- Offer Profile

- Renewable energy from

biogas plants

The number of our locations is growing continuously. The reason for this is that the advantages of biogas spread among governments, farmers and investors. But it is also because potential plant operators prefer searching for experienced partners.

EnviTec Biogas AG covers the entire value chain for the production of biogas - including the planning and turnkey construction of biogas plants as well as their commissioning.

The company provides the biological and technical service, and also offers full plant and operating management.

BIOGAS

-

BIOGAS - The allrounder among renewable energies

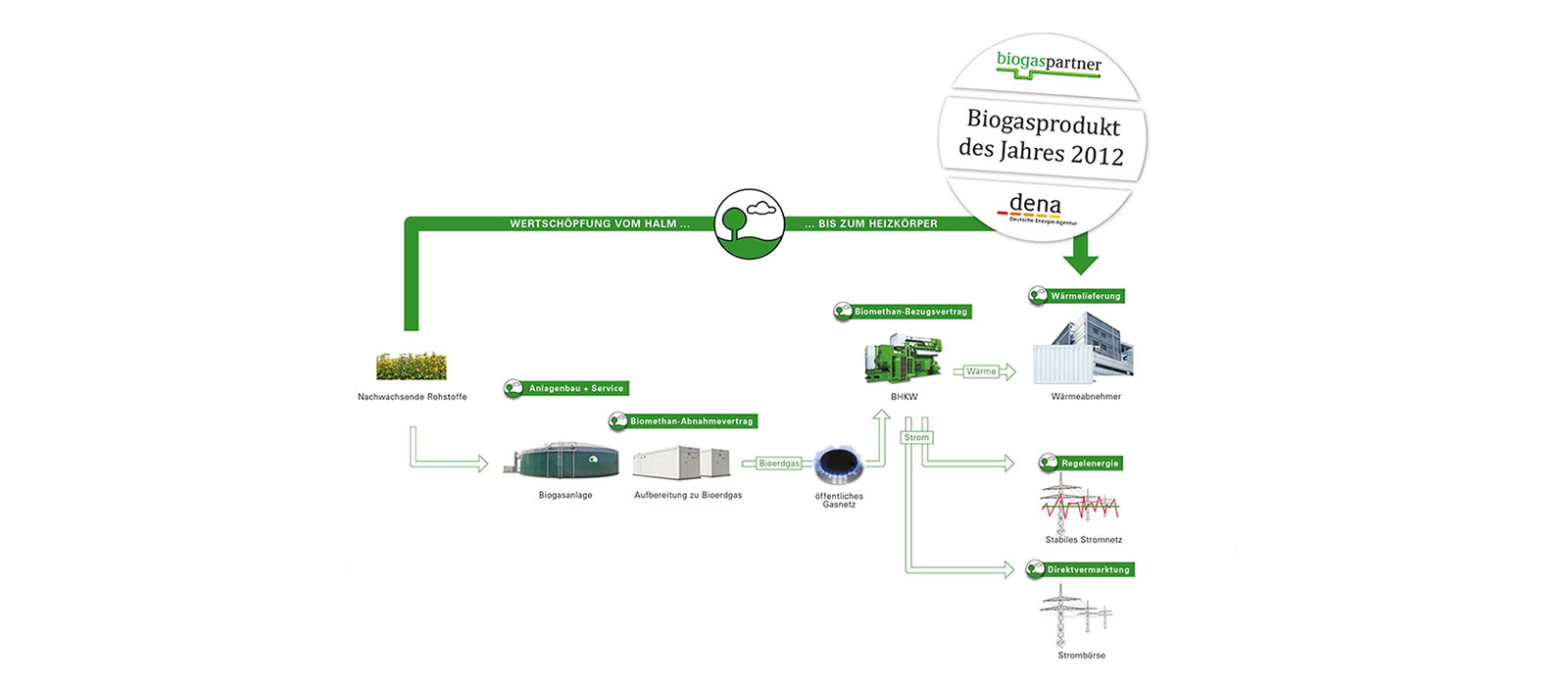

Whether as a source of electricity to generate heat locally, to supply heat by pipeline or to feed into the gas network after processing - Biogas is multi-talented and versatile. The weather-independent generation is a predictable source of revenue for the operator, since energy from biogas is not subject to any price fluctuations. At the same time, a biogas plant actively contributes to environmental protection and energy mix of the future.

