wiefferink

Videos

Loading the player ...

- Offer Profile

- Wiefferink has more than 60 years of experience in designing and manufacturing flexible solutions in plastic sheeting, both nationally and internationally.

We are widely active in the environmental and biogas branches. In order to offer maximum quality, we like to keep the entire process in our own hands.

Wiefferink B.V. focuses on processing flexible synthetic materials. We are one of the leading European specialists in manufacturing and marketing storage and covering solutions in flexible foil. Our main strenght lies in the development and innovation of new solutions and products based on customer needs.

Product Portfolio

OUR SOLUTIONS

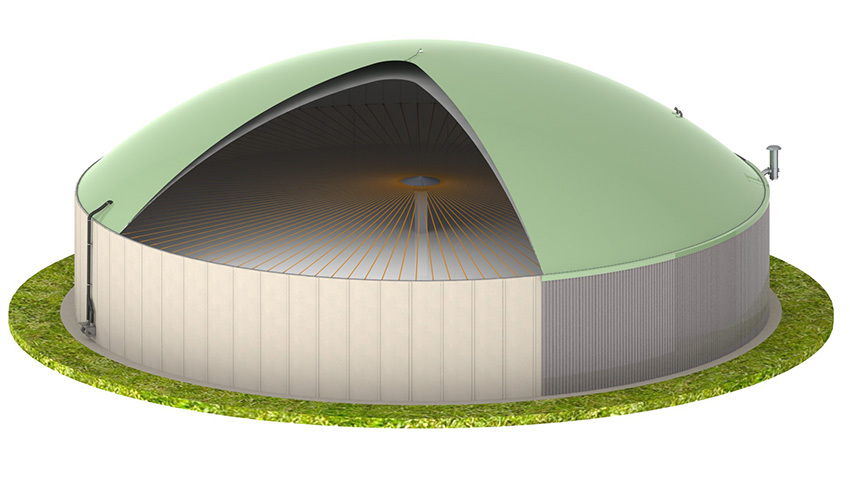

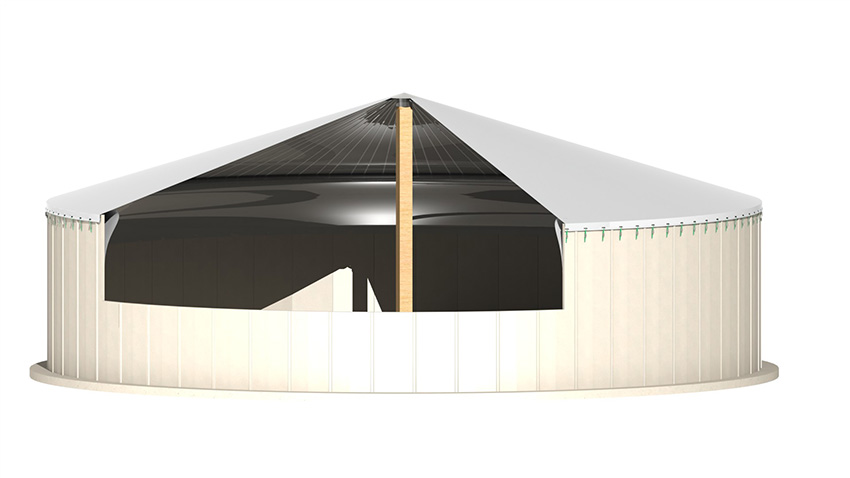

AB Cover

- Durable cover and gasholder

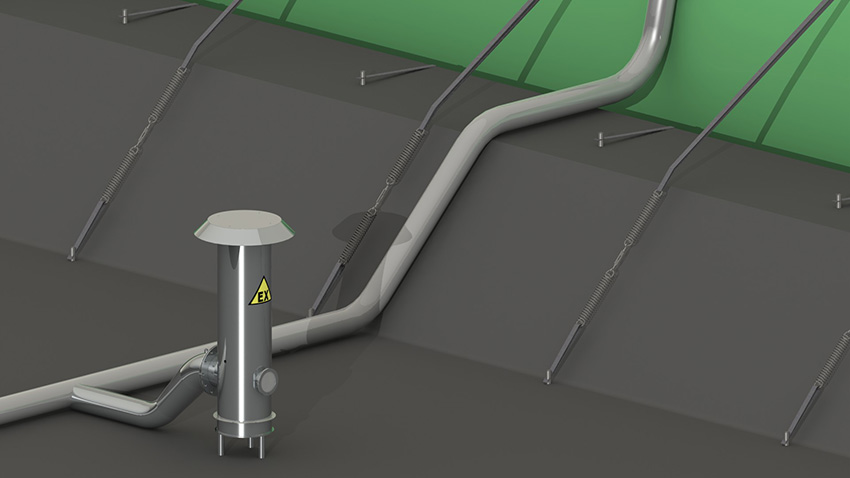

The Air Blown Cover is an innovative double membrane roof with a relatively large, variable gas-storage volume, for biogas installations and other purposes. Its shape and membrane pressure mean that weather influences have little effect on the AB Cover.

Advantages- Gas storage volume at ø 25m is about 230% larger than in conventional designs

- Lower membrane foil has 35% lower gas permeability

- Easy accessibility for maintenance and overhaul activities

- Lower silo load due to hemispherical construction

- Low wind sensitivity and lower chance of snow accumulation due to stable construction

- No condensed, corrosive liquid on the silo walls

The standard version of the AB Cover includes:- An outer membrane of UV-resistant biaxial woven foil

- An inner membrane of chemically resistant biaxial woven foil

- A blower (or blowers) to maintain the pressure on the outer membrane

- Compressed air connections.

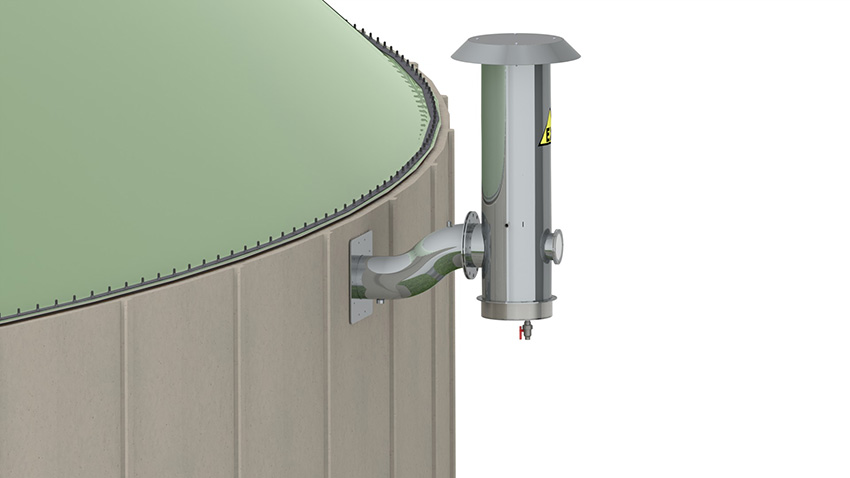

- An over/under-pressure valve

- A manual height gauge, to measure the gas volume

Available options:- ATEX fans

- One or more inspection openings and a viewing window

- Special edge finishes and a height gauge (winter edition)

