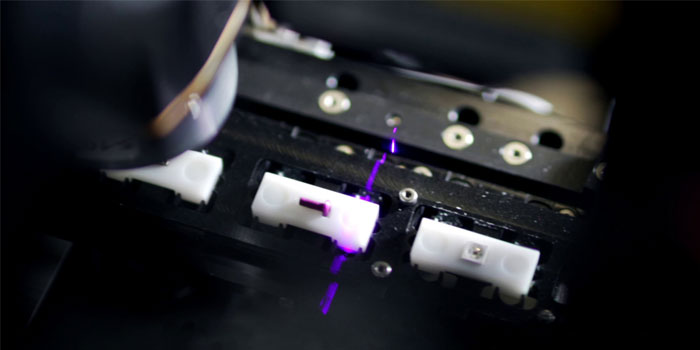

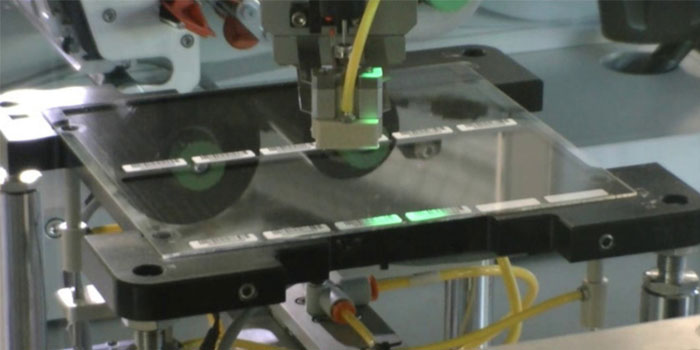

Defect Detection System

-

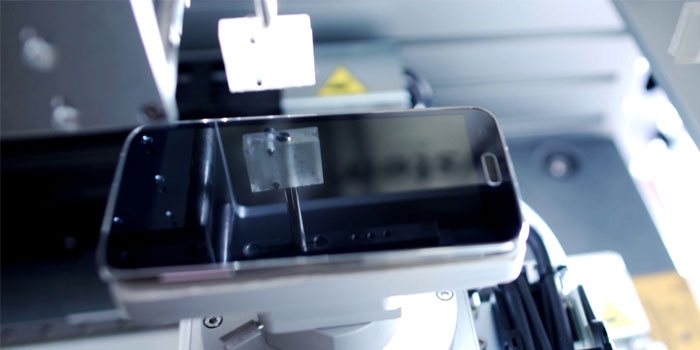

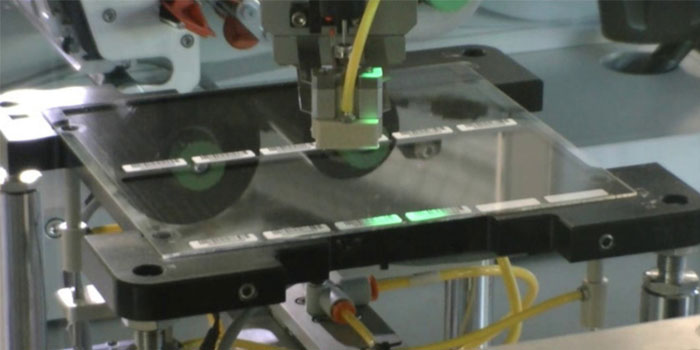

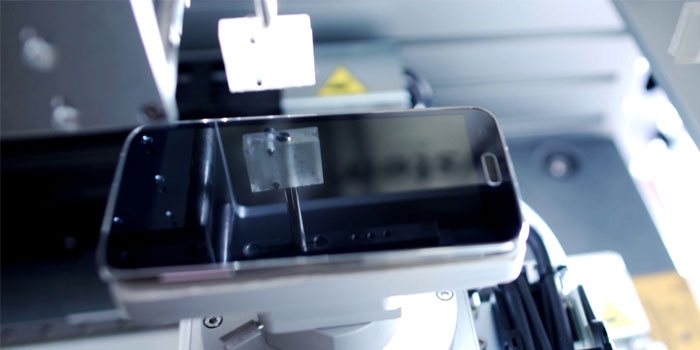

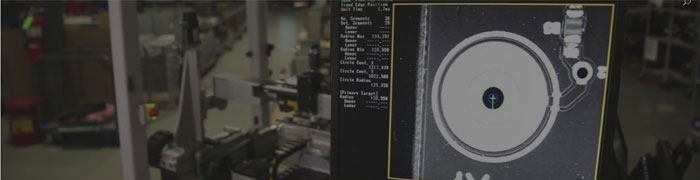

Smart Inspection in Seconds

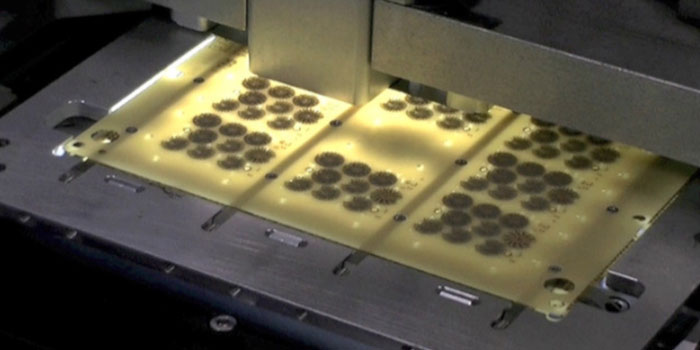

The Defect Detection system quickly identifies defective or anomalous defects on complex surfaces using deep learning technology and advanced machine vision, helping manufacturers reduce costs and meet consumer quality expectations.

While traditional machine vision systems use rules-based algorithms and require precise defect definitions, deep learning software learns from images of good and bad parts, reducing the time needed to specify defects and respond to changing requirements.

The system uses custom lighting solutions and fixturing, and can be combined with advanced material handling to enable rapid surface defect detection and qualification.- Deep Learning

Featuring deep learning technology, the system rapidly identifies surface defects on complex surface (specular, shiny, rough, matte, etc.) using advances machine vision. -

Flexible Design

The platform is flexibile and can be easily adapted for standalone applications or used within an advanced manufacturing inline application. -

Advanced Material Handling

Rapid, non-marring placement and handling of products or parts enable the platform to be used for high-throughput applications.

Specifications (in current configuration)

- Work Volume

203 x 135 x 6 mm (L x W x H) - Coordinate System

X-axis: 600 mm (±2μm repeatability)

Y-axis: 220 mm (±2μm repeatability)

Z-axis: 10 mm (±2μm repeatability) - System Dimensions

112 x 70 x 209 cm (W x D x H) - System Weight

725 kg (1,600 lbs)

- A platform powered by deep learning technology that identifies surface imperfections with speed, reliability, and precision.

