- Offer Profile

- Biomass heating systems from 5 to 1000 kW, from new construction, to heating rehabilitation and biomass heating systems for agriculture, to municipal industrial and hall heating systems. The highly economical pellet heaters, firewood heaters, woodchip heaters and hybrid heaters (heat pump with pellet or firewood and log fires) from GUNTAMATIC are characterized by utmost reliability and maximum comfort.

BIOMASS HEATING IS ONE OF THE MOST ADVANCED HEATING SYSTEMS ON THE MARKET. MODERN IN DESIGN, TRADITIONAL IN VALUES AND INNOVATIVE IN ENERGY CONCEPT.

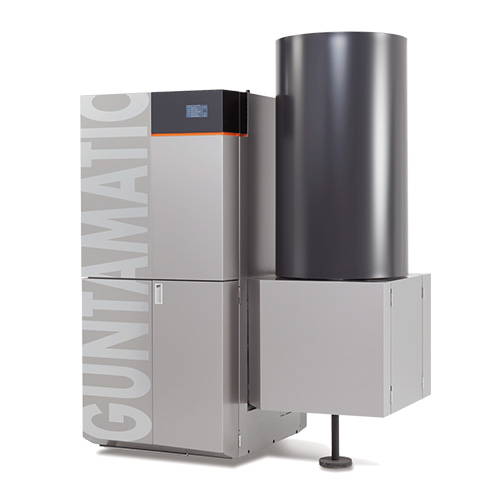

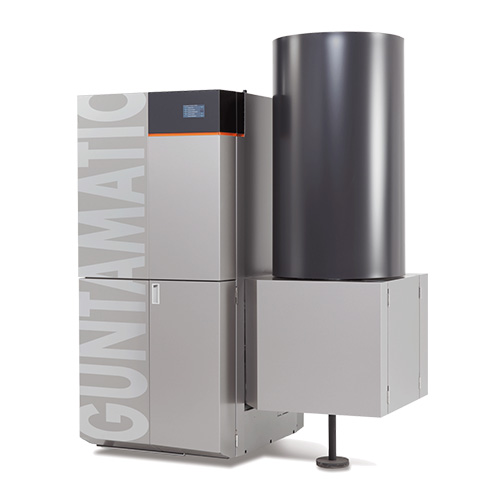

PELLET HEATING SYSTEM

-

PELLET BOILERS FROM GUNTAMATIC STAND FOR QUALITY, INNOVATION, ECONOMY AND SAFETY.

A pellet boiler from Guntamatic is a highly economical heating solution. Thanks to intensive, permanent technical development and an ambitious research team, our pellet heaters work with maximum efficiency and maximum modulation capability. This means our pellet boilers and pellet heating systems are extremely economical, highly comfortable and future-proof even in the low-temperature range. The simple and intelligent operating concept enables uncomplicated control of our heating systems. The devices are extremely robust, durable and low maintenance. Guntamatic pellet boilers are suitable for low-energy houses, farms, communal and industrial heating systems.- Clean operation by rotary combustion

- Industrial step grate technology

- Lambda probes control

- Multi-level security concept

- Easy operation and intelligent control

- Automatic cleaning

- High efficiency

- Low operating and service costs

- Pellet heaters are recoverable

THERM

5/7/10 KW- WITH PATENTED ROTATING COMBUSTION CHAMBER

Our wall mounted Therm Pellet appliances, with highly efficient rotating combustion, are innovative low temperature systems. You benefit from Guntamatic pellet technology, proven over many years. This highly efficient, extremely compact wall mounted boiler for biomass – the world's first to be manufactured in series – offers the opportunity to heat with wood pellets in line with the prevailing demand. It is suitable for new build, as well as the modernisation of older properties.

Benefits

STRAIGHTFORWARD REPLACEMENT

Output and boiler temperature are always perfectly matched to the respective building. Systems with a small buffer storage volume are perfect for new build. Older buildings with a relatively higher heat demand are suitable for operation without buffer cylinder. This enables the easy replacement of existing oil boilers without major effort. Reduced installation costs, a high seasonal performance factor and low consumption make this system highly economical.

FULLY AUTOMATIC CLEANING

Conventional pellet heating systems require frequent cleaning. The Therm system, on the other hand, cleans the combustion chamber, heat exchanger and grate area automatically. The large ash box reduces the remaining effort to a minimum. Only the general cleaning needs to be carried out manually.

PERFECT STORAGE

Guntamatic storage systems, with vacuum delivery systems employing dosing screw conveyors, are highly durable and reliable. Frugal consumption translates into a smaller storage space. For a low energy house, this means approximately 1 x 1.5 m. When the fuel is completely used up, there is no need for the annual storage room cleaning. Depending on requirements, a high grade steel/mesh hopper or sloping floor storage room with discharge screw conveyor are available.

PIONEERING OPERATING CONCEPT

Highly advanced control technology enables you to regulate your interior climate, the system and storage room functions automatically. Individual adjustments can be made easily via the ergonomic touchscreen controller, a room control station (if installed) or an app on a smartphone.

HIGH OVERALL EFFICIENCY

Advanced technology, robust appliance design and careful manufacture are the cornerstones of success for Therm systems. They require little maintenance and are built for an exceptionally long service life. Throughout their life cycle, these appliances deliver environmentally sound heating to their owners with the utmost reliability.

BIOSTAR

12/15/23 KW-

MODULATING PELLET COMBUSTION

Biostar systems feature a unique concept with the highest efficiency and maximum modulation ability. This enables you to operate with extreme efficiency and optimum convenience, even in the low temperature range, keeping your system absolutely futureproof.Benefits

CLEAN COMBUSTION AND EFFICIENT

Our BIOSTAR low temperature boilers are amongst the most innovative pellet heating systems on the market. The flexible combustion concept with variable ember bed height, plus intelligent lambda control, safeguards maximum heating efficiency and compliance with the most stringent emission standards.AFFORDABLE INSTALLATION AND OPERATION

Output and boiler water temperature are matched to the actual demand of the building in a unique fashion. As a result, no buffer cylinder is required. Existing oil boilers can be replaced with minimal effort and cost. In addition, the resulting high seasonal efficiency factor ensures very low consumption.CLEANING HAS NEVER BEEN EASIER

Conventional pellet heating systems still require regular cleaning. The Biostar system, on the other hand, cleans the combustion chamber, heat exchanger and grate area (with the exception of general cleaning) automatically. A large ash box reduces the remaining effort to a minimum.PERFECT STORAGE

Guntamatic storage systems operate with suction discharge and screw conveyor dosing, resulting in outstanding operational reliability and durability. When the fuel is completely used up, there is no need for the annual storage room cleaning. Depending on preference, a high grade steel/mesh hopper or sloping floor storage room with discharge screw conveyor are available.PIONEERING, STRAIGHTFORWARD OPERATING CONCEPT:

Fully automatic control of appliance and storage room functions, as well as regulation of the ambient climate utilising the most advanced control technology. Individual adjustments can be made easily via the clear touchscreen controller, possibly via a room control station or a smartphone app.LOW MAINTENANCE COSTS, LONG SERVICE LIFE

Advanced technology, robust appliance design and careful manufacture are the cornerstones of success for BIOSTAR systems. They require little maintenance and are built for an exceptionally long service life. Throughout their life cycle, these appliances deliver environmentally sound heating to their owners with the utmost reliability.

BIOSTAR

13/17/24/33 KW-

WITH PATENTED ROTATING COMBUSTION

Biostar pellet systems, with rotating combustion, build on the proven Biostar concept. These systems set new benchmarks in terms of fuel utilisation, as well as dust and fine dust emissions. They are also extremely economical in operation, deliver the cleanest combustion, favourable maintenance costs and feature a robust, durable design.Benefits

STRAIGHTFORWARD REPLACEMENT

Existing oil boilers can be replaced without major effort. Output and boiler water temperature are perfectly matched to the actual demand of the relevant building. Buffer cylinders are not required. Reduced installation costs, a high seasonal performance factor and low consumption make this system highly economical.FULLY AUTOMATIC CLEANING

Conventional pellet heating systems require frequent cleaning. The Biostar system, on the other hand, cleans the combustion chamber, heat exchanger and grate area automatically. The large ash box reduces the remaining effort to a minimum. Only the general cleaning needs to be carried out manually.PERFECT STORAGE

Guntamatic storage systems, with vacuum delivery systems employing dosing screw conveyors, are highly durable and reliable. When the fuel is completely used up, there is no need for the annual storage room cleaning. Depending on requirements, a high grade steel/mesh hopper or sloping floor storage room with discharge screw conveyor are available.PIONEERING OPERATING CONCEPT

Highly advanced control technology enables you to regulate your interior climate, the system and storage room functions automatically. Individual adjustments can be made easily via the ergonomic touchscreen controller, a room control station (if installed) or an app on a smartphone.HIGH OVERALL EFFICIENCY

Advanced technology, robust appliance design and careful manufacture are the cornerstones of success for Biostar systems. They require little maintenance and are built for an exceptionally long service life. Throughout their life cycle, these appliances deliver environmentally sound heating to their owners with the utmost reliability.