THE ADVANTAGES OF BIOGAS AT A GLANCE:

- Multifunctional

- Generation of electricity

- Generation of heat and coldness

- Conversion to natural gas

- Highly efficient

- Highest energy recovery amongst all biomass project types

- Use of the whole crop in comparison to other bio fuels

- Variety of feed-stocks can be processed (e.g. organic waste)

- Storable and available

- Peak load capability

- Base load capability

- Power generation unrelated to weather conditions

- Output

- Clear net positive carbon footprint

- Suitable for the development of decentralised energy supply

- Fermentation residues suitable for premium fertilize

HOW DOES A BIOGAS PLANT WORK?

The basic principle of a biogas plant is relatively simple. Renewable raw materials from agriculture, animal droppings, residues from the food and agro-industry, can be used as input materials.

In airtight fermentation vessels - the so-called digesters - a fermentation process is stimulated and produces biogas using bacteria. The bacteria are similar to those which can also be found in the digestive tract of a cow. Main products of anaerobic degradation are energy-rich methane and carbon dioxide. Since both are gaseous, they separate from the fermentation substrate and form the main components of biogas. Carbon dioxide is not oxidized, but then can be supplied together with the energy-rich methane cogeneration power stations of combustion and fed into each locally existing heat network. - Multifunctional

BIOMETHANE - The renewables all-rounder

-

Biomethane upgrading opens up a promising future market for the biogas industry. With feed-in into the public natural gas grid, the green all-rounder is perfect for the decentralised supply of energy, offering a long-term replacement for fossil natural gas and driving the energy transition forward. What’s more, the biomethane manufactured in the gas upgrading plant has the exact same properties as natural gas, being just as flexible in its usage and easier to store than other energy sources. Plus, it’s renewable.

How is this valuable bio natural gas produced?

Anaerobic digestion of organic materials creates a gas composed of methane and carbon dioxide. To upgrade the biogas to natural gas-quality biomethane, the crude gas is first purified and compressed. The membrane technology we use then exploits the different sizes and permeation speeds of the two kinds of gas molecules involved: since carbon dioxide molecules are smaller than methane molecules, they can migrate through the membrane much more quickly. As a result, the methane remains on the high-pressure side, while the CO2 molecules in the biogas pass through. As a result, the gas upgrading needs neither chemicals nor water nor any other resources.

The starting point for producing biomethane doesn’t have to be biogas, however. After a preliminary purification stage, gas from landfill and wastewater treatment plants can also be used to produce biomethane.

The biomethane so produced is the all-rounder among renewable energy sources, and can replace fossil fuel-based natural gas anywhere it is used. On the following pages, you can find out about the many uses for this valuable and renewable natural gas, and how it can play a part in an environmentally-friendly energy supply system.

THE ADVANTAGES OF BIOMETHANE AT A GLANCE:

- FLEXIBILITY OF USE

Whether in the home, as a carbon-neutral fuel (CNG) for the transport sector or converted on-demand into electricity and heat, biomethane is a true all-rounder that can also be used in a decentralised system - INDEPENDENT

Biomethane frees us from our dependence both on fossil natural gas and natural gas importers, thereby helping to support predictable long-term pricing trends in domestic energy market. - EXCELLENT PUBLIC ACCEPTANCE

Biomethane is renewable. This means heating consumers benefit from an improved CO2 footprint and potential savings resulting from the more efficient use of energy. As a highly efficient fuel, biomethane is also a star performer in the fuel market and can help to reduce emissions many times over. - STRONG MARKET POTENTIAL

Since crude gas sources and gas grid infrastructure are both available, neither time nor capital investment is necessary to establish them. On the contrary: the use of biomethane can unburden the electricity network and contribute to a temporary easing of cost-intensive upgrading work. - REGIONAL VALUE CHAINS

Biomethane promotes economic growth both in the feed-in region – which is in the immediate vicinity of the gas generating plant – and in the consuming region, which is independent of the feed-in location. - AN ADDITIONAL PILLAR FOR YOUR BUSINESS

Since our gas upgrading systems are exceptionally efficient and cost-effective, they can offer biogas plant operators another attractive source of revenue from biomethane production.

- FLEXIBILITY OF USE

ENVITHAN BIOGAS UPGRADING

-

REFRESHINGLY SIMPLE AND FLEXIBLE.

Before biogas can be fed into the natural gas grid or used as a fuel, it must first be upgraded to natural gas quality. Our answer to the requirements of the future is therefore EnviThan – our integrated solution from organic waste to the filling station pump!

Want to lose no time in getting started on your own project?

Simply tell us what you need and we’ll get in touch with you to provide tailor-made advice BIOMETHAN - THE ALL-ROUNDER

-

BIOMETHAN - THE ALL-ROUNDER

From a macroeconomic and climate perspective, biomethane is now the most cost-effective, climate-friendly fuel for achieving progress towards climate targets and sustainable transport in Germany and the EU. This all-rounder is virtually carbon-neutral, storable and therefore continuously available – and so not only of interest to the transport sector.

