- Offer Profile

- For over seven decades, we have served markets worldwide with our NEMO®

Progressing Cavity Pumps, TORNADO®

Rotary Lobe Pumps, NOTOS®

Multi Screw Pumps ,PERIPRO®

Peristaltic Pumps, grinding machinesdosing

technology

and accessories, providing customized, sophisticated solutions for a great

variety of applications.

At NETZSCH we strive to use our expanding global technological and market leadership for our customers' benefit. We see ourselves as far more than just a developer and producer; it is our aim to be your partner for everything from project planning to process consulting to integral service.

Pumps & Systems

NETZSCH offers you the perfect pumps & systems for a wide variety of applications

As a worldwide leading supplier in the field of rotary positive displacement pumps, our customers' satisfaction is our top priority.

NETZSCH has been developing, producing and distributing positive displacement pumps worldwide for more than 60 years. Whether environment & energy, chemical & paper, food & pharmaceutical, mining, oil & gas upstream or mid-/downstream: At NETZSCH, we develop the right pump solution for your customers' specifications. We promise you Proven Excellence - outstanding performance in all areas. over.Branches / Industries

Environmental & Energy

- NETZSCH Pump Solutions in the Fields of Environment and Energy

We find and develop the perfect positive displacement pump for your individual application

As a global specialist for pumps and systems in the field of environment and energy, NETZSCH offers you solutions individually tailored to your requirements. The satisfaction of our customers is always our top priority.

Whether for wastewater treatment, lubrication of hydraulic pumps, sludge pumping in sewage treatment plants or for a wide variety of applications in the field of biogas, we support you with our patented solutions. We promise you Proven Excellence - outstanding performance in all areas. In the environment and energy business area, the various pump systems cover almost all applications. TORNADO® rotary lobe pumps, NEMO® progressing cavity pumps and NOTOS® multi screw pumps, also in combination with our grinding systems, guarantee you the optimised solution for your process.

Chemical, Pulp & Paper

-

NETZSCH Pump Solutions in the Chemical, Pulp and Paper Industries

We find and develop the perfect positive displacement pump for your individual application

As a worldwide leading supplier of positive displacement pumps, NETZSCH offers you individually optimised pump solutions in the areas of chemicals, pulp and paper. With our pumps and systems, you can safely convey even the most challenging media.

We globally develop customised and sophisticated solutions for you in the chemical, pulp and paper sectors. Fluids that are hazardous to health and the environment, highly viscous products, products containing solids or sensitive products require pumps that can handle even the most challenging media in hermetically isolated systems. We make no compromises when it comes to your safety. In any case, the satisfaction of our customers is always our top priority.

Food & Pharmaceutical

- NETZSCH Pump Solutions in the Food and Pharmaceutical Sectors

We find and develop the perfect positive displacement pump for your individual application

As the world's leading supplier in the field of positive displacement pumps, NETZSCH offers you an individual and innovative solution in the areas of food and pharmaceuticals. With our pumps and systems, you can convey your products gently and cleanly in compliance with all hygiene guidelines.

Due to the wide variety of applications in the food and pharmaceutical sectors, we develop customised and sophisticated pump solutions for your request on a global level. We promise you Proven Excellence - outstanding performance in all areas. Whether in the beverage industry, in the production of foodstuffs, for pumping cosmetics or pharmaceutical products, in dairy operations or for conveying oils and fats, the satisfaction of our customers is always our top priority.

Oil & Gas Mid-/Downstream

-

NETZSCH Pump Solutions in the Oil and Gas Mid- / Downstream Sectors

We find and develop the perfect positive displacement pump for your individual application

Innovative pump solutions in the oil and gas midstream/downstream sectors: As the global market leader in the field of positive displacement pumps, NETZSCH offers you pumps and systems optimally tailored to you and your application. The satisfaction of our customers is always our top priority.

The variety of general applications in the oil and gas mid/downstream sector ranges from crude oil unloading at a rail terminal to production on offshore platforms and tank emptying to use on ships. We at NETZSCH will work with you to find or develop a customised solution for your application. We promise you Proven Excellence - outstanding performance in all areas.

Oil & Gas - Upstream

-

NETZSCH Pump Solutions in the Oil and Gas Upstream Sector

We find and develop the perfect positive displacement pump for your individual application

Special challenges require innovative and customised solutions. As the world's leading supplier of positive displacement pumps, NETZSCH offers you pumps and systems individually adapted to your requirements in the oil and gas upstream sector on a global level.

Together with you, we find and develop the optimal pump solution for your application. The satisfaction of our customers is always our top priority at NETZSCH. Whether you are a large oilfield operator or a small production company, we dedicate ourselves to your projects with the highest passion. We promise you Proven Excellence - outstanding performance in all areas. To meet the increasing technological requirements, we are continuously researching innovative solutions together with universities and operators of our pumps.

Mining

- NETZSCH Pump Solutions in the Mining Sector

We find and develop the perfect positive displacement pump for your individual application

As the world's leading supplier of positive displacement pumps, NETZSCH offers you customised pump solutions in the field of mining. Our pumps and systems guarantee the pumping of explosive media in compliance with the highest safety standards.

On a global basis, we work together with you to develop pump solutions in the mining sector that are optimised for you and your application. Whether wastewater, mineral slurries, thickened slurries, kaolin suspensions, filtrates, tailings or explosives, NETZSCH always guarantees you the right solution for your process. We promise you Proven Excellence - outstanding performance in all areas.

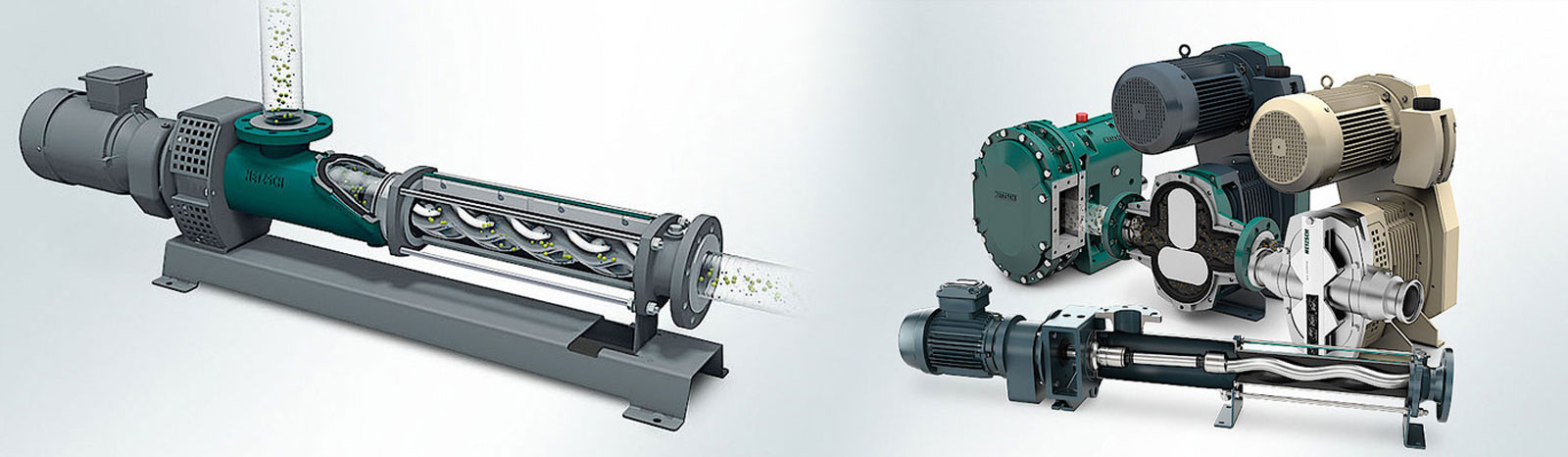

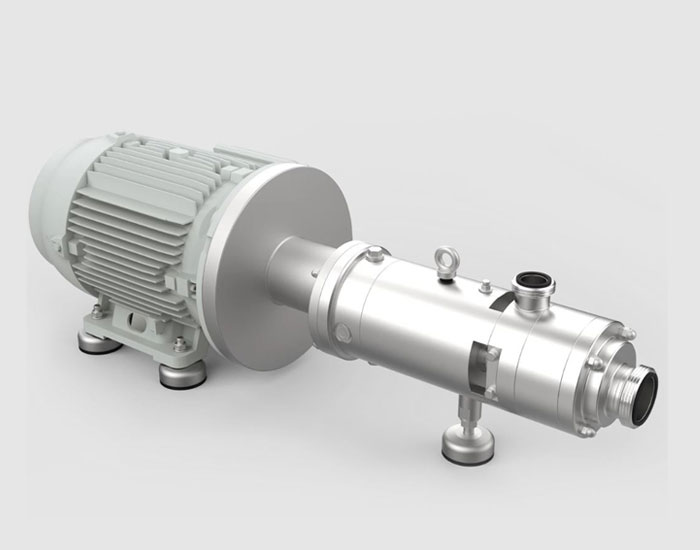

NEMO® Progressing Cavity Pumps

- NEMO®

Progressing Cavity Pumps

NETZSCH pumps cover the most diverse applications in all branches of industry

Versatile, innovative, high-performance: NEMO® progressing cavity pumps cover a wide range of applications in all branches of industry. Progressing cavity pumps offer you continuous, pressure-stable, gentle and low-pulsation pumping of a wide variety of media.

We design each pump precisely to the requirements of your application. As a result, the pumps offer you optimum performance, service life and reliability. Your satisfaction is our top priority. NEMO® progressing cavity pumps are available with different delivery elements so that the optimum selection can always be made for your application. We promise you Proven Excellence - outstanding performance in all areas.