BIOCOM

30/40/50 KW-

INDUSTRIAL STEP GRATE TECHNOLOGY

Biocom heating systems with industrial step grate technology deliver maximum economy with minimum emissions. These boilers can operate with wood pellets of varying quality.Benefits

HIGHLY EFFICIENT COMBUSTION

The wood pellets are gasified on the industrial step grate, where primary air is supplied at an ember bed temperature of around 800 °C. The amount of combustion air and fuel charge is regulated by means of a lambda probe, so that the system achieves a level of efficiency of up to 94 %. With the aid of secondary air, the generated combustion gases are cleanly and efficiently converted into energy in a large rotating combustion zone.FULLY AUTOMATIC CLEANING

Conventional pellet heating systems require frequent cleaning. The Biocom system, on the other hand, cleans the combustion chamber, heat exchanger and grate area automatically. The large ash box reduces the remaining effort to a minimum. Only the general cleaning needs to be carried out manually.PERFECT STORAGE

Guntamatic storage systems, with vacuum delivery systems employing dosing screw conveyors, are highly durable and reliable. When the fuel is completely used up, there is no need for the annual storage room cleaning. Depending on requirements, a high grade steel/mesh hopper or sloping floor storage room with discharge screw conveyor are available.PIONEERING OPERATING CONCEPT

Highly advanced control technology enables you to regulate your interior climate, the system and storage room functions automatically. Individual adjustments can be made easily via the ergonomic touchscreen controller, a room control station (if installed) or an app on a smartphone.DURABLE QUALITY

Biocom systems are particularly reliable in operation and meet the highest quality requirements. They are made entirely in an ultra-modern factory in Austria, using exclusively selected, quality materials. In this way, customer satisfaction is guaranteed for years to come.

BIOCOM

75/100 KW-

INDUSTRIAL STEP GRATE TECHNOLOGY

Biocom heating systems, with industrial step grate technology, combine maximum economy with minimum emissions. These boilers can operate with wood pellets of varying quality.

Benefits

HIGHLY EFFICIENT COMBUSTION

The wood pellets are gasified on the industrial step grate, where primary air is supplied at an ember bed temperature of around 800 °C. The amount of combustion air and fuel charge is regulated by means of a lambda probe, so that the system achieves a level of efficiency of up to 94 %. With the aid of secondary air, the generated combustion gases are cleanly and efficiently converted into energy in a large rotating combustion zone.CLEANING HAS NEVER BEEN EASIER

Conventional pellet heating systems still require regular cleaning. The Biocom system, on the other hand, cleans the heat exchanger and step grate (with the exception of a general clean-up) automatically. Large ash boxes reduce the remaining effort to a minimum.PERFECT STORAGE

Guntamatic storage systems operate with suction discharge and screw conveyor dosing, resulting in outstanding operational reliability and durability. When the fuel is completely used up, there is no need for the annual storage room cleaning. Depending on preference, a high grade steel/mesh hopper or sloping floor storage room with discharge screw conveyor are available.PIONEERING, STRAIGHTFORWARD OPERATING CONCEPT:

Fully automatic control of appliance and storage room functions, as well as regulation of the ambient climate utilising the most advanced control technology. Individual adjustments can be made easily via the clear touchscreen controller, possibly via a room control station or a smartphone app.DURABLE QUALITY

In order to ensure that our appliances meet our high quality aspirations and those of our demanding customers, we manufacture them completely and exclusively using the best possible materials in our ultra-

BIOCOM

CASCADE PRINCIPLE UP TO 400 KW-

INDUSTRIAL STEP GRATE TECHNOLOGY

Biocom heating systems, with industrial step grate technology, combine maximum economy with minimum emissions. These boilers can operate with wood pellets of varying quality.

Benefits

HIGHLY EFFICIENT COMBUSTION

The wood pellets are gasified on the industrial step grate, where primary air is supplied at an ember bed temperature of around 800 °C. The amount of combustion air and fuel charge is regulated by means of a lambda probe, so that the system achieves a level of efficiency of up to 94 %. With the aid of secondary air, the generated combustion gases are cleanly and efficiently converted into energy in a large rotating combustion zone.CLEANING HAS NEVER BEEN EASIER

Conventional pellet heating systems still require regular cleaning. The Biocom system, on the other hand, cleans the heat exchanger and step grate (with the exception of a general clean-up) automatically. Large ash boxes reduce the remaining effort to a minimum.PERFECT STORAGE

Guntamatic storage systems operate with suction discharge and screw conveyor dosing, resulting in outstanding operational reliability and durability. When the fuel is completely used up, there is no need for the annual storage room cleaning. Depending on preference, a high grade steel/mesh hopper or sloping floor storage room with discharge screw conveyor are available.PIONEERING, STRAIGHTFORWARD OPERATING CONCEPT:

Fully automatic control of appliance and storage room functions, as well as regulation of the ambient climate utilising the most advanced control technology. Individual adjustments can be made easily via the clear touchscreen controller, possibly via a room control station or a smartphone app.DURABLE QUALITY

In order to ensure that our appliances meet our high quality aspirations and those of our demanding customers, we manufacture them completely and exclusively using the best possible materials in our ultra-modern Austrian factory.

BIO VARIO

13/17 KW-

PELLETS/LOGS COMBI SYSTEM

The VARIO combines the benefits of the innovative and highly efficient BIOSMART biomass converter with the convenience and economy of the BIOSTAR pellet system. This means the highest level of flexibility, optimum economy and perfect convenience.Benefits

PELLET MODULE Compared to previous pellet/log combi systems (log boiler must be held constantly at a high temperature by the pellet module; no low temperature capability, limited output adjustment, some soiling of the log appliance; ...) the two special high grade appliances that form the Guntamatic VARIO system operate in perfect harmony. The result a significantly higher utilisation level or fuel cost savings of over 15 % particularly in pellet operation. For customers who want to heat with pellets over longer periods or consistently wish to lower their spending, there is really only one choice the VARIO. (For customers who prefer logs and need automatic operation only occasionally, we would recommend our hybrid versions ...)LOG MODULE

The innovative wood gasification technology from GUNTAMATIC enables the log module to operate with high efficiency and extremely low emissions. This results in particularly low heating bills, even with high flow temperatures and when it gets really cold. Logs are amongst the most favourably priced and crisis-resistant fuels available. The high grade log module, with solid cast iron lining, is suitable for logs up to 0.3 m in length.OPTIMUM EFFICIENCY, MINIMUM EMISSIONS

Our unique combustion concept with lateral rotating combustion chamber is clearly superior to conventional combustion systems when it comes to efficiency, flexibility and the protection of the environment. It enables very long periods of extremely clean combustion.HIGHEST CONVENIENCE

When in low temperature mode, the pellet module delivers heat to the heating circuits with high efficiency and matched to the actual demand. By heating up the log module, the Vario system automatically changes into log mode and back again. Complicated changeover effort is therefore avoided. From chore to pleasure the large hopper, optional automatic ignition, the separating out of ash into an ash box and semi-automatic cleaning have transformed the experience of heating with logs.INTELLIGENT CONTROLLER

The innovative touchscreen controller offers the highest operating convenience. The clear user prompts take you exactly where you want to be in just a few steps. This enables straightforward control and fast servicing.HIGH GRADE COMPONENTS

To safeguard unsurpassed reliability, our Vario systems are made exclusively in Austria, from high grade materials.

Extraordinary durability and the lowest maintenance costs are ensured through robust silicon combustion chambers, a particularly solid cast iron lined hopper, induction fans cooled internally by air, robust lambda probes, high grade geared units, ignition fans and air actuators.

