- Offer Profile

- The INDEVA® solutions range of products includes Intelligent Devices for Handling (INDEVAs), Automatic Guided Vehicles (INDEVA® AGVs) and Modular Structures for Lean Manufacturing implementation (INDEVA Lean System®).

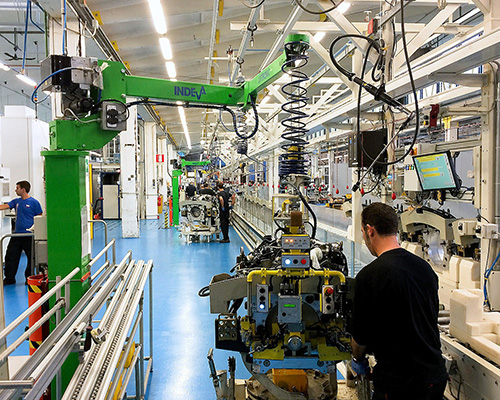

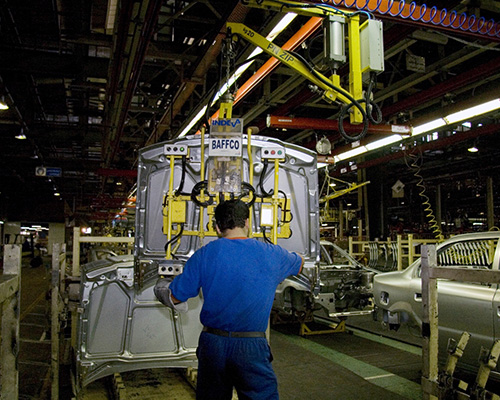

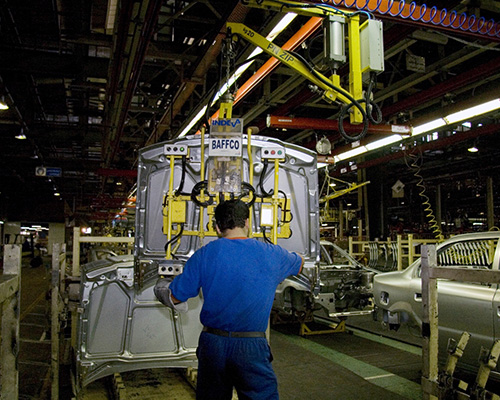

The INtelligent DEVices for hAndling (INDEVAs) are a new generation of advanced industrial manipulators. When linked to bespoke gripping devices designed by our engineers specifically for each application, the INDEVAs can be truly considered ‘human extenders’.

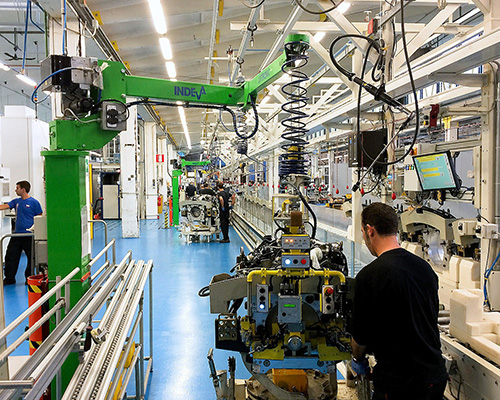

The INDEVA® Automatic Guided Vehicles (INDEVA® AGVs) and INDEVA Industrial Manipulators have been chosen by large manufacturing companies in the Automotive, Mechanical, Electronic and Fashion Industries, because we provide our customers with expert, dedicated attention to their requirements from concept to commissioning and beyond.

Industrial Manipulators and Material Handling Solutions

-

The most complete range of industrial manipulators nowadays on the market

It comprises:

- Intelligent Devices for Handling INDEVA® of the Liftronic® Series featuring advanced electronic control technology

- Traditional industrial manipulators of the PN Series featuring pneumatic control technology

Scaglia Indeva® distinguish themselves from the other manufacturers of industrial manipulators

because of their Intelligent Devices for Handling or INDEVA® (Liftronic® Series) . The INDEVA® are an evolution of the industrial manipulators and feature cutting edge electronic control.

Scaglia Indeva®’s range includes also traditional pneumatic industrial manipulators (PN Series), featuring pneumatic control. in order to satisfy special demands and suit applications in controlled environment with danger of explosion, according to the ATEX Regulations.

Industrial Manipulators

-

The widest range on the market comprising both pneumatic and electronic manipulators.

The INtelligent DEVices for hAndling or INDEVAs feature advanced technology that distinguish them from traditional industrial manipulators, and provide a step forward towards improved productivity, safety and ergonomics. Thanks to intelligent electronic control, an INDEVA® is faster, more reactive and precise, to the point that it can truly be considered a powerful ‘human extender’.

Automatic Guided Vehicles

- The INDEVA® Automatic Guided vehicles (AGVs) are designed by INDEVA® R&D personnel with the cooperation of research institution and universities for the most advanced control techniques. Scaglia Indeva is committed to continuously update its AGV’s software and features to ensure alignment to the technology edge.

Cobotics

- From 2019 the new division of Scaglia Indeva INDEVA COBOTICS is operational for providing turn-key collaborative applications with Doosan Cobots and AGV INDEVA. INDEVA Cobotics develops ready-to-use solutions with Doosan Cobots that ensure safety and ergonomics in the workplace.

Lean System

-

Since the late 1990’s Scaglia Indeva S.p.A. has been supplying modular structures and lose components designed to suit the Lean manufacturing philosophy.

The INDEVA Lean System® comprises a wide range of components that enables you to design and build a variety of structures to suit any need within the manufacturing process.

Technologies

SOLUTIONS

- Industrial manipulators with bespoke gripping tools suitable for all industry sectors. With an INDEVA®, thousands of repeated and satisfied customers worldwide have increased their productivity and operator wellness. Find out the material handling solution that best suits your requirement.

Ergonomics and safety for Manual Material Handling (MMH)

- Manual material handling (MMH) work contributes to a large percentage of musculoskeletal disorders reported annually in Europe and in the United States. Musculoskeletal disordersoften involve strains and sprains to the lower back, shoulders, and upper limbs.

Indeva Lean System® fully supports the principles of the Lean manufacturing

- Indeva Lean System® features versatility and reusability and it is, therefore, the ideal tool for those companies aiming for space optimisation and continuous improvement processes for a total business efficiency and profitability.

Internet of Things (IoT)

- Many are the applications, uses and relative advantages of industrial manipulators interconnected with your IT system and /or other machines in your assembly line or in your warehouse.