- An ultrasonic height gauge

- A gas-tightness test

Applications:- Cover and gas collection in biogas installations

- Cover and gas collection in water treatment installations

AB Cover

- Construction with silo isolation and outside lining

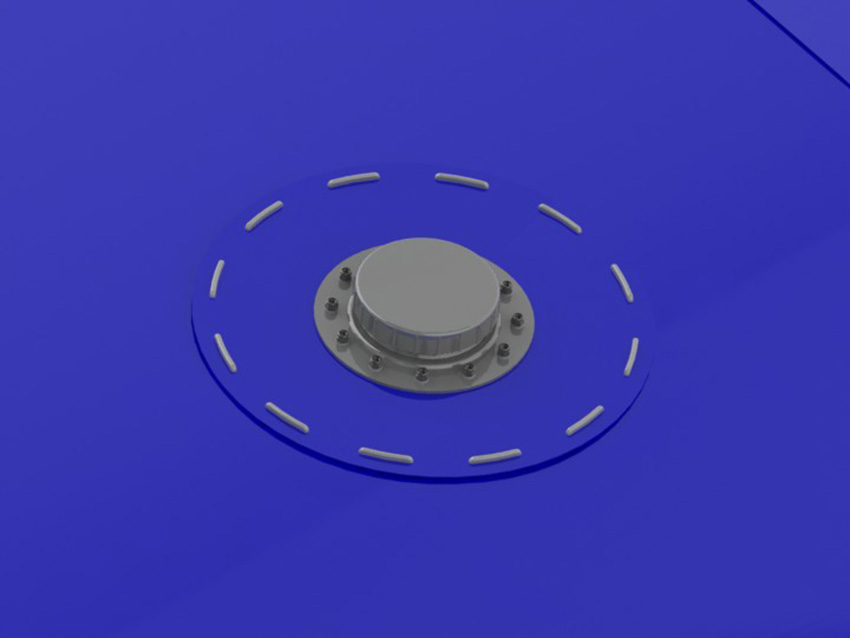

- Over/under-pressure valve

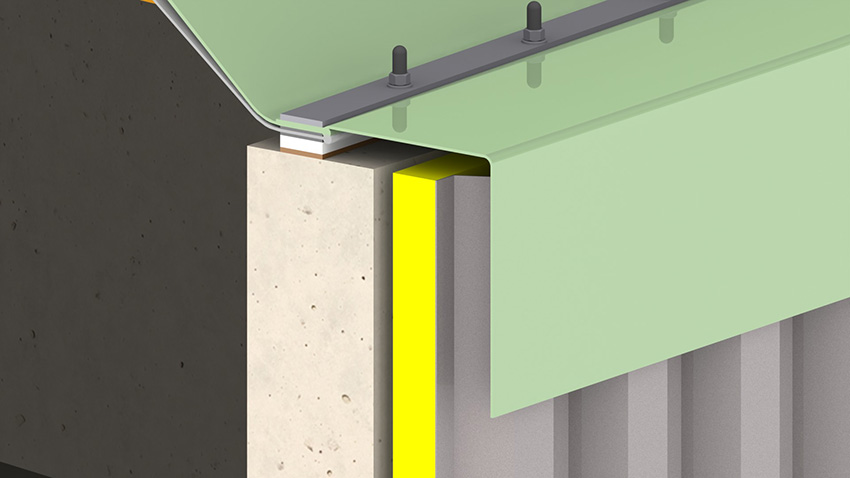

- AB Cover with and without silo isolation

Durable cover and gasholder

Thanks to the high chemical resistance and mechanical strength of the foils, the ab cover satisfies the highest quality standards. New cutting and welding procedures enable the covers to better absorb the biaxial forces exerted on them, and the hemispherical construction ensures low silo wall loading.

The AB Cover is a double membrane cover, in which the outer cover is always pressurised. As a result, rain, snow and wind have little impact on it.

The AB Cover has a huge advantage over silo roofs due to its widely variable gas storage capacity and its ability to function as a cover for a digester or secondary digester, to temporarily collect gas. Of course the AB Cover conforms to all local and European environmental legislation.

CCustomisation for every situation

Each AB Cover is customised to accommodate the client’s wishes and external factors. The cover consists of separately installed upper and lower membranes, which are manufactured from biaxial reinforced fabrics with a high-grade, chemically resistant PVC coating.

Maximally variable gas storage capacity

AB Covers have an enormous gas storage capacity and are available for silos up to a diameter of approximately 40 metres. Operational pressures varying from 0 to 5 mbar and an under-pressure situation up to -1.5 mbar are no problem. Higher pressure can be accommodated on request. The tension straps and net support the upper and lower membranes against under-pressure situations and supports sulphur component flare-outs.

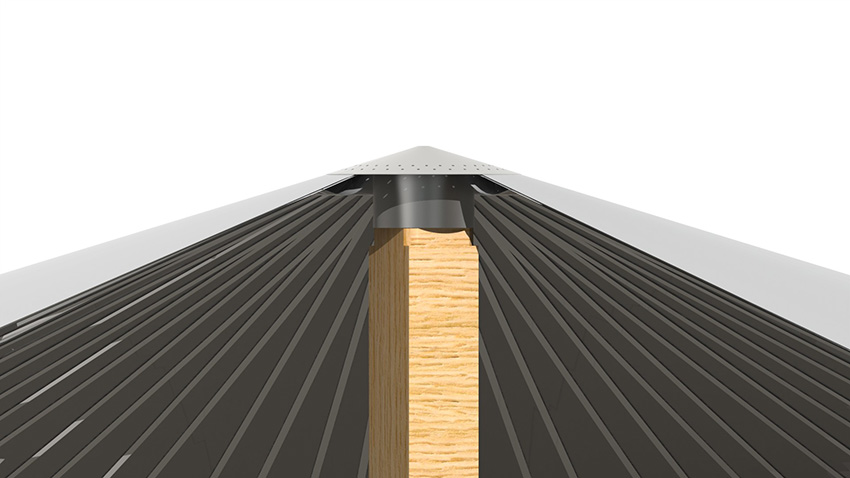

Installation of the AB Cover

The AB Cover is delivered to the building site prefabricated. The support straps (tractive force of 2500 kg and the safety and desulphurisation net (net strength of 400 kg/m2) are installed at an angle. Service openings can also be incorporated as an option. A layer of wooden beams is unnecessary, which saves a considerable amount of money.

Maintenance

The AB Cover must be visually inspected at regular intervals. The glycol level and glycol freezing point must be checked in the over/under-pressure valve.

Silocover

- Durable silo cover

The Silocover is an effective cover that keeps your silo from releasing CO2 It also keeps rainwater out and has an unique, innovative water drainage system. It is an effi cient and economical way to cover various types of silos (concrete, steel and plastic).

Advantages- Durable product with long lifespan

- Fast delivery and installation

- Easily accessible for maintenance and overhaul activities

- Satisfies the most recent environmental directives

- Custom-made for every silo

- Limits odour nuisance and emission of hazardous substances

The standard version of the Silocover includes- A grey cover of flexible foil, reinforced with straps

- A central column

- Inspection opening with rain protection.

- Edge tube system with tension sets for tightening

- Installation

Available options- Extra inspection opening with rain protection

- Gas-tight version

- Green version

Applications- Covering silos.

- The gas-tight Silocover can be used for gas storage from manure or waste flows for biogas installations.

Silocover

- Edge tube system with ratches for tensioning

- Center column

- Silocover on concrete element silo

DURABLE SILO COVER

The silocover by Wiefferink is unique. It has a very long lifespan due to the high-grade materials and innovative production technology used in its manufacture, meaning it is an extremely durable cover for your silo.

In order to contain the emission of hazardous materials, there is a duty to cover stored manure in many European countries. The Silocover is ideal for covering silos. With one or more inspection openings, the mixers often present in the tank can also be maintained. Moreover, rainwater is kept out of a covered silo, so there is no unnecessary volume increase.

In accordance with environmental directives

Every EU member state is currently adjusting its regulations regarding CO2 emissions, making the use of a cover largely necessary or required. This has already been implemented in the Netherlands, Denmark, Belgium, Italy and Eastern European countries, among others.

Our Silocovers satisfy both environmental legislation and construction-related directives.