BMK VARIO-P

20/30 KW-

LOG/PELLET COMBI SYSTEM

The BMK Vario-P combines the benefits offered by the innovative and highly efficient BMK biomass converter with the convenience and economy of the BIOSTAR pellet system. This means the highest level of flexibility, optimum economy and perfect convenience.Benefits

ECONOMICAL PELLET MODULE

The clever combination of the standalone log and pellet modules offers significant benefits compared with conventional systems: the system can be operated in the low temperature range, its output can be adapted flexibly, the log boiler will not get soiled and must not be kept to temperature by the pellet module. This assures you of a significantly higher utilisation level and brings savings of 15 % and more. As a result, the BMK Vario-P is the perfect choice for customers who want to heat constantly, or for longer periods at affordable prices using pellets and are prepared to add logs as and when required.HIGHLY EFFICIENT LOG MODULE

The high grade log module with stainless steel hopper is suitable for logs up to 0.5 m in length. Its innovative wood gasification technology lets it operate with high efficiency and extremely low emissions. This results in particularly low heating bills, even with high flow temperatures and when it gets really cold. Logs are amongst the most favourably priced and crisis-resistant fuels available.EFFICIENCY AND CLEANLINESS

The unique combustion concept with lateral rotating combustion chamber is clearly superior to conventional combustion systems when it comes to efficiency, flexibility and the protection of the environment. It enables very long periods of extremely clean combustion.HIGHEST CONVENIENCE

In low temperature mode, the pellet module delivers heat to the heating circuits with high efficiency. Whilst heating up the log module, the Vario system automatically changes over into log mode and then back again. Complicated changeover procedures are a thing of the past. The large hopper, automatic ignition (option), the separating out of ash into an ash box and semi-automatic cleaning increase your heating convenience further when heating with logs.INTELLIGENT CONTROLLER

The innovative touchscreen controller offers the highest operating convenience. The clear user prompts take you exactly where you want to be in just a few steps. This enables straightforward control and fast servicing.HIGH GRADE COMPONENTS

To safeguard unsurpassed reliability, our Vario systems are made exclusively in Austria, from high grade materials. The robust ones

HYBRID

2.5 TO 16 KW-

PIONEERING PELLET HYBRID HEAT PUMP

Our pioneering Pellet:Hybrid heat pump combines the benefits of an economical heat pump with those offered by a highly efficient pellet heating system. This compact system is suitable for new build and modernisation projects alike. It offers tremendous flexibility and optimum heating convenience.Benefits

PELLET INDOOR UNIT

Highly efficient pellet heating systems are unbeatable when outside temperatures fall below zero and higher heating circuit temperatures are called for. The low temperature technology applied scores highly in terms of its seasonal performance factor and consumption, clean combustion and dust separation, as well as maintenance costs and length of service life. The very clean rotating combustion lets the indoor pellet unit operate with CO2 neutrality, giving users heat that is 100% environmentally responsible.AIR SOURCE OUTDOOR UNIT

When outside temperatures are higher and heating circuits call for lower temperatures, operation with an air source heat pump is both affordable and convenient. The Guntamatic outdoor unit operates very quietly with low inverter output and an extremely high seasonal performance factor (average COP higher than 4).INNOVATIVE HYBRID SYSTEM

When it gets really cold and high heating circuit temperatures are called for, conventional heat pumps turn into veritable electric heaters. This innovative hybrid system avoids this risk by changing over automatically to pellet mode when these conditions arise. This demand-dependent changeover to the most appropriate heating method, plus excellent levels of operating and cleaning convenience make this heating solution truly pioneering.HEATING WITHOUT ENERGY TIES

Energy costs, consumption and availability are issues that will continue to increase in importance in the years ahead. This hybrid system already offers persuasive solutions and makes feasible standalone values of up to 90 % and higher, even in older buildings. To achieve this, an energy supply system for a private home requires a photovoltaic system with the ability to utilise generated power on site (EV), a small battery storage unit and the utilisation of residual power by the air source heat pump, combined with a highly efficient pellet heating system for cold and sunless winter days.SMALLEST STORAGE ROOM

As a result of the combined operation, the required pellet store is relatively small (example: 1x1.5 m). Depending on preference, a high grade steel/mesh hopper or sloping floor storage room with discharge screw conveyor are available to store enough fuel for one or two years. Guntamatic storage systems are extremely reliable, require little maintenance and operate on a fail-safe basis.PIONEERING OPERATING CONCEPT

The specifically developed hybrid management system from Guntamatic selects the most favourably priced or the most efficient operation, depending on selected preference. Highly advanced control technology enables you to regulate your interior climate, the system and storage room functions automatically. Individual adjustments can be made easily via the ergonomic touchscreen controller, a room control station (if installed)

PRO FLEX INDUSTRIAL SYSTEM

175 TO 1000 KW-

LARGE PELLET SYSTEM

The PRO FLEX offers highly economical and futureproof heating convenience using pellets and woodchips. Their modular design enables these systems to be offered with an output range of up to 1000 kW, and makes them suitable for a wide variety of applications.

Benefits

HIGHLY EFFICIENT COMBUSTION

Fuel is gasified with a staged supply of primary air under ideal ember bed temperature conditions. The amount of combustion air and fuel charge is regulated by means of a lambda probe, so that the system achieves an optimum level of efficiency. The released combustion gases are cleanly converted into thermal energy by mixing them with secondary air in a large rotating combustion zone at a temperature of around 1300 °C. The well proven cupola design enables a perfect burnout and long dwell times.HIGHEST OPERATIONAL RELIABILITY

Operational reliability is greatly improved by the multi-stage modular design, particularly where several larger buildings need to be heated. Should one of the boilers connected in series fail, the remaining boilers simply continue to operate. This protects against total failure, which is of particular importance to municipal or commercial users.MODULAR DESIGN

Every section of the PRO industrial system can be handled by means of a pallet truck. Its assembly is perfectly straightforward. There are no long-winded assembly and installation steps to take.STRAIGHTFORWARD OPERATION

Operating the PRO industrial system is especially easy thanks to the well thought-out and user friendly touchscreen interface. All settings and scans of system data can be made in just a few steps.FLEXIBLE APPLICATION OPTIONS

Apart from their safety and economy, PRO systems offer further advantages, such as their flexible discharge solutions and the option of heating with pellets and woodchips.

LOG HEATING SYSTEM

-

THE GUNTAMATIC LOG HEATER MADE OF STAINLESS STEEL STANDS FOR A PRACTICAL, SIMPLE AND CLEAN WOOD BURNING THROUGH MAXIMUM TEMPERATURES IN THE EMBER BED.

Our wood gasification heaters achieve lowest emissions and very high efficiencies. They are ideal if you have wood and want to heat independently and economically. After all, wood chips remain the cheapest source of energy in comparison to the cost of fuel. The solid construction of the firewood heater promises a long life. The Guntamatic concepts for firewood heating combine sophisticated technologies with intelligent control solutions.

- high efficiency

- lowest emissions

- long burning time

- practical and comfortable

- easy to install

- low operating costs

- durable and reliable

- log heaters are recoverable

BIOSMART

14/22 KW-

PREMIUM WOOD GASIFICATION BOILER FOR LOGS UP TO 0.3 M LONG

Highly economical GUNTAMATIC wood gasification boilers for logs up to 0.3 m long are equipped with an innovative combustion concept and represent efficiency of the highest level.

Thanks to their robust stainless steel construction and their rotating combustion chamber, Biosmart wood boilers offer a particularly long service life.

Benefits

EXTREMELY ECONOMICAL

Advanced combustion technology enables BIOSMART boilers to operate with the utmost efficiency and environmental responsibility. In addition, innovative functions and well thought-out details make them especially convenient, too.OPTIMUM EFFICIENCY, MINIMUM EMISSIONS

Our unique combustion concept, with rotating combustion chamber, is clearly superior to conventional combustion systems when it comes to efficiency, flexibility and protection of the environment. It enables very long periods of extremely clean combustion.CONVENIENT SOLUTIONS

A convenient 100 l hopper, semi-automatic heat exchanger cleaning (option) and buffer cylinder with re-charge indicator make BIOSMART heating systems highly practical.AUTOMATIC IGNITION

The automatic ignition (option) with time switch ensures that your home is always warm when you want it to be. You simply need to set the required time and minimum temperature of the buffer cylinder. The Biosmart will start automatically and heat up your home.INTELLIGENT TOUCHSCREEN CONTROLLER

The innovative touchscreen controller offers the highest operating convenience. The clear user prompts take you exactly where you want to be in just a few steps. This enables straightforward control and speedy servicing.LOW OPERATING COSTS

Extremely high efficiency with low energy consumption make the BIOSMART very economical. High grade manufacture and clear appliance concept also ensure low service and maintenance costs.

