BTS

Videos

Loading the player ...

- Offer Profile

We create renewable energy by transforming matter

We build and manage biogas and biomethane plants, in Italy and around the world. We are BTS Biogas, a leading corporation in the renewable energy market for over 25 years.

Cornerstones of every activity: full respect for the environment and nature, the guarantee of a high level of biogas production and maximum operational reliability to ensure the principle of the circular economy..

Product Portfolio

Biogas and Biomethane: clean energy that sustains the planet

A precious renewable energy source from waste

Agricultural plants

- The evolution towards the circular economy is now an unstoppable process and it takes place through the recycling of by-products and waste generated by our cities, industries and agriculture, to become a precious resource for the production of renewable energy.

Agro-industrial plants

- A great opportunity to revisit and enhance the processes aimed at better resource efficiency, focusing on a more sustainable and environmentally friendly economic activity that generates income and employment.

OFMSW

- Where it is not possible to avoid the production of waste, its economic value must be recovered, minimizing the impact on the environment, in compliance with the European Union strategy and the Paris agreement of 2015, but above all for the environmental benefits in terms of lower CO₂ emissions.

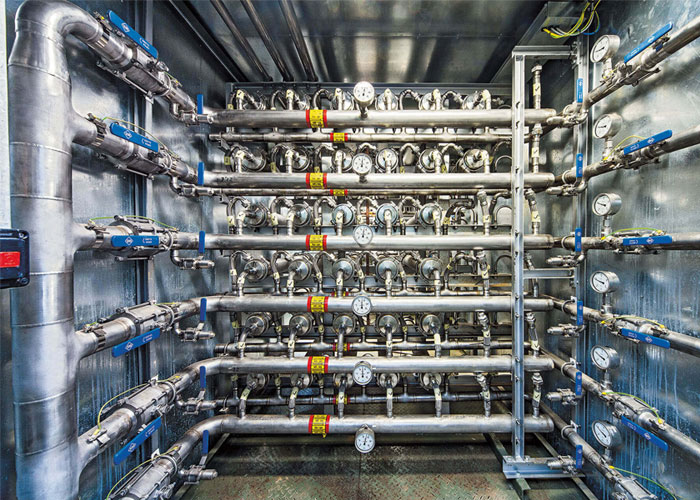

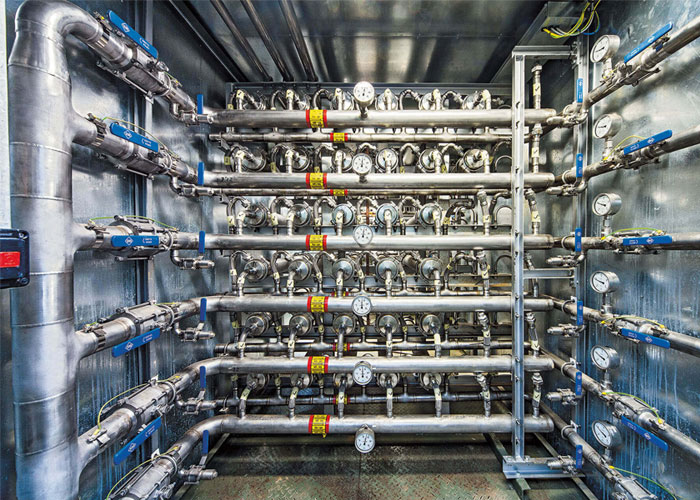

Biogas purification with BTS Biogas technology

Washing process using pressurized water

- With this process, CO₂ and hydrogen sulphide are dissolved in water and separated from biogas.

The biogas is subjected to pressure and purified inside a column filled with countercurrent water. The "unwanted" gases are absorbed by the water while the purified gas, after passing through the column, is drained, dried and made available for entry into the network or for direct use.

At various points in the system, heat is extracted which can be used for heating the tanks of biogas plants.