INDEVA®, Electronic Manipulators Liftronic® Series

-

Advantages of Liftronic® INDEVA® Intelligent Devices for Handling vs. traditional pneumatic manipulators.

- auto-weight sense and auto balancing

- very responsive and precise

- ergonomic and effortless handling

- remote trouble shooting through App-Indeva

- efficient and user-friendly auto diagnostic system: many auto- diagnostic parameters allows for accurate and quick fault diagnostic.

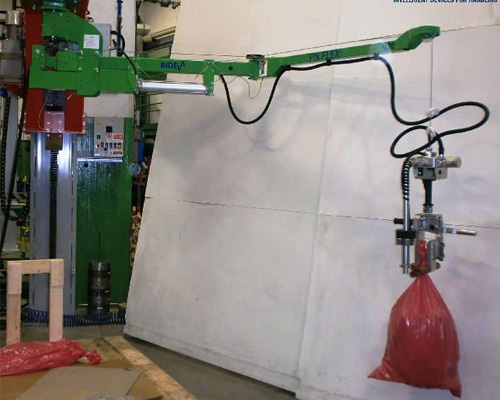

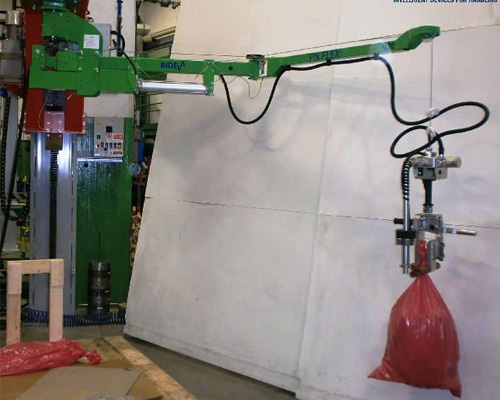

Liftronic® Mobile

-

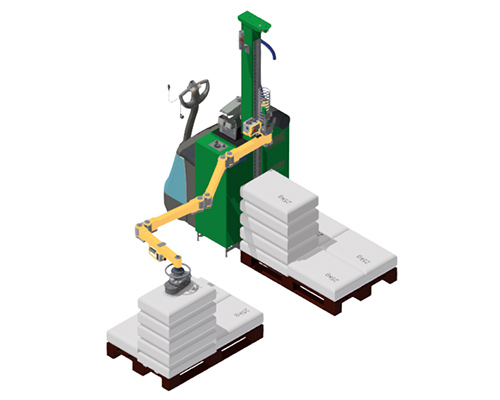

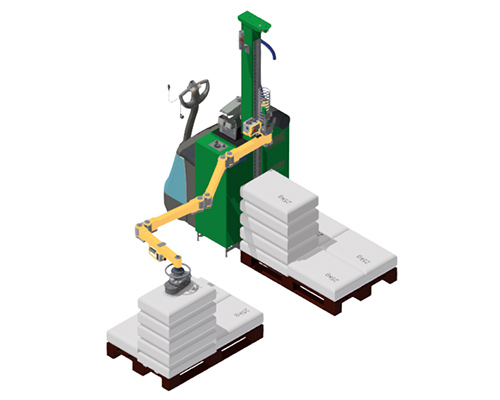

With the Liftronic® Mobile manipulator you can lift and move bags, containers, boxes, bins, components, etc., and place them on a pallet, shelf or conveyor effortlessly, ergonomically, safely, precisely and quickly.

Like all the other models in the Liftronic® Series, this manipulator allows operators to lift and manoeuvre loads as naturally as an extension of the user's arms, with the agility and responsiveness of a human operator coupled with the power of a machine.

It also allows you to move and position the load very precisely, optimising the speed of movement depending on the application or operator's requirements, offering performance benefits that traditional lifting devices cannot provide.

The Liftronic Mobile can be easily mounted on an electric pallet truck.

Its agile 4-jointed arm, which can be folded and locked securely when the pallet truck has to be moved, allows items to be picked from both the right and left sides of the truck.

If required, the swivel joint on the end of the arm allows a continuous rotation of the gripping tool without the risk of the rope twisting.

When using a vacuum suction cup to grip bags or boxes, the piping is contained within the arm, minimising the risk of damage and maximising visibility to the operator.

The Liftronic Mobile is equipped with integral safety devices to ensure maximum safety for the operator and security of the load being handled.

Maintenance operations are simple to perform as the main components are easily accessible behind a removable panel.

The Liftronic Mobile can be equipped with different types of INDEVA pick-up tools in order to handle different types of loads.

A quick-attach device allows the different types of gripping tools to be replaced quickly and easily, without the need for special equipment.