BMK

20/30/40/50 KW-

WOOD GASIFICATION BOILER FOR LOGS UP TO 0.5 M LONG

Our BMK stainless steel biomass converter is the perfect solution for all those who seek an innovative log heating system with rock-solid workmanship. It is extremely user friendly, robust and convenient to use. It sets new benchmarks when it comes to efficiency and reliability.

Benefits

THE NEW GENERATION OF WOOD HEATING SYSTEMS

The BMK is one of the most innovative and convenient wood gasification systems on the market. In many respects, it matches the convenience offered even by gas and electric heating systems. This applies to operation as much as to layout, cleaning and servicing.OPTIMUM EFFICIENCY, MINIMUM EMISSIONS

Our unique combustion concept with lateral rotating combustion chamber is clearly superior to conventional combustion systems when it comes to efficiency, flexibility and the protection of the environment. It enables very long periods of extremely clean combustion.CONVENIENT ASH REMOVAL

The BMK separates combustible gases and ash residues at an early stage. Consequently, the ash can be removed from the large ash box located at the front.AUTOMATIC IGNITION

The automatic ignition (option) with time switch ensures that your home is always warm when you want it to be. You simply need to set the required time and minimum temperature of the buffer cylinder. The BMK will start automatically and heat up your home.INTELLIGENT CONTROLLER

The innovative touchscreen controller offers the highest operating convenience. The clear user prompts take you exactly where you want to be in just a few steps. This enables straightforward control and fast servicing.LOW OPERATING COSTS

Thanks to its extremely high efficiency and low energy consumption, the BMK is very economical. High grade manufacture and clear appliance concept also ensure low service and maintenance costs.

BIO VARIO

13/17 KW-

PELLETS/LOGS COMBI SYSTEM

The VARIO combines the benefits of the innovative and highly efficient BIOSMART biomass converter with the convenience and economy of the BIOSTAR pellet system. This means the highest level of flexibility, optimum economy and perfect convenience.

Benefits

PELLET MODULE

Compared to previous pellet/log combi systems (log boiler must be held constantly at a high temperature by the pellet module; no low temperature capability, limited output adjustment, some soiling of the log appliance; ...) the two special high grade appliances that form the Guntamatic VARIO system operate in perfect harmony. The result a significantly higher utilisation level or fuel cost savings of over 15 % particularly in pellet operation. For customers who want to heat with pellets over longer periods or consistently wish to lower their spending, there is really only one choice the VARIO. (For customers who prefer logs and need automatic operation only occasionally, we would recommend our hybrid versions ...)LOG MODULE

The innovative wood gasification technology from GUNTAMATIC enables the log module to operate with high efficiency and extremely low emissions. This results in particularly low heating bills, even with high flow temperatures and when it gets really cold. Logs are amongst the most favourably priced and crisis-resistant fuels available. The high grade log module, with solid cast iron lining, is suitable for logs up to 0.3 m in length.OPTIMUM EFFICIENCY, MINIMUM EMISSIONS

Our unique combustion concept with lateral rotating combustion chamber is clearly superior to conventional combustion systems when it comes to efficiency, flexibility and the protection of the environment. It enables very long periods of extremely clean combustion.HIGHEST CONVENIENCE

When in low temperature mode, the pellet module delivers heat to the heating circuits with high efficiency and matched to the actual demand. By heating up the log module, the Vario system automatically changes into log mode and back again. Complicated changeover effort is therefore avoided. From chore to pleasure the large hopper, optional automatic ignition, the separating out of ash into an ash box and semi-automatic cleaning have transformed the experience of heating with logs.INTELLIGENT CONTROLLER

The innovative touchscreen controller offers the highest operating convenience. The clear user prompts take you exactly where you want to be in just a few steps. This enables straightforward control and fast servicing. HIGH GRADE COMPONENTS To safeguard unsurpassed reliability, our Vario systems are made exclusively in Austria, from high grade materials.

Extraordinary durability and the lowest maintenance costs are ensured through robust silicon combustion chambers, a particularly solid cast iron lined hopper, induction fans cooled internally by air, robust lambda probes, high grade geared units, ignition fans and air

BMK VARIO-P

20/30 KW-

LOG/PELLET COMBI SYSTEM

The BMK Vario-P combines the benefits offered by the innovative and highly efficient BMK biomass converter with the convenience and economy of the BIOSTAR pellet system. This means the highest level of flexibility, optimum economy and perfect convenience.

Benefits

ECONOMICAL PELLET MODULE

The clever combination of the standalone log and pellet modules offers significant benefits compared with conventional systems: the system can be operated in the low temperature range, its output can be adapted flexibly, the log boiler will not get soiled and must not be kept to temperature by the pellet module. This assures you of a significantly higher utilisation level and brings savings of 15 % and more. As a result, the BMK Vario-P is the perfect choice for customers who want to heat constantly, or for longer periods at affordable prices using pellets and are prepared to add logs as and when required.HIGHLY EFFICIENT LOG MODULE

The high grade log module with stainless steel hopper is suitable for logs up to 0.5 m in length. Its innovative wood gasification technology lets it operate with high efficiency and extremely low emissions. This results in particularly low heating bills, even with high flow temperatures and when it gets really cold. Logs are amongst the most favourably priced and crisis-resistant fuels available.EFFICIENCY AND CLEANLINESS

The unique combustion concept with lateral rotating combustion chamber is clearly superior to conventional combustion systems when it comes to efficiency, flexibility and the protection of the environment. It enables very long periods of extremely clean combustion.HIGHEST CONVENIENCE

In low temperature mode, the pellet module delivers heat to the heating circuits with high efficiency. Whilst heating up the log module, the Vario system automatically changes over into log mode and then back again. Complicated changeover procedures are a thing of the past. The large hopper, automatic ignition (option), the separating out of ash into an ash box and semi-automatic cleaning increase your heating convenience further when heating with logs.INTELLIGENT CONTROLLER

The innovative touchscreen controller offers the highest operating convenience. The clear user prompts take you exactly where you want to be in just a few steps. This enables straightforward control and fast servicing.HIGH GRADE COMPONENTS

To safeguard unsurpassed reliability, our Vario systems are made exclusively in Austria, from high grade materials. The robust ones

BIO-HYBRID

14/22 KW-

CONVENIENT LOG HYBRID HEAT PUMP

The innovative combination of a highly efficient log heating system and advanced heat pump technology offers optimum heating convenience with first rate levels of economy.

Benefits

LOG INDOOR UNIT

The high grade log module, with solid cast iron lining, is suitable for logs up to 0.3 m in length. Its innovative wood gasification technology lets it operate with high efficiency and extremely low emissions. This results in particularly low heating bills, even with high flow temperatures and when it gets really cold. Logs are amongst the most favourably priced and crisis-resistant fuels available.AIR SOURCE OUTDOOR UNIT

The combination with the air source outdoor unit makes heating with logs even more attractive. The automatic selection between economical log operation when temperatures drop and utilising the air source heat pump in milder weather, when lower flow temperatures are required, makes this system particularly efficient. The automatic holiday mode, dual mode fail-safe assurance and the utilisation of power generated on site offer a unique level of log heating convenience previously unseen.EFFICIENCY AND CLEANLINESS

The unique combustion concept, with rotating combustion chamber, is clearly superior to conventional combustion systems when it comes to efficiency, flexibility and protection of the environment. It enables very long periods of extremely clean combustion.INCREDIBLE CONVENIENCE

Optional automatic ignition offers the highest level of convenience in log burning mode not forgetting the highly useful ash separation/ash box, and robust, semi-automatic, cleaning operation. Logs can be ignited subject to time and temperature. The ignition can also be used to provide a useful heat-up function. Naturally, operation can also be continued automatically by means of the air source outdoor unit.HEATING WITHOUT ENERGY TIES

Energy costs, consumption and availability are issues that will continue to increase in importance in the years ahead. This hybrid system already offers persuasive solutions and makes feasible standalone values of up to 90 % and higher, even in older buildings. To achieve this, an energy supply system for a private home requires a photovoltaic system with the ability to utilise generated power on site (EV), a small battery storage unit and the utilisation of residual power by the air source heat pump, combined with a highly efficient pellet heating system for cold and sunless winter days.HIGH GRADE COMPONENTS

To safeguard unsurpassed reliability, our Biosmart systems are made exclusively in Austria, from high grade materials. The perfectly made cast iron lined hopper, the temperature resistant fireclay and ceramic combustion chamber, the internally air cooled induction fan, the robust lambda probe and the high grade air servomotor achieve previously unattainable longevity and low maintenance costs.