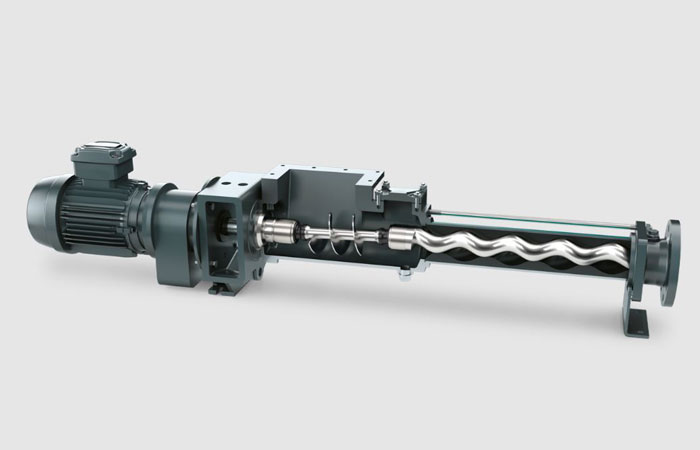

The technology of the progressing cavity pump

Progressing cavity pumps belong to the group of positive displacement pumps. The main components are a rotating rotor and a stationary stator. The rotor, hinged or elastically attached on one side, is a round-threaded screw. On the output side, the axial position oscillates. The hollow stator is elastic and has the same pitch length as the rotor. This leaves conveying spaces between the stator and the rotor, which move continuously from the inlet to the outlet side. The size of the delivery spaces and the associated delivery rate depends on the size of the construction. Except for the rotor and stator, all other components are identical.

This means that if the flow rate or pressure of already installed NEMO® progressing cavity pumps is subsequently changed, they can be adapted to the new operating conditions by simply replacing the rotor and stator. Since the shape of the cavities is always constant, the pumped medium is not compressed. This allows you to pump not only fluids but also solids. Due to the meagre shear forces, you can even pump whole fruits undamaged. Another advantage of the valveless progressing cavity pumps is that they convey continuously and with low pulsation. Even highly viscous and abrasive media can be pumped safely and without problems. They are also suitable as submersible pumps in wells and with open end connections for emptying barrels.

NEMO® Progressing Cavity Pump in FSIP® Design

-

Full Service in Place: Where maintenance and service friendliness matter

Save up to 66 percent of servicing time, the NEMO® progressing cavity pumps in FSIP® design make it possible. They are available in three variants and can generally be used in all industrial areas where very different media have to be conveyed with low pulsation, as well as unaffected by fluctuations in pressure and viscosity, or dosing tasks.

Advantages

- Rotor

Can be changed easily without initial torque - FSIP®

Design

Fully compatible to the BY series and is designed to upgrade already installed pumps - Standards

Pump connections in accordance with national and international standards, as well as in specially designed models

Further Advantages

- Wearing parts can easily be replaced

- Up- or sideward removal of the rotor-stator unit reduces installation space both with conventional stator and with eco-friendly iFD-Stator®

- Various rotor/stator geometries and a large spectrum of materials

- Robust and compact block construction

- The right joint for any application available

- Easy maintenance

- Standard mechanical seal, other seals optional

- Rotor

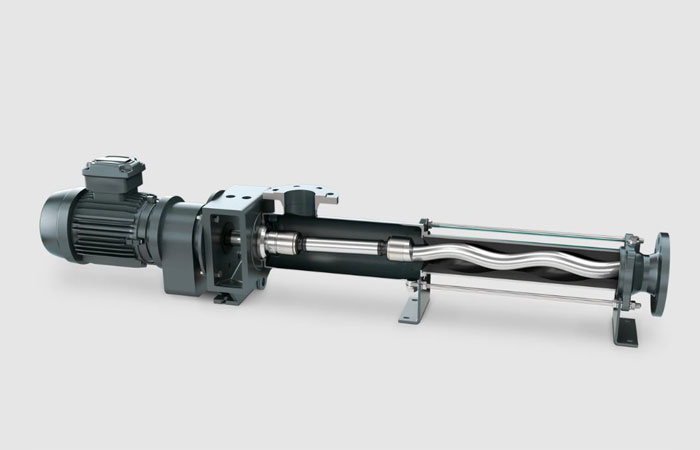

NEMO® BY Progressing Cavity Pump in Industrial Design

-

The solution to convey and accurately dose a wide range of media in various industries

From low-viscosity media to hardly flowing products, with or without solid content, shear-sensitive, sticky or abrasive, with the NEMO® BY progressing cavity pump even difficult substances can be conveyed gently and with low pulsation, regardless of fluctuations in pressure and viscosity.Advantages

- Construction

Robust and compact block construction - Service

Easy serviceability - Standards

Pump connections in accordance with national and international standards, as well as in specially designed models

Further Advantages

- Gentle product conveyance

- Variable modular system

- Various rotor/stator geometries and a large spectrum of materials

- The right joint for any application

- Standard mechanical seal, other seals optional

- Construction

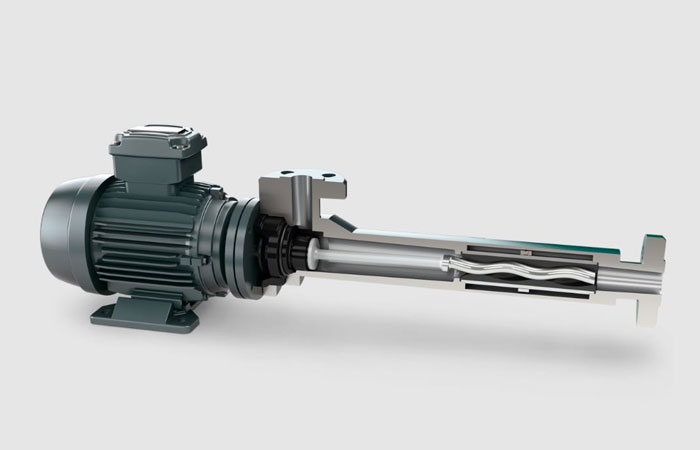

NEMO® SY with Bearing Housing and Free Shaft End

-

Used worldwide for demanding applications in every branch of industry

NEMO® SY progressing cavity pumps are used in demanding applications for continuous, pressure-stable, gentle and low-pulsation conveyance as well as dosing in proportion to speed in nearly every branch of industry worldwide. The progressing cavity pump convinces through an extremely broad spectrum of applications.

Advantages

- Service

Easy serviceability - Pressure

Delivery pressure up to 72 bar - Standards

Pump connections in accordance with national and international standards, as well as in specially designed models

Further Advantages

- Variable, modular construction system

- Various rotor/stator geometries and a wide range of materials

- The right joint for any application available

- Gentle product conveyance

- Mechanical seal as standard, other seals optional

- Service

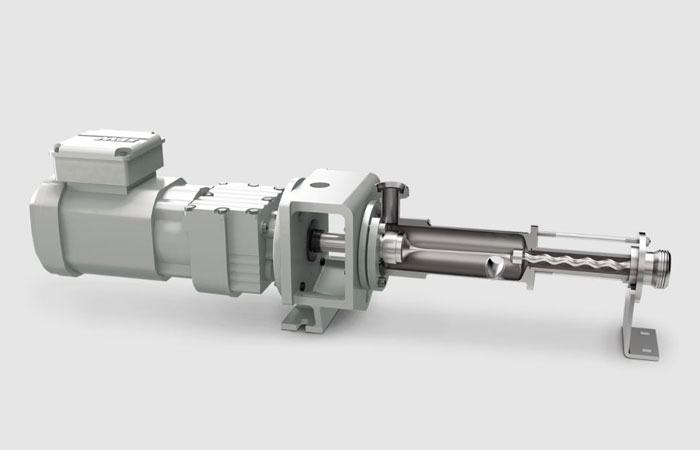

NEMO® C.Pro Dosing Pump Made of Synthetic Materials

-

The solution for dosing and conveying of different kinds and types of chemicals

The NEMO® C.Pro dosing pump is a fully synthetic pump for precise dosing as well as gentle and low-pulsation conveying of a wide variety of chemicals in the fields of environmental technology and the chemical industry.

Advantages

- Rotation

Reversible direction of rotation and dosing - Service

Easy serviceability - Universally applicable

for many media - even acids and bases - Clean

All product-contacting surfaces are polished to prevent built- up of the medium and facilitate cleaning.

Further Advantages

- Constant and nearly pulsation-free dosing

- Dosing in proportion to rotation speed

- Large dosing range

- Gentle product conveyance

- Rotation

NEMO® BH Hygienic Pump in Compact Block Design

-

Solution for applications in the food, pharmaceutical, cosmetic and chemical industry

The NEMO® BH hygienic pump in compact block design is used for hygienic applications in the food, pharmaceutical, cosmetic and chemical/biochemical industries because of its optimal process characteristics.

Advantages

- Heating

Optional heating of pump housing and stator - Design

Flow-favourable, crevice-free housing design prevents settling of the product - Vacuum

Product acceptance under vacuum conditions up to almost absolute vacuum

Further Advantages

- All wetted surfaces are polished to prevent build-up of the medium and facilitate cleaning (CIP and SIP capability)

- Horizontal and vertical mounting possible

- Service friendliness

- Gentle product conveying

- Heating

NEMO® Mini BH Hygienic Pump

-

The optimal pump for the highest dosing precision in hygienic applications

The NEMO® Mini BH hygienic pump ensures continuous and low-pulsation conveying and is used for hygienic applications and optimum cleaning, especially in the food, pharmaceutical, cosmetics, chemical and biochemical industries.

