- Offer Profile

-

Innovative technology and many years of experience

streisal GmbH was founded in 1988 as a manufacturer of submersible motors. Over the course of the years, we have developed into an internationally active, medium-sized full-range provider of agitators and mixing systems for all kinds of applications, thanks to a large number of technical innovations:

- Biogas plants

- Waste water treatment

- Industrial process technology

international explosion-protection approvals

-

THE APPROPRIATE AGITATOR TECHNOLOGY FOR YOUR REQUIREMENTS – AND THAT'S WORLDWIDE

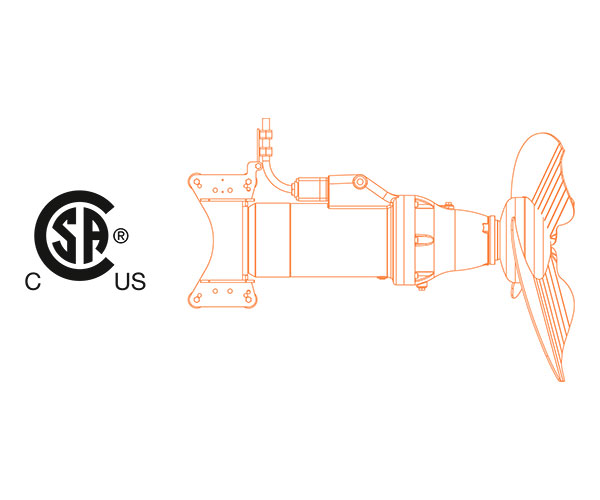

Atex, CSA/UL, IECEx – we supply you with explosion-proof agitators with international approval.