- Deep Learning

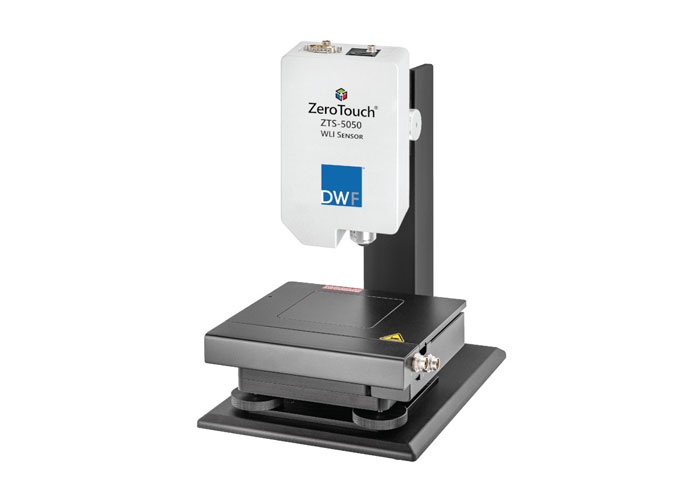

ZeroTouch®

- Explore the expanding ZeroTouch® family of high-speed, non-contact metrology and inspection platforms for gears, bores, discs, and complex geometries.

We specialize in high-speed, non-contact inspection and metrology solutions characterized by high repeatability and reproducibility through the integration of custom software, machine vision, multispectral lighting, state-of-the-art sensors, advanced robotics, and precision motion control.

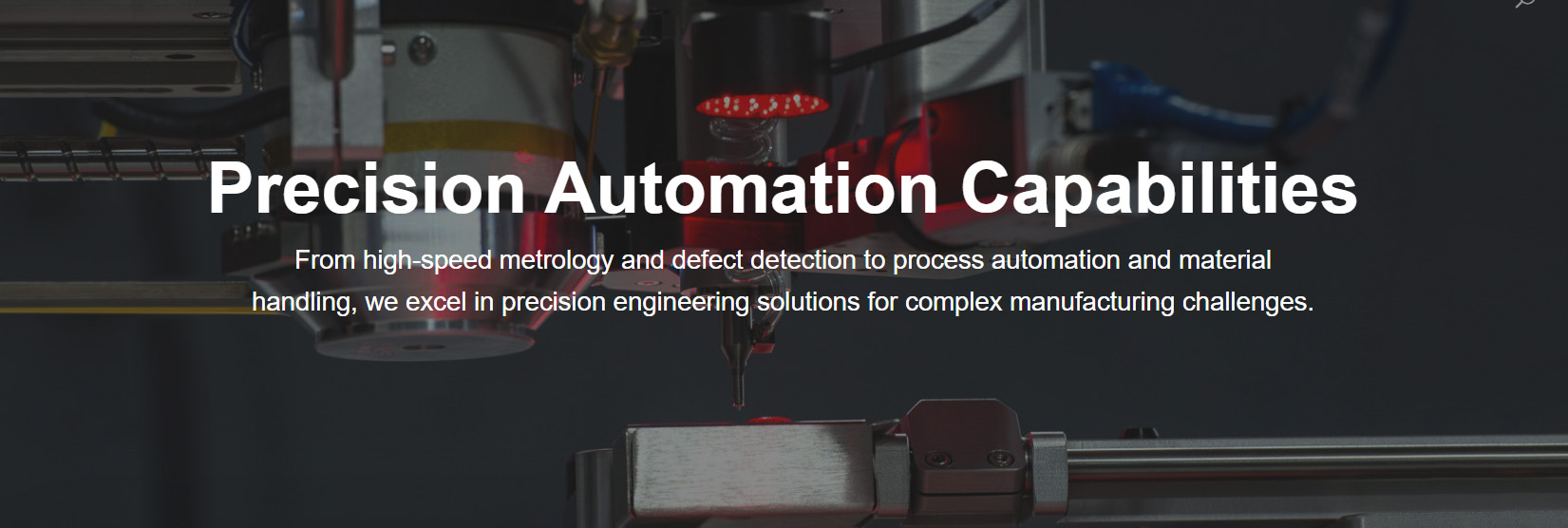

Precision Automation Capabilities

From high-speed metrology and defect detection to process automation and material handling, we excel in precision engineering solutions for complex manufacturing challenges.

Our comprehensive automation design capabilities focus on inspection, metrology, and precision assembly, with a set of core competencies that enable our clients to maximize ROI and dramatically improve operational efficiencies.Research & Development

We designed our state-of-the-art R&D lab based on our years of experience solving our customers’ complex problems. Our onsite R&D lab has one objective: To test our innovative and cutting edge concepts, optimizing our ability to deliver compelling platform solutions to our customers.- Rapid Proof of Principle (PoP) development

- Component qualification & calibration

- Advanced machine vision lighting design & testing

- Machine vision camera and 3D sensor testing

- Custom software and application development

- System prototyping

Guaranteed Process & Performance

- Rigorous risk management process that includes feasibility studies, risk identification, and recommended alternate manufacturing strategies.

- Professional project management, supply chain, sales, service, and operations teams support every project, from launch through installation and validation.

Industries & Applications

- Consumer

- Electronics

- Precision Manufacturing

- Automotive

- Medical Devices

- Aerospace

- Energy Storage

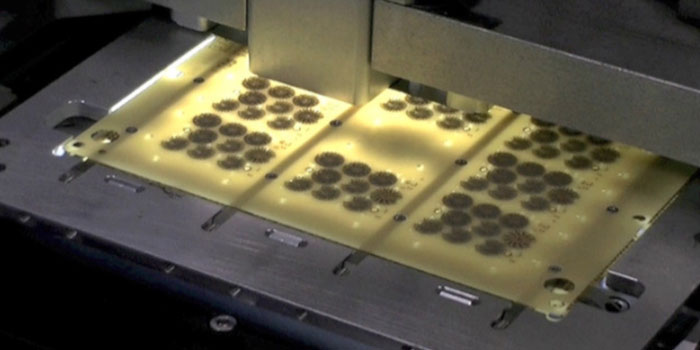

High-Speed Metrology

-

Our systems and solutions are capable of submicron accuracy and repeatability to meet your challenging GRR standards

We design and develop advanced, automated, non-contact metrology solutions that help ensure superior quality and maximize throughput.

- Non-Contact Inspections

Using our proprietary lighting, strobe controllers, and sequencing software, we routinely deliver systems capable of inspecting parts traveling at 250 millimeters per second with 2μm accuracy and 10% GRR. Our solutions sort and bin parts based on measurement results, and include non-marring part handling capabilities for delicate parts, such as ESD devices and medical implants. - Multi-Sensor 3D Data Measurements