Advantages

- Heat

The pump housing and stator can be optionally heated - Pressure

Foodstuff-suitable shaft seals with compression-proof bolted seal casing enable reversal of the direction of rotation and thereby also of the direction of conveyance, up to the maximum pump pressure - Clean

Product acceptance under vacuum conditions up to almost absolute vacuum

Further Advantages

- Streamlined, crevice-free housing model prevents sedimentation of the product

- Gentle product conveyance

- Long production cycles with contamination-proof, sterile pump construction

- CIP and SIP capability

- Product admission under vacuum conditions up to almost an absolute vacuum

- Open, patented hygienic joints for smearing media

- Horizontal and vertical installation

- Easy serviceability

- Heat

NEMO® SH Plus Hygienic Pump With Bearing Housing

-

For hygienic applications and optimal cleaning with maintenance-free flexible rod

The NEMO® SH Plus Hygienic Pump is employed for hygienic applications in the foodstuff, pharmaceutical, cosmetic and chemical/biochemical industries in order to provide continuous, pressure-stable, gentle and low-pulsation conveyance with optimal cleaning and dosing in proportion to speed.

Advantages

- Heat

Optional heating of pump housing and stator - Pressure

Direction of rotation and thus reversal of the conveyance direction up to the maximum pump pressure - Cleaning

All product-contacting surfaces are polished to prevent build-up of the medium and facilitate cleaning

Further Advantages

- Streamlined, crevice-free housing model prevents sedimentation of the product

- Flexible rod design for uncompromising hygiene and long service life

- Long production cycles with contamination-proof, sterile pump construction

- Product admission under vacuum conditions up to almost an absolute vacuum

- Open, patented hygienic joints for smearing media

- Elastomers approved for foodstuffs in accordance with FDA Horizontal and vertical installation

- Easy serviceability

- Horizontal and vertical installation

- Heat

NEMO® SA Aseptic Pump

-

The perfect conveying partner, for hygienic and aseptic applications

The NEMO® SA aseptic pump with bearing housing with a maintenance-free rod is crevice free and used, because of its cleanability (CIP/ SIP process), for aseptic and hygienic applications in food, pharmaceutical, cosmetic and chemical/biochemical industries for continuous, pressure-stable, gentle and low-pulsation conveyance as well as dosing in proportion to speed.Advantages

- Double-layered

All hermetic areas are double-layered and sealed - Pressure

Foodstuff-suitable shaft seals with compression-proof bolted seal casing enable reversal of the direction of rotation and thereby also of the direction of conveyance, up to the maximum pump pressure - Cleaning

All product-contacting surfaces are polished to prevent build-up of the medium and facilitate cleaning

Further Advantages

- Streamlined, crevice-free housing model with reduced diameter prevents sedimentation of the product

- Conveyance under aseptic conditions

- Flexible rod design for uncompromising hygiene and long service life

- Long production cycles with contamination-proof, sterile pump construction

- CIP and SIP capability

- Product admission under vacuum conditions up to almost an absolute vacuum

- Elastomers approved for foodstuffs in accordance with FDA Horizontal and vertical installation

- Easy serviceability

- Double-layered

NEMO® BO/SO Hopper Pump with Cutting Device

-

Combines the cutting and conveying of large particles in many industrial sectors

Conveying and cutting in one process step without expensive additional equipment, this is exactly what the NEMO® BO/SO hopper pump with integrated cutting device makes possible. With the progressing cavity pump, for example in the food industry, large solids such as particles of fruit or vegetables can be easily and quickly chopped and pumped for further processing

Advantages

- Construction

Robust and compact construction - Service

Ease of service - Replace

Replacing additional machinery

Further Advantages- Variable modular system for optimum conveyance and cutting

- Continuous low-pulsation conveyance una ected by fluctuations in pressure and viscosity

- Conveyance volume in proportion to rotation speed with high dosing precision over a broad rotational-speed range

- Construction

NEMO® BO/BS Pump with Hopper in Block Construction

-

Ideal pump for crumbly media in compact design for nearly all branches of industry

The NEMO® BO/BS progressing cavity pump with hopper and coupling rod with feeding screw as well as force-feed chamber for improved product feed into the conveying elements is used for applications in the environmental technology, food and chemical industries. .

Advantages

- Service Easy serviceability

- Geometries Various rotor/stator geometries and a large spectrum of materials

- Standards Pump connections in accordance with national and international standards, as well as in specially designed models

Further Advantages

- Variable modular system

- Robust and compact block construction

- The right joint for any application

- Standard mechanical seal, other seals optional

- Gentle product conveyance

- Pump connections in accordance with national and international standards, as well as in specially designed models

11. NEMO® BF Hopper-Shaped Pump With Feed Screw

-

Solution for highly viscous and crumbly substances that do not tend to bridge-building

The NEMO® BF is used in all branches of industry for continuous, pressure-stable, gentle and low-pulsation conveyance as well as for dosing in proportion to speed, especially of highly viscous, compacted and crumbly media that do not tend to bridge.

Advantages

- Block Design

Robust and compact block design - Service

Easy serviceability - Standards

Pump connections in accordance with national and international standards, as well as in special design

Further Advantages

- Gentle product conveyance

- Variable, modular construction system

- Wide range of materials

- The right joint for every application

- Mechanical seal as standard, other seals optional

- Block Design

NEMO® BF Hopper-Shaped Pump With aBP-Module®

-

The solution for highly viscous and crumbly substances that tend to bridge

For optimum product feed into the conveying elements, the pump housing is designed with an enlarged, rectangular feed hopper and conical force-feed chamber as well as a special coupling rod with patented, positioned conveying screw. The additionally attached aBP-Module® - asynchronous Bridge Preventing - consists of a top shaft with two internal spoke wheels.Advantages

- Block Design

Robust and compact block design - Service

Easy serviceability - Standards

Pump connections in accordance with national and international standards, as well as in special design

Further Advantages

- No bridging

- Ideal adaptation of the differential speed of the spoked wheels to the respective fluid

- Variable, modular construction system

- Wide range of materials

- The right joint for every application

- Mechanical seal as standard, other seals optional

- Block Design

NEMO® B.Max Mixing Pump in Block Design

-

Solution for mixing and conveying in biogas technology and environmental technology

NEMO® B.Max mixing pump: Maximum mixing of substratesThe position-optimized tangential inlet on the hopper housing facilitates maximum mixing of the substrates. The B.Max is particularly suitable for continuous and low-pulsation conveying of fermented renewable raw materials, liquid manure, process water, ground biowaste, food waste, pre-processed slaughterhouse waste, concentrated substrates, thickened substrate and slop.

Advantages

- Gas

Increased gas production - Pressure

High pressure capability - Safety

High operating safety

Further Advantages

- Maximum homogenization of the substrate

- Continuous low-pulsation conveyance independent of pressure and viscosity

- Robust drive seals

- Reinforced screw

- Gas

NEMO® BT Immersible Pumps With Bracket or Flanges

-

The ideal solution for emptying containers, sewage tanks or pits in confined spaces

NEMO® BT immersible pumps with hanging bracket for crane suspension or dome cover flanges are used for the low-pulsation emptying or conveying out of open or closed barrels, tanks, clarifiers, pits and similar containers.

Advantages

- Pressure

Can be operated under high conveying pressures and at high capacities - Service

Easy serviceability - Low Costs

Low life cycle costs

Further Advantages

- Capable of pumping a great variety of substances

- Capacities can be adjusted proportionally

- Four different geometries to meet your application requirements

- Perfect dosing precision

- Pressure

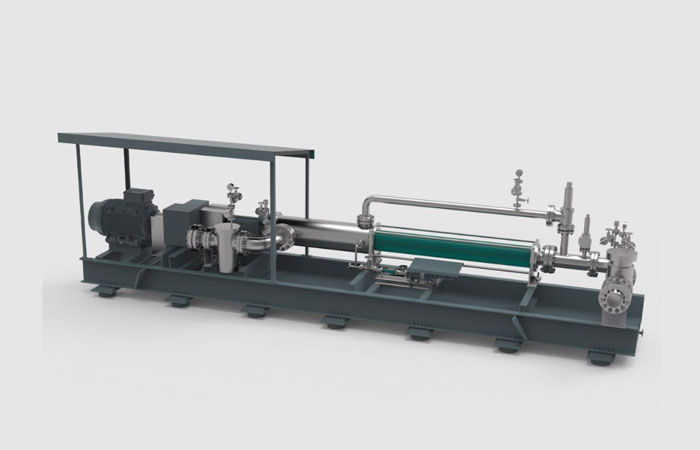

NEMO® Multiphase Progressing Cavity Pump

-

Increased efficiency and conservation of fossil resources in oil and gas production

Maximum profitability and simultaneous conservation of resources: With NEMO® Multiphase progressing cavity pumps, you increase oil and gas production efficiency despite declining oil field quality. In this way, you prevent a premature shutdown of low-pressure wells.Advantages

- Gas

Replaces separation equipment in the oilfield - Pressure

Increased production rates - Safety

Low wear even with abrasive solids

Further Advantages

- Avoiding the shutdown of low-pressure wells Integration of low-pressure wells into high-pressure flow lines

- Few potential leak points in the oil field compared to conventional separation plants

- Few personnel required (uncrewed operation) Low operating costs

- Avoidance of flaring in fields

- Efficient pumping of highly viscous media

- Optimal for conveying media with high sand and gas content

- Efficient transport of oil-water mixtures

- Gas

NEMO® L.Cap Progressing Cavity Pumps

-

Highest performance for the biggest challenges in the oil, gas and mining industry

High flow rates and high pressure in the oil and gas industry: This is what the NEMO® L.Cap progressing cavity pump offers you. It is available in single, twin, and vertical versions and is ideally suited for various applications such as tanks.