In addition, the all-rounder can be used wherever fossil natural gas had been used previously to date: this includes CHP applications, demand-based power and heat generation, and use as an input material in the chemicals industry.

Biomethane is therefore an important building block for the energy transition.

AN ADVANCED FUEL

-

The advantages of bio-LNG (liquefied natural gas) as a carbon-neutral fuel are obvious: in the transport sector alone, the use of biomethane allows a CO2 reduction of up to 97 percent compared to fossil fuels.

For this reason, we are tapping into a new field of the future as a plant manufacturer by constructing Germany's first integrated bio-LNG plant, which will both make heavy goods transport greener and also allow biogas plant operators to profit. This is because the reduction in greenhouse gas emissions required of the German fuel mix by the Renewable Energy Directive RED II means that green fuel production is being implemented ambitiously for the first time. As a result, those placing fuels on the market must now cut their GHG emissions by 25 percent by 2030 compared with 1990 levels.

Following the expiry of state subsidies for biogas plants, our all-round concept for gas treatment offers a sustainable solution for the profitable continued operation of existing plants through the sale of your biomethane or potentially its contract liquefaction into bio-LNG.

Heat

- To boost the share of heat from renewable sources to 14 percent by 2020, using biomethane in combined heat and power (cogeneration) plant is one of the most sustainable technologies currently available. Especially in cases where other kinds of renewable energy technologies or measures to reduce energy requirements are not deployable to the extent needed for structural reasons, the use of biomethane in heating-only applications is a useful alternative.

There are several usage models for biomethane-based heating. Typical consumers are the plant operator’s own property or business premises, housing complexes or public facilities fed via heating grids, as well as horticultural, commercial and manufacturing companies. All of this makes biomethane an inexpensive and efficient renewable energy option on the heating market.

Electricity

- A reliable electricity supply requires a balance between electricity production and demand at all times. Accordingly, the load at any point in time must be met by a guaranteed level of (power generation) performance. As power generation from fossil fuels and nuclear power plants starts to be wound down, alternative solutions to provide this level of performance are required. Flexible power generation plants are a viable option here: these can respond quickly to changes in electricity generation from the fluctuating feed-in of renewable energy sources and handle the tasks required to secure the energy supply. The use of biomethane enables the provisioning of the relevant system services on the basis of renewable energy sources and so reduces the need for fossil-based power plants.

CO2 recovery

- The CO2 generated during biomethane production can be reused and liquefied. Ultrapure carbon dioxide offers an interesting additional source of revenue for plant operators, and can be utilised in a wide variety of industries (such as the food industry, in horticulture, for firefighting or in refrigeration plants).

Energy management

-

WHY WE MANAGE ENERGY?

Quite simply, because we have more than 20 years of expertise as a biogas plant manufacturer. For us, everything revolves around the renewable multi-energy biogas. That's why we not only use our extensive expertise to plan, build and maintain biogas and biogas upgrading plants, but naturally also help our customers to market the energy produced. Because when it comes to energy, it's like the butcher: we always answer the question "Can I have a little more?" in the affirmative! A little more green energy not only improves the CO2 balance, but of course also provides heat, electricity or even fuel for a climate-neutral transport sector.

- Forward-looking, organised, systematic

Our energy management is one thing above all: forward-looking. Without the foresighted and systematised coordination of procurement, conversion, distribution and use of green energy to meet the respective individual requirements of the customer, we would not get very far either. Our aim is to create a win-win situation for our customers and for us as a buyer or seller of green energy, taking into account ecological and economic objectives. In our home market of Germany, we focus exclusively on the purchase and sale of biomethane and on contract liquefaction for the production of bio-LNG for the green transport transition. - Simply sell it

Do you have leftover biomethane and don't know what to do with it? We will gladly accept your surplus energy and even pay for it - including guaranteed price security over a long-term period. So you and we can plan better. - Simply deliver

You have managed to get started with gas processing. Now you would also like to benefit from the attractive GHG quota payments. With our contract liquefaction offer, you can get started right away. You supply us with your biomethane and we liquefy it into bio-LNG. We only charge you a service fee per kilogramme of LNG and you market the LNG and GHG quota yourself. This means that you retain the full added value, save yourself the authorisation and do not take any technical risk - Simply ask

Are you unsure which of our concepts is right for you? We will be happy to help you gain more clarity. Simply let us know which topic you would like us to inform you about - free of charge and without obligation, of course!

- Forward-looking, organised, systematic