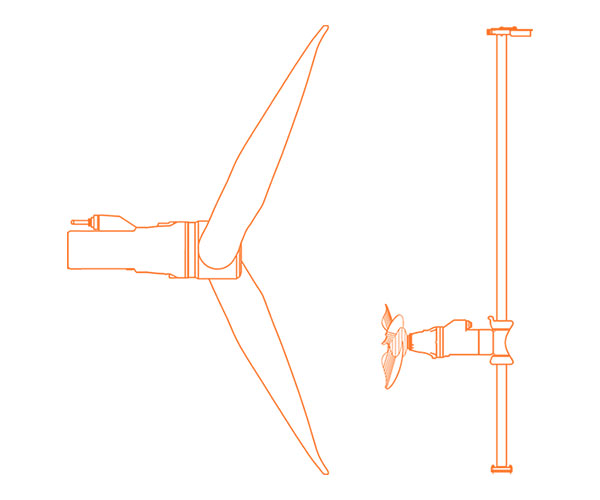

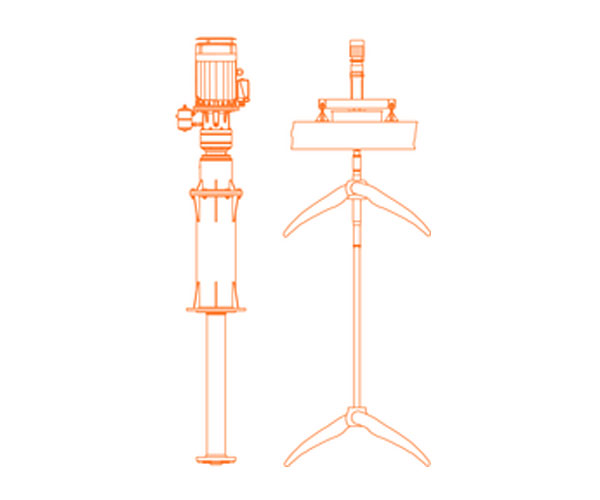

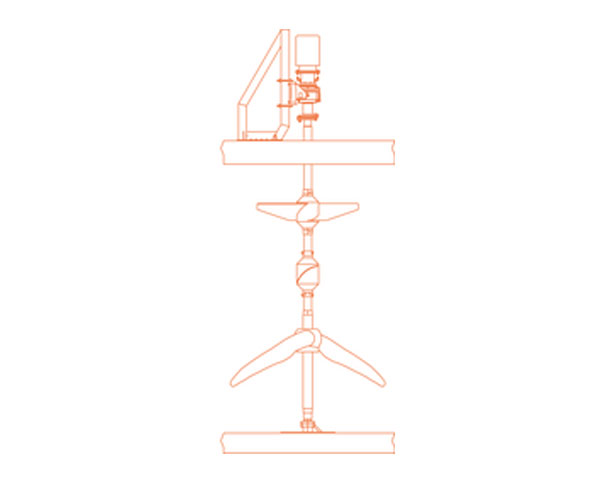

Submersible agitators

Highly efficient submersible agitators

-

from 1 to 18.5 kW

HIGH-PERFORMANCE, RELIABLE, ENERGY-EFFICIENT

For more than 30 years, streisal GmbH has been working on the use of submersible agitators in process technology applications. The technical performance, reliability and energy efficiency of our agitators has always been at the centre of our thinking and actions. The standard equipment of streisal submersible motor agitators includes the mechanical seal in highly wear-resistant silicon carbide that is protected against corrosion in a stainless steel holder, as well as temperature monitoring in the motor winding and a high-volume oil chamber with seal monitoring. Installation can be on flexible lowering devices or fixed stand units. As a result, all kinds of tank geometries can be used at any time without difficulties. Moreover, it is possible to adapt the design of the installation accessories to special installation situations.

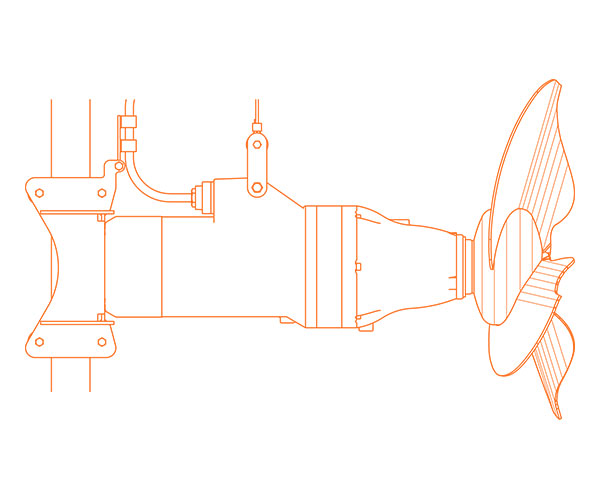

Submersible agitators TSR

-

TECHNICAL PROPERTIES

- Power range: 1.5 – 18.5 kW

- Mains frequency: 50 or 60 Hz

- Axis thrust: up to 4,920 N

- Circulating rate: up to 5,079 m³/h

- Propeller diameter: up to 1,015 mm

- Coolant/medium temperature: max. 60 °C

- Mechanical seal: SiC/SiC pairing

- Immersion depth: max. 20 m

INNOVATIVE PROPELLER GEOMETRY

A decisive feature for comparing the efficiency of agitators is what is referred to as the first performance number as a quotient of the generated thrust force and the energy observed at the operating point. The propeller geometry that has undergone further development in the streisal fluid mechanics laboratory involving the use of the latest measuring technology and has been optimised in the test tank (large scale) means that enormously high thrust values are possible with a low power consumption. This means much lower and operating costs!

TSR with CSA/UL

- TECHNICAL PROPERTIES

- Power range: 10–22 HP (7.5–16 kW)

- Mains frequency: 60 Hz

- Axis thrust: up to 967 lbf (4,300 N)

- Circulating rate: up to 19,773 gal/min (4,491 m³/h)

- Propeller diameter: up to 37.8“ (960 mm)