Absorbs external forces

The Silocover is manufactured from heavy polyester fabric with a synthetic coating on both sides. As a result, it can withstand manure and other aggressive substances and protects against many years of extreme weather conditions. The Silocover is equipped with an unique system of edge pipes and tension sets, which transfer the forces from the cone to the silo circumference. It is also possible to adjust the tension later. An inspection opening provides access to the silo for maintenance. The Silocover is available in a gas-tight and a non-gas-tight version.

KOMO certified

Odour nuisance and the emission of hazardous substances are minimised by the Silocover. The Wiefferink Silocover has a KOMO certificate and satisfies all statutory requirements.

Installation of the Silocover

The Silocover is delivered ready-to-use. For every silo, the roof construction is calculated based on wind and snowfall values for your location.

Maintenance and lifespan

The Silocover requires very little maintenance; after a large snowfall the snow must be removed, and the Silocover must be kept at the right tension.

Gasbuffer

- Flexible gas storage, for both temporary and long-term gas storage

The gas buffer has been developed for the storage of various gas types. A gas buffer also enables the conditioning and mixing of the gas. The use of double membrane technology ensures a flexible gas storage volume. Our wide range of gas buffers provides for an effi cient construction for the most diverse storage criteria and project objectives.

Advantages- Storage of large quantities of gas from 50 to 30,000 cubic metres

- Easily accessible service box

- Project-specific forms and designs possible

- High operating pressures to 5 – 70mbar depending on the design

- Complete installation including blower, gas inlet/outlet, pressure relief valves and sensors

- Short delivery and installation periods

Implementation variants:- Gas buffer Spherical

- 3/4 Gas buffer

- Gas buffer Cylinder

Available options:- Ultrasonic height gauge

- Condensation tank

- Pressure relief valve

- Gas pressure sensor Blower Sight glass

Advantages:- Storage of large quantities of gas from 50 to 30,000 cubic metres

- Easily accessible service box

- Project-specific forms and designs possible

- High operating pressures to 5 – 70mbar depending on the design

- Complete installation including blower, gas inlet/outlet, pressure relief valves and sensors

- Short delivery and installation periods

Gasbuffer

- Flexible gas storage, for both temporary and long-term gas storage

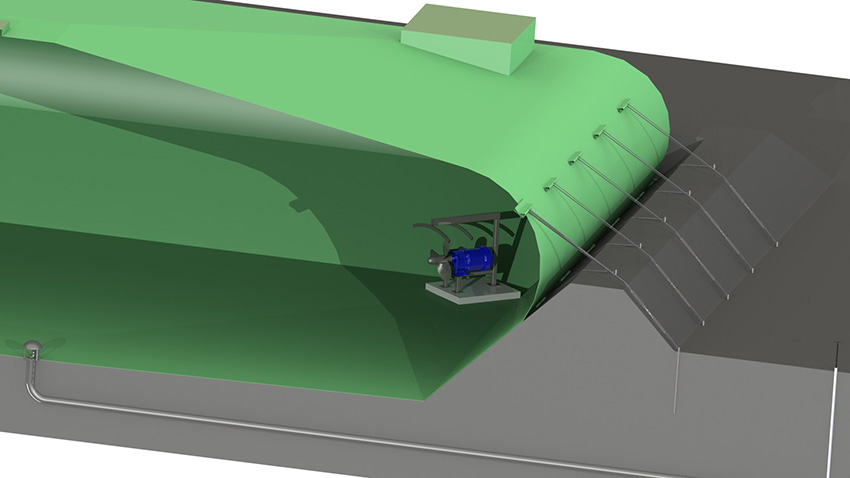

Wiefferink offers the right solution for any type of gas storage. The need for gas storage is projectspecific and usually depends on the gas production and the space available. Gas buffers can be used free-standing, but can also be installed in tanks, containers or buildings.

The type of foil of both the inner and outer membranes is selected depending on the type of gas and the gas storage location. The gas storage systems are suitable for products including (refi ned) biogas, (pure) CO2 and natural gas. A static analysis is a standard part of each project. Depending on the design, a gas buffer can store up to 30,000 cubic metres.

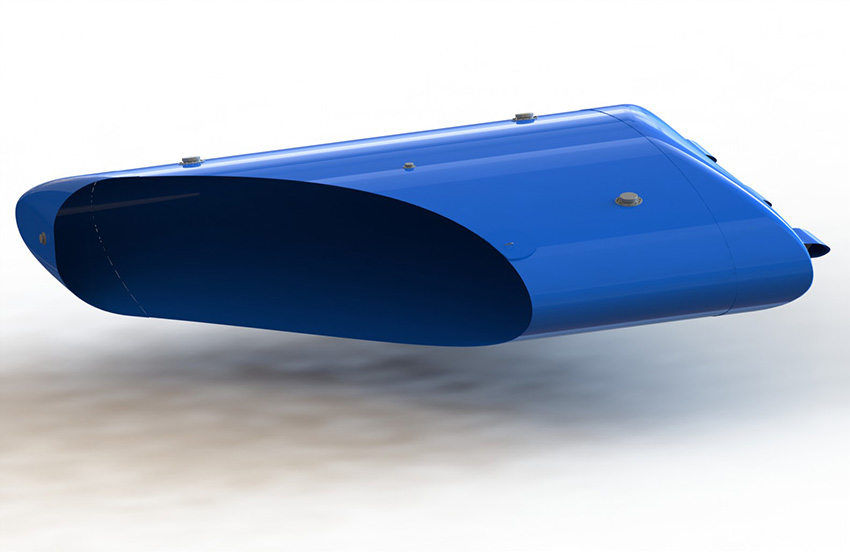

Service-box

The innovative design of the service box enables all connections to be above the ground and consequently simple to make. The blower, control unit and sensors also remain easily accessible during operation, so operating costs are very low. The service box is in 316 stainless steel, meaning weather infl uences have no impact on the technical installation.

High quality, certified materials

The gas buffer is produced on the basis of high quality materials and gas-resistant foils. The welding work is high-frequency or thermal, depending on the foil type. The production method is ISO-certifi ed and carried out by experienced employees so that Wiefferink can guarantee the highest quality.