Advantages

- Gas and Sand

Optimal for media with a high proportion of sand and gas - Multiphase

Conveying of multiphase fluids possible - NPSHr

Extremely low NPSHr

Further Advantages

- Wide operating range, turndown ratios of 1:10 and more possible

- Minimal influence on performance due to fluctuating product viscosity

- Minimal influence on performance due to varying delivery pressure

- Optimal for conveying abrasive materials

- Optimal for light but also weighty crude oils

- Low shear prevents emulsification of oil/water mixtures

- Low operating and maintenance costs

- High efficiency and reliability

- Gas and Sand

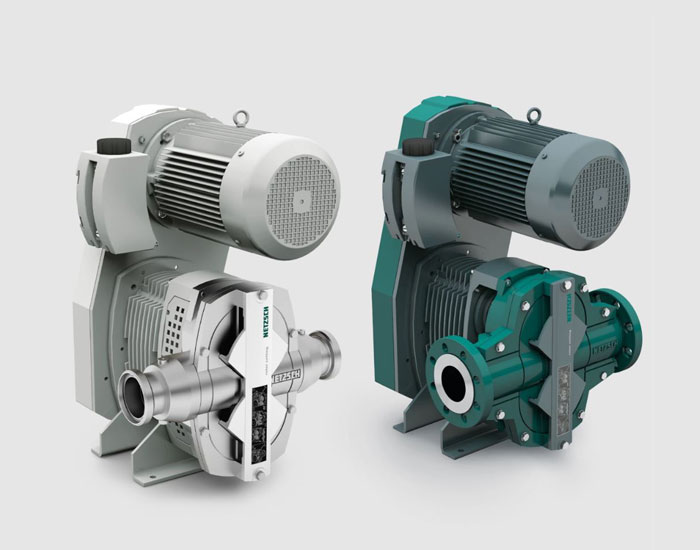

TORNADO® Rotary Lobe Pumps

NETZSCH pumps convince with highest power density, reliability and serviceability

Compact, robust, powerful: The self-priming and valveless TORNADO® rotary lobe pumps are potent and require little space due to their compact design. Rotary lobe pumps offer you continuous and gentle delivery and dosing proportional to rotation speed of almost all media in a wide range of applications.

We design each pump precisely to the requirements of your application. As a result, the rotary lobe pumps offer you the highest power density and reliability. Your satisfaction is our top priority. Since all parts in contact with the medium are accessible without dismantling the piping or drive, TORNADO® rotary lobe pumps are straightforward to service and maintain. We promise you Proven Excellence - outstanding performance in all areas.The technology of the rotary lobe pump

Rotary lobe pumps are self-priming, valveless and rotating positive displacement pumps with two rotary lobes running in a mesh. The rotation of the rotors creates a vacuum on the suction side, which draws in the pumped medium.

The rotors displace the medium into the pressure area. Two to six-room fillings are substituted per rotation, depending on the number of rotor blades. This enables dosing proportional to rotation speed. Due to the unique spatial separation between pump and gear chamber, TORNADO® rotary lobe pumps also offer you maximum operational reliability. With rotary lobe pumps, you can pump both low and high viscosity media. Due to the significant free ball passage and the low speeds, they are insensitive to blockages, clogging and foreign bodies. Varying solids contents have just as little influence on the flow rate as pressure changes. This enables continuous and powerful pumping.

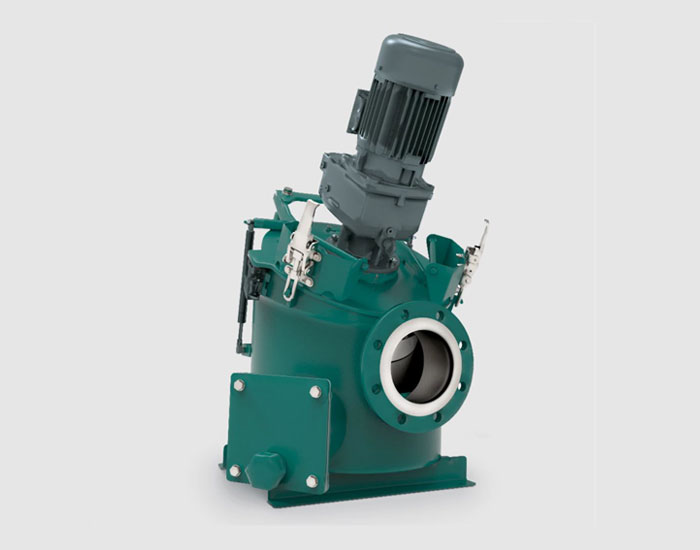

TORNADO® T.Envi® Rotary Lobe Pump

-

FSIP® design enables service-friendly conveyance in environment and biogas technology

Resistant, powerful, easy to service: The compact TORNADO® T.Envi® rotary lobe pumps are optimally adapted to your individual requirements in environmental and biogas technology and impress with easy maintenance thanks to the innovative FSIP® (Full Service in Place) design.Advantages :

- Safety

Maximum operational safety thanks to spatial separation of pump and gearbox compartments - FSIP®

Design

FSIP® design simplifies and reduces service times and costs - Construction

Robust and durable construction due to material reversal

Further Advantages

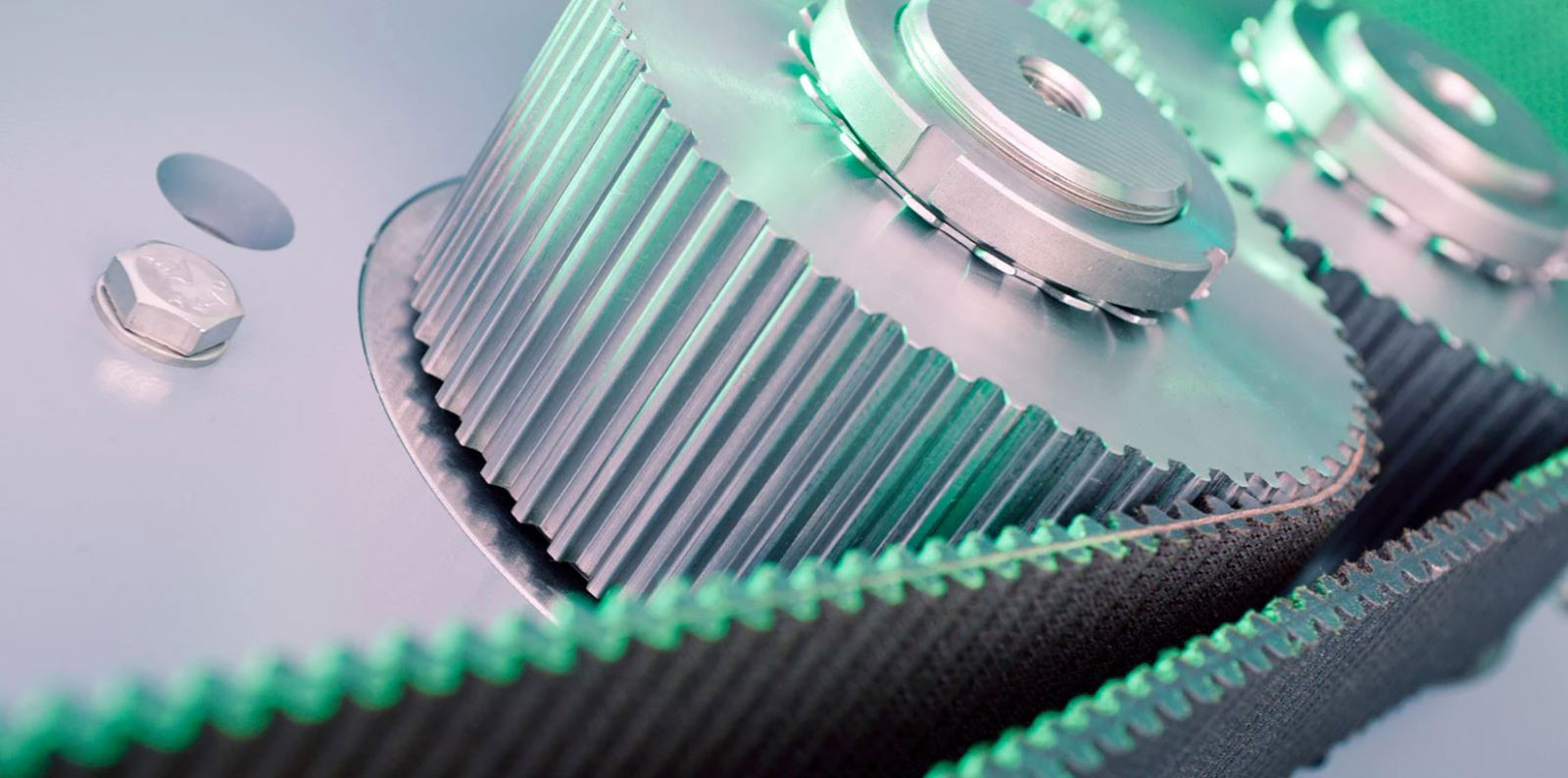

- Oil-free belt drive ensures less vibration and stress on components

- Low-pulsation housing design

- Individual design according to your requirements

- Insensitive to dry running

- Can handle any type of inhomogeneous, gaseous and abrasive media with solids

- Safety

TORNADO® T1 Rotary Lobe Pumps

-

Individual adjustment to the properties of the pumped medium and the place of use

The universally applicable and individually matched TORNADO® T1 rotary lobe pumps convince with the GSS technology (Gearbox Security System), a spatial separation between pump chamber and gear box. The rotary lobe pumps are insensitive to dry running and are used in applications in the fields of environment & energy, chemicals & paper as well as oil & gas mid-/downstream.