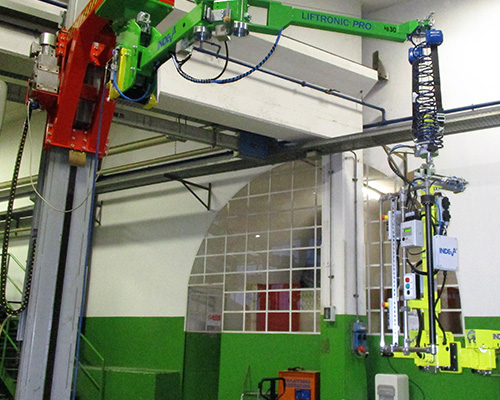

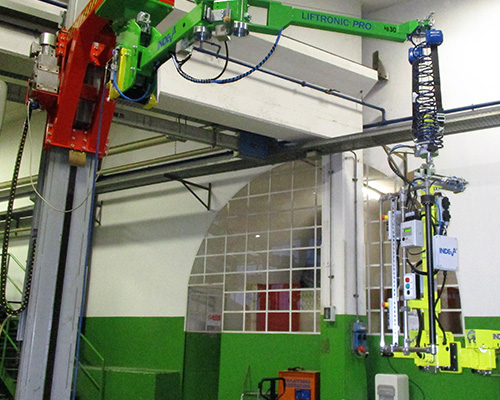

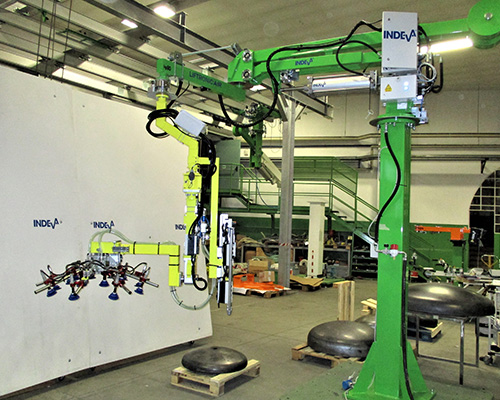

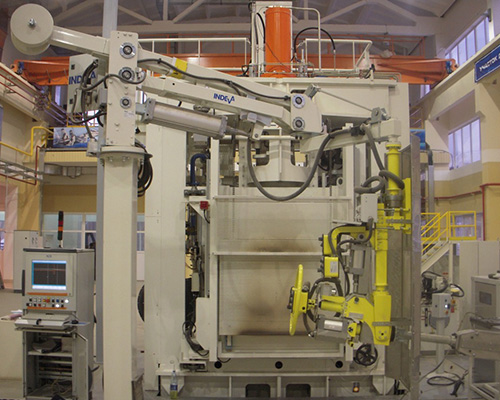

Liftronic® Pro

-

Liftronic® Pro belongs to the INDEVA® intelligent industrial manipulators Liftronic® Series

Suitable for custom handling solutions involving load rotation or vacuum gripping and/or special handing controls.

Models are available from 80 to 320 kg capacity, including the end effector. It can be applied to different supports such as column with Orbit_Arm, ceiling, overhead rail and bridge crane system, Liftruck.

The INDEVA® (or IAD – Intelligent Assist Devices) are electronic zero gravity balancers and represent a new ergonomic solution in material handling, solving today’s urgent need for increased productivity and safety.

Liftronic® Easy

-

Liftronic® EASY belongs to the INDEVA® Liftronic® Series of intelligent industrial manipulators

Designed for simple applications and non-complex and rapid work cycles. Only standard gripping tools applicable underneath the force sensing handle. A quick coupling device allows for quick and easy replacement of gripping tools to suit different load types.

Different models are available for capacities up to 320 kg and for applications on different supports such as freestanding column, ceiling, overhead rails and jibs.

Liftronic® EASY offers all the advantages of an INDEVA® at a price slightly higher than a hoist. Compared to a hoist or to a pneumatic manipulator Liftronic® Easy allows for quicker load handling movements, more precise load placing, auto-weight sense and auto balancing feature, greater user-friendliness with consequent increase of the overall productivity as well as of ergonomics for the operators and safety for delicate loads. It is simple to install and to maintain. All this together with its competitive price makes Liftronic® EASY a really cost effective investment with very high short term returns.

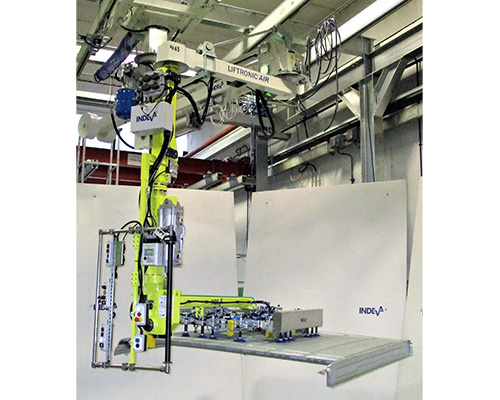

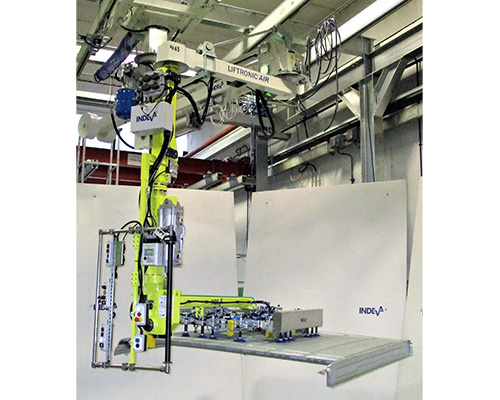

Liftronic® Air

-

Liftronic® Air belong to the INDEVA® Liftronic® Series of intelligent industrial manipulators

It combines the intelligent control system of the Liftronic® Series with the rigid parallelogram arm structure alike the pneumatic manipulators of the PN Series.

They represent the state of the art technology for handling offset loads.

Liftronic® Air is the latest technology and has no direct competition on market!!

Latest generation industrial manipulators of the INDEVA® family. They combine the strength of traditional pneumatic manipulators with the intelligence of the INDEVA®. Their power for lifting is pneumatic, but they are electronically controlled. Models are available from 80 to 250 kg, that can be supplied either column, ceiling or overhead rail mounted. Compared to traditional pneumatically controlled manipulators, Liftronic® Air offers important advantages which help improve safety, egonomics and productivity.

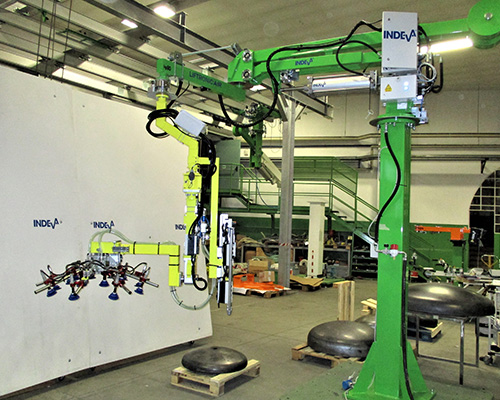

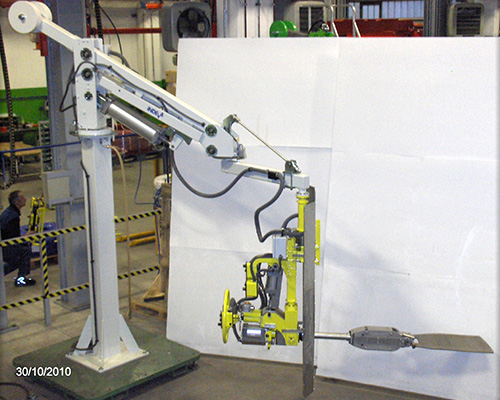

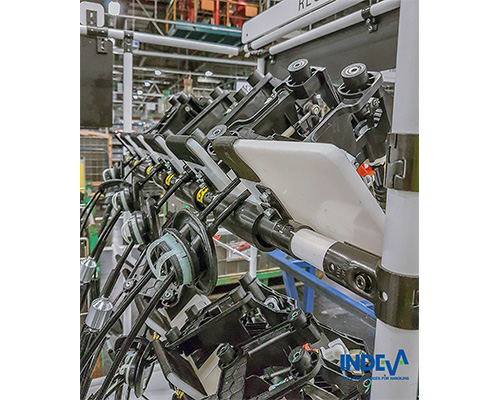

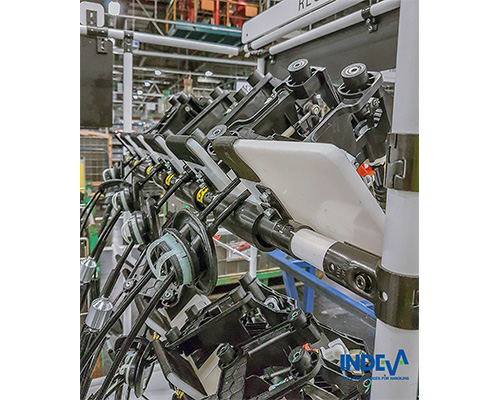

Liftronic® Pro end effectors

-

End of arm toolings (EOAT) for Liftronic® Pro are designed using the INDEVA® MODULO concept and parts