BMK-HYBRID

20/30 KW-

CONVENIENT LOG HYBRID HEAT PUMP

The innovative combination of a highly efficient log heating system and advanced heat pump technology offers you optimum heating convenience with first rate levels of economy.Benefits

LOG INDOOR UNIT The high grade log module with stainless steel hopper is suitable for logs up to 0.5 m in length. Its innovative wood gasification technology lets it operate with high efficiency and extremely low emissions. This results in particularly low heating bills, even with high flow temperatures and when it gets really cold. Logs are amongst the most favourably priced and crisis-resistant fuels available.AIR SOURCE OUTDOOR UNIT

The combination with the air source outdoor unit makes heating with logs even more attractive. The automatic selection between economical log operation when temperatures drop and utilising the air source heat pump in milder weather, when lower flow temperatures are required, makes this system particularly efficient. The automatic holiday mode, dual mode fail-safe assurance and the utilisation of power generated on site offer a unique level of log heating convenience previously unseen.EFFICIENCY AND CLEANLINESS

The unique combustion concept, with lateral rotating combustion chamber, is clearly superior to conventional combustion systems when it comes to efficiency, flexibility and protection of the environment. It enables very long periods of extremely clean combustion.INCREDIBLE CONVENIENCE

Optional automatic ignition offers the highest level of convenience in log burning mode not forgetting the highly useful ash separation/ash box, and robust, semi-automatic, cleaning operation. Logs can be ignited subject to time and temperature. The ignition can also be used to provide a useful heat-up function. Naturally, operation can also be continued automatically by means of the air source outdoor unit.HEATING WITHOUT ENERGY TIES

Energy costs, consumption and availability are issues that will continue to increase in importance in the years ahead. This hybrid system already offers persuasive solutions and makes feasible standalone values of up to 90 % and higher, even in older buildings. To achieve this, an energy supply system for a private home requires a photovoltaic system with the ability to utilise generated power on site (EV), a small battery storage unit and the utilisation of residual power by the air source heat pump, combined with a highly efficient pellet heating system for cold and sunless winter days.HIGH GRADE COMPONENTS

To safeguard unsurpassed reliability, our BMK systems are made exclusively in Austria, from high grade materials. The perfectly made and acid resistant stainless steel hopper, the resilient silicon combustion chamber, the internally air cooled induction fan, the robust lambda probe and the high grade air servomotor achieve previously unattainable longevity and low maintenance costs.

HYBRID HEATING

-

THE GUNTAMATIC HYBRID SYSTEM HAS ALL THE ARGUMENTS ON ITS SIDE. IT PROTECTS THE ENVIRONMENT AND THE CASH REGISTER.

The unique GUNTAMATIC hybrid management has been developed in conjunction with universities, research and testing institutes. It uses the strengths of heat pump, pellet heating, and firewood by choosing the ecologically and economically optimal heating mode. It uses stored pellets and electricity prices as well as individual preferences. In coordination with the outside and flow temperatures, the Smart Control system optimally adjusts the heating systems optimally.

- Choose log security

- Use pellet comfort

- Highly efficient combustion

- Easy operation and intelligent control

- Also as central heating with log fire in the living room

- Maximum security

- High profitability

- Ecologically sensible

- Hybrid heaters are supported with funding

HYBRID

2.5 to 16 kW-

PIONEERING PELLET HYBRID HEAT PUMP

Our pioneering Pellet:Hybrid heat pump combines the benefits of an economical heat pump with those offered by a highly efficient pellet heating system. This compact system is suitable for new build and modernisation projects alike. It offers tremendous flexibility and optimum heating convenience.Benefits

PELLET INDOOR UNIT

Highly efficient pellet heating systems are unbeatable when outside temperatures fall below zero and higher heating circuit temperatures are called for. The low temperature technology applied scores highly in terms of its seasonal performance factor and consumption, clean combustion and dust separation, as well as maintenance costs and length of service life. The very clean rotating combustion lets the indoor pellet unit operate with CO2 neutrality, giving users heat that is 100% environmentally responsible.AIR SOURCE OUTDOOR UNIT

When outside temperatures are higher and heating circuits call for lower temperatures, operation with an air source heat pump is both affordable and convenient. The Guntamatic outdoor unit operates very quietly with low inverter output and an extremely high seasonal performance factor (average COP higher than 4).INNOVATIVE HYBRID SYSTEM

When it gets really cold and high heating circuit temperatures are called for, conventional heat pumps turn into veritable electric heaters. This innovative hybrid system avoids this risk by changing over automatically to pellet mode when these conditions arise. This demand-dependent changeover to the most appropriate heating method, plus excellent levels of operating and cleaning convenience make this heating solution truly pioneering.HEATING WITHOUT ENERGY TIES

Energy costs, consumption and availability are issues that will continue to increase in importance in the years ahead. This hybrid system already offers persuasive solutions and makes feasible standalone values of up to 90 % and higher, even in older buildings. To achieve this, an energy supply system for a private home requires a photovoltaic system with the ability to utilise generated power on site (EV), a small battery storage unit and the utilisation of residual power by the air source heat pump, combined with a highly efficient pellet heating system for cold and sunless winter days.SMALLEST STORAGE ROOM

As a result of the combined operation, the required pellet store is relatively small (example: 1x1.5 m). Depending on preference, a high grade steel/mesh hopper or sloping floor storage room with discharge screw conveyor are available to store enough fuel for one or two years. Guntamatic storage systems are extremely reliable, require little maintenance and operate on a fail-safe basis.PIONEERING OPERATING CONCEPT

The specifically developed hybrid management system from Guntamatic selects the most favourably priced or the most efficient operation, depending on selected preference. Highly advanced control technology enables you to regulate your interior climate, the system and storage room functions automatically. Individual adjustments can be made easily via the ergonomic touchscreen controller, a room control station (if installed)

BIO-HYBRID

14/22 KW-

CONVENIENT LOG HYBRID HEAT PUMP

The innovative combination of a highly efficient log heating system and advanced heat pump technology offers optimum heating convenience with first rate levels of economy.Benefits

LOG INDOOR UNIT

The high grade log module, with solid cast iron lining, is suitable for logs up to 0.3 m in length. Its innovative wood gasification technology lets it operate with high efficiency and extremely low emissions. This results in particularly low heating bills, even with high flow temperatures and when it gets really cold. Logs are amongst the most favourably priced and crisis-resistant fuels available.AIR SOURCE OUTDOOR UNIT

The combination with the air source outdoor unit makes heating with logs even more attractive. The automatic selection between economical log operation when temperatures drop and utilising the air source heat pump in milder weather, when lower flow temperatures are required, makes this system particularly efficient. The automatic holiday mode, dual mode fail-safe assurance and the utilisation of power generated on site offer a unique level of log heating convenience previously unseen.EFFICIENCY AND CLEANLINESS

The unique combustion concept, with rotating combustion chamber, is clearly superior to conventional combustion systems when it comes to efficiency, flexibility and protection of the environment. It enables very long periods of extremely clean combustion.INCREDIBLE CONVENIENCE

Optional automatic ignition offers the highest level of convenience in log burning mode not forgetting the highly useful ash separation/ash box, and robust, semi-automatic, cleaning operation. Logs can be ignited subject to time and temperature. The ignition can also be used to provide a useful heat-up function. Naturally, operation can also be continued automatically by means of the air source outdoor unit.HEATING WITHOUT ENERGY TIES

Energy costs, consumption and availability are issues that will continue to increase in importance in the years ahead. This hybrid system already offers persuasive solutions and makes feasible standalone values of up to 90 % and higher, even in older buildings. To achieve this, an energy supply system for a private home requires a photovoltaic system with the ability to utilise generated power on site (EV), a small battery storage unit and the utilisation of residual power by the air source heat pump, combined with a highly efficient pellet heating system for cold and sunless winter days.HIGH GRADE COMPONENTS

To safeguard unsurpassed reliability, our Biosmart systems are made exclusively in Austria, from high grade materials. The perfectly made cast iron lined hopper, the temperature resistant fireclay and ceramic combustion chamber, the internally air cooled induction fan, the robust lambda probe and the high grade air servomotor achieve previously unattainable longevity and low maintenance costs.