Advantages

- Reliability

GSS (Gearbox Security System) technology for long term reliability - Access

Easy access to the shaft seal flushing connections - Maintenance

Maintenance without the need to disconnect the inlet and outlet pipework

Further Advantages- Maximum operational safety, insensitive to dry running

- No penetration of the medium into the synchronous gearbox

- No penetration of the gear oil into the pump chamber

- Short repair times, thanks to few components

- Excellent energy efficiency

- Reliability

The NETZSCH TORNADO® Mobile

-

Rotary lobe pump on wheels for universal use at the most unusual of locations

The TORNADO® Mobile combines the flexibility and independence of a mobile unit with the proven technology of a TORNADO® T1 rotary lobe pump from NETZSCH. Mobility through mounting on a car or truck trailer enables the pumping of large quantities of fluids with high solid content, wastewater and slurry at the most diverse and unusual locations. Depending on the application, the TORNADO® rotary lobe pump is mounted on a trailer with diesel unit in the appropriate size.

Advantages

- Low Cost

Low life cycle costs - Cooling

Lubrication/cooling of the seal through easily accessible flushing/sealing water connections - Speed

High pumping speed up to eight mWS

Further Advantages- Flexible use in the most unusual places through mounting on trailers

- Extended operational reliability, insensitive to dry running

- No ingress of the pumped media into the pump gearbox in the event of a product leaking

- No ingress of pump gearbox oil into the pump chamber

- Maximum operational

- Easy operation due to electronic motor control management

- Low Cost

TORNADO® T.Proc® Rotary Lobe Pump

-

Maximum reliability for your applications in the chemical and industrial industry

Compact, reliable, easy to maintain: The wear-resistant TORNADO® T.Proc® rotary lobe pump is available in both all-metal and metal-elastomer versions. Thanks to the innovative FSIP® (Full Service in Place) design, it is particularly easy to maintain.Advantages:

- Safety

Maximum operational safety thanks to spatial separation of pump and gearbox compartments - FSIP®

Design

FSIP® design simplifies and reduces service times and costs - Oil-free

Oil-free belt drive ensures less vibration and stress on components

Further Advantages

- Low-pulsation housing design

- Insensitive to dry running

- Can handle any kind of inhomogeneous, gaseous and abrasive media with solids and/or fibres

- Dead space free pump chamber in the all-metal design

- All-metal design is CIP- and SIP-capable

- Self-priming

- Safety

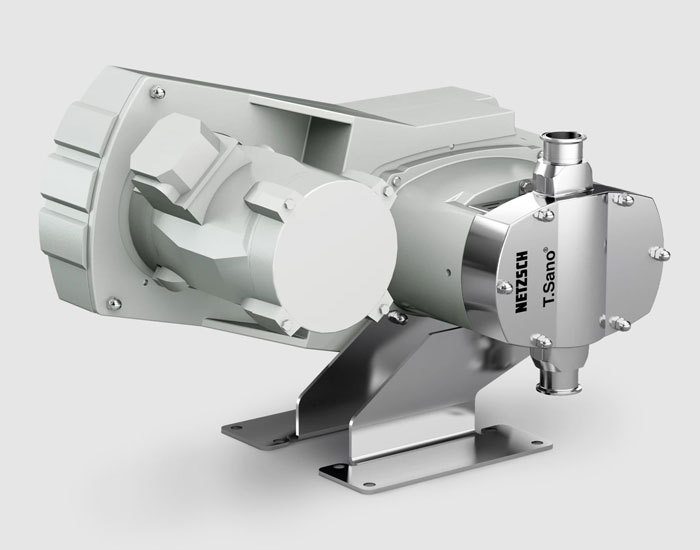

TORNADO® T.Sano® All-Metal Rotary Lobe Pump

-

Dead space free design and FSIP® - full service in place for hygienic applications

The TORNADO® T.Sano® rotary lobe pump in all-metal design is the optimum solution for your applications in the hygiene sector due to its oil and dead space free design. It is also easy to maintain thanks to the FSIP® (Full Service In Place) concept. Primarily, the all-metal pump is used in the chemical, cosmetical, food and pharmaceutical sectors.Advantages

- Oil-free belt drive

Oil-free, synchronising belt drive - low maintenance - Wide temperature range

- Easy maintenance

Thanks to FSIP® design

Further Advantages

- Dead space free pump housing

- All-metal design

- Space-saving, compact design with high power density

- CIP and SIP capable

- Insensitive to dry running

- Resistant to aggressive media

- Gentle conveying of sensitive media

- Self-priming

- Conveying of low-viscosity to highly viscous substances

- Conveying of media with high solids content, thanks to large ball passage

- Oil-free belt drive

TORNADO® T.Sano® Rotary Lobe Pump with Smooth Surface

-

Oil-free pumping of demanding media in the hygienic sector due to innovative design

With the oil-free TORNADO® T.Sano® Smooth in smooth surface, you can pump even the most demanding media in compliance with the strictest hygiene regulations. Its gentle product handling and pulsation-free pumping are particularly suitable for the food and beverage industry.Advantages

- Oil-free belt drive

- Also available in mobile design

- Low pulsation due to housing design

Further Advantages

- Dead space free design, with rotor mounting outside the pump chamber

- Cavity-free design, lobes mounted outside the pump chamber

- CIP capability (Cleaning-In-Place)

- Service- and maintenance-friendly due to FSIP® design

- 3A standard and EHEDG-certified

- Low space requirement due to compact design

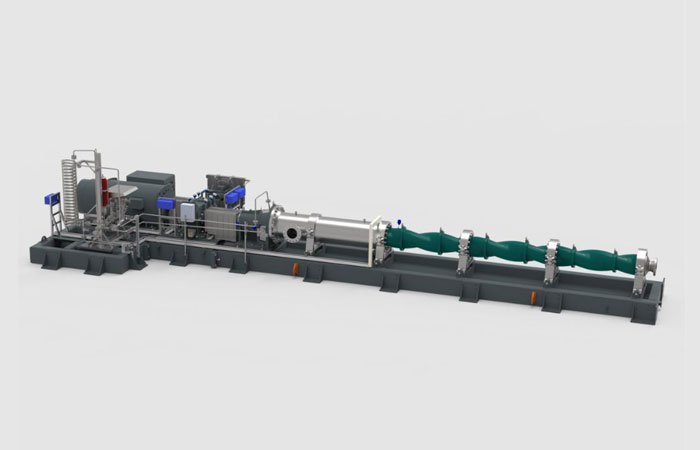

NOTOS Multi Screw Pumps

-

NETZSCH pumps cover many industries with their efficient and unique design

Flexible, efficient, reliable: NOTOS® multi screw pumps serve many industrial sectors and applications. NOTOS® pumps are designed to handle low to highly lubricating liquids with low to high viscosity, as well as shear-sensitive or chemically aggressive media.

The pumps have been optimised using the High-Efficiency Unique Design (HEUD) concept to give you maximum performance. Your satisfaction is always our top priority. That is why we offer you a wide range of materials. Our range of metallic materials extends from grey cast iron and chrome-nickel steel to duplex, super duplex or Hastelloy steel. We promise you Proven Excellence - outstanding performance in all areas.

The technology of the multi screw pump

The multi screw pump is a rotating positive displacement pump in which the shape of the rotors resembles a screw. It consists of two or more counter-rotating rotors and a housing that encloses the rotors.

The rotors are designed with a regular, thread-like profile and mesh with each other like cogwheels. The cavities created by these three construction elements form the conveying spaces. When the rotors rotate, they move out in one machine direction and convey the medium from the suction side to the pressure side. The helical design also reduces noise compared to straight-toothed gear pumps. This significantly reduces your noise level in production. In addition, this type of pump is particularly suitable for incompressible, even viscous media for generating high pressures.

NOTOS® 2NS Two Screw Pumps

Long service life when conveying non-abrasive to slightly abrasive media

The convenience through continuous conveying with low pulsation, which ensures gentle product handling. NOTOS® two screw pumps have one drive screw, transferring torque trough a hydrodynamic film to the rotating intermeshing driven screw. To spindle pumps are particularly suitable for non-abrasive to slightly abrasive, corrosive as well as non-corrosive and low to highly lubricating liquids. They have also proven themselves for low to high flow rates as well as pressures

Multi screw pump meets standards of API

To achieve maximum efficiency, the pump has been optimized using the High Efficiency Unique Design (HEUD) concept. This is characterized by extremely precise tolerances due to state-of-art technology as well as the optimized spindle profile. The wide range of materials, from grey cast iron and chrome nickel steel to duplex, superduplex or Hastelloy steel, ensures optimum pumping conditions in a wide variety of applications. Optionally, the pumps can be upgraded according to the standards of the American Petroleum Institute (API). These special requirements are mainly relevant in the oil & gas and petrochemical industries.

Advantages

- High Efficiency

- Quiet operation

- Excellent suction capability

Further Advantages

- Long service life

- Hydraulically balanced

- Wide range of applications Wide range of materials Optionally according to API 676 (American Petroleum Institute) requirements Low pulsation

NOTOS® 3NS Three Screw Pump

-

Lightweight and universally applicable due to small footprint

Suitable for use in a wide range of industrial sectors and applications, the self-priming NOTOS® 3NS three screw pumps are true lightweights and have a small footprint.

