MARPOSS

Videos

Loading the player ...

- Offer Profile

-

Marposs, leading global supplier of precision metrology equipment for shop-floor inspection, measurement and process control solutions, provides:

- gauging and compensation systems for grinders and other machine tools;

- manual gauges, sensors, probes and other gauge components;

- automatic measurement and inspection systems;

- industrial computers, hw and sw for data collection, process analysis, SPC and process control;

- equipment for leak detection, non-destructive testing, functional checks

Product Portfolio

INDUSTRIES

MACHINE TOOLS - MACHINING PROCESSES

- Marposs offers a wide range of solutions for machine tools, aimed at enhancing performance, precision and process control.

These solutions help optimize tool life, reduce set up time, prevent machining failures and optimize maintenance schedule.

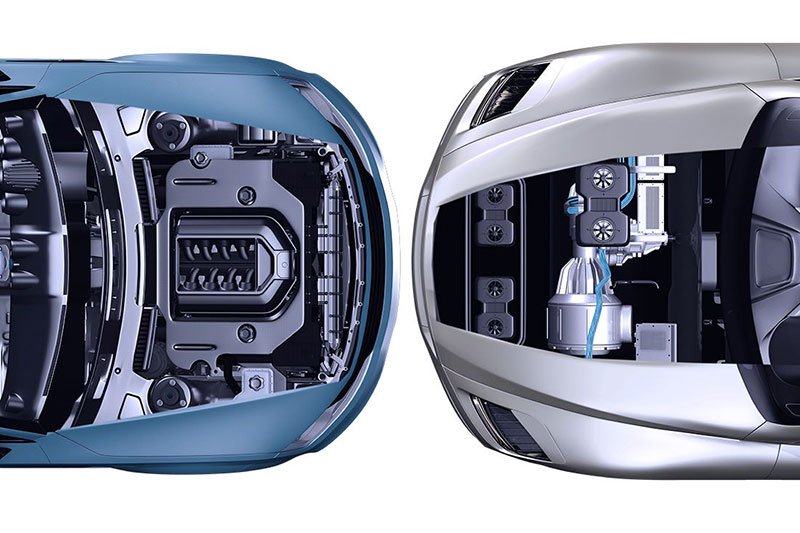

AUTOMOTIVE & TRANSPORTATION (ICE + EV)

- Marposs has always been a strong reference for car manufacturers, providing a full range of measuring and testing solutions.

In the transition from ICE to EV, Marposs remains the ideal partner to face the new challenges of the E_Mobility era.

Traditional product lines have been integrated with new technologies to ensure the complete monitoring of the main EV components production process.

AEROSPACE

- Aerospace is among the most demanding industries Marposs works with, offering effective and innovative solutions that match the strict quality requirements of the customers in production.

Marposs has three big groups of requirements that characterize the aerospace industry: to ensure a safe production, to avoid scrap parts, and to produce economically.

PUMPS & COMPRESSORS - WHITE APPLIANCES

- Marposs offers several solutions that can be applied to the white goods manufacturing processes.

These applications can be used to measure critical dimensions, detect defects and verify the integrity of components, contributing to the overall quality.