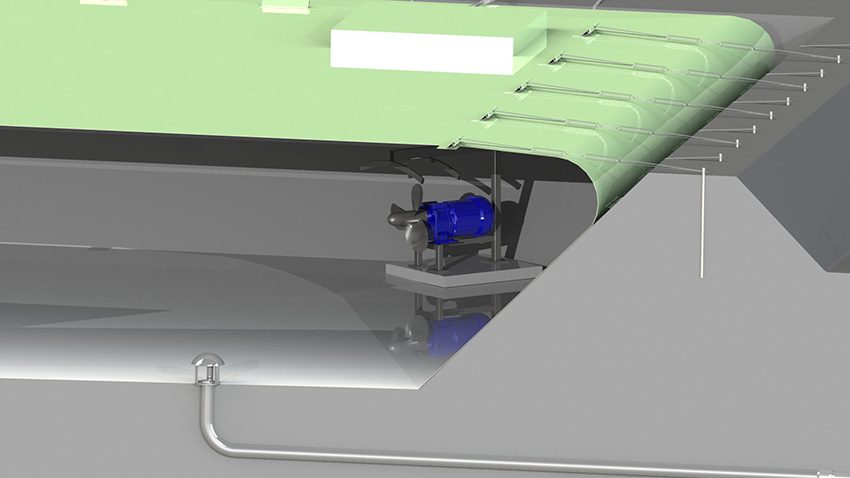

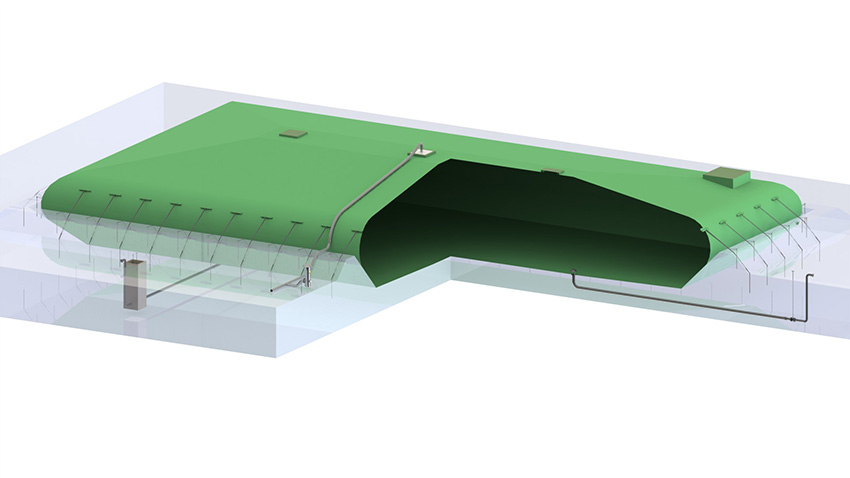

Ecobag

- The Ecobag is a flexible storage for up to 10.500m3. It can be used, for example, as a storage option when spreading manure is not permitted,

or as a buffer for a biogas installation. The Ecobag is a low-cost investment with fast installation and a landscape-friendly appearance.

Advantages- Large, semi-permanent storage that can be installed quickly

- Simple permit process; sometimes notification is sufficient

- Low profile and green colour

- Low investment costs

- Usage lifespan of approx. 10 to 15 years

- No high decontamination costs at end-of-life

The Ecobag includes- Flexible foil with very strong mechanical propertiesand high chemical resistance

- Sufficient fastening points, straps and earth anchors

- Vent pipes

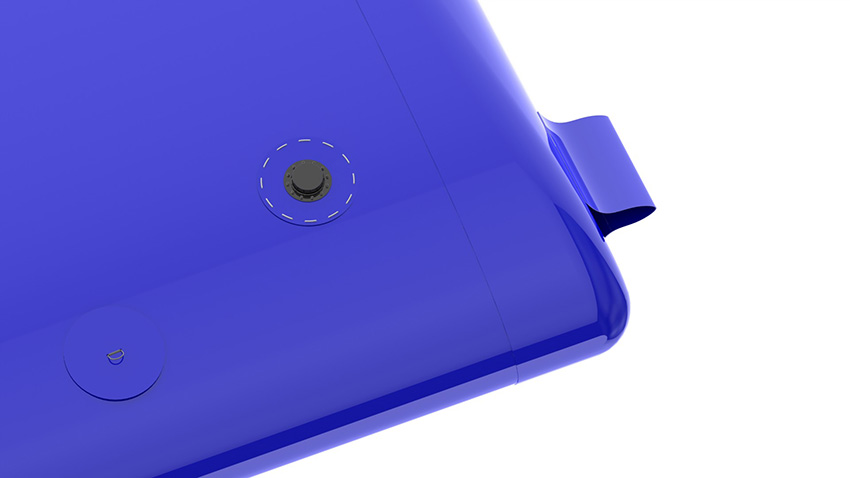

- Inspection opening with safety edge

Available options- Inspection opening with stainless steel hatch

- Different foil colours, strengths and chemical resistances

- Electric mixer

- Power take-off mixer (under certain conditions)

Applications- As storage for manure when spreading is not permitted

- As storage for digestate in combination with a biogas installation

- For storage of waste flows, liquids or fuels (special foil required)

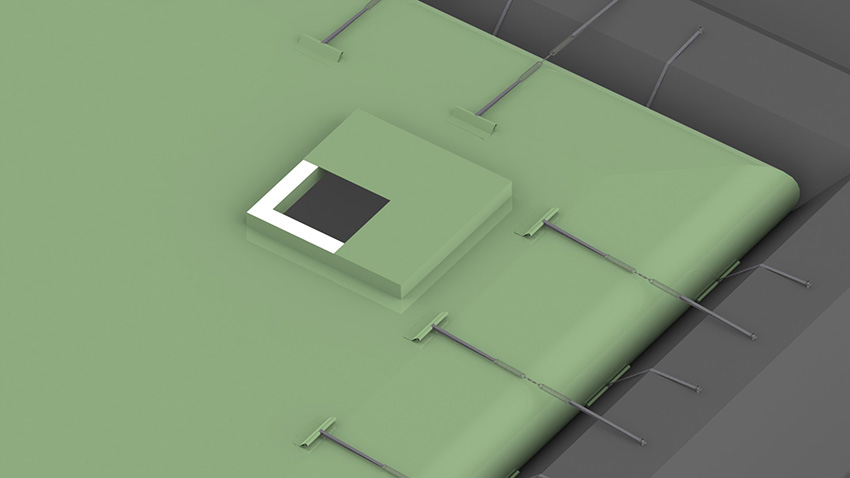

Ecobag

- Electro mixer

- Electro mixer

- Ecobag piping parts

Environmentally friendly storage system for manure, digestate and other liquid waste flows

The ecobag is a system that Wiefferink has developed to store manure, digestate and other liquid waste flows in an odourless manner. The specially developed eco-green colour of the ecobag means it is hardly noticeable in the landscape. The storage system is easy to install, without an architectural construction, on most ground types.

Regulations and standards relating to spreading manure and storing manure and waste flows are becoming ever stricter. In addition, the resistance against large, conspicuous, grey manure bags around villages and cities is also growing, due to the fear of odour nuisance and landscape pollution.

The Wiefferink Ecobag offers a solution to this. Blends into the landscape

The Ecobag can be provided with a specially developed odour filter, with filters the gases released so that there can be no odour nuisance. In order to blend into the landscape, an eco-green colour was developed in addition to grey. No building permit necessary No building permit is required because there is no permanent construction required. Depending on local legislation, however, it may be necessary to apply for an installation permit, though sometimes simply notifying the authorities of the installation is sufficient. Installation of the Ecobag The Ecobag is installed within an earth bank, for which no supporting structure is necessary. In most cases, the Ecobag can simply be placed on the loose ground. The groundwork must satisfy the local standards for installing a manure basin. Wiefferink supplies the drawings for dimension of the groundwork. Before installation, our experts inspect the sizing and the situation at your location, so that we can complete the installation as quickly and effectively as possible, ready to use. Additional options for the Ecobag include the patented odour filter and a mixer to keep the stored manure homogeneous. Maintenance and lifespan The Ecobag requires very little maintenance. Only the vent pipes and possibly the odour filters need to be checked for silting up. An Ecobag typically lasts 10 to 15 years.

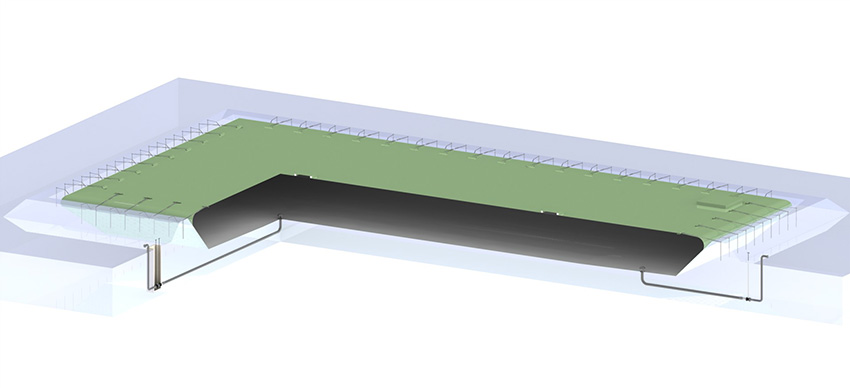

Combibag

- Combibag is a flexible storage for up to 10.000m3 of manure and digestate, which captures the gases released during the digestion processes. The relatively low investment, fast installation and landscape-friendly appearance are the main advantages.