BMK-HYBRID

20/30 KW- CONVENIENT LOG HYBRID HEAT PUMP

The innovative combination of a highly efficient log heating system and advanced heat pump technology offers you optimum heating convenience with first rate levels of economy.Benefits

LOG INDOOR UNIT

The high grade log module with stainless steel hopper is suitable for logs up to 0.5 m in length. Its innovative wood gasification technology lets it operate with high efficiency and extremely low emissions. This results in particularly low heating bills, even with high flow temperatures – and when it gets really cold. Logs are amongst the most favourably priced and crisis-resistant fuels available.AIR SOURCE OUTDOOR UNIT

The combination with the air source outdoor unit makes heating with logs even more attractive. The automatic selection between economical log operation when temperatures drop and utilising the air source heat pump in milder weather, when lower flow temperatures are required, makes this system particularly efficient. The automatic holiday mode, dual mode fail-safe assurance and the utilisation of power generated on site offer a unique level of log heating convenience previously unseen.EFFICIENCY AND CLEANLINESS

The unique combustion concept, with lateral rotating combustion chamber, is clearly superior to conventional combustion systems when it comes to efficiency, flexibility and protection of the environment. It enables very long periods of extremely clean combustion. INCREDIBLE CONVENIENCE

Optional automatic ignition offers the highest level of convenience in log burning mode – not forgetting the highly useful ash separation/ash box, and robust, semi-automatic, cleaning operation. Logs can be ignited subject to time and temperature. The ignition can also be used to provide a useful heat-up function. Naturally, operation can also be continued automatically by means of the air source outdoor unit.HEATING WITHOUT ENERGY TIES

Energy costs, consumption and availability are issues that will continue to increase in importance in the years ahead. This hybrid system already offers persuasive solutions and makes feasible standalone values of up to 90 % and higher, even in older buildings. To achieve this, an energy supply system for a private home requires a photovoltaic system with the ability to utilise generated power on site (EV), a small battery storage unit and the utilisation of residual power by the air source heat pHIGHump, combined with a highly efficient pellet heating system for cold and sunless winter days.GRADE COMPONENTS

To safeguard unsurpassed reliability, our BMK systems are made exclusively in Austria, from high grade materials. The perfectly made and acid resistant stainless steel hopper, the resilient silicon combustion chamber, the internally air cooled induction fan, the robust lambda probe and the high grade air servomotor achieve previously unattainable longevity and low maintenance costs.

WOODCHIP HEATING SYSTEM

-

THE GUNTAMATIC WOOD CHIP HEATING SYSTEMS STAND FOR INTELLIGENT, INDEPENDENT AND FLEXIBLE HEATING.

GUNTAMATIC woodchip heaters have a very high efficiency and work fully automatically, while woodchips are particularly cost-effective as fuel. On request, you can also burn other fuels such as miscanthus or pellets. A big advantage lies in the extremely robust, industrially usable and versatile discharge solutions. The systems are easy to set up, easy to maintain and therefore very reliable.

- Highly efficient combustion

- flexible fuel option

- Industrial step grate technology

- Self-cleaning heat exchanger

- Electronic control

- Easy handling

- Massive, high quality components

- Easy installation

- Wood chip heating systems are eligible

POWERCHIP

20/30/40/50 KW-

WOODCHIP/PFL HEATING SYSTEM WITH STEP GRATE TECHNOLOGY

Our Powerchip heating systems, with step grate technology, effectively combine maximum economy and minimum emissions. Subject to approval and model, these boilers can also be converted to alternative fuels, such as pellets, miscanthus and plant matter.

Benefits

HIGHLY EFFICIENT COMBUSTION

The woodchips are gasified on the step grate, where primary air is supplied, at an ember bed temperature of around 850 °C. The amount of combustion air and fuel charge is regulated by means of a lambda probe, so that the system achieves a level of efficiency of up to 94 %. With the aid of secondary air, the generated combustion gases are cleanly and efficiently converted into energy in a large rotating combustion zone.LOW POWER CONSUMPTION

The pioneering discharge system operates with slow turning motors that consume very little power and develop extremely high torque of up to 1200 Nm. In addition, the progressive screw conveyor incline and the optimised trough geometry ensure the highest operational reliability.ADVANCED TOUCHSCREEN CONTROLLER

Operating POWERCHIP heating systems is particularly easy thanks to the well thought-out and user friendly touchscreen interface. All settings and scans of system data can be made in just a few steps.HIGHEST CLEANING CONVENIENCE

An ash screw conveyor transports the ash from the self-cleaning step grate into an especially large moveable ash box. Dust from the automatic heat exchanger cleaning process is also continuously moved into a separate, easy-to-empty container. The optional automatic vacuum ash discharge into a 200 litre drum is highly convenient.DURABLE QUALITY

In order to ensure that our appliances meet our high quality aspirations and those of our demanding customers, we manufacture them completely and exclusively using the best possible materials in our ultra-modern Austrian factory.

POWERCHIP

75/100 KW-

WOODCHIP HEATING SYSTEM WITH STEP GRATE TECHNOLOGY

Our Powerchip heating systems, with step grate technology, effectively combine maximum economy and minimum emissions. Subject to approval and model, these boilers can also be converted to alternative fuels, such as pellets, miscanthus and plant matter.

Benefits

HIGHLY EFFICIENT COMBUSTION

The woodchips are gasified on the step grate, where primary air is supplied, at an ember bed temperature of around 850 °C. The amount of combustion air and fuel charge is regulated by means of a lambda probe, so that the system achieves a level of efficiency of up to 94 %. With the aid of secondary air, the generated combustion gases are cleanly and efficiently converted into energy in a large rotating combustion zone.LOW POWER CONSUMPTION

The pioneering discharge system operates with slow turning motors that consume very little power and develop extremely high torque of up to 1200 Nm. In addition, the progressive screw conveyor incline and the optimised trough geometry ensure the highest operational reliability.ADVANCED TOUCHSCREEN CONTROLLER

Operating POWERCHIP heating systems is particularly easy thanks to the well thought-out and user friendly touchscreen interface. All settings and scans of system data can be made in just a few steps.HIGHEST CLEANING CONVENIENCE

An ash screw conveyor transports the ash from the self-cleaning step grate into an especially large moveable ash box. Dust from the automatic heat exchanger cleaning process is also continuously moved into a separate, easy-to-empty container. The optional automatic vacuum ash discharge into a 200 litre drum is highly convenient.DURABLE QUALITY

In order to ensure that our appliances meet our high quality aspirations and those of our demanding customers, we manufacture them completely and exclusively using the best possible materials in our ultra-modern Austrian factory.

POWERCHIP

UP TO 400 KW-

WOODCHIP HEATING SYSTEM WITH STEP GRATE TECHNOLOGY

Our Powerchip heating systems, with step grate technology, effectively combine maximum economy and minimum emissions. Subject to approval and model, these boilers can also be converted to alternative fuels, such as pellets, miscanthus and plant matter.

Benefits

HIGHLY EFFICIENT COMBUSTION

The woodchips are gasified on the step grate, where primary air is supplied, at an ember bed temperature of around 850 °C. The amount of combustion air and fuel charge is regulated by means of a lambda probe, so that the system achieves a level of efficiency of up to 94 %. With the aid of secondary air, the generated combustion gases are cleanly and efficiently converted into energy in a large rotating combustion zone.LOW POWER CONSUMPTION

The pioneering discharge system operates with slow turning motors that consume very little power and develop extremely high torque of up to 1200 Nm. In addition, the progressive screw conveyor incline and the optimised trough geometry ensure the highest operational reliability.ADVANCED TOUCHSCREEN CONTROLLER

Operating POWERCHIP heating systems is particularly easy thanks to the well thought-out and user friendly touchscreen interface. All settings and scans of system data can be made in just a few steps.HIGHEST CLEANING CONVENIENCE

An ash screw conveyor transports the ash from the self-cleaning step grate into an especially large moveable ash box. Dust from the automatic heat exchanger cleaning process is also continuously moved into a separate, easy-to-empty container. The optional automatic vacuum ash discharge into a 200 litre drum is highly convenient.DURABLE QUALITY

In order to ensure that our appliances meet our high quality aspirations and those of our demanding customers, we manufacture them completely and exclusively using the best possible materials in our ultra-modern Austrian factory.

PRO INDUSTRIAL SYSTEM

175 to 1000 kW-

LARGE WOODCHIPS SYSTEM

The PRO offers highly economical and futureproof heating convenience using pellets and woodchips. Their modular design enables these systems to be offered with an output range of up to 1000 kW, and makes them suitable for a wide variety of applications.