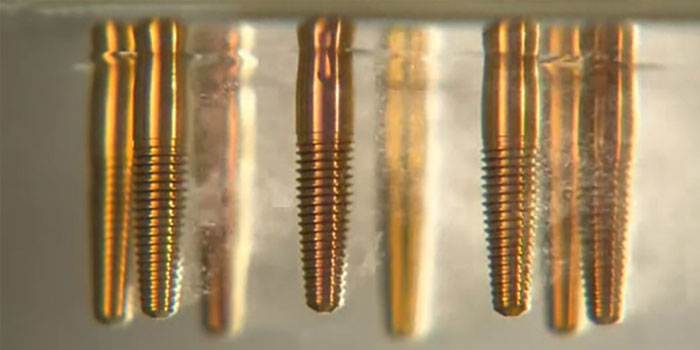

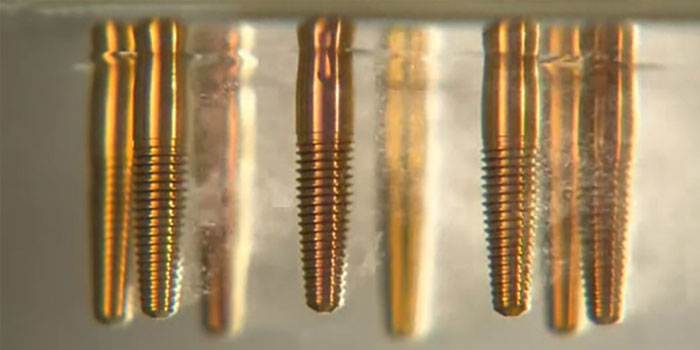

We have deployed systems with more than 15 sensors that rapidly gather both 2D and 3D data to enable low GRR, perform simultaneous measurements, and decrease cost and footprint. - Bore & Thread Inspections

Our systems provide advanced measurement capabilities to inspect bores and internal features critical to the aerospace, automotive, medical device, and oil and gas industries. - In-Situ Measurements

We have experience measuring parts as they are being manufactured, enabling process feedback for high-yield, quality production.

- Non-Contact Inspections

Defect Detection & Classification

-

Our custom, high-speed, automated inspection systems identify and classify micron-level defects and surface flaws across a wide range of materials, including transparent and translucent materials

We design and develop solutions that help optimize upstream processes, improve product quality, and avoid costly device recalls before products reach consumers.

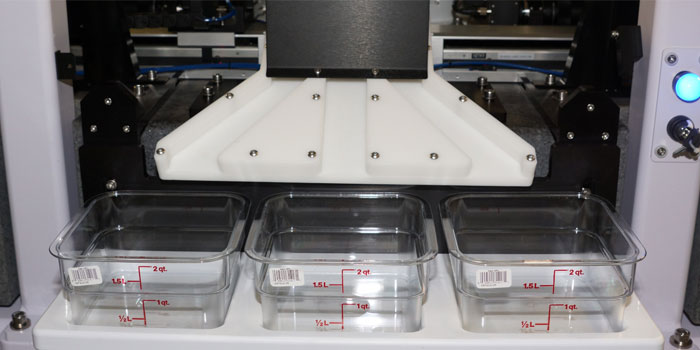

- Package Seal Inspection

Our systems perform defect inspection and classification for Class 3 medical device seals and labels across different material types, such as Poly-Poly and Poly-Tyvek. We inspect packages moving at 250 millimeters per second with 11 pixel² resolution machine vision cameras, custom strobe lighting, and deep learning software to capture 50μm diameter defects. - Label Inspection

We design and build ultra-precise systems with a combination of high-performance machine vision, multiple robots, and sophisticated custom software to print, place, and inspect labels with better than 70μm accuracy every 7.5 seconds. - Component Verification

Using multi-sensor vision systems and AI-driven machine learning software, our high-speed solutions inspect complex final assemblies to verify that all components have been properly included and assembled. Our smart systems are trained to recognize correct assemblies and robustly classify defects based on sample images. - Part Defects

Our defect detection systems perform smart inspection of consumer electronics and medical devices in seconds using automatic orientation to precisely place parts without marring part surfaces. Advanced machine vision and custom strobe lighting is integrated with deep learning algorithms to detect micron-level cosmetic defects on glossy, shiny, and rough surfaces. - Classify & Bin

Not only can we sort and bin both good and bad products, but our systems feature deep learning software and advanced machine vision capable of classifying defects to sort products based on the type of defect.

- Package Seal Inspection

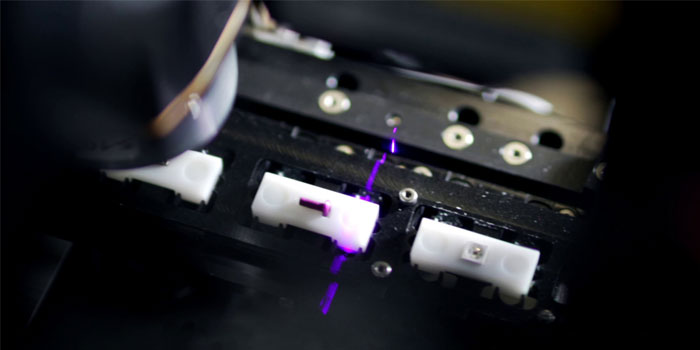

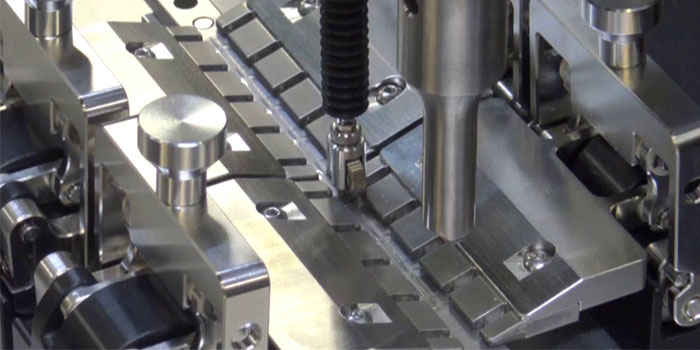

Process Automation

-

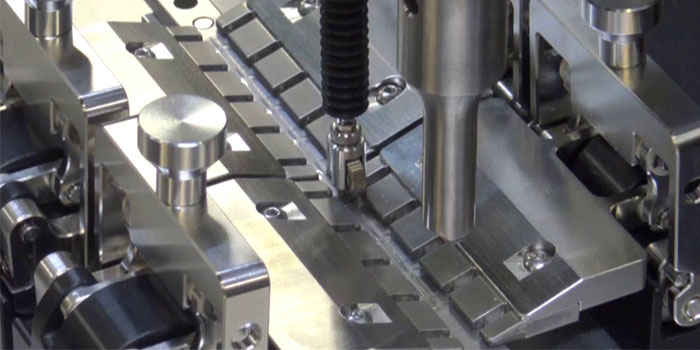

We specialize in high-speed, precision assembly and test automation across various manufacturing applications

We are recognized in the industry for delivering the most innovative solutions, incorporating process elements such as precision dispense, welding, and force sensing. All of our systems are characterized by precision and speed to enable high throughput and product quality.