Advantages- Large, flexible storage with gas storage

- Simple permit process; sometimes notification is sufficient

- Fast delivery and assembly landscape-friendly due to low profile and green colour

- Low investment costs

The Combibag includes:- Very strong, chemically resistant, flexible foil

- More than enough reinforced fastening points, straps and anchors

- Gas-tight inspection opening with stainless steel hatch

- Safety edge and separate gas removal points

- Over/under-pressure valve

Available options:- Extra inspection opening with stainless steel hatch and safety edge

- Electric mixer

- Pressure and/or fill level measurement

- Heating

- Connections with non-return valve(s) for biogas installations.

Advantages:- As storage for manure when spreading is not permitted

- As final digester in combination with a biogas installation

- For temporary or permanent storage of waste flows with gas formation

Combibag

- Over/Under-pressure valve

- Electro mixer

- Combibag piping parts

Environmentally friendly storage system for manure and digestate with gas capture

The combibag is a system that Wiefferink has developed to store manure and digestate in an odourless manner, while also providing space to capture the methane given off by the slurry. The special eco-green colour of the combibag means it is hardly noticeable in the landscape. The storage system is easy to install on most ground types.

The Combibag is produced with a special foil suitable for the digestion process and for capturing gas. In comparison with our Ecobag, it has more, heavier fastening points, tension straps and anchors. These are appropriate for absorbing the forces resulting from the gas pressure.

The Combibag is fitted with an over pressure valve and has a maximum gas pressure of 1.5 mbar.

Blends into the landscape

The Combibag captures the gases released, to prevent odour nuisance in the vicinity. In addition, the Combibag is available in grey and a special new eco-green colour to blend in with the landscape.

No building permit No building permit is required, because no permanent construction is required for the Combibag. Depending on local legislation, however, it may be necessary to apply for an installation permit, though sometimes simply notifying the authorities of the installation is sufficient.

Installation of the Combibag

The main advantage of the Combibag is that it can be installed in almost any location, without a supporting structure. The Combibag is placed within an earth bank for side support. Wiefferink supplies the drawings for dimension of the groundwork. Before installation, our experts inspect the sizing and the situation at your location, so that we can complete the installation as quickly and effectively as possible, ready to use.

Additional options for the Combibag include a gas pump installation, pressure measurement, heating and a mixer.

Maintenance and lifespan

The Combibag requires very little maintenance. It is, however, necessary to check the volume of the gas production, the intended gas removal and the operation of the over/under-pressure valve.

Flexitank

- Flexible liquid storage

The Flexitank is designed to store liquids: from clean water and fuels to wastewater, fire extinguishing water and liquid buffers for industrial use. It is a unique product that makes safe, durable storage of liquids possible in any location.

Advantages- Storage for large volumes of water

- Flexible system

- Easily applicable

- Available in standard volumes and client-specific sizes

- Available in remote locations

- Easy to transport due to relatively small volume and low weight 44%

- Higher carrying capacity than vats, when transported in containers Takes up just 2% of the maximum volume when empty

- Rainwater drinking water fire-extinguishing water irrigation water wastewater

- Edible oils

- Fruit juices

- Wine

- Latex

- Pharmaceutical liquids

- Cleaning products

- Fuels

- De-icing fluid

- Manure

Flexitank

- Flexible liquid storage

The Wiefferink flexitank (also known as pillowbag internationally) is suitable for both temporary and permanent storage. the advantages of a flexible installation over a permanent structure makes the flexitank ideal in countries where building permits or construction materials are difficult to acquire.

The Wiefferink Flexitank can be filled and emptied via lead-throughs. The product is ideal for connection to a filter system. The Flexitank concept is used in such places as Somalia, Pakistan and South Africa in this way, mainly in locations where drinking water cannot be offered in a regular manner.

Clean drinking water worldwide

The Flexitank is used by Dutch and international water companies for both emergency drinking water provision and regular drinking water supply. Wiefferink Flexitanks are also used at international sporting events, such as the soccer World Cup and European Cup and London 2012.

In cooperation with these companies and relief organisations, the Flexitank has been further developed and granted drinking water certification, FDA certification and UK WRAS certification. In order to supply the world’s citizens with clean drinking water, a fully-fledged, safe and durable drinking water system was created. Moreover, the Flexitank is easy to install on location and can be used immediately in case of emergency.

High-grade, certified materials

The Wiefferink Flexitank is manufactured for repeated use. We use high-grade materials that are extremely strong, light and flexible. These materials are thermally and high-frequency welded with care. The production method has been recorded in ISO documentation and certified by KIWA.

Flexitank for fuels and other liquids

Because the Flexitank can be made of special chosen flexible foil that is impermeable to a certain liquid, it can be used to store manure, diesel, for example, or kerosene, de-icing fluid, liquid chemicals, fire-extinguishing water or wastewater.

Easy to transport

The small Flexitanks are extremely easy to transport in containers, pick-ups or flatbed trailers. Empty, the product takes up just 2% of its maximum volume. The Flexitank can be set up quickly and easily and it provides optimum protection for the liquid. This efficient liquid storage can be supplied in a variety of standard volumes (5, 10, 15, 20 and 25 m3) or in a custom size, up to 2000m³, entirely according to your specifications.

PROJECTS

AGRI PROJECTS

- We offer flexible cover solutions in the agricultural sector

Wiefferink supplies and installs flexible storage and covering solutions for the agricultural entrepreneur at home and abroad.

France

- Product : Silocover non gastight

Application : Digestate

Location : French Alpes

Outside diameter : 19,50 m

Special : High snowload

Pepowo Poland

- Location : Pepowo Poland

Medium : Storage of manure

Shape : Single membrane non gastight

Dimensions : Ø42,00m x 6,00 m

Perpignan France

- Location : Perpignan France

Medium : Storage of manure

Shape : Single membrane non gastight

Dimensions : Ø41,70m x 6,00m

Flexitank Waikato NZ

-

Location : Waikato New Zealand

Dimensions : Ø30.5 m x 1.4 m

Storage capacity : 1000 m³

Shape : Round dyer

Medium : Storage of liquids

Flexitank New Zealand

- Location : New Zealand

Dimensions : Ø30.5 m x 1.4 m

Storage capacity : 1000 m³

Shape : Round

Application : Storage of liquid content

Medium : diluted effluent (i.e wash water from dairy shed)

Lüdinghausen Germany

- Location: Lüdinghausen Germany

Medium: : Storage of manure

Form: : Single Membrane non gastight

Dimensions: : Ø14,74m x 5,0 m

Löningen Germany

- Location : Löningen Germany

Medium : Storage of manure

Shape : Single Membrane non gastight

Dimensions : Ø16,38m x 5,0 m

Borstel Germany

- Location : Borstel Germany

Medium : Storage of manure

Shape : single membrane non gastight

Dimensions : Ø31,48m x 8,00 m

Sendenhorst Germany

- Location : Sendenhorst Germany

Medium : Storage of manure

Shape : Single membrane non gastight

Dimensions : Ø20,38m x 5,92 m

Sulingen Germany

- Location : Melle Germany

Medium : Storage of manure

Shape : Single membrane non gastight

Dimensions : Ø18,00m x 8,00 m

Cover Slot Silo

- Location : Diffelen Netherlands

Medium : Cover slot silo

Dimensions : 45,00m x 9,50m

Melle Germany

- Location : Stemwede Germany

Dimensions : Ø12,38m x 5,0 m

Type Roof : Single membrane, non gastight

Application : Storage of manure

Warendorf Germany

- Location : Warendorf Germany

Medium : Storage of manure

Shape : Single membrane non gastight

Dimensions : Ø17,26m x 6,28 m

Bethen Germany

- Location : Bethen Germany

Medium : Storage of manure

Shape : Single membrane non gastight

Dimensions : Ø17,90m x 5,00 m

Ecobag New Zealand

- Location : New Zealand

Dimensions : ~30.0 x 20.0 x 4.50 m (L x W x H)