- Coolant/medium temperature: max. 60 °C

- Mechanical seal: SiC/SiC pairing

- Immersion depth: max. 20 m

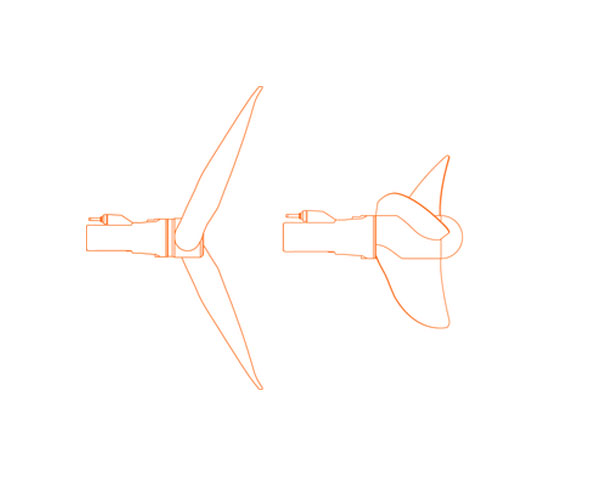

TSRL Hybrid

- TECHNICAL PROPERTIES

- Power: 7.5 kW and 11 kW

- Mains frequency: 50 or 60 Hz

- Axial thrust: up to 4,215 N

- Circulating rate: up to 5,975 m³/h

- Propeller diameter: up to 1,290 mm

- Coolant/medium temperature: max. 60 °C

- Mechanical seal: Pairing of SiC/SiC

ATP/BTP

- TECHNICAL PROPERTIES

- Power range: 1.5 – 11 kW

- Mains frequency: 50 or 60 Hz

- Axis thrust: up to 4,000 N

- Circulating rate: up to 10,829 m³/h

- Propeller diameter: up to 2,650 mm

- Coolant/medium temperature: max. 60 °C

- Mechanical seal: SiC/SiC pairing

- Immersion depth: max. 20 m

TRV

- TECHNICAL PROPERTIES

- Power range: 1.1 kW

- Mains frequency: 50 Hz

- Circulating rate: 300 m³/h

- Propeller diameter: 220 mm

- Coolant/medium temperature: max. 40 °C

- Mechanical seal: SiC/SiC pairing

- Immersion depth: max. 20 m

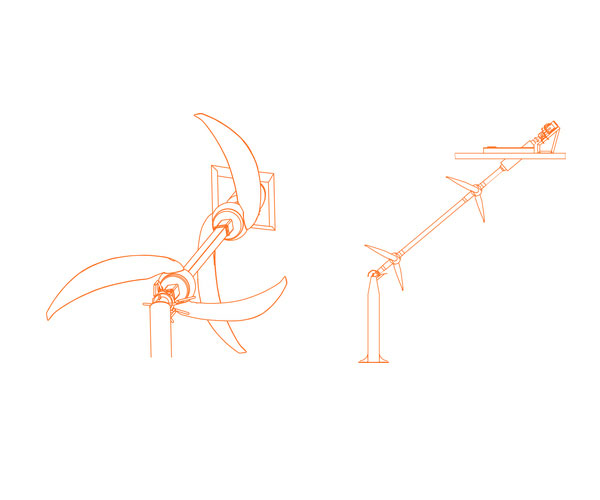

Vertical/inclined agitators

Powerful vertical/inclined agitators

- TECHNICAL PROPERTIES

- Power range: 1 – 30 kW

- Mains frequency: 50 or 60 Hz

- Circulating rate: up to 25,000 m³/h

- Propeller diameter: up to 2,800 mm

- Shaft cross-section: solid from 100 x 100 mm to 200 x 200 mm

- Temperature of medium: max. 60 °C

The energy-saving digester agitator Biobull®

- TECHNICAL PROPERTIES

- Type: BIOE 114 G

- Power rating: 11 kW

- Current rating: 21.5 A

- Nominal speed: 38 rpm

- Thrust force: approx. 7,000 N

- Circulating rate: approx. 22,600 m³/h

Vertical Biobull BIOS

- TECHNICAL PROPERTIES

- Power range: 1 – 15 kW

- Mains frequency: 50 or 60 Hz

- Circulating rate: up to 22,600 m³/h

- Propeller diameter: 2,650 mm, 1,500 mm or as required

- Shaft cross-section: solid from 100 x 100 mm up to 200 x 200 mm

- Temperature of medium: max. 60 °C