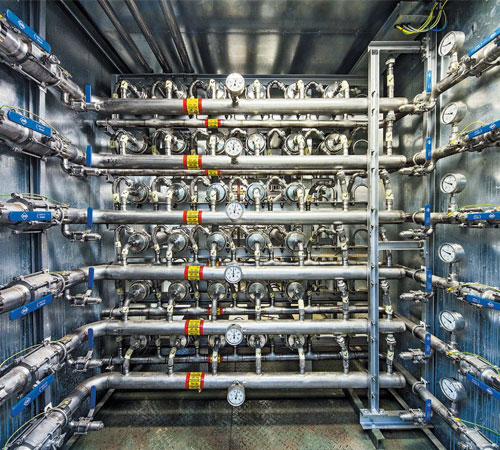

Process using membranes

- In the process that uses membranes, the biogas with pressurized water is first purified of hydrogen sulphide and brought to a higher pressure using compressors.

Methane is then separated from the CO₂ using membranes. It is thus possible to extract all of the methane from the raw biogas, with a dispersion of less than 0.1%.

The part containing CO₂ is further compacted in the separation with membranes and then condensed to obtain 100% pure CO₂, which can be used above all in the food industry.

While washing with pressurized water provides greater benefits if performed in large plants (> 2 MW), it is preferable to carry out the treatment using membranes in small and medium-sized plants.

PSA technology, oscillating pressure adsorption

- The separation of CO₂ from methane takes place inside columns containing adsorbent material.

The pressure varies in the columns so that by increasing this value, the CO₂ is absorbed by the material. The system consists of several parallel columns.

When the absorbent properties of one column become saturated, the raw biogas is conveyed to the next column.

Chemical washing

- In this case, the raw biogas and a CO₂ absorption liquid are conveyed into a countercurrent absorption column.

The outgoing gas acquires a purity similar to that of natural gas. While the CO₂ impregnated absorption liquid is used for stripping for the separation of the latter.

After suitable cooling, pure CO₂ with a high commercial value is obtained.

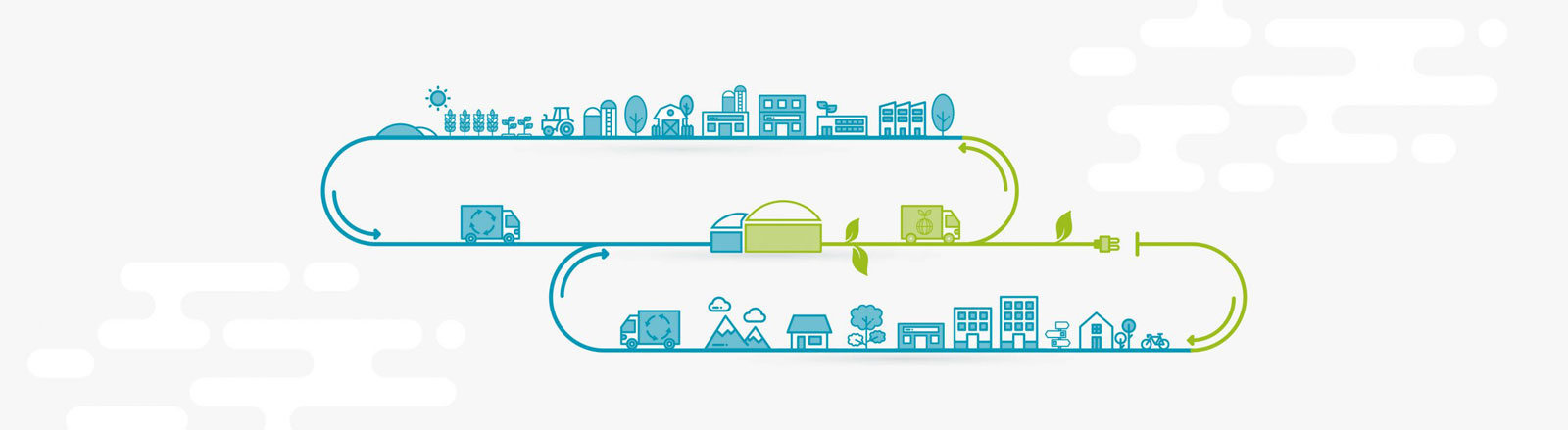

Our DNA is green - Circular economy: recovering to create value

WHAT IS THE CIRCULAR ECONOMY?

The circular economy is a model based on the idea of an economy that is capable of regenerating itself.

The term circular is used precisely to indicate the contrast with the common (linear) economic model based on: production, use and waste.- Return biological materials to the environment

- Give new life to technological components, preventing them from affecting the environment

In fact, in the case of the circular economy the key concept is the recovery and reuse of existing materials and products.