Due to the optimization by means of the High Efficiency Unique Design (HEUD) concept, three screw pumps convince with a high efficiency. In addition, continuous delivery with low pulsation and a flow of the medium with minimal turbulence is ensured. This results in gentle product handling. It is assured by means of state-of-the-art technology, precise tolerances and an optimized screw profile. In addition to a drive screw that transmits torque via a thin hydrodynamic film, 3NS three screw pumps have two rotating, intermeshing driven screws.Advantages

- High Efficiency

- Extremely low noise and vibration

- Small footprint

Further Advantages

- Easy maintenance

- Low life cycle costs

- Wide range of applications

- Wide range of materials

- Optionally according to API 676 (American Petroleum Institute) requirements

NOTOS® 4NS Geared Twin Screw Pump

Continuous conveying without metal-to-metal contact of the spindles

Self-priming NOTOS® 4NS geared twin screw pumps convince by high flow with minimal turbulence without metal-to-metal contact of the screws.Advantages

- High Efficiency

- No metal to metal contact

- Small footprint

Furher Advantages

- Long service life

- excellent suction capability

- wide range of applications

- Wide range of materials

- Optionally according to API 676 (American Petroleum Institute) requirements

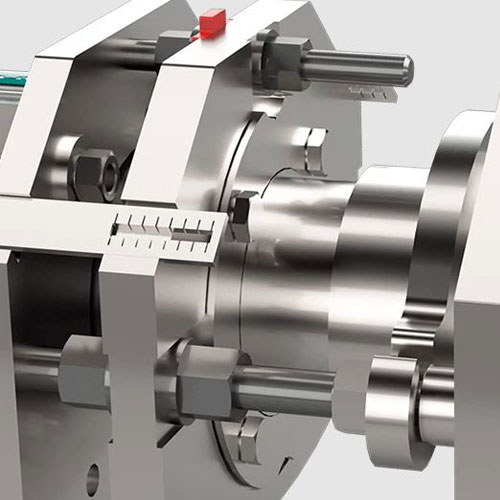

NOTOS® 2NSH Hygienic Twin Screw Pump in FSIP® Design

Full service in place and maximum performance for hygienic applications

The NOTOS® 2NSH hygienic twin screw pump in FSIP® (Full Service in Place) design impresses with gentle pumping, low pulsation, simple maintenance and ease of operation in the process.Advantages

- Seals with food-grade certification

- High suction capacity

- Reversible pump direction

Further Advantages

- Metal parts made of stainless steel

- No contact between rotating parts

- No dead spaces

- FSIP® (Full Service in Place), easy maintenance: simple assembly / disassembly

- Low pulsation

- Can be used as a feed pump and CIP pump in one process

- Smooth feeding of the pumped media

- Flexibility: The same equipment can be used for pumping fluids with low or high temperature / viscosity

NOTOS® 2NSH Hygienic Twin Screw Pump

Small installation space due to compact construction with optional heating jacket

The NOTOS® 2NSH hygienic twin screw pump in the conventional, round pump housing offers different options and advantages. In addition to an optional heating or cooling jacket, the screw pump convinces a compact and robust design.Advantages

- Optional heating or cooling jacket

- Reversible flow

- No contact between rotating parts

Further Advantages

- Compact and robust design

- No dead spaces

- Seals with food-grade certification

- Conveying of a wide variety of media possible

- Low pulsation

- High suction capability

- Large capacity and pressure range

- Smooth feeding of the medium to the conveying elements

PERIPRO® Peristaltic Pumps

Peristaltic pumps from NETZSCH are particularly robust and easy to maintain

Robust, reliable, strong: PERIPRO® peristaltic pumps are particularly suitable in a wide range of applications for aggressive and abrasive media with a solids content of up to 70 percent. The group of peristaltic pumps includes, among others, the hose pumps, these offer you an extremely high suction capacity with minimal maintenance at the same time.

Together we will find the pump optimally suited to you and your application, whether it’s industrial, chemical or food. Your satisfaction is our top priority. The corrosion-resistant and hygienic hose pumps also guarantee you the highest dosing accuracy. We promise you Proven Excellence - outstanding performance in all areas.The technology of the peristaltic pump

Peristaltic pumps and all other pumps from NETZSCH belong to the group of rotating positive displacement pumps. They only have one wearing part, the hose. Therefore you have minimal maintenance effort.

The medium to be conveyed is forced through the hose by external mechanical deformation of the hose. The hose is supported by the housing of the pump head and is clamped by rollers. The rollers rotate on a rotor. The rotation causes the pinch-off point to move along the hose, thus propelling the pumped medium. The elasticity of the hose material generates the suction vacuum. Due to their design, peristaltic pumps are insensitive to dry running.

PERIPRO® Hose Pump Industrial Version

Robust and powerful design for conveying abrasive and aggressive media

Highly durable and maximum serviceability at the same time: The robust design of the PERIPRO® hose pump in the industrial version from NETZSCH enables you to convey abrasive and aggressive media in a wide variety of applications in a maintenance-friendly way.Advantages

- Applications

Flexible use in a wide range of applications - Few wearing parts

No valves or mechanical seals - Robust construction

Heavy-duty design with XXL-rollers

Further Advantages

- Long service life of the hose thanks to large rollers

- Insensitive to dry running

- Easy conveying of large solids and fibres (up to 70%)

- Easy to service thanks to low lubricant consumption

- Extremely high suction capacity

- Gentle and reversible conveying possible

- High dosing accuracy

- Corrosion resistant

- Applications

PERIPRO® Hose Pump Food Version

Contamination-free conveying of food and particularly easy cleaning

Easy cleaning processes with maximum efficiency at the same time: With its innovative design, the PERIPRO® hose pump in food version enables you contamination-free conveying in the food industry as well as effortless cleaning.

Advantages

- Easy to clean

Thanks to CIP capability - Easy maintenance

and handling for continuous operation - High dosing accuracy

Deviation less than one percent

Further Advantages

- FDA certified

- Sanitary connections according to DIN 11851 or Tri-Clamp

- Extremely high suction capacity

- Gentle and reversible pumping possible

- Long hose life thanks to large rollers

- No mechanical seals or valves (few wearing parts)

- High temperature resistance of the hose

- Easy to clean

PERIPRO® Hose Pump Chemical Version

Highest reliability as well as safety in conveying and dosing corrosive media

Especially in the chemical industry, process reliability plays a central role. The PERIPRO® hose pump in chemical design offers you the highest reliability even in conveying corrosive media with maximum dosing accuracy at the same time.

Advantages

- Easy maintenance

and handling for continuous operation - No mechanical seals

or valves (few wearing parts) - Capacity

Extremely high suction capacity

Further Advantages

- Sensor for hose leakage

- Corrosion-resistant rollers, hoses and connections

- High metering accuracy (deviation less than one percent)