- Vision Feedback

We use machine vision feedback systems to precisely orient components within single-digit microns and microradians. Through-beam transmitters and receivers ensure chucks are clear before loading new parts, identification lasers confirm parts remain stable on conveyors, and barcode readers scan part IDs for recipe-driven process customization. - Precision Dispense

We excel at precision dispense applications. Vision systems locate and align multiple components up to 5μm, providing vision feedback for accuracy and repeatability. Multi-head glue dispense systems apply 0.034 microliters of adhesive while vision and confocal systems perform in-situ volume detection and final gap measurements to confirm part quality. - Ultrasonic Welding

We integrate precision touch probes capable of 12.7μm resolution into ultrasonic weld heads to sample points across seams prior to welding. Our systems accurately map lapped seam profiles across materials with nonuniform thickness variations, automatically adjusting and calibrating the height as needed to ensure uniformity. - Plasma Surface Treatment

Using a multi-axis ball screw precision gantry, single- and multi-head dispense systems, UV curing, and laser ablation, our systems precisely dispense nano liters of material as dots, lines, or irregular shapes on edges of connectors without weeping over edges. - Laser Processing

We use laser processing in many applications, including etching, marking, and ablation. Our laser ablation systems precisely remove surface coatings from specific areas of materials, while our etching systems integrate advanced robotics and machine vision to orient, laser engrave, and assemble components into final assemblies. - Force Sensing

We use three-axis force sensors to guide advanced robotics when applying pressure in bonding applications or removing masking layers, and torque sensors to drive screws. These technologies help with delicate material handling. - In-Process Component Weighing

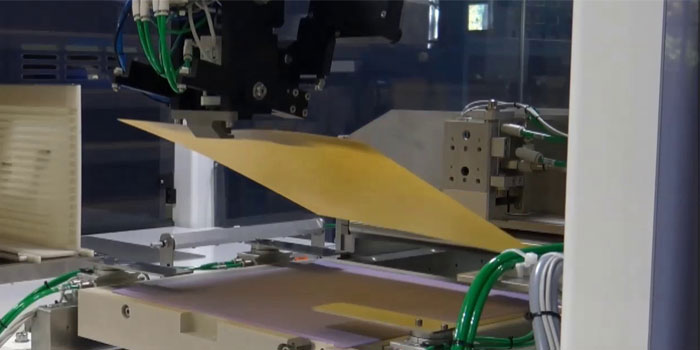

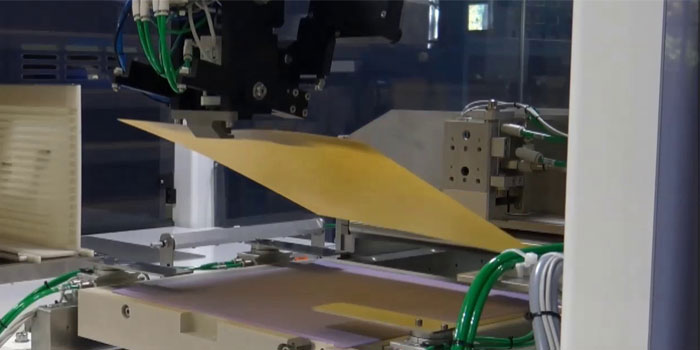

Our automation systems can include dead nest weighing stations where final products are weighed to meet predefined client standards. By transmitting accurate weight data through networks at high speeds, our systems ensure maximum throughput and high quality. - Excise & Attach

We have designed and built excise and attach systems that die-cut and attach nozzles with 10μm accuracy to semiconductor wafers using multiple 150μm adhesive dots with 20μm accuracy. Our systems are also capable of rapidly cutting and inserting 5mil wires into 10mil diameter holes. These flexible systems utilize vision technologies to locate components, multifunctional grippers to interface with custom load cells to transfer components bewteen processes, and recipe-driven custom control software. - Lamination

Our lamination systems employ multiple subsystems including label applicators, laminating nests, laminating rollers, input & output cassettes, pick & place actuators, and reject handling systems. Our systems have been deployed in semiconductor applications and fan-out technology enablement. - Etching

We specialize in electroprocessing medical implant devices to anodize interior surfaces for color coding, prepare surfaces for final coating, or improve porosity for bonding. - Swaging

Our high-speed assembly systems orient, assemble, swage, and inspect components at a rate of 1.25 seconds per assembly. Using custom control software, the automated processes are recipe driven based on client and product requirements, sorting and binning final products onto packaging lines and reject bins.

- Vision Feedback

Advanced Material Handling

Quality. Precision. Innovation.

Whether you need an automated, high-speed assembly or inspection solution, or a contract manufacturing partner, we’ve got you covered.

Solutions

Explore our expanding product line of high-speed, non-contact metrology and inspection solutions.

We specialize in high-speed, non-contact inspection and metrology solutions characterized by high repeatability and reproducibility through the integration of custom software, machine vision, multispectral lighting, state-of-the-art sensors, advanced robots, and precision motion control.Research & Development

To enable our cutting-edge designs, our facility houses a state-of-the-art engineering lab, optimized and equipped to support our innovative and compelling platform solutions.- Rapid Proof of Principle (PoP) development

- Component qualification & calibration

- Advanced machine vision lighting design & testing

- 2D and 3D inspection of customer parts

- Machine vision camera and 3D sensor testing, and application development

- Rapid prototyping using 3D printers

- Software development

- Defect detection using deep learning

- Advanced high-speed metrology product & platform development

Technical Expertise

Our world-class engineers stay current on the latest technological developments, including the most cutting-edge materials and processes. Our technical expertise includes:- Custom controls software

- 2D and 3D vision multi-sensor analysis

- 3D data analysis

- Defect detection using deep learning

- Rapid data acquisition and processing

- Motion control (PC- and PLC-based architecture)

- Customizable GUI development including SPC charts

- Clean room equipment design

-

Capabilities

From high-speed metrology and inspection to process automation and material handling, we create brilliant precision manufacturing solutions. -

Products & Platforms

Explore our expanding product line of industry-leading, high-speed, non-contact metrology and precision inspection solutions. - Support & Service

We provide support services for every machine shipped worldwide, whenever and wherever our clients need us.

Industries & Applications

- Consumer Electronics

- Precision Manufacturing

- Automotive

- Medical Devices

- Aerospace

- Energy Storage

Engineer-to-Order Systems

- When you need a cost-effective, robust design for a complex manufacturing challenge, we are your precision automation partner.

We are The Precision Automation Experts™

Not all automation is the same. Precision custom automation requires another level of expertise—that’s what defines us.

We specialize in high-speed, precision assembly and test automation for advanced manufacturing. Our world-class engineering and project management teams are recognized in the industry for delivering the most innovative solutions, incorporating our custom software, best-in-class sensors, machine vision systems, robots, dispense equipment, and precision material handling.

We tackle your most challenging automation problems. Whether it is a single system or an entire line, a challenging process flow that you would like to make more efficient, a new product introduction, or you are grappling with manufacturing efficiencies (high-volume, or low-volume/high product mix scenario)—we are your custom automation partner.- Our Collaborative Process

Our objective is to provide exemplary service to our clients by continually collaborating with their engineering teams. We conduct robust DFM and GD&T analysis to enable 100% inspection (zero-defect) and SPC. - Our Capabilities

Our core capabilities in precision inspection, metrology, and assembly automation enable us to help our clients maximize their ROI and dramatically improve operational efficiencies. Our systems and solutions are capable of submicron accuracy to meet your challenging GRR standards. - Our People

Our vast expertise comes, not only from heavy investments in R&D, but also from the breadth of knowledge our employees bring from decades

- Our Collaborative Process

Global Build-to-Print Services

- Our People. Our Process. Your Design.

Bring Your Designs to Life

Our contract manufacturing partners benefit from our world-class production technicians, global supply chain partnerships, MRP-inventory controls, configuration management capabilities, project management process, and global service and support model.