Once it reaches the end of its life cycle, a product can be broken down into its parts and reintroduced into the economic cycle, thereby reusing it in the production cycle and generating value.Unlike the linear economic model which provides for enormous quantities of energy and raw materials to be used in the production phase and which does not focus on the problem of waste, the circular economy starts from waste, to reduce the quantities and lengthen the life-cycle of products.

The circular economy results in:- A favorable impact on the climate. Reduction of energy consumption and CO₂ emissions

- More rational use and processing of raw materials, to reduce environmental exploitation

- Increased competitiveness and a drive towards innovation

- Economic and employment growth

Biogas: recovering to create energy

- Biogas is able, with a single process, to recover scrap and waste, to give it a new location and make it useful again and to create a necessary product such as energy. All without burdening mankind or the environment.

Waste management

- Where it is not possible to avoid the production of waste, its economic value must be recovered, minimizing the impact on the environment, in line with the European Union strategy and the Paris agreement of 2015, but above all for the environmental benefits. in terms of lower CO2 emissions.

Agricultural plants

- The evolution towards the circular economy is now an unstoppable process and passes through the recycling of by-products and waste generated by our cities, agro-industries and agriculture, to become a precious resource for the production of renewable energy.

Agro-industrial plants

- A great opportunity to revisit and enhance the processes aimed at better resource efficiency, focusing on a more sustainable and environmentally friendly economic activity that creates income and employment.

Organic Waste

- Where it is not possible to avoid the production of waste, its economic value must be recovered, minimizing the impact on the environment, in line with the European Union strategy and the Paris agreement of 2015, but above all for the environmental benefits. in terms of lower CO2 emissions.

Our DNA is green - Renewable energies for a greener world

The potential of Biogas as green energy

Biogas is able, with a single process, to recover scraps and waste, to give a new location and new usefulness and to create a necessary product such as energy. All without burdening man and the environment.

In the general framework of renewable energy, biogas is the most programmable energy, able to balance the contribution of other renewable sources that cannot be planned.

It is the most flexible element, since it can be stored in the form of heat, electricity or biomethane, so that energy can be used when and where it is needed.

It contributes to the important sustainability process represented by valorizing urban waste.

The use of plant biomass in biogas plants to produce energy is one of the most efficient systems for reducing greenhouse gas emissions, in implementation of the 1998 Kyoto agreements and in compliance with the European Union decarbonisation goals by 2030.

Among the renewable energies, Biogas is the greenest, not only because it manages to reconcile the disposal of waste material with the production of clean energy, but also because it requires less energy for the plant’s production and life-cycle.Biology and Assistance: Biology and innovation at the service of Biogas

-

In a constantly growing and changing market such as that of renewable energy and anaerobic digestion, in BTS Biogas we established the first private laboratory in Italy dedicated exclusively to biogas years’ ago.

In the present day, our work continues in this direction. Our goal is to constantly work on improving products and services.

In all the activities we carry out, attention is paid to: use of cutting-edge technologies and standards, safeguarding of environmental protection requirements, ensuring safe and profitable operation, obtaining an optimal production process. MetanLab

- Using a state-of-the-art laboratory, we work on the development of a new generation of plants, to ensure even more lasting, safe and profitable operation.

dinaMETAN

- Following scientific methods, we collect empirical data that describes the production processes and the yields of biogas in different conditions.

Thanks to this data, it is possible to constantly improve the design and management of biogas plants, by inserting the data in the dinaMETAN database.

BIOLOGICAL CONSULTANCY

- To keep a plant in good condition it is essential to analyze and monitor the progress of the conditions that determine production and profitability.

OUR METANLAB LABORATORY PROVIDES BIOLOGICAL ADVICE WITH OVER

- 8000 ANALYZES PER YEAR

- 130 PLANTS IN EUROPE

The biological variables are comprehensively analyzed, monitoring performance and yields, so as to ensure a stable anaerobic digestion process and better biogas production.

The team, composed of analysts, biologists and agronomists, works in the field in close contact with customers and processes the data collected to provide the best solutions for the production of biogas.- All kinds of analyzes necessary to optimize the biological process are carried out.