Benefits

HIGHLY EFFICIENT COMBUSTION

Fuel is gasified with a staged supply of primary air under ideal ember bed temperature conditions. The amount of combustion air and fuel charge is regulated by means of a lambda probe, so that the system achieves an optimum level of efficiency. The released combustion gases are cleanly converted into thermal energy by mixing them with secondary air in a large rotating combustion zone at a temperature of around 1300 °C. The well proven cupola design enables a perfect burnout and long dwell times.HIGHEST OPERATIONAL RELIABILITY

Operational reliability is greatly improved by the multi-stage modular design, particularly where several larger buildings need to be heated. Should one of the boilers connected in series fail, the remaining boilers simply continue to operate. This protects against total failure, which is of particular importance to municipal or commercial users.MODULAR DESIGN

Every section of the PRO industrial system can be handled by means of a pallet truck. Its assembly is perfectly straightforward. There are no long-winded assembly and installation steps to take.STRAIGHTFORWARD OPERATION Operating the PRO industrial system is especially easy thanks to the well thought-out and user friendly touchscreen interface. All settings and scans of system data can be made in just a few steps.

FLEXIBLE APPLICATION OPTIONS

Apart from their safety and economy, PRO systems offer further advantages, such as their flexible discharge solutions and the option of heating with pellets and woodchips.

HEATING SYSTEM FOR PLANT-BASED FUELS

-

THE ENERGY GRAIN PLANT HEATER HAS AN EXCELLENT CALORIFIC VALUE THANKS TO A SPECIAL COMBUSTION PROGRAM.

No matter what kind of building you want to heat - a private building or a small local heating network - the Powercorn plants offer the right solution by means of a highly efficient firing concept. The energy grain heater has the proven stair grate technology and enables a slag-free combustion of free-flowing fuels. A specially developed stainless steel lining and a chlorine separation make this plant heating particularly safe. Powercorn plants can be tuned for operation with wood pellets, energy grain (triticale and barley) and free-flowing miscanthus or agropellets.

- Industrial step grate technology

- Highly efficient combustion

- Multi-level security concept

- Easy operation and intelligent control

- Minimal cleaning effort

- High efficiency

- Versatile applicability

- Plant heaters are eligible

POWERCHIP

20/30/40/50 KW-

WOODCHIP/PFL HEATING SYSTEM WITH STEP GRATE TECHNOLOGY

Our Powerchip heating systems, with step grate technology, effectively combine maximum economy and minimum emissions. Subject to approval and model, these boilers can also be converted to alternative fuels, such as pellets, miscanthus and plant matter.

Benefits

HIGHLY EFFICIENT COMBUSTION

The woodchips are gasified on the step grate, where primary air is supplied, at an ember bed temperature of around 850 °C. The amount of combustion air and fuel charge is regulated by means of a lambda probe, so that the system achieves a level of efficiency of up to 94 %. With the aid of secondary air, the generated combustion gases are cleanly and efficiently converted into energy in a large rotating combustion zone.LOW POWER CONSUMPTION

The pioneering discharge system operates with slow turning motors that consume very little power and develop extremely high torque of up to 1200 Nm. In addition, the progressive screw conveyor incline and the optimised trough geometry ensure the highest operational reliability.ADVANCED TOUCHSCREEN CONTROLLER

Operating POWERCHIP heating systems is particularly easy thanks to the well thought-out and user friendly touchscreen interface. All settings and scans of system data can be made in just a few steps.HIGHEST CLEANING CONVENIENCE

An ash screw conveyor transports the ash from the self-cleaning step grate into an especially large moveable ash box. Dust from the automatic heat exchanger cleaning process is also continuously moved into a separate, easy-to-empty container. The optional automatic vacuum ash discharge into a 200 litre drum is highly convenient.DURABLE QUALITY

In order to ensure that our appliances meet our high quality aspirations and those of our demanding customers, we manufacture them completely and exclusively using the best possible materials in our ultra-modern Austrian factory.

POWERCHIP

75/100 KW-

WOODCHIP HEATING SYSTEM WITH STEP GRATE TECHNOLOGY

Our Powerchip heating systems, with step grate technology, effectively combine maximum economy and minimum emissions. Subject to approval and model, these boilers can also be converted to alternative fuels, such as pellets, miscanthus and plant matter.

Benefits

HIGHLY EFFICIENT COMBUSTION

The woodchips are gasified on the step grate, where primary air is supplied, at an ember bed temperature of around 850 °C. The amount of combustion air and fuel charge is regulated by means of a lambda probe, so that the system achieves a level of efficiency of up to 94 %. With the aid of secondary air, the generated combustion gases are cleanly and efficiently converted into energy in a large rotating combustion zone.LOW POWER CONSUMPTION

The pioneering discharge system operates with slow turning motors that consume very little power and develop extremely high torque of up to 1200 Nm. In addition, the progressive screw conveyor incline and the optimised trough geometry ensure the highest operational reliability.ADVANCED TOUCHSCREEN CONTROLLER

Operating POWERCHIP heating systems is particularly easy thanks to the well thought-out and user friendly touchscreen interface. All settings and scans of system data can be made in just a few steps.HIGHEST CLEANING CONVENIENCE

An ash screw conveyor transports the ash from the self-cleaning step grate into an especially large moveable ash box. Dust from the automatic heat exchanger cleaning process is also continuously moved into a separate, easy-to-empty container. The optional automatic vacuum ash discharge into a 200 litre drum is highly convenient.DURABLE QUALITY

In order to ensure that our appliances meet our high quality aspirations and those of our demanding customers, we manufacture them completely and exclusively using the best possible materials in our ultra-modern Austrian factory.

POWERCHIP

UP TO 400 KW-

WOODCHIP HEATING SYSTEM WITH STEP GRATE TECHNOLOGY

Our Powerchip heating systems, with step grate technology, effectively combine maximum economy and minimum emissions. Subject to approval and model, these boilers can also be converted to alternative fuels, such as pellets, miscanthus and plant matter.

Benefits

HIGHLY EFFICIENT COMBUSTION

The woodchips are gasified on the step grate, where primary air is supplied, at an ember bed temperature of around 850 °C. The amount of combustion air and fuel charge is regulated by means of a lambda probe, so that the system achieves a level of efficiency of up to 94 %. With the aid of secondary air, the generated combustion gases are cleanly and efficiently converted into energy in a large rotating combustion zone.LOW POWER CONSUMPTION

The pioneering discharge system operates with slow turning motors that consume very little power and develop extremely high torque of up to 1200 Nm. In addition, the progressive screw conveyor incline and the optimised trough geometry ensure the highest operational reliability.ADVANCED TOUCHSCREEN CONTROLLER

Operating POWERCHIP heating systems is particularly easy thanks to the well thought-out and user friendly touchscreen interface. All settings and scans of system data can be made in just a few steps.HIGHEST CLEANING CONVENIENCE

An ash screw conveyor transports the ash from the self-cleaning step grate into an especially large moveable ash box. Dust from the automatic heat exchanger cleaning process is also continuously moved into a separate, easy-to-empty container. The optional automatic vacuum ash discharge into a 200 litre drum is highly convenient.DURABLE QUALITY

In order to ensure that our appliances meet our high quality aspirations and those of our demanding customers, we manufacture them completely and exclusively using the best possible materials in our ultra-modern Austrian factory.

POWERCORN

30/50 KW-

INDUSTRIAL STEP GRATE TECHNOLOGY

Our POWERCORN systems are as convenient as they are highly efficient and offer optimum economy with heating output from 30 to 75 kW. Industrial stepped grate technology enables these systems to combust free flowing fuels without generating slag.Benefits

ECOLOGICALLY SOUND ECONOMY Our Powercorn heating systems, with industrial step grate technology, combine maximum economy with minimum emissions. These systems can operate with wood pellets and also with energy grain (e.g. triticale and barley), as well as free flowing miscanthus or agri pellets.HIGHLY EFFICIENT COMBUSTION

Fuel is gasified on the industrial step grate, where primary air is supplied, at a regulated ember bed temperature of around 800 °C. The amount of combustion air and fuel charge is regulated by means of a lambda probe, so that the system achieves a level of efficiency of up to 94 %. With the aid of secondary air, the generated combustion gases are cleanly and efficiently converted into energy in a large rotating combustion zone.CLEANING HAS NEVER BEEN EASIER

Where conventional heating systems still require regular cleaning, the Powercorn system cleans the heat exchanger as well as the step grate (with the exception of general cleaning) automatically. Large ash boxes reduce the remaining effort to a minimum.PERFECT STORAGE

Guntamatic storage systems operate with suction discharge and screw conveyor dosing, giving them leading operational reliability and durability. When the fuel is completely used up, there is no need for the annual storage room cleaning. Depending on preference, a high grade steel/mesh hopper or sloping floor storage room with discharge screw conveyor are available.PIONEERING, STRAIGHTFORWARD OPERATING CONCEPT:

Fully automatic control of appliance and storage room functions, as well as regulation of the ambient climate, utilising the most advanced control technology. Individual adjustments can be made easily via the ergonomic touchscreen controller, a room control station (if installed) or an app on a smartphone.DURABLE QUALITY

In order to ensure that our appliances meet our high quality aspirations and those of our demanding customers, we manufacture them completely and exclusively using the best possible materials in our ultra-modern Austrian factory.