Most of the end effectors, or end of the arm toolings, designed for a Liftonic® Pro include industrialized parts and modules which are being used on all our end effectors, thus granting maximum reliability. Most of the end effectors for a Liftronic® Pro are custom designed to suit specific requirements, but some applications are very common and allow the use of typical solutions for the end of arm toolings (EOAT).

Liftronic® Easy standard end effectors

-

The universal tool head of Liftronic® Easy allows quick applications of different types of end effectors such as hooks, pantograph chucks, jaws, clamps, etcÂ

With one Liftronic Easy you can use different end effectors should you need to handle different types of loads at different times. A quick coupling system allows to switch end effectors quickly and easily.

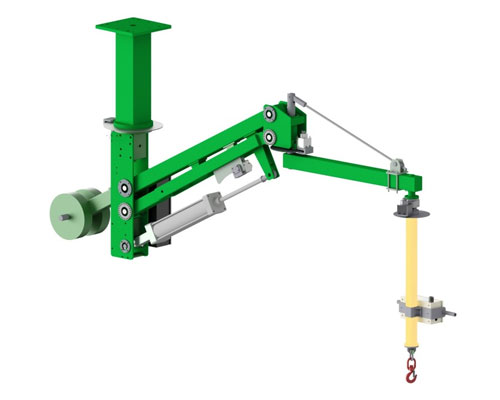

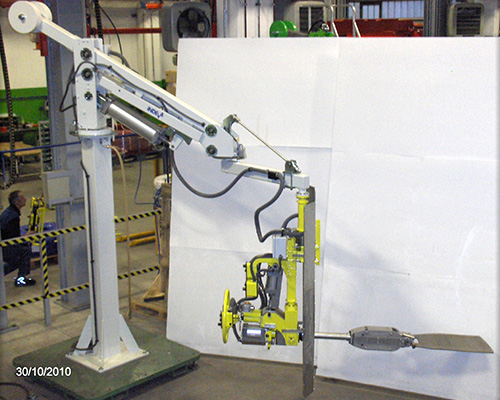

Pneumatic Manipulators: PN Series

-

Pneumatic manipulators are traditional industrial manipulators, featuring pneumatic drive and control

PN series manipulators are traditional industrial manipulators featuring pneumatic control and drive.

PN series balancers can be designed according to the ATEX regulations as per the EU Directives 94/9 regarding applications in controlled environments with danger of explosion, classified classes 1 and 2 (Gas).

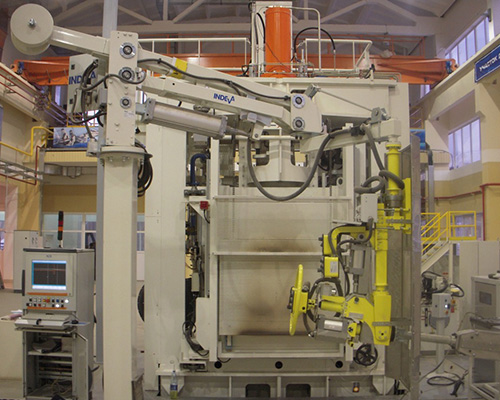

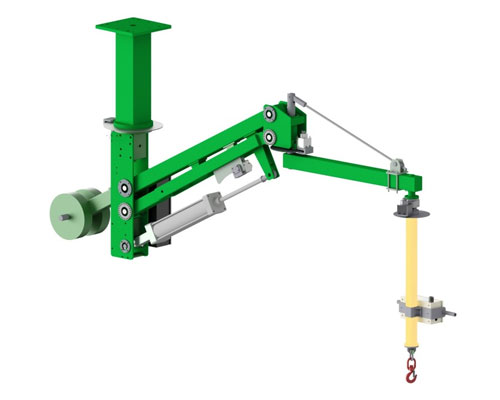

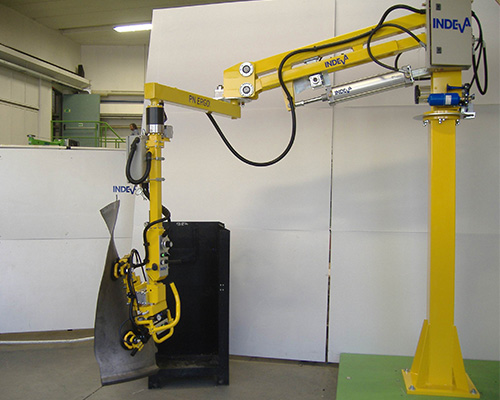

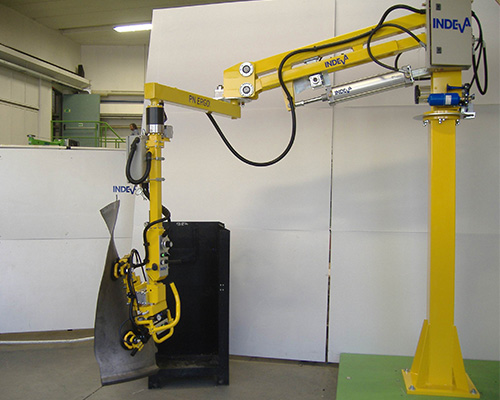

PN ERGO (PN)

-

Manipulator with pneumatic control and drive

PN ERGO are pneumatic industrial manipulators with rigid vertical arm, suitable for handling large size loads, especially when loads are not reachable from the top (offset handling).