- Estimates are made regarding possible biological problems, so as to avoid loss of production.

- The yield of plants is maximized through optimal recipes and the use of micronutrients.

- Problems are determined and prompt action is taken on possible inhibitions to the microbiological process.

- Software management, developed directly in our laboratories, for the management of biomass and for the organization of substrate supply based on the supply recipes of the plants.

- Renewable energy production towards a circular economy with

Agricultural plants - A more sustainable and environmentally friendly economic activity with

Agro-industrial plants - Recover the economic value, minimizing the impact on the environment with

OFMSW

Plants: Plants Development

We develop systems to achieve maximum efficiency

At BTS Biogas we constantly strive to improve products and services to provide customers with solutions that support business activities in terms of economic and environmental sustainability, without neglecting profitability.

We analyze the production processes and the primary needs of customers to realize projects that make the most of incoming products and enhance outgoing products.

All plants are designed to generate a system capable of:- improving the use of organic waste materials to create environmental benefits, such as reducing emissions and enhancing the soil,

- generating final products and concretely implementing the circular economy,

- producing energy in a sustainable cycle,

- ensuring a high level of profitability.

+250

We construct plants for every need: for the agricultural, agro-industrial industries and for every city, enhancing urban organic waste.

plants in the world

Various types of biomass can be used, from agricultural manure to energy crops to agricultural residues, as well as industrial by-products and Organic Waste, Organic Fraction of Urban Solid Waste (wet), generated by the separate collection of organic waste in municipal facilities.BTS Biogas plants

Agricultural plants

- Supplied by slurry and manure, by-products and second crops, agricultural biogas plants are a fundamental element for the primary economy world.

The plants ensure the possibility of returning precious organic substance to fields.

In fact, biogas digestate is an organic substance stabilized due to the anaerobic process. It penetrates the soil more easily than slurry and improves its physical and chemical characteristics.

This therefore results not only in better efficiency of use, but also agricultural production that protects the soil and the environment.

Biogas is necessarily part of the good practices of contemporary agriculture.

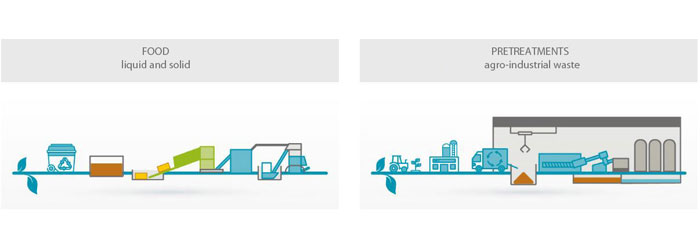

Agro-industrial plants

- From large-scale food distribution to slaughterhouses, from the bakery industry to the cosmetics industry, any organic material, except for wood, can be improved through anaerobic digestion.

Thus, the concept of organic waste disappears. With biogas it is possible to produce energy, biomethane, CO2 for the food industry and much more with great environmental and economic benefits.

Organic Waste plants

- With an ever-increasing amount of organic matter, available through the separate collection of domestic users, cities and municipalities can optimize waste management.

A decision that brings important benefits in terms of efficiency, consensus and environmental protection.

TECHNOLOGIES

- Our technical and biological know-how, together with vast experience in the operation of biogas plants have led to the development of countless solutions and products that have become part of plant standards.

These are systems for the production, operation and control of plants, pre and post treatment of substrates and technologies for the production of biomethane. PRE-TREATMENT

The various innovative technologies for pre-treatment allow:

- Maximum possible increase in biogas yield

- Biomass savings and cheaper operation of biogas plants

- Reduction of the residence time in fermenters and increase of the organic load

- Lower volumes in tanks and reduction of investment costs

- Prevention of the formation of floating layers and deposits in tanks

- Prevention of the penetration of pollutants into fermenters

- Reduction of costs due to the agitation of the material and the self-consumption of the plants

BIOaccelerators

- A BIOaccelerators is an extruder that optimizes the decomposition of the inlet substrates through defibration, to achieve a greater biogas yield.

In this way, new substrates can be added more quickly to the fermentation process.

Thanks to the thermo-mechanical treatment of the substrate, the input material is subjected to an already high temperature, so as to reduce the consumption of electricity.