The height-adjustable rod agitator Biosubstrator®

- TECHNICAL PROPERTIES

- Type: BIOS 114 G

- Power rating: 11 kW

- Current rating: 21.5 A

- Nominal speed: 54 rpm

- Thrust force: approx. 6,000 N

- Circulating rate: approx. 8,300 m³/h

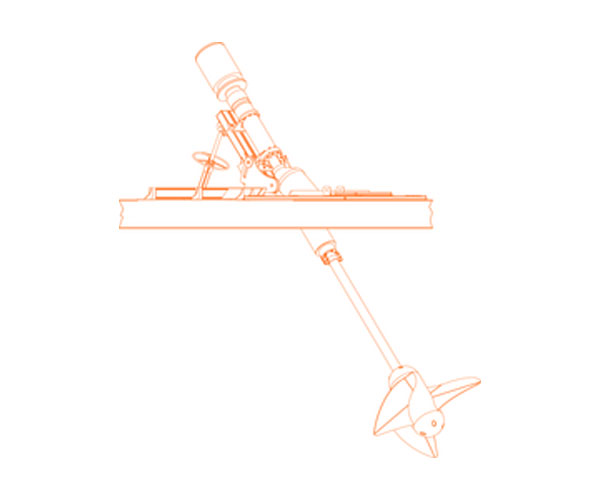

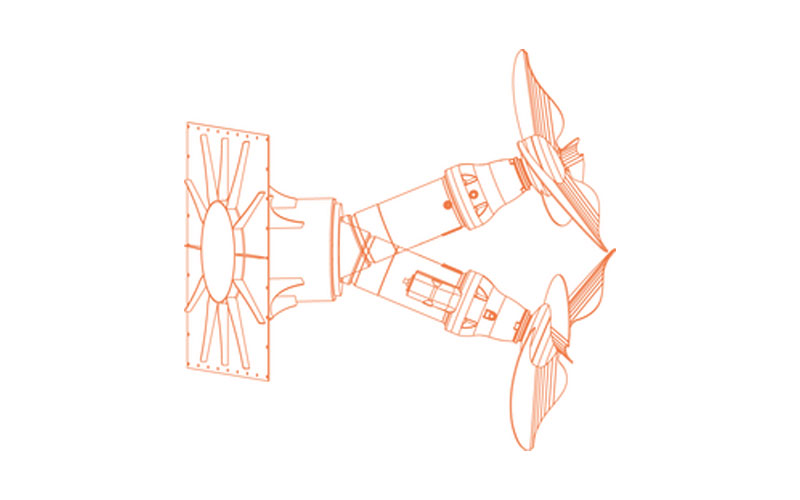

High-performance agitating systems: Maischebull®/Hydrobull®

- TECHNICAL PROPERTIES

- Type: BIOE 114 (M)D – Power rating: 11 kW, Current rating: 21.5 A, Rotation speed: 38 rpm

- Type: BIOE 154 (M)D – Power rating: 15 kW, Current rating: 31 A, Rotation speed: 38 rpm

- Type: BIOE 184 (M)D – Power rating: 18.5 kW, Current rating: 36.6 A, Rotation speed: 38 rpm

- Type: BIOE 304 (M)D – Power rating: 30 kW, Current rating: 55 A, Rotation speed: 55 rpm

Switching and control devices

- Optimum control of agitators is a complex task that has a significant influence on economic success. streisal offers a wide range of switching, starting and control devices for this purpose, and provides high-quality support in the planning, configuration and selection of the right technology.

Switching and control devices

-

Optimum control of agitators is a complex task that has a significant influence on economic success. streisal offers a wide range of switching, starting and control devices for this purpose, and provides high-quality support in the planning, configuration and selection of the right technology.

Frequency inverters

For operation with optimum use of energy, and for monitoring the agitators, we recommend streisal frequency converters with parameterised safety software.

SafeGuard

Automatic torque monitoring and control system for the use of agitators in tanks with changing filling levels.

SafeBox

Vibration monitors that switch off the agitator motor in the event of excessive vibrations via the PTC feeder cable.