Shape : Rectangular

Medium : Storage of liquid content

Storage capacity : ~2.000 m³

Höör Sweden

- Location : Höör Sweden

Medium : Storage of manure

Shape : Silocover single membrane non gastight

Dimensions : Ø25,56m x 4,00m

Nijeveen Netherlands

- Location : Nijeveen Netherlands

Medium : Storage of manure

Shape : Single membrane non gastight

Dimensions : Ø31,00m x 6,00 m

Koekelare Belgium

- Location : Koekelare Belgium

Medium : Storage of manure

Shape : Single membrane non gastight

Dimensions : Ø19,95m x 6,00 m

Ecobag Japan

- Location : Japan

Dimensions : 70.0 x 46.0 x 3.85 m (L x W x H)

Shape : Oval

Medium : Storage of manure

Storage capacity : ~10.000 m³

Marsberg Germany

- Location : Marsberg Germany

Medium : Storage of manure

Shape : Single membrane non gastight

Dimensions : Ø29,20m x 6,00 m

Dünsen Germany

- Location : Dünsen Germany

Medium : Storage of manure

Shape :Single membrane non gastight

Dimensions : Ø22,40m x 8,00m

Ostbevern Germany

- Location : Ostbevern Germany

Medium : Storage of manure

Shape : Single membrane non gastight

Dimensions : Ø18,49m x 5,92 m

Poppenhausen Germany

- Location : Poppenhausen Germany

Medium : Storage of manure

Shape : Single membrane non gastight

Dimensions : 2 x Ø22,36m x 5,00m

Coesfeld Germany

- Location : Coesfeld Germany

Medium : Storage of manure

Shape : Single membrane, non gastight

Dimensions : Ø17,61m x 4,00m

Coesfeld Lette Germany

- Location : Coesfeld Lette Germany

Medium : Storage of manure

Shape : Single membrane non gastight

Dimensions : Ø24,96m x 4,47m

Dinklage Germany

- Location : Dinklage Germany

Medium : Storage of manure

Shape : Single membrane non gastight

Dimensions : Ø20,40m x 8,00m

Kaarst Germany

- Location : Kaarst Germany

Medium : Storage of manure

Shape : Single membrane non gastight

Dimensions : Ø19,40m x 5,92m

Kalkar Germany

- Location : Kalkar Germany

Medium : Storage of manure

Shape : Single membrane non gastight

Dimensions : Ø24,96m x 5,92m

Kempen Germany

- Location : Kempen Germany

Medium : Storage of manure

Shape : Single membrane non gastight

Dimensions : Ø18,49m x 4,38m

Kleve Germany

- Location : Kleve Germany

Medium : Storage of manure

Shape : Single membrane non gastight

Dimensions : Ø24,04m x 5,92m

Klinkow Germany

- Location : Klinkow Germany

Medium : Storage of manure

Shape : Single membrane non gastight

Dimensions : Ø37,22m x 6,00m

Luckau Germany

- Location : Luckau Germany

Medium : Storage of manure

Shape : Single membrane non gastight

Dimensions : Ø40,60m x 10,15m

Schöppingen Germany

- Location : SchöppingenGermany

Medium : Storage of manure

Shape : Single membrane non gastight

Dimensions : Ø20,38m x 4,46m

Waltrop Germany

- Location : Waltrop Germany

Medium : Storage of manure

Shape : Single membrane non gastight

Dimensions : Ø20,32m x 5,82m

Mendionde France

- Location : Mendionde France

Medium : Storage of manure

Shape : Single membrane non gastight

Dimensions : Ø15,30m x 3,00m

Hörby Sweden

- Location : Hörby Sweden

Medium : Storage of manure

Shape : Single membrane non gastight

Dimensions : Ø20,20m x 4,00m

Ecobag France

- Location : Bords France

Dimensions : 42,5 x 23,5 x 3,5m

Shape : Rectangle

Medium : Storage of liquid

Content : ~3.000 m³

Silocover Denmark

- Location : Hærup Denmark

Medium : Storage of manure

Shape : Single membrane non gastight

Dimensions : Ø15,56m x 4,00m

Münster Germany

- Location : Münster Germany

Medium : Storage of manure

Shape : Single membrane non gastight

Dimensions : Ø14,30m x 3,60m

Lüdinghausen Germany

- Location : Lüdinghausen Germany

Medium : Storage of manure

Shape : Single membrane non gastight

Dimensions : Ø16,66m x 5,92 m

Alveringem Belgium

- Location : Alveringem Belgium

Medium : Storage of manure

Shape : Single membrane non gastight

Dimensions : Ø36,29m x 6,00m

Ferwert Netherlands

- Location : Ferwert Netherlands

Medium : Storage of manure

Shape : Single membrane non gastight

Dimensions : Ø27,30m x 5,00m

3x Silocover Denmark

- Location : Denmark

Medium : Storage of manure

Shape : Single membrane non gastight

Dimensions : 3x Ø31,12m x 4,00m

Silocover Cumbria UK

- Location : Cumbria United Kingdom

Medium : Storage of manure

Shape : Single membrane non gastight

Dimensions : Ø34,80m x 5,00m

Geldern Germany

- Location : Geldern Germany

Medium : Storage of manure

Shape : Single membrane non gastight

Dimensions : Ø18,49m x 5,82m

Stemwede Germany

- Location : Stemwede Germany

Dimensions : Ø12,38m x 5,0 m

Type Roof : Single membrane, non gastight

Application : Storage of manure

Silocover Fousenant France

- Location : Fousenant France

Medium : Storage of manure

Shape : Single membrane non gastight

Dimensions : Ø23,00m x 6,28m

Wallhausen Germany

- Location : Wallhausen Germany

Medium : Storage of manure

Shape : Single membrane non gastight

Dimensions : Ø36,90m x 5,62 m

Streyl Germany

- Location : Streyl Germany

Medium : Storage of manure

Shape : Single membrane non gastight

Dimensions : Ø16,40m x 6,0 m

Bingen Germany

- Location : Bingen Germany

Medium : Storage of manure

Shape : Single membrane non gastight

Dimensions : Ø20,45m x 5,00m

BIOGAS PROJECTS

- Coverage solutions for the biogas industry

Biogas comes from the fermentation of many types of organic (residual) material. This can be manure, but also other organic waste streams.