- High serviceability thanks to low lubricant consumption

- Gentle and reversible pumping possible

- Long service life of the hose thanks to large rollers

- Very low lubricant consumption

- Easy maintenance

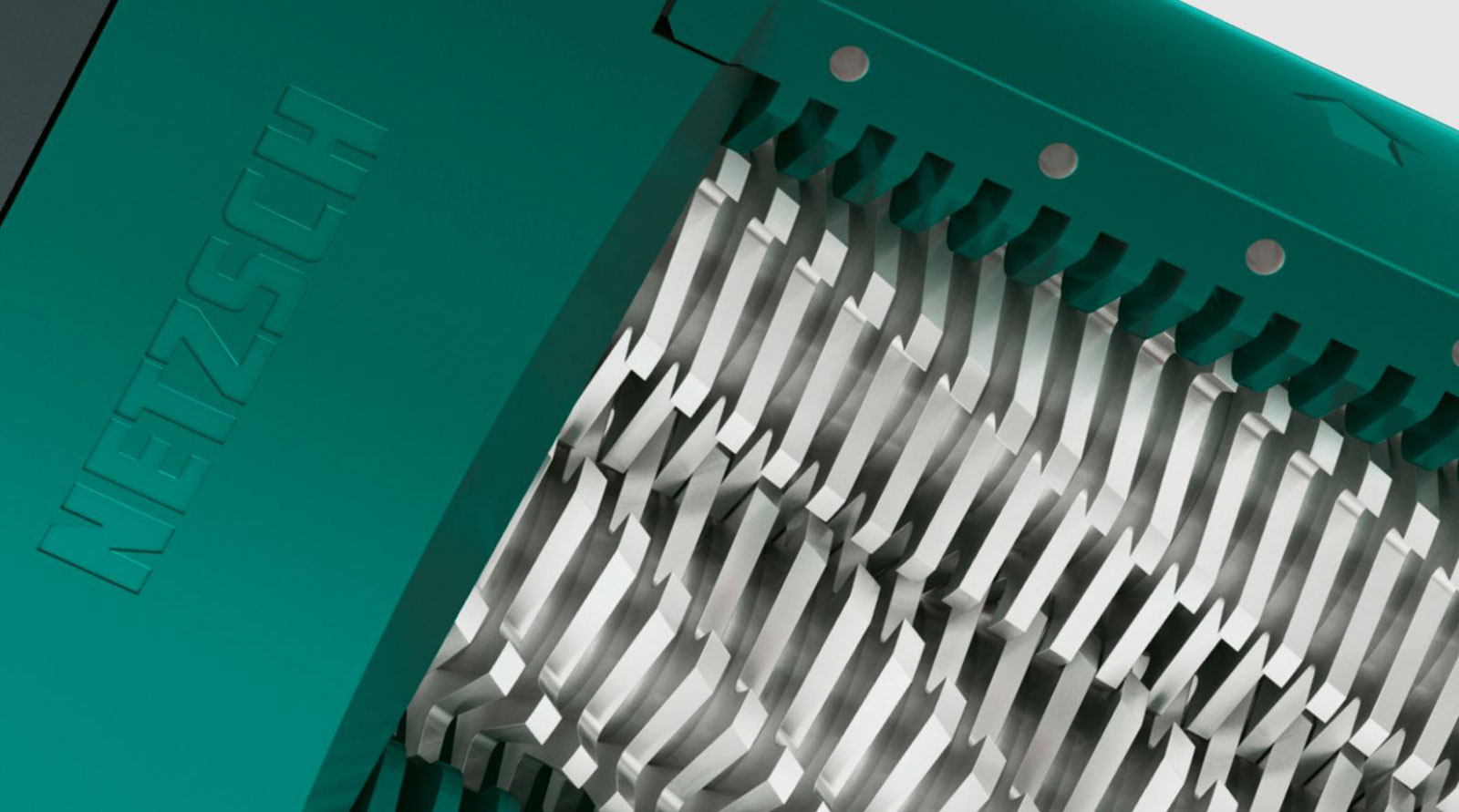

Grinders and Macerators

NETZSCH offers you suitable solutions for the prevention of blockages and clogging

Robust, versatile, powerful: To protect your systems and the pump units they contain, we offer you high-performance grinding systems. These ensure that impurities are shredded ready for pumping. In this way, you can prevent the risk of blockages and clog in your pump systems.

Grinding systems can be used wherever necessary to reliably break down impurities such as textiles, plastics, or similar liquids to prevent damage to pumps or other systems. The large selection of different grinding systems enables an optimal and economical reduction of solids in a wide range of applications. Together with you, we will find the right system for your application. We promise you Proven Excellence - outstanding performance in all areas.The technology of the grinders

Grinders can be divided into two categories based on the different technologies. On the one hand, there is the technology of the M-Ovas® universal cutting plate macerator and, on the other hand, the N.Mac® twin shaft grinder. In the cutting plate macerator, the shreddable parts are pressed against the perforated plate by the flow or are partly drawn into the holes. More significant amounts accumulate in front of the perforated plate and are ground by the cutter head until they are flushed through the openings. This effectively protects connected units from blockages. By replacing the perforated plate, you can change the hole size and thus the degree of shredding. The twin shaft grinder technology is suitable for particularly coarse and solid contaminants. Here, the two knife blocks grind washed-up solids such as textiles or plastic waste in liquid media. Thanks to numerous different blade combinations, you can quickly determine the degree of shredding yourself. This prevents possible clogging in the pump chamber.

M-Ovas® Universal Cutting Plate Macerator

-

Reliable grinding of impurities to protect pump systems and equipment

Grinding systems protect your system. With the universally applicable M-Ovas® cutting place macerator, you can prevent possible damage to your pump caused by impurities. The individually adjustable cutting place prevents the entry of substantial solids into the following systems such as pumps. It is ideal for use in biogas or wastewater plants.

Advantages- Integrated clean-out port

With separate cleaning and drain opening - Cutting plate can be used on both sides

- Particularly maintenance friendly

No removal from the pipeline necessary

Further Advantages- Protects the system from large solids and possible consequential damage

- High cutting efficiency avoids clogging by materials such as fabric remnants or long fibres

- Compact design with high throughput

- Easy and quick removal of the cutting plate, saves time and costs

- Low energy consumption at high throughput rates

- Shaft sealed by mechanical seal with grease lubrication Different perforated plated depending on the application

- Different perforated plated depending on the application

- Integrated clean-out port

N.Mac® Channel Twin Shaft Grinder

-

Full service in place for grinding a wide range of demanding solids in sewers

The N.Mac® channel twin shaft grinder crushes fragmenting large and solid particles in liquid media and impresses with its innovative FSIP® concept (Full Service in Place). It is ideal for a wide range of applications, from wastewater treatment to food and fruit residues.Advantages

- Easy on-site maintenance

Thanks to innovative FSIP® design - Anti-vibration system

Exclusive elastomer to seal the lower bearings and absorb vibrations generated during shredding - Protects the system from damage caused by contaminants

Further Advantages

- Bearing and mechanical seal cartridges to protect the bearings

- Optional cleaning brush fro fibrous materials removes material in the gap between the blades

- Cutting devices in the cartridge system

- Modular design of the cutter blocks allows individual combinations

- Optional extended shaft for channel designs that allows the motor to be installed above the medium

- Retractable suspension lugs to facilitate disassembly

- Easy on-site maintenance

N.Mac® Inline Twin Shaft Grinder

-

Full service in place for grinding impurities in pipeline installations

Protect your system from impurities: The N.Mac® inline twin shaft grinder crushes fragmenting large and solid particles in liquid media and impresses with its FSIP® concept (Full Service in Place). It is ideal for various applications, from wastewater treatment and substrates to food and fruit residues for biogas plants.

Advantages- Easy on-site maintenance

Thanks to innovative FSIP® design - Anti-vibration system

Exclusive elastomer to seal the lower bearings and absorb vibrations generated during shredding - Protects the system from damage caused by contaminants

Further Advantages- Bearing and mechanical seal cartridges to protect the bearings

- Optional cleaning brush fro fibrous materials removes material in the gap between the blades

- Cutting devices in the cartridge system

- Modular design of the cutter blocks allows individual combinations

- Retractable suspension lugs to facilitate disassembly

- Easy on-site maintenance

Dosing and Emptying

-

Emptying, conveying or dosing - NETZSCH has the optimal solution for your application

Precise, product-friendly, flexible: NEMO® dispensers guarantee you the highest dosing accuracy and reproducibility. So nothing stands in the way of clear and repetitive dosing. The barrel emptying systems automatically suck themselves towards the bottom of the barrel and empty barrels and containers almost entirely in a wide range of applications.

Together with you, we will find the suitable barrel emptying system and the dosing system optimally matched to your application. The barrel emptying systems are available with a NEMO® progressing cavity pump and a NOTOS® multi screw pump. This means that nothing stands in the way of flexible and gentle conveying. We promise you Proven Excellence - outstanding performance in all areas.Dispenser and barrel emptying technology

The heart of the barrel emptying and dispensing systems is formed by the proven technologies of the NEMO® progressing cavity pumps and NOTOS® multi screw pumps. In both cases, these are rotating positive displacement pumps.

The cavities created by these three design elements within the pumps form the delivery spaces and remain constant. This means that the pumped medium is not compressed. Therefore, continuous and low-pulsation delivery, as well as dosing, is possible. The dosing accuracy can be flexibly adjusted in proportion to the speed. The innovative design of the container discharges also enables you to empty with a residual quantity of less than one per cent. This significantly reduces waste and saves you money at the same time. When the pump is switched on, a vacuum forms under the follower plate. At the same time, this exerts a slight pre-pressure on the medium to ensure constant suction into the pump. Thanks to the continuous delivery, you protect your system from shock loads and reduce wear.

NEMO® Dispensers and Handdispensers

-

Highest reproducibility and dosing accuracy in a wide range of applications

Precision, versatility and gentle conveying: NEMO® dispensers guarantee you the highest dispensing accuracy and reproducibility. Because of these properties, they are used in various applications in the cosmetics industry, in the chemical industry, in the area of consumer or industrial goods, in the electrical appliance industry and the size of electronic components.Advantages

- No dripping or stringing even with low-viscosity media

Due to universally adjustable retraction of the nozzle - Compact design

For easy installation in robotic applications - Low-pulsation conveying enables highest dosing accuracy

Features of NEMO® Dispensers and Hand Dispensers

- very gentle conveyance

- compact dimensions at a high number of stages

- large cross sections of inlet

- conveyance also of compacted products

- conveyance of solids

Further Advantages

- Gentle conveying of products containing solids

- Temperature and and viscosity-independent conveying of a wide variety of products

- No dripping or stringing even with low-viscosity media

Barrel Emptying System With NEMO® BY Pump

-

Independent and almost residue-free emptying of barrels and containers

NEMO® barrel emptying systems are versatile and suction themselves towards the bottom of the barrel. With NETZSCH emptying systems, you can empty your barrels and containers in the chemical, pharmaceutical and food industries almost wholly.