Brilliant People Thrive Here

Our collaborative manufacturing team includes experienced mechanical and controls technicians, electromechanical assemblers, manufacturing engineers, production coordinators, project assistants, materials coordinators, and support staff. Some areas of expertise include:- Wiring Panel & frame build

- Single-micron precision alignment

- System integration I/O check

- Power up

- System debug

- Pneumatics

- Robot integration & teaching

- Sensor build & Alignment

- Calibration

- Fixture & tool design

- Process optimization

- Build sequencing

- Make/By analysis

- Material status

- Documentation review

- Crating & delivery logistics

And when the time comes in your product life-cycle that you need a partner to provide Value Analysis/Value Engineering, we can support that too.

ZeroTouch®

Explore the expanding ZeroTouch® family of high-speed, non-contact metrology and inspection platforms for gears, bores, discs, and complex geometries.

We specialize in high-speed, non-contact inspection and metrology solutions characterized by high repeatability and reproducibility through the integration of custom software, machine vision, multispectral lighting, state-of-the-art sensors, advanced robotics, and precision motion control.- Products & Platforms

Explore our expanding product line of industry-leading, high-speed, non-contact metrology and precision inspection solutions. - AMP 3100

Automated, high-speed metrology system ideal for 100% high-volume precision inspection of small parts. - Defect Detection System

Defect detection platform that uses deep learning technology to detect and classify surface imperfections.

Industries & Applications

- Consumer Electronics

- Precision Manufacturing

- Automotive

- Medical Devices

- Aerospace

- Energy Storage

- Products & Platforms

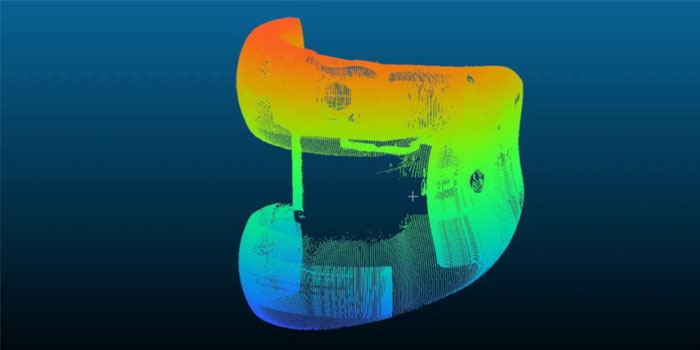

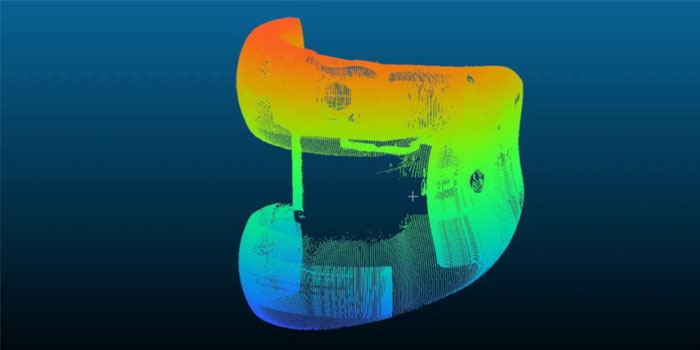

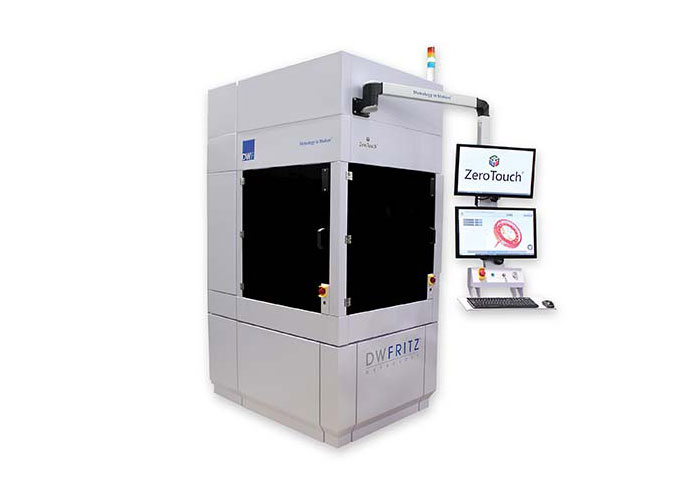

ZeroTouch® Multipurpose Inspection System - ZTM-333

-

A high-speed, non-contact metrology and inspection platform for processing complex geometries faster than a traditional CMM

- Improve Accuracy

ZeroTouch uses a unique 5-axis architecture and best-in-class sensors, improving measurement quality. - Increase Throughput

ZeroTouch captures complex dimensional measurements in minutes. - Advances Production

ZeroTouch rapidly performs multiple measurements simultaneously.

A robust, non-contact metrology platform, ZeroTouch rapidly captures millions of data points to create a high-precision 3D point cloud, enabling rapid measurement of complex part geometries and precise inspection of the most intricate parts with low GRR.

Features & Benefits- Rapid 3D micron-level precision point cloud generation

- High repeatability

- GD&T measurements of complex geometries such as chamfers, knife edges, undercuts and bores

- Configurable metrology sensor bridge, including laser, confocal sensors and high-resolution cameras with multi-spectral lighting

- Advanced analytics integration with application specific tools

- Simple part inspection programming

- Rapid identification of production defects enables upstream process optimization

- Ease of part fixturing reduces setup time per part

Specifications

- Machine Size

- System Dimensions

(W x D x H) 2,400 mm (95 in) x 1,600 mm (63 in) x 1,900 mm (75 in) - System Weight

3,550 kg (7,825 lbs)

- System Dimensions

- Environmental

- Temperature (Transport/Storage)

2°C (3.6°F) per hour - Temperature (Operational)

18°C (64.4°F) to 22°C (71.6°F) Rate of Change

2°C (3.6°F) per hour - Electrical Supply

Electrical Service 208/230/240VAC, 50/60Hz 30A, 1-PHASE + GND

- Temperature (Transport/Storage)

- Improve Accuracy

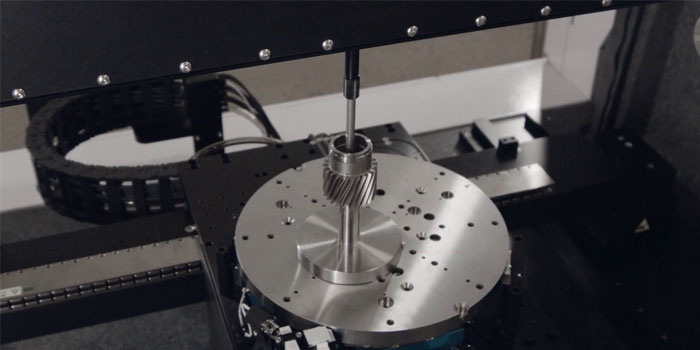

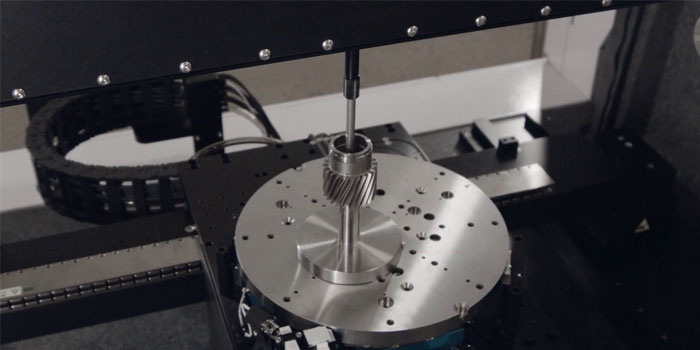

ZeroTouch® Gear Inspection System - ZTG-2580

-

A high-speed, precision inspection machine for 100% near-line or inline gear inspections

Non-contact 3D Gear Inspection System

ZeroTouch® ZTG-2580 is a non-contact gear inspection system that generates a 3D point cloud, providing manufacturers with real-time metrology and inspection data to optimize production processes and improve ROI.