Combibag VK

- Product : Combibag

Application : Storage of digestate and gas

Location : United Kingdom

Combibag dimensions : 38 m x 40.0m x 8.75 m (excl. slope 2%)

Shape : Rectangle

Storage capacity (liquid) : ~16.000 m³

Storage capacity (gas) : ~2,500 m³ - 8,000m³

Particulars : placed in a lagoon with containment

Ecobag Toncza Poland

- Location : Toncza Poland

Dimensions Ecobag : ~65,00 x 32,00 x 4,75 m Shape : Rectangular

Application : Storage of liquid content

Storage capacity : ~7.000 m³

Liquid content : Thin fraction of digestate from energy crops, pig/cow manure, food and slaughter waste

Gasbuffer Fredenbeck Germany

- Location : Fredenbeck Germany

Dimensions : Ø23,35m x 17,70m

Storage capacity : 5000 m³

Shape : 3/4

Application : Biogas

AB Cover Isle of Wight UK

- Location : Isle of Wight United Kingdom

Dimensions : Ø32,36m x 6,00m

Storage capacity : ca. 2.415 m³

Shape : AB Cover

Medium : Biogas

Ecobag Kupin Poland

- Location : Kupin Poland

Dimensions : 65 x 65 x 76 x 5m

Shape : Ecobag Triangular

Medium : Storage of liquid content

Storage capacity : ~8.000 m³

Liquid content : Thin fraction of digestate from energy crops, pig/cow manure, food and slaughter waste

Ecobag Falknowo Poland

- Location : 14-240 Falknowo, Polen

Dimensions Ecobag : ~65.0 x 42.0 x 4.0 m (L x W x H)

Shape : Rectangular

Application : Storage of liquid content

Storage capacity : ~10.000 m³

Liquid content : Thin fraction of digestate from energy crops, pig/cow manure, food and slaughter waste

AB Cover Denmark

- Location : Near the North Sea, Danemark

Dimensions : : Ø40,33m x 6,00m

Storage capacity : : 3.400 m³

Shape : 4 x AB Cover

Application : Slurry and Biogas

Gasbuffer France

- Location : Sausheim France

Dimensions : Ø16,20m x 14,00m

Storage capacity : ca. 2.550 m³

Shape : 3/4

Application : Biogas

Silocover with long Bellin Germany

- Location : Bellin Germany

Dimensions : Ø31,17m x 6,00m

Shape : Silocover with Lung Gastight

Application : Biogas

AB Cover Bombeck Germany

- Location : Bombeck Germany

Dimensions : Ø40,95m x 9,00m

Storage capacity : ca. 5.489 m³

Shape : AB Cover

Medium : Biogas

AB Cover Klein Schwechten Germany

- Location

:

Klein Schwechten Germany

Dimensions : Ø27,55m x 7,00m

Storage capacity : 1.620 m³

Shape : AB Cover

Medium : Biogas

Gasbuffer Campillos Spain

- Location : Campillos Spain

Application : Biogas

Shape : Gasbuffer 3/4 spherical

Storage capacity : ca. 3.000m³

Gasflow 565m³/hr

AB Cover Cyprus

- Location : Cyprus

Dimensions : Ø25,014m x 6,30m

Storage Capacity : ca. 830 m³

Shape : AB Cover

Medium : Biogas

Combibag Uddel NL

- Product : Combibag

Application : Storage of manure

Location : Uddel(NL)

Dimensions : 25 x 64 x 3,5m

Storage capacity : ca. 5.000m³

Combibag Guatamala

- Location : Guatamala

Dimensions : 45 x 32 x 3,5m

Storage capacity : ca. 3.500 m³

Product Combibag

Medium : Storage of pig manure

Combibag Andover VK

- Location : Andover UK

Dimensions : 54 x 30 x 3,5m

Storage capacity : ca. 4.000 m³

Product : Combibag

Medium : Storage slurry

AB Cover Trinidad

- Location : Laventille, Trinidad and Tobego

Dimensions : Ø23,30m x 12,08m

Storage capacity : 1.232 m³

Shape : AB Cover

Medium : Biogas

Special details : Installation of a large servicebox to gain easy access to the mixers

AB Cover Poland

- Location : Falknowo Poland

Dimensions : Ø24,20m x 8,00m

Storage capacity : ca. 1.300 m³

Shape : AB Cover

Medium : Biogas

AB Cover Wittenburg

- Location : Wittenburg Germany

Dimensions : Ø27,74m x 6,00m

Storage capacity : ca. 1.600 m³

Shape : AB Cover

Medium : Biogas

Gasbuffer Belgium

- Location : Belgium

Dimensions : Ø16,20m

Storage capacity : 1000 m³

Shape : 1/2

Medium : Biogas

2x AB Cover Philippines

- Location : Davao City Philippines

Dimensions : Ø22,00m x 7,50m

Storage capacity : ca. 1.100 m³

Shape : 2x AB Cover

Medium : Biogas

AB Cover Cloppenburg

- Location : Cloppenburg Germany

Dimensions : Ø25,40m x 6,00m

Storage capacity : ca. 3.050 m³

Shape : AB Cover

Medium : Biogas

AB Cover USA

- Location : Byron USA

Dimensions : Ø32,92m x 5,49m

Storage capacity : ca. 2.530 m³

Shape : AB Cover

Medium : Biogas

AB Cover Lierop NL

- Location : Lierop Netherlands

Dimensions : Ø17,59m x 7,00m

Storage capacity : ca. 800 m³

Vorm : 3x AB Cover

Medium : Biogas

AB Cover Rumania

- Location : Rumania

Dimensions : Ø25,52m x 7,00m

Storage capacity : ca. 1.400 m³

Shape : AB Cover

Medium : Biogas

Gasbuffer France

- Location : France

Dimensions : Ø16,2m x 14,00m

Storage capacity : ca. 2.500 m³

Shape : 3/4

Medium : Biogas

Combibag Bassevelde Belgium

- Location : Bassevelde Belgium

Dimensions : Ø13,20 m x 2,95 m

Shape : Combibag

Medium : Storage of manure and biogas

Storage capacity : 380m³

Silocover with lung Belgium

- Location : Belgium

Dimensions : Ø9,80m x 4,00m

Shape : Silocover with Lung Gastight

Application : Biogas

AB Cover Latvia

- Location : Dobeles Rajons Letland

Dimensions : Ø21,40m x 6,00m

Storage capacity : ca. 1.200 m³

Shape : AB Cover

Medium : Biogas

AB Cover Esbeek NL

- Location : Esbeek Netherlands

Dimensions : Ø20,40m x 6,00m

Shape : AB Cover

Medium : Biogas

AB Cover Klein Schwechten

- Location : Klein Schwechten Germany

Dimensions : Ø32,54m x 8,02m

Storage capacity : ca. 2.430 m³

Shape : AB Cover

Medium : Biogas

AB Cover Langwetzendorf

- Location : Langwetzendorf Germany

Dimensions : Ø29,90m x 6,00m

Storage capacity : 3.085m³

Shape : AB Cover

Medium : Biogas

AB Cover Denmark

- Location : Jutland Denmark

Dimensions : Ø37,80m x 6,00m

Storage capacity : ca. 3.075m³

Shape : AB Cover

Medium : Biogas

AB Cover Stiens NL

- Location : Stiens Netherlands

Dimensions : Ø15,50m x 6,00m

Storage Capacity : 675 m³

Shape : AB Cover

Medium : Biogas

AB Covers Rahden Germany

- Location : Rahden Germany

Dimensions : 2x Ø32,48m x 8,00m

Storage Capacity : ca. 1.920 m³

Shape : AB Cover Medium : Biogas

AB Cover Vliermaal Belgium

- Location : Vliermaal Belgium

Dimensions : Ø35,28m x 6,00m

Storage capacity : ca. 2.499 m³

Shape : AB Cover

Medium : Biogas

AB Cover Brunau Germany

- Location : Brunau Germany

Dimensions : Ø40,98m x 8,02m

Storage capacity : ca.4.235 m³

Shape : AB Cover

Medium : Biogas

AB Cover Zeewolde NL

- Location : Zeewolde

Dimensions : Ø25,37m x 6,00m

Storage Capacity : 966 m³

Shape : AB Cover

Medium : Biogas

Gasbuffer Turkey

- Location : Turkey

Dimensions : Ø19,80m x 14,90m

Storage capacity : ca. 3.000 m³

Shape : 3/4

Application : Biogas

WWTP PROJECTS

- Waste water treatment plants…

Wiefferink provides solutions for safe (temporary) storage of water. In addition we provide customized solutions for flexibele coverings for water treatment. We are active in the following sectors: regional water authorities and governments.