Technical features- Lift speed from 15 to 30 m/min

- Control: pneumatic

- Air pressure: min 6,5 Bar

- Temperatures of exercise: da +5° a +50° C

- Noise level:

- Main column axis brake

- Intermediate joint axis brake

- Continuous column rotation

- Safety devices: in case of pressure failure slow descent till the floor

Available options

- Conformity to the ATEX

- Regulations for applications in controlled environment with danger of explosion,

- Rotating joint on the articulate axis

- System lock for the lift capacity

- Brake for up/down movement

- Special painting

- Steel platform

- Sliding trolley

- Limit switch for the main and intermediate Joint axis

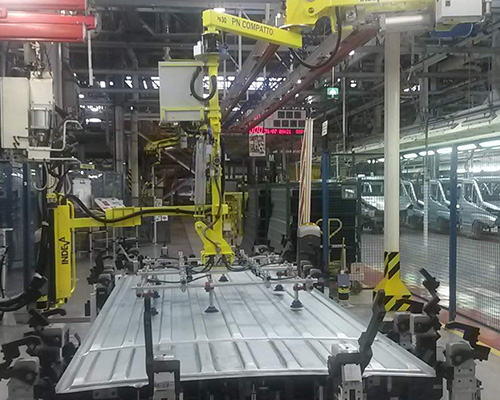

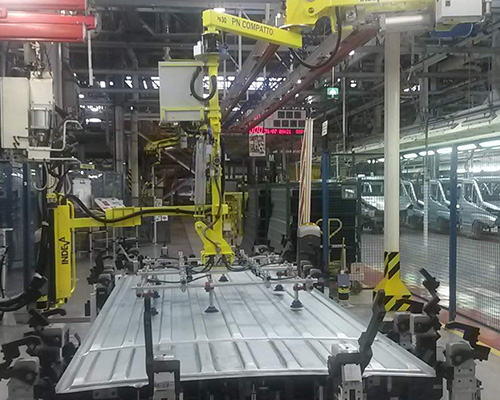

PN COMPATTO

-

Pneumatic industrial manipulators

PN COMPATTO are pneumatic industrial manipulators with rigid vertical arm, suitable for applications in small size, low ceiling work areas.

Technical Features- Lift speed from 15 to 30 m/min

- Control: pneumatic

- Air pressure: min 6 bars

- Work Temperatures: from +5° to +50° C

- Noise level:

- Main column axis brake

- Intermediate joint axis brake

- Continuous column rotation

- Safety devices: in case of pressure failure a safety devices retains the grip on the load, and the tooling descends slowly till the floor. Special brakes keep the arm and gripping tool still when not used

Available options

- Rotating joint on the articulate axis

- System lock for the lift capacity

- Brake for up/down movement

- Double braking force on the main and intermediate axis

- Special painting

- Sliding trolley

PN ZIP

-

Pneumatic Industrial Manipulators PN ZIP Series

Pneumatic industrial manipulators, light and compact, suitable for applications with a short vertical excursion and quick work cycles.

Technical features- Max load capacity: kg 80

- Control: pneumatic

- Air pressure: 6,0 Bar

- Work Temperatures: from +5° to +50° C

- Noise level:

- Safety devices: in case of pressure failure slow descent till the floor

Available options- Conformity to the ATEX

- Regulations for applications in controlled environment with danger of explosion,

- Special painting

PN FLEX (PNF)

-

Pneumatic Manipulator PN Flex

Pneumatic manipulator with a flexible rope in place of the vertical rigid arm. The PN Flex pneumatic manipulators are suitable for handling loads having their barycenter on the Z axis of the vertical arm. They allow flexible load picking/releasing movements.

Technical Features- Max load capacity: kg 80

- Max lift speed: 45 m/mn

- Control: pneumatic

- Air pressure: 6,0

- Bar Work Temperatures: from +5° to +50° C

- Noise level:

- Main joint axis friction

- Intermediate joint axis friction

- Safety devices: in case of pressure failure slow descent till the floor

Available Options

- Conformity to the ATEX

- Regulations for applications in controlled environment with danger of explosion,

- Special painting Steel platform

Automatic Guided Vehicles – INDEVA® AGV

-

Extensive expertise in the design of Automatic Guided Vehicles, materials handling solutions and industrial automation.

Scaglia Indeva® is in the business of the low cost automation since 1980 and has been supplying solutions for lean manufacturing applications, namely components for modular structures (Indeva Lean System®) and Automatic Guided Vehicles (AGVs) since year 2000.

INDEVA® Automatic Guided vehicles (AGVs) have been designed expressly for companies that apply the lean manufacturing principles. Thanks to their modularity, flexibility and easy-to-use features they represent an effective and low cost solution for assembly lines and logistics. The use of automatic guided vehicles proved to increase efficiency and reduce costs related to the task of carrying material from warehouse to the assembly line.

Emphasis on ‘easy-to-use’ and ‘make-it-yourself’ principles is the main focus of our INDEVA® AGVs overall design. In fact we do strongly believe that in a fast changing world the user has an important advantage in being independent in the programming, maintenance and possible modifications of their vehicles.

The INDEVA® Automatic Guided vehicles (AGVs) are designed by INDEVA® R&D personnel with the cooperation of research institution and universities for the most critical and advanced control techniques. Indeva is committed to continuously update its AGV’s software and features to ensure alignment to the technology edge.

Scaglia Indeva® is the only European company that designs and manufacture in Europe modular Automatic Guided vehicles (AGVs) for Lean manufacturing.

Nowadays Scaglia Indeva® can boast wide expertise and know-how in supplying state of the art internal material handling solutions with a large portfolio of satisfied customers among the most important corporations in the Automotive and non-Automotive industries.

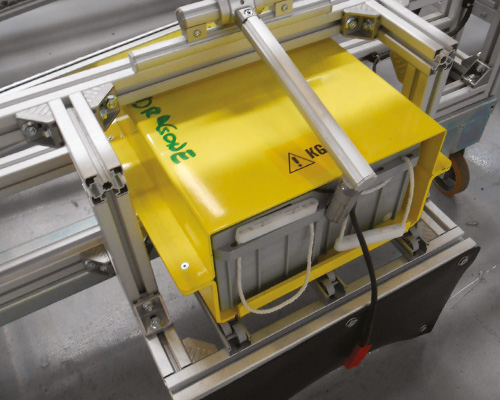

INDEVA® AGV – Standard Models

-

Main features:

The AGVs follow a magnetic tape which is quickly and easily laid along the required route.

Each standard AGV can be configured for different functions and can be upgraded from a range of optional accessories.

An AGV INDEVA® is programmed for automatic start by means of either a preset timing or reception of a signal from customer’s line.