Advantages

- Stainless steel, easy-to-clean design

- Low life-cycle costs combined with high serviceability

- Delivery rates proportional to speed

Further Advantages- Constant, low-pulsation delivery prevents pressure reversal points or pressure drop in the line or system

- Gentle conveying of demanding media

- Residual quantity in the container after emptying less than one percent of the total quantity

Barrel Emptying System With NOTOS® 2NSH Pump

Hygienic barrel emptying with absolute minimum of product waste

NETZSCH barrel emptying units pump their way through your products, reaching the bottom of the barrel or container in the food, chemical, and pharmaceutical industry with the absolute minimum waste of product – resulting in less than one percent residual product in the barrel.Advantages

- Variable speed for easy adjustment

- Smooth and steady pumping

- Infinitely adjustable application rate

Further Advantages

- No pressure or flow interruption

- Emptying of conical barrels

- Low-pressure conditions in the entire system

- Possible to dose directly from the barrel

- Flow in direct proportion to pump speed

- Equipped with VSD for easy adjustment

- Simple, single-rail design

- Low pulsation

- Low shear rate

- Suitable for products containing solids in suspension

- Flow rate independent of temperature or viscosity

- Almost complete discharge, residual products less than one percent

Barrel Emptying System With NEMO® BH Pump

-

Independent hygienic container emptying with a minimum of residual content

NEMO® Dispensers guarantee the highest level of precision in dosing and reproducibility. For this reason, NEMO® Dispensers and NEMO® Hand Dispensers are employed in a great variety of applications and industries.Advantages

- Stainless steel, easy-to-clean design

- Delivery rates proportional to speed

- Low life cycle costs combined with high serviceability

Further Advantages

- Hygienic design of the components and machines, as well as cleanability of the system parts

- Constant, low-pulsation delivery prevents pressure reversal points or pressure drop in the line or system

- Gentle conveying of challenging media

- Residual quantity in the container after emptying less than one percent of the total quantity

Accessories and Auxiliary Equipment for Pumps and Systems

Increased operational safety for your pump systems to reduce downtime

With our large portfolio of accessories and auxiliary equipment, we provide increased operational reliability for your pump or system. This allows you to significantly reduce your everyday downtime and improve performance at the same time.

In addition to innovative process monitoring via app, our accessories include protection and travel devices, seal supply units or tools and additional equipment. We have the optimal supplement for your individual application. These are available to you in all production areas such as environment & energy, food & pharmaceuticals, chemicals & paper or oil & gas.

MultiProtector: The Monitoring and Protection Unit

Pump protection module for positive displacement pumps enables damage prevention

The MultiProtector monitoring and protection unit offers you monitoring and analysis of pump data and warns you at an early stage of emerging damage to positive displacement pumps. The unit and the associated app enable the definition of threshold values, documentation of the fault history and live diagnostics.

Advantages- Simple analysis of diagnostic data

- Optimum condition monitoring via smartphone, tablet or PC

- Simple commissioning through setup via app

Further Advantages- Adjust and evaluate several sensors with one device

- Simple installation, as only one device is required for all sensors Increased operational safety through advance warning and shutdown in the event of a fault

- Prolongation of service life through information on preventive maintenance

- Simple parameterisation, diagnosis and reporting in the MultiProtector app

iFD-Stator® 2.0 for NEMO® Progressing Cavity Pumps

Save costs in an environmentally friendly way and achieve higher performance

The further development of the proven iFD-Stator® : If performance, economy and environmental compatibility are essential to you, the iFD-Stator® 2.0 is the perfect choice for your NEMO® progressing cavity pump. With its further development, NETZSCH has succeeded in realising all of these points in a unique system.

The iFD-Stator 2.0 is compatible with all NEMO® progressing cavity pumps of the NM series and can be easily replaced due to its design. iFD stands for:- Integration of performance and environmental protection

- Flexibility of the sealing line due to the mobility between the components

- Dual system of stator and stator housing

Advantages- Higher efficiency during operation

- Environmentally friendly product

Due to pure production, as a prerequisite for high-quality recycling - Certified according to ATEX

Further Advantages- Compatible with all NEMO® pumps of the NM series

- Significantly simplified stator replacement due to easy-to-open stator housing

- Stator change without preloading

- Long service life, low life cycle costs, low energy costs due to significantly easier start-up

- High operational safety due to robust design and certified elastomer qualities

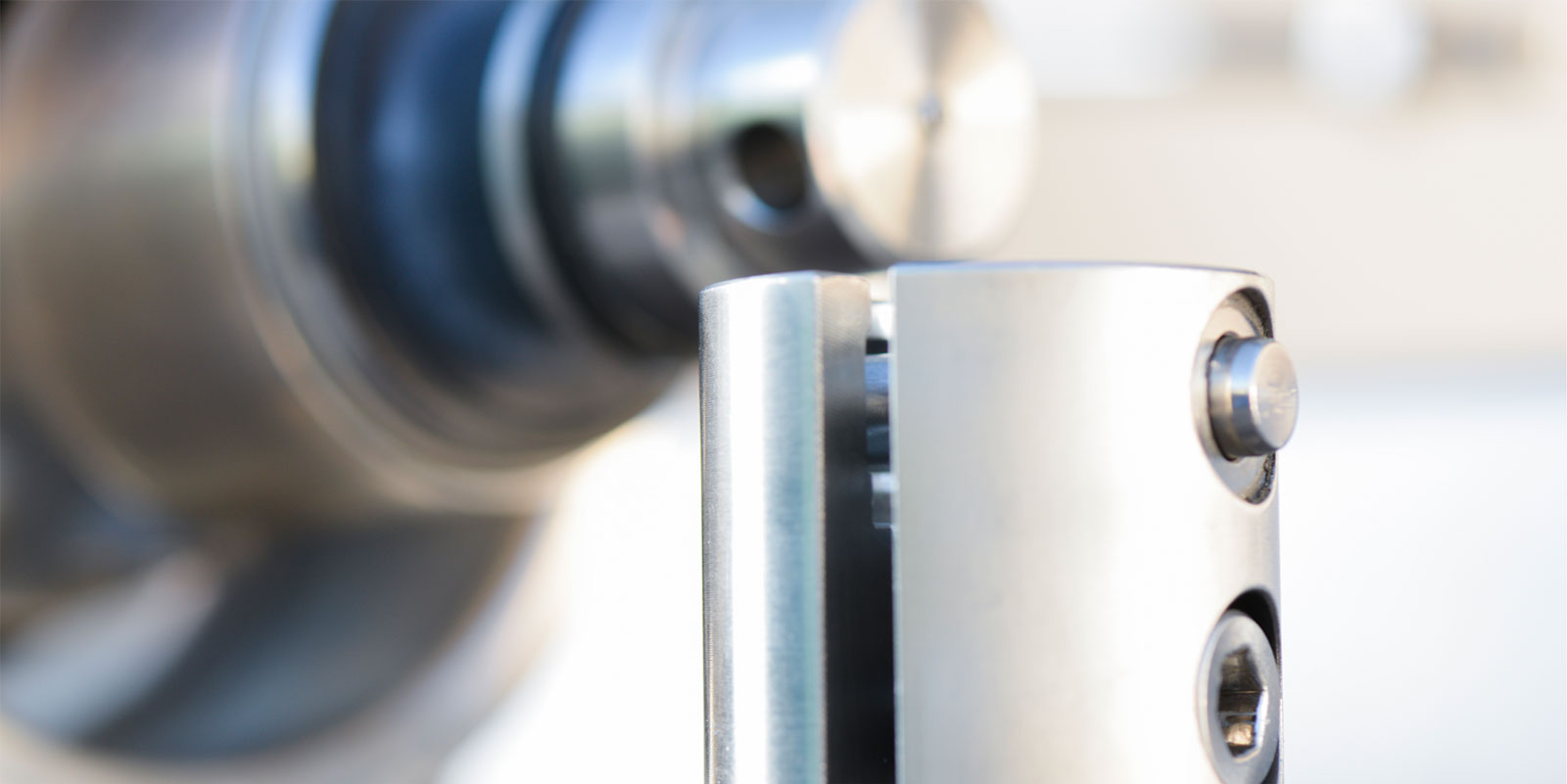

xLC® Stator Adjustment System

Service life extension of NEMO® progressing cavity pumps by more than three times

Optimum performance and significantly extended service life for your progressing cavity pump: With the xLC® stator adjustment system, you can increase the service life of your pump by more than three times, especially in wear-intensive applications. The stator adjustment system is used to readjust the easy-to-replace, maintenance- and environmentally-friendly iFD-Stator® 2.0.

Advantages- Service life extended by more than three times

Depending on the application - Better maintenance planning

Due to display of residual potential - Upgrading of the pump without additional space requirement

Further Advantages- No adaptation of piping and pump base plate required for retrofitting

- Controlled, defined adjustment of the xLC® adjustment system

- High reliability due to robust design and simple operation

- Permanently high efficiency of the NEMO® pump through readjustment of the stator

- Rapid amortisation of the purchase due to reduced need for spare parts and longer maintenance intervals

- Service life extended by more than three times

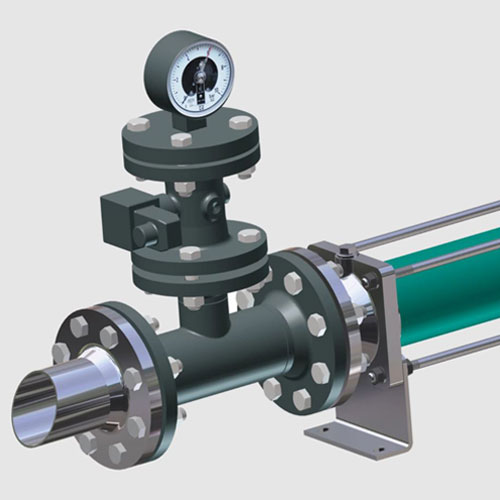

Accessories and Optional Equipment for Pumps & Systems

- The ideal supplement for the various requirements of NETZSCH products

- Dry Running Protection for NEMOLAST® Stators

- Flow Sensing Unit for Solid Stators

- Speed Monitoring Device

- Diaphragm Pressure Gauge

- Pressure Control Device DTSL 3

- Multi-Function Pressure Instrument

- Quench Pot

- Permanent Lubricator

- Pressurized Flushing for Double Mechanical Seal Systems

- Gear Joint Filling Unit

- Ring Dosing Nozzle

- Chemical Anchors

- Stator Removal Tool

- Trolley Assemblies

- Machine Feet

- Covers for Drive Monitors