Silocover Den Bosch NL

- Solution : Rotating silocover

Shape : Single membrane non gastight

Medium : Storage of waste water

Dimensions : 5165 cm

Location : Den Bosch NL

Biogas Reactor Portugal

- Location : Dardico Portugal

Medium : Storage of manure and agricultural crops

Shape : Biogas reactor

Dimensions : Ø27,8m x 6,00 m

Gasbuffer Dendermonde Belgium

- Location : Dendermonde Belgium

Dimensions : Ø15,40m x 11,50m

Storage capacity : 1390 m³

Shape : 3/4

Medium : Biogas

Silocover Texas USA

- Location : Texas USA

Medium : Storage of water

Shape : Silocover single membrane non gastight

Dimensions : Ø30,6m x 4,75 m

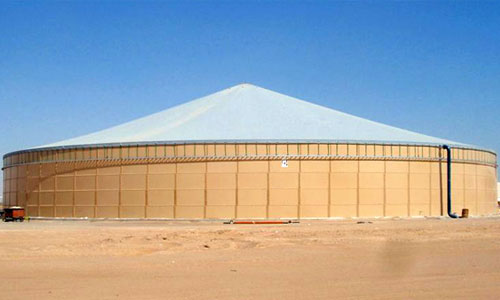

Silocover United Arab Emirates

- Bauort : United Arab Emirates

Medium : Storage of water

Shape : Silocover single membrane non gastight

Dimensions : Ø 59,34m x 6,86m

Silocover Losser NL

- Location : Losser Netherlands

Dimensions : 3 x Ø17,52m x 3,5 m

Shape : Single Membrane, non gastight

Medium : Storage of liquid

Silocover Zwolle NL

- Location : Zwolle Netherlands

Dimensions : 2 x Ø11,27m

Shape : Single membrane, non gastight

Medium : Storage of thick sludge and thin sludge

Special : Silocover out of 2 halves

Silocover Duiven NL

- Location : Duiven Netherlands

Dimensions : Ø10,23m x 7,03m

Shape : Single membrane non gastight

Medium : Storage of waste

Silocover Hengelo NL

- Location : Hengelo

Dimensions : Ø20,50m x 6,00m

Shape : Single Membrane, 2x halves can be completely opened

Medium : Storage of wastewater

Silocover Nijverdal NL

- Location : Nijverdal, Netherlands

Dimensions : Ø13,75m x 6,0 m

Type Roof : Single membrane, non gastight

Application : Storage of liquid content

Silocover Goor NL

- Location : Goor Netherlands

Medium : Storage of waste water

Shape : Silocover single membrane non gastight

Dimensions : 60x40x3,20m

Gasbuffer Turkey

- Location : Kayseri Turkey

Dimensions : Ø19,80m x 14,90m

Storage capacity : 3.000 m³

Shape : 3/4

Medium : Biogas

Silocover France

- Location : Fouesnant France

Medium : Storage of manure

Shape : Single membrane, non gastight

Dimensions : Ø23,00m x 6,28m

Silocover Oldenzaal NL

- Location : Oldenzaal

Dimensions : Ø14,83m x 3,50m

Type Roof : Single membrane, non gastight

Medium : Storage of liquid content

Mesh cover Weert NL

- Location : Weert Netherlands

Dimensions : Ø16,55m x 5,00m

Shape : Mesh cover

Medium : Storage sludge discharge buffer

Cover overflow gutter

- Location : Den Bosch Netherlands

Dimensions : Ø48m

Shape : Cover overflow gutter

Silocover Den Helder NL

- Location : Vriezenveen

Dimensions : Ø9,12m

Type Roof : Single membrane, non gastight, custom made

Medium : Storage of liquid content

Silocover Vriezenveen NL

- Location : Rijssen

Dimensions : Ø14,90m x 4,00m

Type Roof : Single membrane, non gastight

Medium : Storage of liquid content

Silocover Rijssen NL

- Location : Enschede

Dimensions : Ø20,50m

Type Roof : Single membrane, non gastight

Medium : Storage of liquid content

Silocover Enschede NL

- Location : Steenwijk

Dimensions : Ø18,60m x 4,00m

Type Roof : Single membrane, non gastight

Medium : Storage of liquid content

Silocover Steenwijk NL

- Location : Hoogezand Sappemeer

Dimensions : Ø21,97m x 3,00m

Type Roof : Single membrane, non gastight

Medium : Storage of liquid content

Silocover Sappemeer NL

- Location : Hoogezand Sappemeer

Dimensions : Ø21,97m x 3,00m

Type Roof : Single membrane, non gastight

Medium : Storage of liquid content

Silocover Diever NL

- Location : Diever

Dimensions : Ø21,90m x 3,50m

Type Roof : Single membrane, non gastight

Medium : Storage of liquid content

Silocover Alkmaar NL

- Location : Alkmaar

Dimensions : Ø17,60m x 6,00m

Shape : Single membrane non gastight Medium : Storage of waste water

INDUSTRY PROJECTS

- We provide customized solutions for flexible coverings for the industry sector.

Flexitank Utrecht

- Location : Utrecht Netherlands

Dimensions : 233 x 565 x 110 cm

Contents : 15m³

Shape : Flexitank

Medium : Storage of drinking water

Gasbuffer in 40ft seacontainer

- Form : Gasbuffer in 40ft Seacontainer

Dimensions : 10,0 x 2,5 x 2,6mtr

Storage capacity : 65 m³

Medium : 60% Air with 40% CO2

Silocover Schiphol

- Location : Schiphol

Dimensions : Ø32,64m x 7,00m

Shape : Silocover single membrane non gastight

Medium : Storage de-icing

Wood chips silo Italy

- Location : 29012 Caorso (PC) – Italy

Dimensions : Ø18,50 x 12.0m

Shape : Silocover non gastight on a self supporting construction

Application : Protect wood chips for weather infuences

Details : Filled from above through a conveyor-belt and and emptied from the bottom through a piston..

Heat storage bag

- Location : Different development sites in the Netherlands

Dimensions : Standard 4,0 x 6,0 x 0,5m³

Details : The heat storage bag will be measured on site and than produced custom made

Medium : Storage of thermal energy to use during cold periods

Lagoon cover

- Location : Belgium

Dimensions : 68,50m x 52,50m

Shape : Lagoon cover

Silocover Vlissingen

- Location : Vlissingen Netherlands

Medium : Silocover on a cable basket

Shape : Single membrane non gastight

Dimensions : Ø 14,20m

Temporary Roof

- Shape : Temporary cover as roof on a pilot plant

Dimensions : 21,76m x 8,40m x 5,50m

Details : The cover has been pulled as a shell around the construction underneath

Wood chips silo France

- Location : 76190 Yvetot France

Dimensions : Ø18,50 x 19,0m

Shape : Silocover non gastight on a self supporting construction

Application : Protect wood chips for weather infuences

Co2 Buffer Sirjansland

- Location : Sirjansland Netherlands

Dimensions : Ø22,00m x 16,50m

Storage capacity : 4000m³

Shape : 3/4

Medium : Buffer Storage of Co2

Gasbuffer Switzerland

- Location : Zürich Switzerland

Dimensions : Ø13,71m x 5,30m

Storage capacity : 1000m³

Medium : Biogas

AB Cover Puerto Rico

- Location : Puerto Rico

Dimensions : Ø14,67m x 14,00m

Storage capacity : ca. 620 m³

Shape : AB Cover

Medium : Biogas

AB Cover Spakenburg NL

- Location : Spakenburg Netherlands

Dimensions : Ø17,98m x 6,00m

Storage Capacity : ca. 814 m³

Shape : AB Cover

Medium : Biogas

2x Silocover Halle Germany

- Location : Halle Germany

Shape : 2x Silocover single membrane non gastight

Dimensions : Ø14,67m x 7,00m