Comes complete with standard interfaces. Customer can use these to perform special functions or to control external devices.

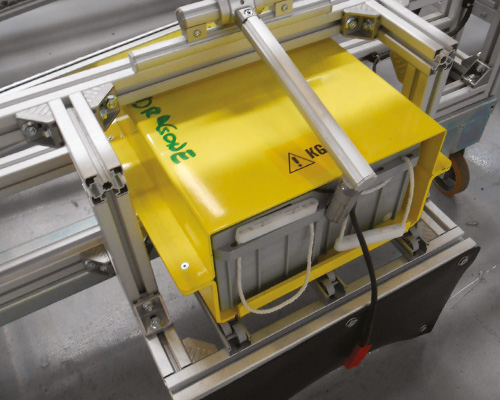

INDEVA® AGV – Custom Solutions

-

A custom built INDEVA® AGV is designed specifically to meet special site and operational requirements regarding structure, layout, size and program.

A custom built INDEVA® AGV is designed to your exact specifications using either modular pipes and joints from our INDEVA Lean System range of components or a steel base structure.The INDEVA® AGV shown above is complete with power driven rollers for uploading large containers from the conveyor line that carries material between the warehouse and assembly line. It can carry loads up to 1500 kg.

An INDEVA® custom gravity AGV is used to transport boxes and small containers in both directions between the warehouse and assembly line. The loading/unloading of the boxes from/to the AGV is carried out with a completely automatic and simple mechanism using gravity to slide boxes from the AGV to the rack and vice-versa.

INDEVA® AGV – Trolleys, Accessories and Options

-

A range of accessories and options are available to enhance your INDEVA® AGV: power system, route & markers, communication & control and custom trolleys.

Supervisor and ControllerIt is the brain interacting with all the vehicles in the entire system: it receives from the AGVs information on their position and work parameters and controls crossings and overall traffic flow.

• controls AGV and all the other line components we supply such as roller conveyors, trolleys, WI-FI start-stop, etc…

• controls crossings

• controls position on the route

• assigns the task to be completed by the AGV

• controls battery level and other parameters

• informs about failure and position of the AGV in case of unplanned stop.

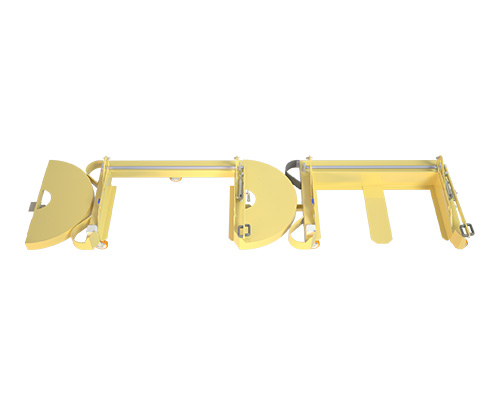

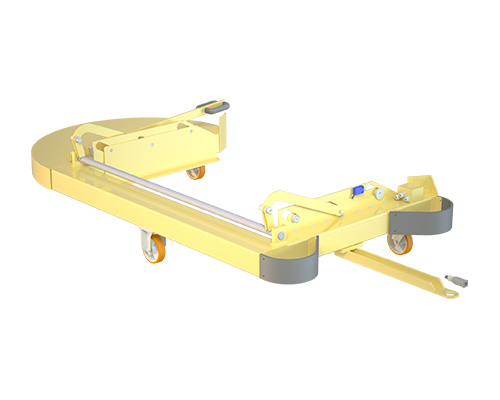

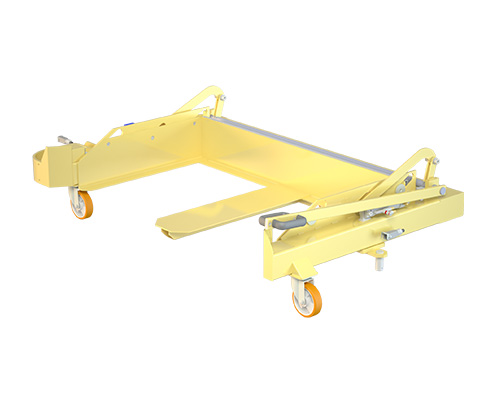

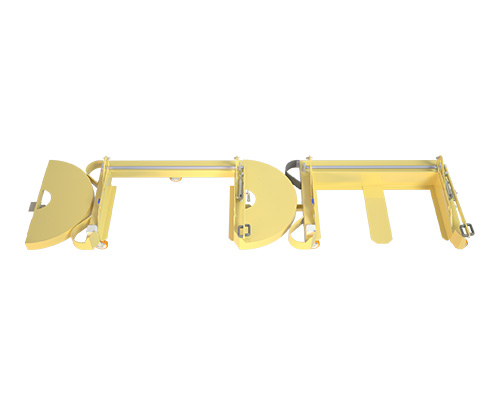

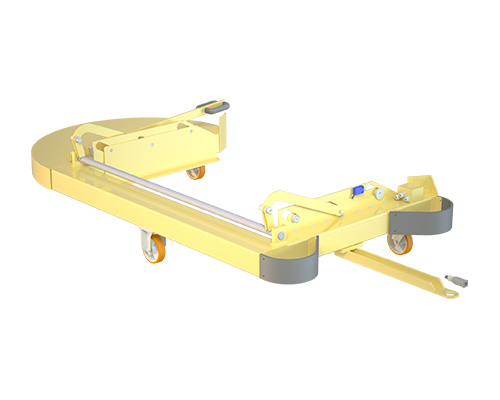

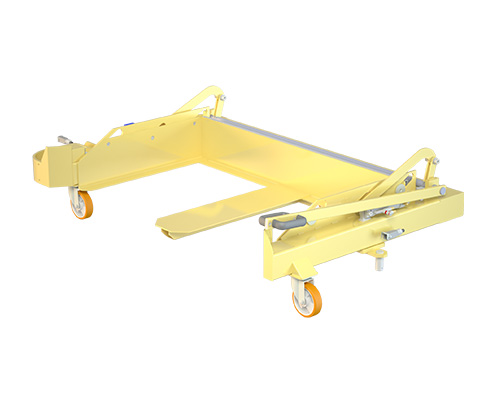

Intralogistics Systems

-

A wide range of Intralogistics Sytems to suit transport of a great variety of goods

In order to satisfy the great variety of requests from our customers with large size production sites, e.g. in the automotive, aerospace, fashion, mechanics, etc.. industry fields, we can provide a wide range of intralogistics systems for carrying all types of trolleys in an efficient and safe way.