A New Way to Inspect Gears

Using multiple laser triangulation sensors that acquire millions of data points per sensor, the ZeroTouch® ZTG-2580 gear inspection system performs 3D inspections of complex gear geometries and surface defects with speed, accuracy, and flexibility.

Features & Benefits- 100% inspection of gear and teeth geometries with cycle times from 30 seconds per part

- Installed in the immediate vicinity of the production line

- Fast identification of production defects, enabling adjustment of upstream processes

- 3D inspection of complex geometries using multiple sensors

- Captures dense precision point cloud data with speed and accuracy

- Advanced analytics integration with application-specific tools

- Profile, helix, pitch, and runout measurements

- Surface defect detection and characterization capabilities

- Multiple laser line triangulation metrology sensors

- Real-time data capture and storage for SPC analysis

Specifications

- Gear Dimensions

- External Ring: 80 mm max. diameter

- Part Height: Up to 25 mm

- Inspection Speed

- Typical Cycle Time: ~30 seconds

- Tolerances: 5-10 μm

- Surface Defect Detection: 50µm (min. defect size)

- Measurements

- Profile evaluations (Fα-fHα-ffα-Cα)

- Helix evaluations (Fβ-fHβ-ffβ-Cβ)

- Pitch and roudness evaluations (Fp-fp-Fr)

- Diameter over balls (Mdk)

- System Dimensions

- 2,000 x 1,000 x 2,000 mm (W x D x H)

- System Weight

- 1,500 kg (3,300 lbs)

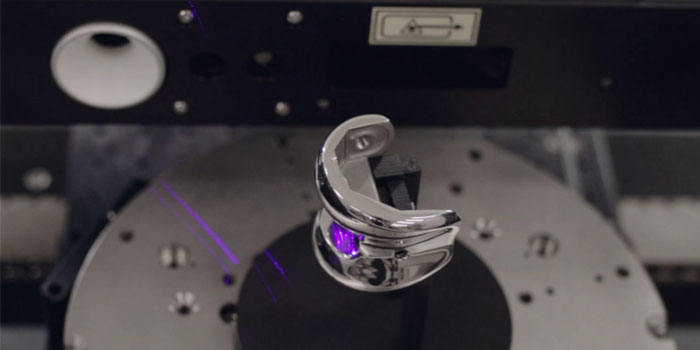

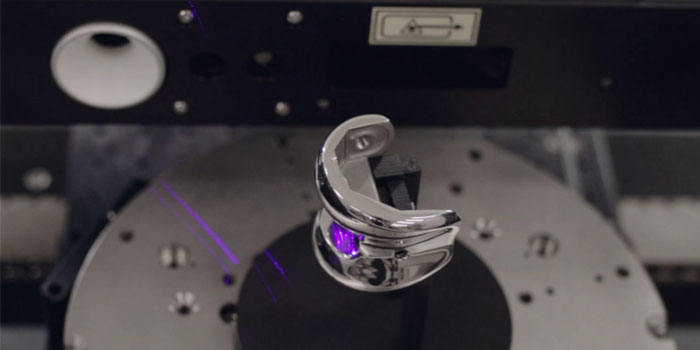

ZeroTouch® Rotational Metrology Platform - Traction Motor Inspection

-

A non-contact 3D traction motor inspection system that measures complex geometries and performs defect detection

Non-contact 3D Motor Inspection System

The ZeroTouch® traction motor inspection system is a non-contact motor inspection system that generates a 3D point cloud, providing manufacturers with real-time metrology and inspection data to optimize production processes, detect defects, and improve ROI.- Increases Accuracy

- Increases Throughput

- Detects Defects

ZeroTouch measured the entire part surface, generating a high-density, micron-level point cloud.

ZeroTouch executed the entire stator frame inspection plan in just 20 seconds versus the tactile methods, which took several minutes.

ZeroTouch executed the entire stator assembly inspection plan in a few minutes versus the tactile methods, which took several hours.

ZeroTouch measured all surfaces on all leads in 3D and identified weld defects too.Specifications

- Dimensions

- External Ring: 300 mm diameter (typical)

- Part Height: 300 mm (typical)

- Inspection Speed

- Typical Cycle Time: ~20 seconds (typical)

- Accuracy

- Tolerances: 5-10µm

- Surface Defect Detection: 120µm (min. defect size)

- System Dimensions

- 2,000 x 1,000 x 2,000 mm (W x D x H)

- System Weight

- 1,500 kg (3,300 lbs)

ZeroTouch® Surface

Explore the expanding ZeroTouch® family of high-speed, non-contact surface profiling platforms.

Based on white-light interferometry (WLI), the ZeroTouch® Surface (ZTS) profiler systems are a complete solution for performing high-resolution, non-contact, 3D surface measurements quickly and reliably.Industries & Applications

- Consumer Electronics

- Precision Manufacturing

- Automotive

- Medical Devices

- Aerospace

- Energy Storage

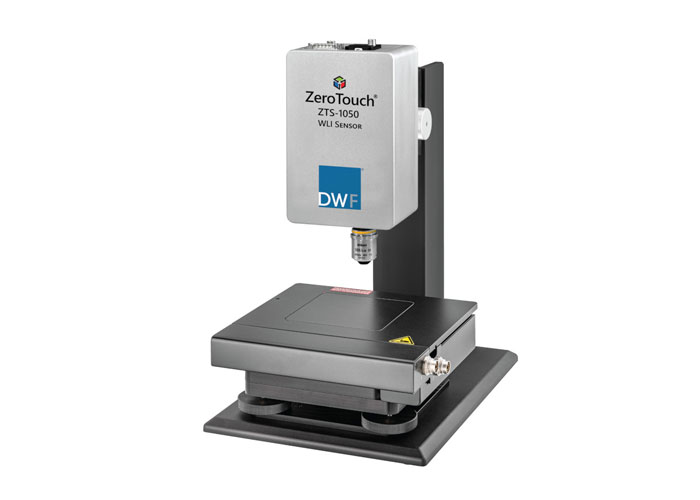

ZTS-1020 / ZTS-1050

-

A high-speed, precision surface profiling inspection sensor for shop-floor installation

Non-contact 3D Surface Profiling Sensor

The ZeroTouch® 1000 Series non-contact surface profiling sensor generates a 3D point cloud of micro-geometries and micro-structures with an extended scanning range in the Z axis up to 5mm.