POWERCORN

75 KW-

INDUSTRIAL STEP GRATE TECHNOLOGY

Our POWERCORN systems are as convenient as they are highly efficient and offer optimum economy with heating output from 30 to 75 kW. Industrial stepped grate technology enables these systems to combust free flowing fuels without generating slag.

Benefits

ECOLOGICALLY SOUND ECONOMY

Our Powercorn heating systems, with industrial step grate technology, combine maximum economy with minimum emissions. These systems can operate with wood pellets and also with energy grain (e.g. triticale and barley), as well as free flowing miscanthus or agri pellets.HIGHLY EFFICIENT COMBUSTION Fuel is gasified on the industrial step grate, where primary air is supplied, at a regulated ember bed temperature of around 800 °C. The amount of combustion air and fuel charge is regulated by means of a lambda probe, so that the system achieves a level of efficiency of up to 94 %. With the aid of secondary air, the generated combustion gases are cleanly and efficiently converted into energy in a large rotating combustion zone.

CLEANING HAS NEVER BEEN EASIER Where conventional heating systems still require regular cleaning, the Powercorn system cleans the heat exchanger as well as the step grate (with the exception of general cleaning) automatically. Large ash boxes reduce the remaining effort to a minimum.

PERFECT STORAGE

Guntamatic storage systems operate with suction discharge and screw conveyor dosing, giving them leading operational reliability and durability. When the fuel is completely used up, there is no need for the annual storage room cleaning. Depending on preference, a high grade steel/mesh hopper or sloping floor storage room with discharge screw conveyor are available.PIONEERING, STRAIGHTFORWARD OPERATING CONCEPT:

Fully automatic control of appliance and storage room functions, as well as regulation of the ambient climate, utilising the most advanced control technology. Individual adjustments can be made easily via the ergonomic touchscreen controller, a room control station (if installed) or an app on a smartphone. DURABLE QUALITY In order to ensure that our appliances meet our high quality aspirations and those of our demanding customers, we manufacture them completely and exclusively using the best possible materials in our ultra-modern Austrian factory.

BIG PLANTS

-

HIGHLIGHTED AND WITH A MULTI-STAGE SAFETY CONCEPT, OUR BIG BIOMASS BOILERS ARE THE STANDARD FOR DISTRIC HEATING, BIG- BUILDINGS, COMMUNAL, COMMERCIAL AND INDUSTRIAL

The high quality of workmanship, the safe multi-chamber operation and the multi-level safety concept make our pellet and wood chip plants to highly reliable heaters and meet the strictest safety and environmental requirements with an efficiency of over 94%. Thanks to the modular construction system, the large biomass heating systems are available in a power range up to 1000 kW and can be used flexibly. From the hall heating in the large trade over hotels, schools, kindergarten up to the structure of district heating nets or residential buildings.

- Maximum reliability

- Multi-level security concept

- Highly efficient combustion

- Efficiency over 94%

- Multi operation

- Easy operation and intelligent control

- Flexible use

- Compensates within a short time

PRO FLEX INDUSTRIAL SYSTEM

175 to 1000 kW-

LARGE PELLET SYSTEM

The PRO FLEX offers highly economical and futureproof heating convenience using pellets and woodchips. Their modular design enables these systems to be offered with an output range of up to 1000 kW, and makes them suitable for a wide variety of applications.Benefits

HIGHLY EFFICIENT COMBUSTION

Fuel is gasified with a staged supply of primary air under ideal ember bed temperature conditions. The amount of combustion air and fuel charge is regulated by means of a lambda probe, so that the system achieves an optimum level of efficiency. The released combustion gases are cleanly converted into thermal energy by mixing them with secondary air in a large rotating combustion zone at a temperature of around 1300 °C. The well proven cupola design enables a perfect burnout and long dwell times.HIGHEST OPERATIONAL RELIABILITY

Operational reliability is greatly improved by the multi-stage modular design, particularly where several larger buildings need to be heated. Should one of the boilers connected in series fail, the remaining boilers simply continue to operate. This protects against total failure, which is of particular importance to municipal or commercial users.MODULAR DESIGN

Every section of the PRO industrial system can be handled by means of a pallet truck. Its assembly is perfectly straightforward. There are no long-winded assembly and installation steps to take.STRAIGHTFORWARD OPERATION

Operating the PRO industrial system is especially easy thanks to the well thought-out and user friendly touchscreen interface. All settings and scans of system data can be made in just a few steps.FLEXIBLE APPLICATION OPTIONS

Apart from their safety and economy, PRO systems offer further advantages, such as their flexible discharge solutions and the option of heating with pellets and woodchips.

PRO INDUSTRIAL SYSTEM

175 to 1000 kW-

LARGE WOODCHIPS SYSTEM

The PRO offers highly economical and futureproof heating convenience using pellets and woodchips. Their modular design enables these systems to be offered with an output range of up to 1000 kW, and makes them suitable for a wide variety of applications.Benefits

HIGHLY EFFICIENT COMBUSTION

Fuel is gasified with a staged supply of primary air under ideal ember bed temperature conditions. The amount of combustion air and fuel charge is regulated by means of a lambda probe, so that the system achieves an optimum level of efficiency. The released combustion gases are cleanly converted into thermal energy by mixing them with secondary air in a large rotating combustion zone at a temperature of around 1300 °C. The well proven cupola design enables a perfect burnout and long dwell times.HIGHEST OPERATIONAL RELIABILITY

Operational reliability is greatly improved by the multi-stage modular design, particularly where several larger buildings need to be heated. Should one of the boilers connected in series fail, the remaining boilers simply continue to operate. This protects against total failure, which is of particular importance to municipal or commercial users.MODULAR DESIGN

Every section of the PRO industrial system can be handled by means of a pallet truck. Its assembly is perfectly straightforward. There are no long-winded assembly and installation steps to take.STRAIGHTFORWARD OPERATION

Operating the PRO industrial system is especially easy thanks to the well thought-out and user friendly touchscreen interface. All settings and scans of system data can be made in just a few steps.FLEXIBLE APPLICATION OPTIONS

Apart from their safety and economy, PRO systems offer further advantages, such as their flexible discharge solutions and the option of heating with pellets and woodchips.

Filter

EC FILTER

24/85/250 KW- DRY ELECTRIC FILTER

The EC filter with protected technology is available in various sizes. It is the perfect supplement that makes your biomass heating system even more environmentally responsible. It operates in a two-stage mode: coarse flue gas particles are separated out by the integral cyclone. The electric filter, encased in the immersion pipe of the cyclone, filters the fine dust from the flue gas. The height of the immersion pipe of the cyclone can be adjusted. Consequently, the flue gas can flow through the bypass in certain operating phases. This is particularly necessary during the start-up and non-stationary phases.

BENEFITS AT A GLANCE- The EC filter is suitable for floorstanding and wall mounted installations (except EC filter 250)

- Very low wearing and low maintenance

- Extremely low energy consumption

- Two-stage separation (pre-separation via cyclone; fine dust separation inside the electric filter)

- Highly compact design

- Extremely high level of separation

- Automatic filter cleaning

- Integral bypass circuit

- May be retrofitted (requires a touchscreen controller on the boiler)

Cylinders

-

A BUFFER STORE OR HOT WATER BOILER BY GUNTAMATIC IS PERFECTION AND THUS QUALITY FOR LIFE.

Our buffer storages are the manager of your heat supply with coordinated system hydraulics as stratified storage with shift channel. Thick-walled quality steel and a top foam insulation keep it completely tight. The buffer tanks and system tanks with fresh water station are available in different sizes and with high-performance solar coils. In the case of low-energy and passive houses, if the minimum power consumption can not be guaranteed, the use of a heat storage tank or a water heater is recommended.

- Top quality

- High quality steel

- Optimized flow

- Innovative hot water temperature

- Protection against calcification

- Fast installation

AKKUTHERM

600 TO 2000 LITRE-

BUFFER CYLINDER

Buffer cylinders are made from strong quality steel and are fitted with excellent insulation, made from 120 mm Neopor®/fleece.BENEFITS