These Intralogistics sytems can be pulled by an INDEVA® TUGGER AGV or by any other AGV in your shopfloor.

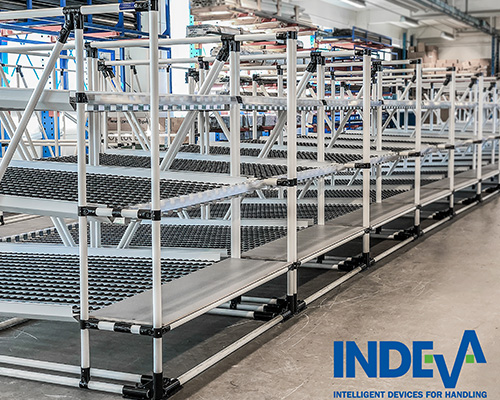

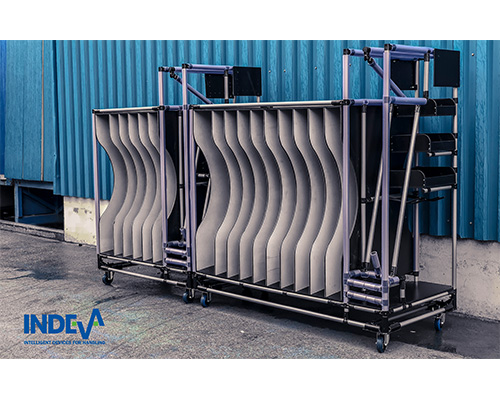

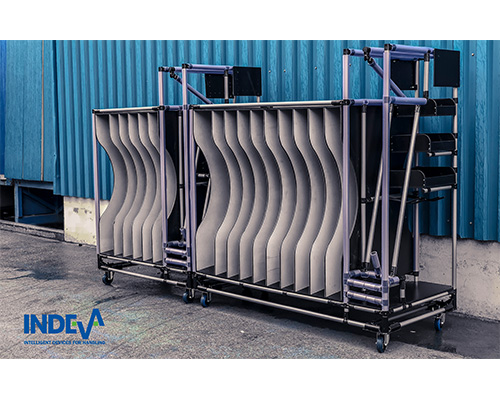

INDEVA LEAN SYSTEM®

-

Scaglia Indeva’s modular system is called “INDEVA Lean System®”.

Since the late 1990′s Scaglia Indeva S.p.A. has been supplying modular structures and lose components designed to suit the Lean manufacturing philosophy.

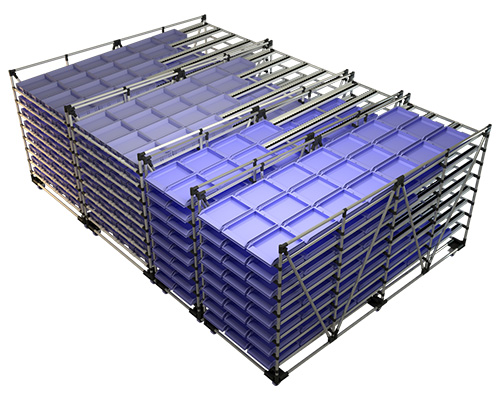

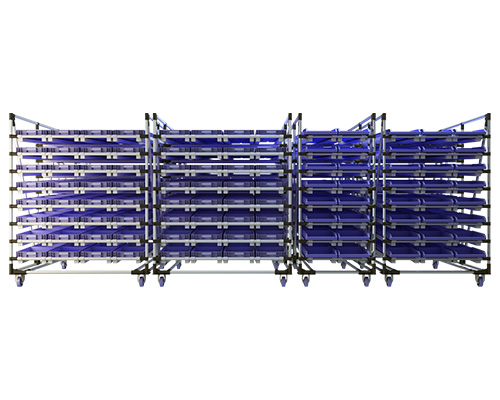

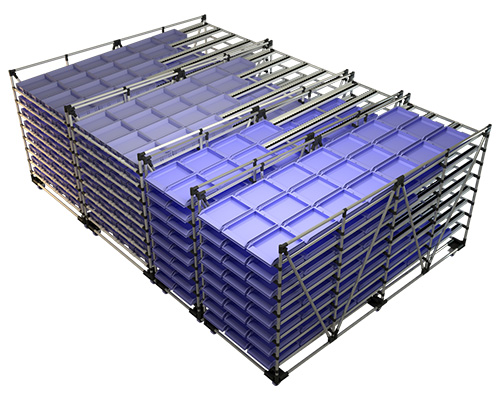

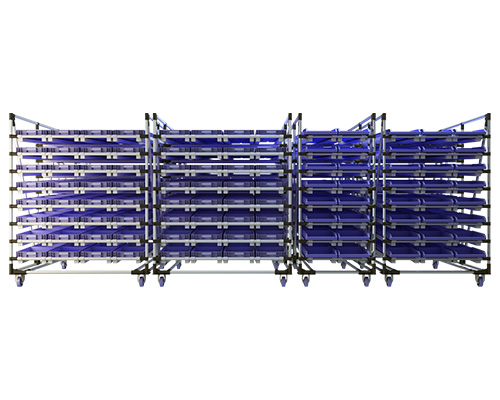

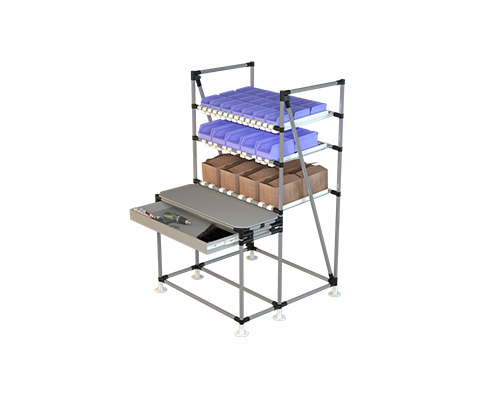

The INDEVA Lean System® comprises a wide range of components including abrasion resistant plastic-coated steel tubes, steel joints, roller tracks and accessories. This enables you to design and build a variety of structures to suit any need within the manufacturing process. Applications could include ergonomic workstations, trolleys, carts and dollies, flow racks, gravityfed racks, line-side racks, shelving and modular stage systems.

With the INDEVA Lean System® you can design and build material handling and work assist structures to your exact specifications and requirements, thus helping to meet Lean manufacturing goals.