Fast, Precise 3D Surface Measurements

The ZeroTouch® 1000 Series sensor evaluates several thousand surface profiles using advanced white-light interferometry technology to capture high-speed, precision data acquisition and real-time 3D surface roughness measurements. Using high-resolution cameras, the sensor provides highly significant results without the limits of tactile measuring systems.- Surface Measurements

High-resolution cameras measure both smooth and rough specimen surfaces without contact, characterizing mechanically processed surfaces such as mirrors, semiconductor wafers, micro-lenses, glass, metal, plastic, composite, or other surfaces. - Precision Height Mapping

The sensor works with interference objectives from 2.5x to 50x, yielding fast, precise representation of the height information and the relevant surface parameters using a piezo objective adjuster and broadband wavelength spectrum lighting. - ISO Conform Roughness Measurements

Objectives starting from 10x and higher can be used for ISO confirm roughness measurements in accordance with ISO 25178 and ISO 4287.

Features & Benefits- Non-contact measurements of smooth, rough, and specular surfaces such as glass, metal, plastic, and composites

- Precise measurement of height and relevant surface parameters

- Installed in the immediate vicinity of the production line

- Inspects mirrors, semiconductor wafers, microlenses, and solar cells

- Micron-level, fast measurements of various surface profiles

- 3D sensor with manually interchangeable objective

- White-light interferometry-based, very high-resolution sensors (5 MP and 2.3 MP)

- Piezo positioning system with interferometric calibrated closed-loop controller (up to 5,000µm scan range)

- Optional XY positioning table with manual Z adjustment

- Advanced algorithms improve speed and reduce system noise

Specifications

- System Performance

- 1-σ Reproducibility 0.4 μm Step Height

- Reproducibility 12 μm Step Height

- Reproducibility 100 μm Step Height

- Machine Size

- Sensor Weight ~2 kg (4.4 lbs)

- Coarse Positioning Range (max.) (manual Z positioning) 70 mm

- Fine Positioning Range (manual Z positioning) 1.9 mm

- Tilted Angle (leveling device) ±3°

- Surface Measurements

ZTS-3020 / ZTS-3050

-

A high-speed, precision surface profiling inspection sensor for shop-floor installation

Non-contact 3D Surface Profiling Sensor

The ZeroTouch® 3000 Series non-contact surface profiling sensor generates a 3D point cloud of micro-geometries and micro-structures down to single atom layers.

Fast, Precise 3D Surface Measurements

The ZeroTouch® 3000 Series sensor evaluates several thousand surface profiles using advanced white-light interferometry technology to capture high-speed, precision data acquisition and real-time 3D surface roughness measurements. Using high-resolution cameras, the sensor provides highly significant results without the limits of tactile measuring systems.- Surface Measurements

High-resolution cameras measure both smooth and rough specimen surfaces without contact, characterizing mechanically processed surfaces such as mirrors, semiconductor wafers, micro-lenses, glass, metal, plastic, composite, or other surfaces. - Precision Height Mapping

The sensor works with interference objectives from 2.5x to 50x, yielding fast, precise representation of the height information and the relevant surface parameters using a piezo objective adjuster and broadband wavelength spectrum lighting. - ISO Conform Roughness Measurements

Objectives starting from 10x and higher can be used for ISO confirm roughness measurements in accordance with ISO 25178 and ISO 4287.

Features & Benefits- Non-contact measurements of smooth, rough, and specular surfaces such as glass, metal, plastic, and composites

- Precise measurement of height and relevant surface parameters

- Installed in the immediate vicinity of the production line Inspects mirrors, semiconductor wafers, microlenses, and solar cells

- Micron-level, fast measurements of various surface profiles

- 3D sensor with manually interchangeable objective

- White-light interferometry-based, very high-resolution sensors (5 MP and 2.3 MP)

- Piezo positioning system with interferometric calibrated closed-loop controller (up to 400µm scan range)

- Optional XY positioning table with manual Z adjustment

- Advanced algorithms improve speed and reduce system noise

Specifications

- System Performance

- 1-σ Reproducibility 0.4 μm Step Height

- 1-σ Reproducibility 12 μm Step Height

- 1-σ Reproducibility 100 μm Step Height

Machine Size- Sensor Weight ~2 kg (4.4 lbs)

- Coarse Positioning Range (max.) (manual Z positioning) 70 mm

- Fine Positioning Range (manual Z positioning) 1.9 mm T

- ilted Angle (leveling device) ±3°

- Surface Measurements

ZTS 5000 Series

-

A high-speed, precision surface profiling inspection sensor for shop-floor installation

Non-contact 3D Surface Profiling Sensor

With a scanning range of 100µm, the ZeroTouch® ZTS-5000 Series non-contact surface profiling sensor system is optimized for nano structures and functional micro structures.

Fast, Precise 3D Surface Measurements

The ZeroTouch® 5000 Series sensor evaluates several thousand surface profiles using advanced white-light interferometry technology to capture high-speed, precision data acquisition and real-time 3D surface roughness measurements. Using high-resolution cameras, the sensor provides highly significant results without the limits of tactile measuring systems.- Surface Measurements

High-resolution cameras measure both smooth and rough specimen surfaces without contact, characterizing mechanically processed surfaces such as mirrors, semiconductor wafers, micro-lenses, glass, metal, plastic, composite, or other surfaces. - Precision Height Mapping

The sensor works with interference objectives from 2.5x to 50x, yielding fast, precise representation of the height information and the relevant surface parameters using a piezo objective adjuster and broadband wavelength spectrum lighting. - ISO Conform Roughness Measurements

Objectives starting from 10x and higher can be used for ISO confirm roughness measurements in accordance with ISO 25178 and ISO 4287.

Features & Benefits- Non-contact measurements of smooth, rough, and specular surfaces such as glass, metal, plastic, and composites

- Precise measurement of height and relevant surface parameters

- Installed in the immediate vicinity of the production line

- Inspects mirrors, semiconductor wafers, microlenses, and solar cells

- Micron-level, fast measurements of various surface profiles

- 3D sensor with manually interchangeable objective

- White-light interferometry-based, high-resolution 5 MP sensor

- Piezo positioning system with interferometric calibrated closed-loop controller (up to 100µm scan range)

- Optional XY positioning table with manual Z adjustment

- Advanced algorithms improve speed and reduce system noise

Specifications

- System Performance

- 1-σ Reproducibility 0.4 μm Step Height

- 1-σ Reproducibility 12 μm Step Height

- Machine Size

- Sensor Weight ~2 kg (4.4 lbs)

- Coarse Positioning Range (max.) (manual Z positioning) 70 mm

- Fine Positioning Range (manual Z positioning) 1.9 mm

- Tilted Angle (leveling device) ±3°

- Surface Measurements

ZTS-7020 / ZTS-7050

-

A high-speed, precision surface profiling inspection sensor for shop-floor installation

Non-contact 3D Surface Profiling Sensor

A universal lab measurement system, the ZeroTouch® 7000 Series non-contact surface profiling sensor features up to four exchangeable objectives and automated objective recognition.