BIOacceleratorz

- A BIOacceleratorz is a biomass shredder that allows the fermentation of non-fermentable or difficult to process substrates without treatment. In this case, the incoming material is separated and mechanically shredded by the hammers and the rotating defibration elements at the bottom of the tank.

BIOseparatorw

- In the BIOseparatorw, the biomass is cleaned of contaminants and shredded with hammers and a grinder filter and then flows into the storage tank or is directly pumped. Contaminants (glass, metals, plastics, etc.) are expelled from the exit tray. A screw extruder is integrated in the outlet mouth which uses all the liquids still contained in the contaminants and re-supplies the process.

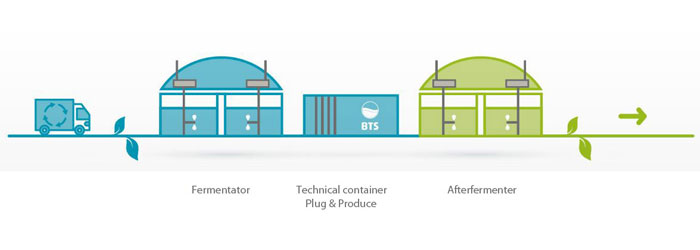

PLUG & PRODUCE

- This technical module, developed in our BTS Biogas workshop, serves as the technical center for biogas plants.

It is compact and modular, has standard sizes, which can be customized if necessary.

It requires less investment than a common building installation.

This technology results in savings in terms of production time and therefore assembly costs.

The module is manufactured and tested on the company’s premises, thus ensuring greater reliability.

It is available in various customizable sizes, for both new and existing plants.

The following are positioned inside the module: gas measuring instruments, desulphurization blowers, the system for the distribution of heating and pumps, the air conditioning system, the running water distribution system and also, where required, a heat exchanger that is placed on the roof.

Service Box

- With the BTS Biogas serviceBOX, maintenance and repairs can be carried out quickly and efficiently starting from the fermenter agitator.

The serviceBOX & servicePLATFORM combination ensures:- Working in total safety during maintenance work on the fermenter

- No biogas loss thanks to the stainless steel "miniskirt" inside the tank

- No emptying of the tank or stoppage of biogas production during maintenance

- Adjustment of the height and orientation of the agitators for precise agitation that prevents the formation of crusts

- Lighted porthole for biomass control inside fermenters

- Surveillance camera with cleaning nozzles for internal control of fermenters

DIGITALIZATION

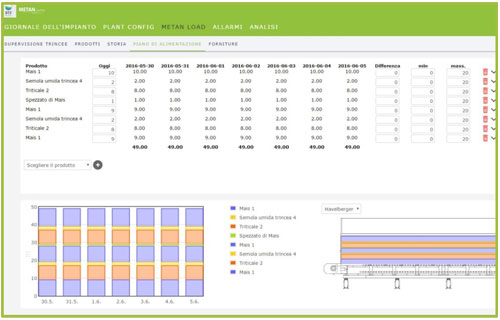

METANload

- The METANload system is a software developed by BTS Biogas, for visualization and control of the filling of the hopper.

It is an intelligent calculation application, with integrated hardware components, which helps the operator to optimally supply the biogas plant.

Plant managers receive precise information in real time on what has already entered the plant and on which substrate components must be added to obtain optimal proportions of the mixture.