Big Companies in different industry sectors, mainly Automotive, Manufacturing, Mechanics, have chosen Scaglia INDEVA as their Corporate Supplier of components and modular structures.

supermarkets

- A supermarket in an industrial production site is the location where a preset standard inventory is kept to supply downstream processes.

Gravity fed flow racks

- Flow racks, also known as first-in-first-out ("FIFO") racks or gravity racks or gravity-fed rack ("GFR").

Work station

- Waiting time, repetitive strain and unconfortable positions will be only a sad memory for the operator that use INDEVA Lean System® modular work stations!

Train sets - Tugger carts

- INDEVA Lean System® modular tugger carts can be used in a train set od individually for being towed by an AGV.

Kitting trolleys

- Thanks to 3D simulation we can provide a wide range of tailor-made storage solutions and exhibitors.

Shooter trolleys

- Shooter trolleys made with INDEVA Lean System® allow handling heavy loads and move them from one trolley to another one or from one fixed structure to a cart, through an efficient gravity fed sliding system.

Welded structures

- INDEVA Design & Manufacture welded structures according to customers specifications.

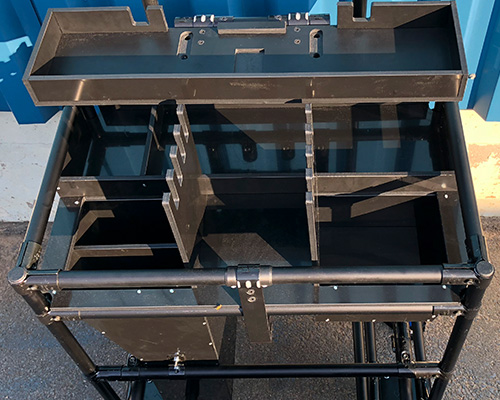

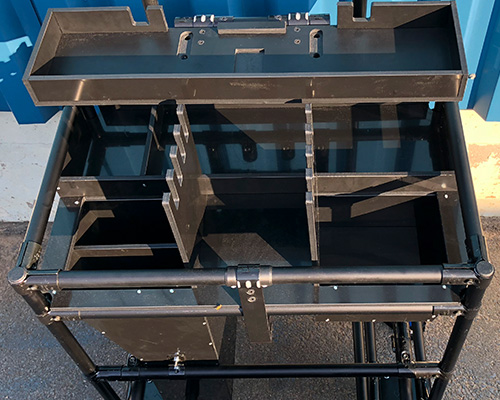

Work in process carts

- INDEVA Lean System® is ideal for the design and assembly of in-house material handling carts.

Dunnege bags for kitting

- INDEVAs Dunnage bags combines the strength & versality for handling sensitive parts.

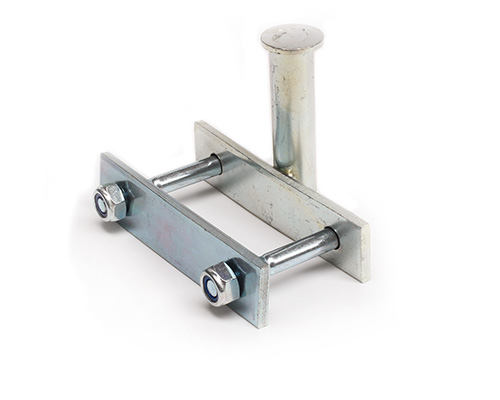

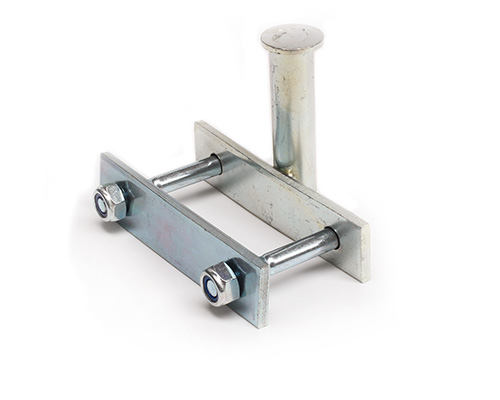

INDEVA® Lean System® Component Range

- The pipes & joints INDEVA Lean System® comprises a wide range of components including abrasion resistant plastic coated steel tubes, steel joints, roller tracks and accessories.This enables you to design and build a variety of modular structures to suit any need within the manufacturing process.

Applications range from ergonomic workstations to trolleys, carts and dollies, flow racks, gravity fed racks, line-side racks, shelving and modular stage systems.

Kit boxes

-

From simple to specialized, large and complex kit boxes for all types of manufacturing requirements.

Most Companies with large production sites in different industry fields have implemented the lean manufacturing principles and continue doing so because it is a mayor key to their business success.

The production manager of a large company has stated: “we have created a department to kit final goods. Kits can range from simple bagging to specialized kit boxes to large complex kits for all types of industry requirements. Our application of LEAN MANUFACTURING culture has led us to design efficient kitting to streamline procurement, , minimize inventory, reduce part handling and eliminate parts shortage. Using bespoke kit boxes reduces cycle time, improves project readiness and helps shorten production schedules, thus lowering overall production costs.

We can provide complete bespoke solutions from prototype development to 3D simulation and serial production.

INDEVA® Lean System® Supply Options

-

In order to meet specific demands, Scaglia Indeva offer following supply options for INDEVA Lean System® components and solutions

ASSEMBLED STRUCTURES

Our engineers design and assemble the structures at our facility and ship them complete and ready for use upon delivery.KITTED STRUCTURES

Our engineers provide a design suitable for your requirements and supply all the parts pre-cut and packaged in a kit for you to build.BULK COMPONENTS

Who knows your need better than yourself? Scaglia indeva guarantee quick delivery of the components for your own staff to design and build suitable structures.3D SIMULATION & PROTOTYPING

Detailed simulation of your production set-up available prior to manufacture.LEAN TECHNICIAN

Our design and build team will come to your site, assess the requirement, design and build the solution and hand it over on completion.

INDEVA Cobotics: process automation with collaborative robots

- From March 2019 the new division of Scaglia Indeva INDEVA COBOTICS is operational, completely dedicated to propose collaborative applications with Doosan and AGV INDEVA Cobots.

Doosan A-series

- The perfect Cobot for simple and fast work cyclesthat do not require sophisticated controls.

Doosan H-series

- H Series

The most powerful Cobot on the market.

Maximum payload of 25 kg and optimal safety thanks to its 6 torque sensors.

Doosan M-series

- M Series

The ideal Cobot for complex work cycles.

Its high control technology enables it to handle work cycles with dexterity while ensuring maximum safety and collision sensitivity.