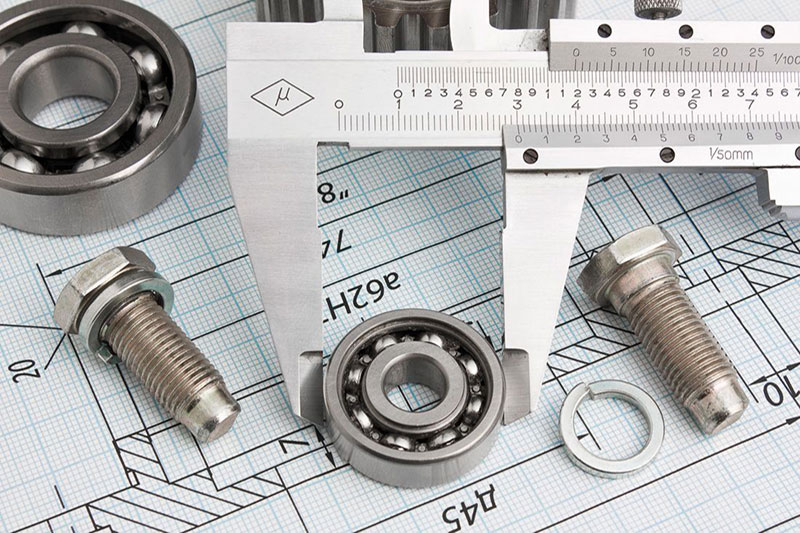

MECHANICAL COMPONENTS

-

Marposs offers solutions for measurement and control on Machine Tools as well as manual benches and automatic gauging machines for the inspection of an extremely wide range of mechanical components, including:

- Car components (gears, bearings, fasteners, etc.)

- Hi-tech (hard disks, etc.) and office appliances

- Electronic home appliances

- Electric motor components

- Bio-medical (prostheses, hematic filters, syringes, etc.)

- Electrical contacts (plugs, connectors, lead frames etc)

- Mechanical elements (chain, hose clamps, washers)

SEMICONDUCTORS - LED & CONSUMER ELECTRONICS

- In the semiconductor industry, Marposs offers a wide range of products to ensure the quality and precision of semiconductors manufacturing processes.

Marposs' expertise in quality control is leveraged in the semiconductor industry where an high level of innovation is requested.

ENERGY

- Marposs' long-term experience in process monitoring and in-line control has been applied to the manufacturing process of batteries and fuel cells with the development of tailored solutions to check the integrity, dimension and functionality of all components.

This can include the measurement, inspection and test of critical parts used in power generation systems, renewable energy devices and energy sotrage systems.

BIOMEDICAL & GLASS CONTAINERS

- The biomedical industry requires 100% production control with tight tolerances since reliability is a basic requirement.

Marposs solutions enable the detection of non-conformities quickly, cost-effectively and easily.

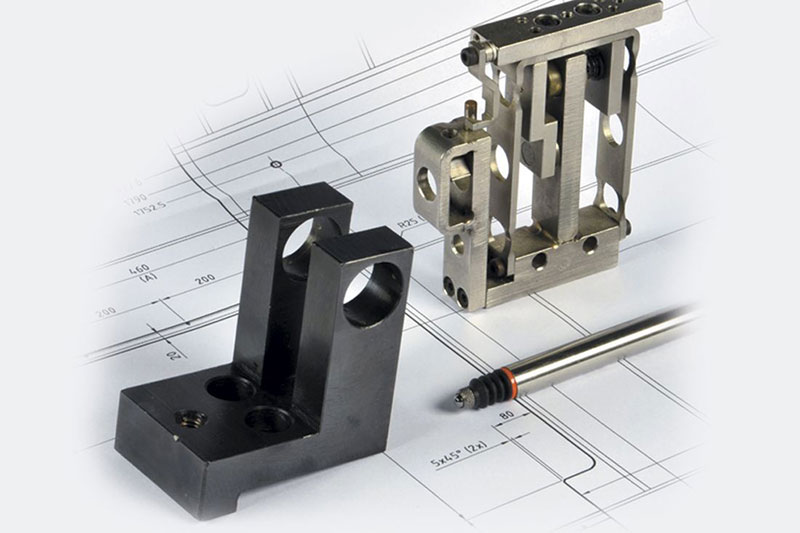

GAUGE & FIXTURE MAKERS

-

Marposs provides mechanical and electronic components to build gauging stations and fixtures.

These components include:

- Probes and measurement transmission elements: mechanical components and sensors

- Indicators and display units: mechanical and electronic units to elaborate and display results

- Signal converters: to convert sensor values between devices

- Data acquisition systems: interface units to connect analog and digital sensors to an industrial PC

- Industrial Computers (embedded computers, panel PC and workstations) for data processing and control

- Application software to create distributed shop-floor data acquisition systems for Statistical Process and Quality control (SPC).