Fast, Precise 3D Surface Measurements

The ZeroTouch® 7000 Series sensor evaluates several thousand surface profiles using advanced white-light interferometry technology to capture high-speed, precision data acquisition and real-time 3D surface roughness measurements. Using high-resolution cameras, the sensor provides highly significant results without the limits of tactile measuring systems.-

Surface Measurements

High-resolution cameras measure both smooth and rough specimen surfaces without contact, characterizing mechanically processed surfaces such as mirrors, semiconductor wafers, micro-lenses, glass, metal, plastic, composite, or other surfaces. -

Precision Height Mapping

The sensor works with interference objectives from 2.5x to 50x, yielding fast, precise representation of the height information and the relevant surface parameters using a piezo objective adjuster and broadband wavelength spectrum lighting. -

ISO Conform Roughness Measurements

Objectives starting from 10x and higher can be used for ISO confirm roughness measurements in accordance with ISO 25178 and ISO 4287.

Features & Benefits- Non-contact measurements of smooth, rough, and specular surfaces such as glass, metal, plastic, and composites

- Precise measurement of height and relevant surface parameters

- Installed in the immediate vicinity of the production line

- Inspects mirrors, semiconductor wafers, microlenses, and solar cells

- Micron-level, fast measurements of various surface profiles

- 3D sensor with manually interchangeable objective

- White-light interferometry-based, very high-resolution sensors (5 MP and 2.3 MP)

- Piezo positioning system with interferometric calibrated closed-loop controller (up to 400µm scan range)

- Optional XY positioning table with manual Z adjustment

- Advanced algorithms improve speed and reduce system noise

Specifications

- System Performance

- 1-σ Reproducibility 0.4 μm Step Height

- 1-σ Reproducibility 12 μm Step Height

- 1-σ Reproducibility 100 μm Step Height

- Machine Size

- Sensor Weight ~3 kg (6.6 lbs)

- Coarse Positioning Range (max.) (manual Z positioning) 70 mm

- Fine Positioning Range (manual Z positioning) 1.9 mm

- Tilted Angle (leveling device) ±3°

-

Surface Measurements

ZTS-9020 / ZTS-9050 / ZTS-9090

-

A high-speed, precision surface profiling inspection sensor for shop-floor installation

Non-contact 3D Surface Profiling Sensor

Optimized for very high resolution surface profiling of cylindrical structures, the ZeroTouch® ZTS-9000 Series system can scan cylinders up to 200mm in depth.

Fast, Precise 3D Surface Measurements

The ZeroTouch® 9000 Series sensor evaluates several thousand surface profiles using advanced white-light interferometry technology to capture high-speed, precision data acquisition and real-time 3D surface roughness measurements. Using high-resolution cameras, the sensor provides highly significant results without the limits of tactile measuring systems.- Surface Measurements

High-resolution cameras measure both smooth and rough specimen surfaces without contact, characterizing mechanically processed surfaces such as mirrors, semiconductor wafers, micro-lenses, glass, metal, plastic, composite, or other surfaces. - Precision Height Mapping

The sensor works with interference objectives from 5x to 100x, yielding fast, precise representation of the height information and the relevant surface parameters using a piezo objective adjuster and broadband wavelength spectrum lighting. - ISO Conform Roughness Measurements

Objectives starting from 10x and higher can be used for ISO confirm roughness measurements in accordance with ISO 25178 and ISO 4287.

Features & Benefits- Non-contact measurements of smooth, rough, and specular surfaces such as glass, metal, plastic, and composites

- Precise measurement of height and relevant surface parameters

- Installed in the immediate vicinity of the production line

- Inspects mirrors, semiconductor wafers, microlenses, and solar cells

- Micron-level, fast measurements of various surface profiles

- 3D sensor with manually interchangeable objective

- White-light interferometry-based, very high-resolution sensor

- Piezo positioning system with interferometric calibrated closed-loop controller (up to 200µm scan range)

- Variable configurations for multiple inspection tasks

- Advanced algorithms improve speed and reduce system noise

Specifications

- System Performance

- 1-σ Reproducibility 12 μm Step Height

- Scanning

- Scan Range Up to 200 μm

- Scanning Speed, Full Resolution 5.9 μm/s

- Maximum Scanning Speed ~148 μm/s

- Digitization Up to 0.01 pm

- Machine Size

- Sensor Weight ~16 kg (35.2 lbs)

- Cylinder Diameter 70-125 mm (standard configuration)

- Standard Insertion Axis ~188 mm

- Extended Insertion Axis ~270 mm

- Motorized Insertion Axis ~200 mm / stitching

- Surface Measurements

Industries

Precision Solutions for High Performance Markets

By applying our technical expertise and extensive experience, we design innovative solutions to solve complex challenges across industries.Brilliant Solutions. Brilliant Execution.™

As a leading provider of automated inspection, high-speed metrology and precision assembly solutions, we provide precision automation solutions tailored to each client’s market, environment, and business goals. Our core capabilities allow us to serve a wide range of market sectors, such as Medical Devices, Consumer Electronics, Aerospace, Automotive, Precision Manufacturing, Energy Storage, Semiconductors, and Metrology Instrumentation.

Medical Devices

- Precision assembly, inspection, and dispense solutions to help global medical device manufacturers meet the highest quality standards.

Meeting the high standards for medical devices to be safe and effective for human use is a major challenge. Products such as cardiovascular or ocular implants have smaller and more complex features, which are very challenging to manufacture and inspect. We help top-tier medical device manufacturers solve their toughest assembly and inspection problems. From inspecting heart valves and detecting micron-level defects in sterile medical packages to automating complex implant assemblies, we have the expertise to take your manufacturing to the next level.

Aerospace

- Automated inspection systems of critical aerospace components made from challenging materials.

Our adept use of custom lighting solutions and multiple vision technologies results in industry-leading solutions to complex challenges when assembling and inspecting critical aerospace components that are made from challenging, specular materials such as titanium, aluminum, and carbon fiber composites.

Consumer Electronics

- High-speed, non-contact solutions designed for the dynamic consumer electronics market.

Our high-speed, non-contact techniques are unparalleled, ensuring 100% metrology, defect detection and classification, while dramatically improving product quality with extraordinary ROI.

Precision Manufacturing

- Custom precision engineering solutions for the precision manufacturing industry.

Precision part manufacturers around the world seek our help to solve their most complex production challenges. Whether it is building high-speed, inline inspection automation systems; complex material handling and assembly; high-speed, non-contact metrology; precision dispensing; or defect detection, we have the capability to deliver. By leveraging our core strengths, we develop high performance integrated systems that can solve your toughest micron-level manufacturing problems.

Energy Storage

- Custom solutions designed with advanced machine vision and sensor technology to meet the demands of this cutting-edge industry.

We use the latest technlogies to build state-of-the-art automation solutions to assemble and inspect battery packs and other energy storage systems, ensuring the reliability and high quality the industry has come to expect. Whether you need a storage solution for the electric vehicle market or the solar industry, we have the capability to design, manufacture, and install automation systems that solve your manufacturing challenges.

Automotive

- Precision, high-speed systems to improve product quality without sacrificing throughput on the automotive production line.

Our years of proven experience designing precision, high-speed automation systems fill the need in the automotive industry for high-volume solutions guaranteed to meet high quality standards and ensure 24/7 production.

Semiconductor

- High-performance solutions designed, built, and integrated to reduce waste and optimize efficiency for semiconductor manufacturers.

Our systems deliver high-performance solutions designed, built, and integrated to ensure optimum results for all your precision manufacturing challenges.