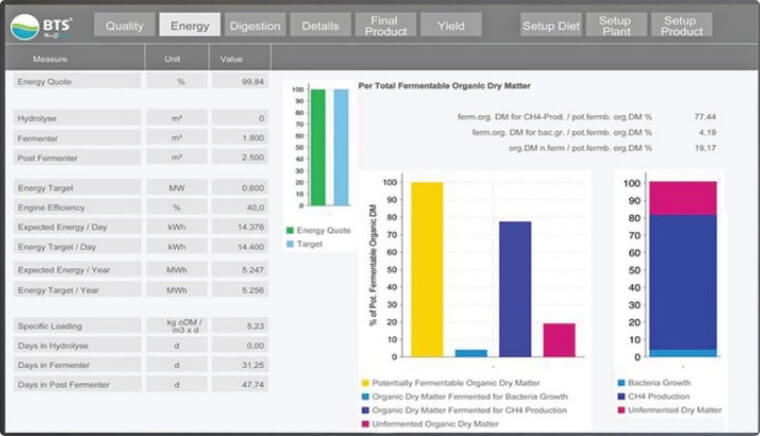

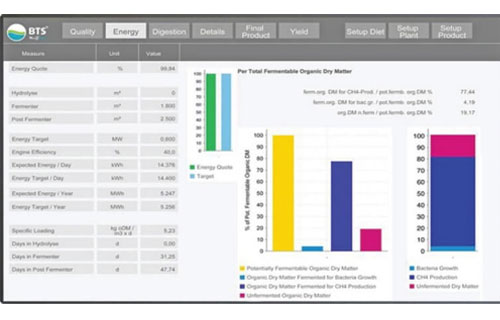

dinaMETAN

- DinaMetan allows the calculation of the optimal biological yield, maximum energy production, the degradation rate of the substrates, the need for bacteria during the fermentation process, ideal spatial exposure, optimal retention time in fermenters and the most beneficial costs of the substrates for each kWh produced.

INFOmodule

- Thanks to INFOmodule, a system developed internally by BTS Biogas, the personnel in charge of a plant’s operation can remotely check and intervene on it at any time.

In the event of anomalies, the system sends voice alerts by telephone, classified according to defined priorities.

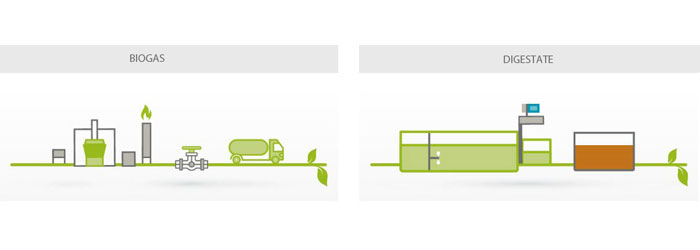

POST-TREATMENT

- Well thought-out post-treatment means our customers can reuse residual digestate in a variety of ways.

BIODry

- Drying is the most efficient method to use the excess heat of the biogas plant and to transform the slurry into a precious fertilizer.

A solid and a liquid product are obtained from this process: dried digestate (BIOdry) and ammonium sulphate.

Drying allows the optimization of the biogas plant by adding an additional source of income.

Soil quality is improved because of the high organic content of the fertilizer, and its components have a lasting effect.

NITROStripp

- Stripping is a method that solves the nitrogen problem. It is mainly used in biogas plants supplied with a lot of slurry.

The stripping process can also be carried out without using chemical additives.

BIOPellet

- The resulting material of the anaerobic digestion process can be pelleted with considerable benefits in economic, managerial and agronomic terms.

The material, previously dried with BIOdry, is filtered, pressed, sifted and added. The pellets are then packaged in Big-Bags or 15/25kg bags.

This technology alternatively allows the production of digestate pellets and BIOfire wood pellets, giving flexibility and investment profitability benefits.

Repowering

- We are not only dedicated to the design of plants from scratch, but we also carry out interventions on plants that have already been built.

By combining our different technologies with the experience gained in the field, we modify the power supply and related processes connected to plants to achieve maximum technical, biological and economic efficiency.

Plants: Revamping

Are you the owner of a biogas plant which is at the end of the 15-year incentive rate?

You may be wondering how to make the most of your investment and we can help you decide how to face the future.Revamping

BTS Biogas is available to convert your existing plant by adapting it to the new regulations.What are the benefits for your company?

Achieve continuity with regard to your previous investment and ensure a sustainable future with biomethane.

If you wish to find out more about this opportunity, we can do the following for you and with you:- Submission of an offer that is tailored to your needs

- Development of a Business Plan

- Complete authorisation process

- Analysis of by-product yields using our MetanLab and our team of biologists

- Verification of the yield and re-development of a new power supply solution

- Verification of the sustainability criteria

Selling

Have you decided not to renew your system?

BTS Biogas is interested in purchasing it.What does this mean for your company?

Get a significant amount of capital right away, without having to make additional investments and manage the business for 15 years.