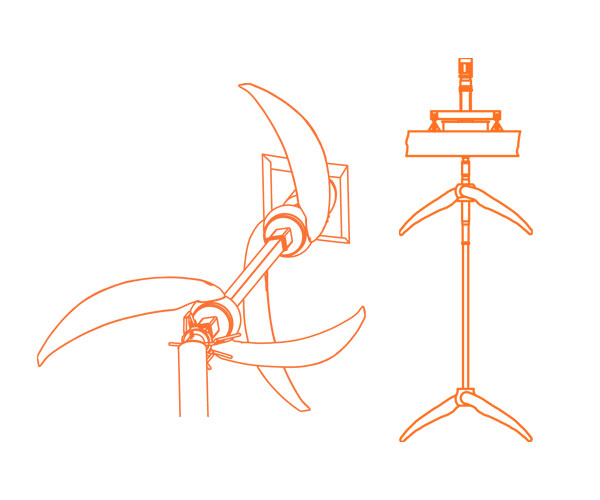

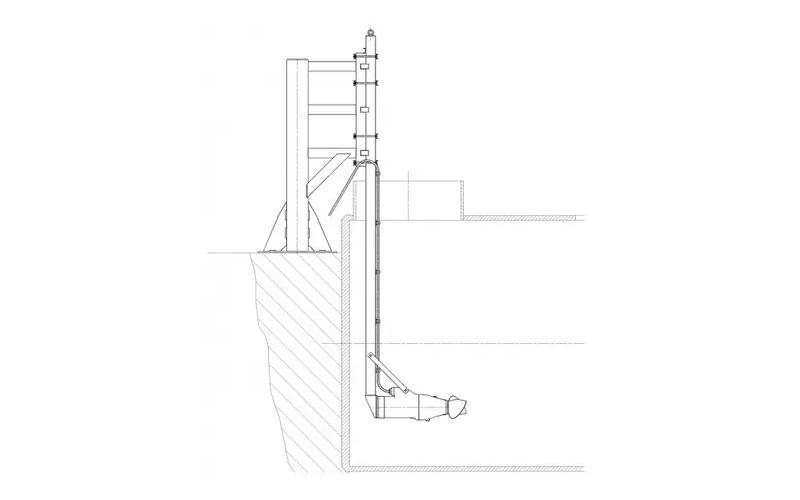

Installation accessories

High-quality installation accessories

-

High-quality installation accessories

An extensive range of robust accessories is available according to the particular agitator and individual installation situation. Supports, guide rails with wall or cover attachment, stand units, slides, flexible lowering devices and many other accessories are produced by streisal in-house according to our own plans. Sturdy constructions and highly resistant materials guarantee a long service life and durability. This means our agitators can be used without difficulty in all kinds of tank geometries. Furthermore, it is possible to adapt the design of the installation accessories according to the particular installation situations.

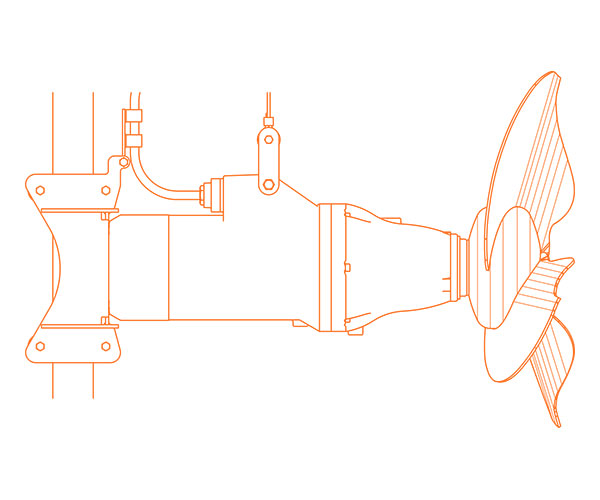

sideEntry

-

TECHNICAL PROPERTIES

- Compatible with streisal submersible agitators from 1.5 to 18.5 kW

- Stainless steel version (1.4301 or 1.4571)

- Required wall opening 1080 x 1080 mm

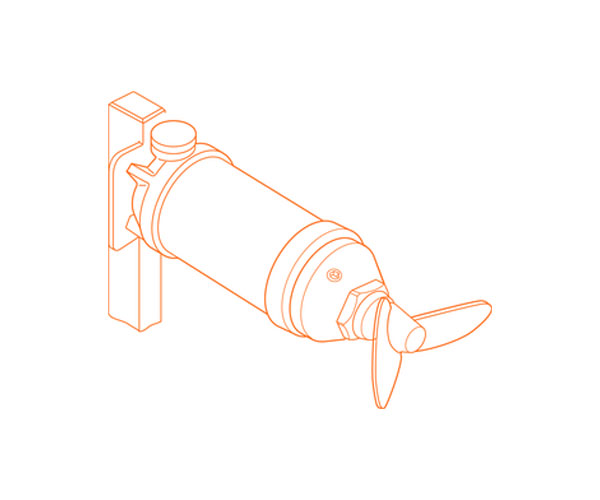

Energy-saving TSRM submersible motors

TSRM

- TECHNICAL PROPERTIES

- Power range: 1.5 – 18.5 kW

- Mains frequency: 50 or 60 Hz

- Coolant/medium temperature: max. 60 °C

- Shaft seal: Silicon carbide mechanical seal

- Immersion depth: max. 20 m

Projects and references

-

Efficient agitator technology in use around the world

Since 1988, streisal has been delivering agitators and mixing systems to customers worldwide. The many plants that we have equipped include biogas and sewage treatment plants as well as innumerable applications in industrial process technology. We will be happy to send you detailed information for your specific requirement on request. Please get in touch with us about this.

Pommerehne, Germany

- Turbo mash with streisal Hydrobull® mixing system as a step towards increasing flexibility of the biogas plant.

Lana, Italy

- Three new digesters with energy-efficient vertical agitators for the AD Lana plant expansion.

Dole Surallah, Philippines

- Digester with streisal Biobull® agitators generate biogas from pineapple waste.