If you wish to find out more about this opportunity, we can do the following for you and with you:- Analysis of the operational state of the system

- Verification of the feasibility of connection to the gas network (distance and inlet pressure)

- Analysis of the Business Plan based on the current regulations (best and worst case)

- Verification of the yield of a potential new power supply solution

- Verification of the sustainability criteria

- Support for accessing eligible contributions

- Signing of a potential letter of intent or contract

Biology and Assistance

Complete assistance for customized plants

To ensure optimal and continuous operation of high-tech plants, great importance and constant investment has always been attributed to the development of a punctual and complete assistance service.

The customer can count on a highly specialized team and on the assurance of very short intervention times in all areas where the service is available. A team of experts is in fact available to customers 24 hours a day, 365 days a year.

Complete assistance, biological, technical and automation, allows you to maximize profit by ensuring reliability and optimal technical-operational conditions.

BIOLOGICAL ASSISTANCE

- All types of analyzes necessary to optimize the biological process are carried out.

- Estimates are made about possible biological problems, so as to avoid loss of production.

- The yield of plants is maximized through optimal recipes and the use of micronutrients.

- The problems are determined, and action is taken promptly on possible inhibitions of the microbiological process.

- Software management, developed directly in our laboratories, for the management of biomass and for the organization of the supply of substrates based on the supply recipes of the plants.

TECHNICAL ASSISTANCE

- Our priority is to minimize intervention times on plants to achieve high profitability.

The interventions, carried out by specialized and qualified personnel, mechanics, electrical technicians, software and automation experts or systems engineers, can be carried out on call or take place according to periodic maintenance, to always maintain maximum efficiency.

THE ASSISTANCE INVOLVES INTERVENTIONS ON:- mechanical, hydraulic and electrical parts

- pre and post treatment systems

- upgrading systems

ASSISTANCE ON THE AUTOMATION SYSTEM

- Our automation system allows us to remotely manage all parts of a plant. Plants can be constantly monitored to communicate any anomalies in real time to the operator and to the BTS Automation Service.

THE ASSISTANCE ALLOWS:-

24/7 plant monitoring

security back-up on our server. -

setting alarms

alarms are managed in real time and, if necessary, a team is immediately sent for on-site intervention, -

drafting of intervention records

classification of any interventions with precise priority standards

-

24/7 plant monitoring

A wide range of services for all needs

To support each customer and meet the specific needs that each enterprise or entrepreneur has to face, we have defined a wide range of specific packages to make our services available.

FULL SERVICE

Our Full Service contract provides complete technical and biological services and consultancy:- PERIODIC MAINTENANCE

- CONSTANT MONITORING OF THE ALARM SYSTEM

- REPLACEMENT OF CONSUMABLES INCLUDED

- ON-SITE INTERVENTION SERVICE WITHIN 24 HOURS, 7 DAYS A WEEK

- PREVENTIVE MEASURES AND INTERVENTIONS

- 24/24 TELEPHONE ASSISTANCE

- BIOLOGICAL CONTROL OF SUPPLY MATERIALS

- COMPLETE DOCUMENTATION OF THE INTERVENTIONS

SERVICE LIGHT

Our Service-Light contract offers flexibility and a customized plant maintenance service:- TELEPHONE SERVICE WITHIN 24 HOURS AND 7 DAYS A WEEK

- COMPLETE DOCUMENTATION OF THE INTERVENTIONS

- PERIODIC CHECKS OF PLANTS BY OUR TECHNICAL EXPERTS (NUMBER TO BE DEFINED WITH THE CUSTOMER)

- SEVERAL HOURLY PACKAGES AVAILABLE FOR EXTRAORDINARY MAINTENANCE

Biology and Assistance: Warehouse and Logistic Center

MAXIMUM EFFICIENCY AND RAPID INTERVENTIONS

With more than 25,000 square meters of surface located between Italy, France, UK and the US, and more than 10,000 spare parts available, we are able to ensure maximum efficiency and rapid interventions.

Technicians ensure safe commissioning and routine maintenance with precise and planned inspections. In this way, downtime is minimized to ensure high profitability.

The speed of resolution of interventions is ensured by the availability of the technical components present in our logistics centers.

In 2021 our plants operated with an average production rate of 96%, working for over 8,450 average hours per year. This reliability is due to the experience gained in over 25 years of activity and to the management of maintenance and assistance.

We are always close to our customers with assistance activities in the field, safely and in compliance with regulations, using our remote monitoring and intervention system.