INVENT

Videos

Loading the player ...

- Offer Profile

- INVENT develops, produces and globally implements innovative components, systems and processes for the treatment of water and wastewater.

INVENT focuses on applications in the municipal and industrial water and wastewater treatment.

The product portfolio spans the following areas:- innovative stirring and mixing technology

- innovative aeration technology

- intelligent system solutions

- engineering & consulting

- software products

Product Portfolio

Mixing Technology

-

Water and wastewater treatment plants are usually created as a made-to-measure design and lay-out for a particular project. Depending on the original situation and the intended treatment, various process engineering steps are combined so that the aim of the process engineering is safely within reach. While doing so, the engineer draws from a range of known unit processes. The most important processes from this range are stirring and mixing processes. They play a decisive role in nearly all water and wastewater treatment plants.

Applications Mixing task Mixing and equalization tank Suspension and Homogenization Neutralization Flash-Mixing Pre-Mixing of Precipitants Flash-Mixing Precipitation Suspension and Homogenization Coagulation Suspension and Homogenization Biological phosphate elimination Suspension and Homogenization Denitrification Suspension and Homogenization BOD or COD removal Homogenization and Dispersion Disinfection Flash-Mixing Sludge treatment Suspension and Homogenization Storage of chemicals/chemical solution Suspension

CYBERFLOW Accelerator

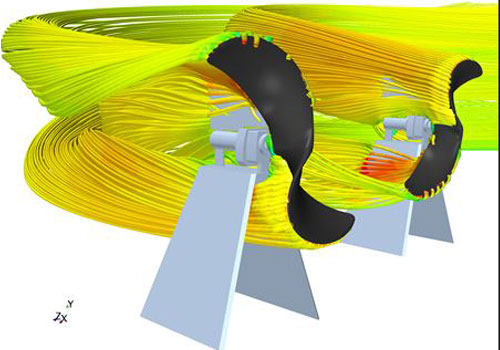

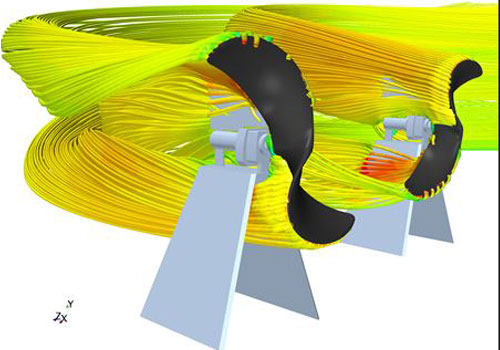

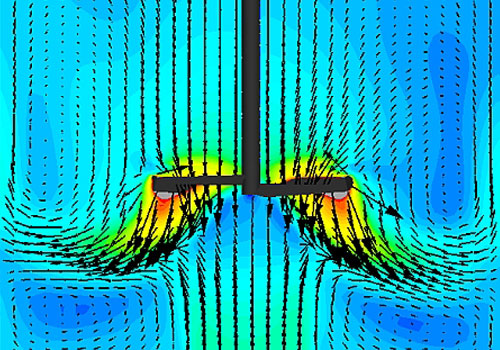

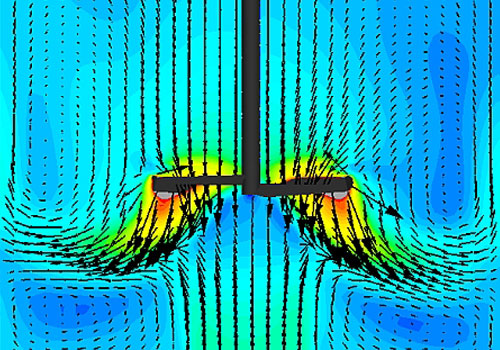

- The INVENT CYBERFLOW®- Accelerator has been specially developed and optimised for the energy-efficient the generation of a horizontal flow in the recirculation basin for biological wastewater treatment. The overall fluid mechanics concept used here is revolutionary in comparison to conventional flow generators. This results in improvements in the level of efficiency of up to 30%, irrespective of the application. This is made possible by a holistic, fluid mechanics optimisation approach which considers not only the propeller design, but the entire machine in the interaction with the flow passage. This approach is based on the knowledge that themes which have so far been ignored, for example the

- installation location

- installation position

- flow direction

- incident flow

- wake

- design of the foot

play an important role in addition to the propeller design for the overall level of efficiency of a horizontal flow accelerator. INVENT has studied these topics in depth and as a result created an exceptionally energy-efficient product for biological wastewater treatment.

CYBERPITCH Flash Mixer

- The INVENT CYBERPITCH®- Mixer is particularly used for mixing applications where a high local energy intake is required. In the field of drinking water preparation it is used to thoroughly mix in flocculants and precipitant ideally followed by the well-known INVENT Hyperboloid mixers in the consecutive steps.

Also in the wastewater treatment, the CYBERPITCH®- Mixer can be used, for instance for the suspension of activated carbon in a contact basin for further removal of non-biodegradable substances.

CYBERSLUDGE Mixer

- Mixing - Circulation - Homogenization in Waste Sludge Digesters

One of the key-parameters for the overall energy efficiency of a biological wastewater treatment plant is the ability to produce a high amount of methane gas in the waste sludge digesters. The more gas can be delivered to the biogas fire motors (engines), the more energy can be produced to run the various machinery concepts on the plant.

The amount of the gas production in a sludge digester depends on the quality of the sludge and the correct mixing, circulation, and homogenization of the waste sludge in the digester.

INVENT’s fluid mechanical know-how, its vast experience in the field of mixing in general and sludge mixing in particular, and its passion for developing innovative products, has led to CYBERSLUDGE®, the INVENT mixing system for sludge digesters.

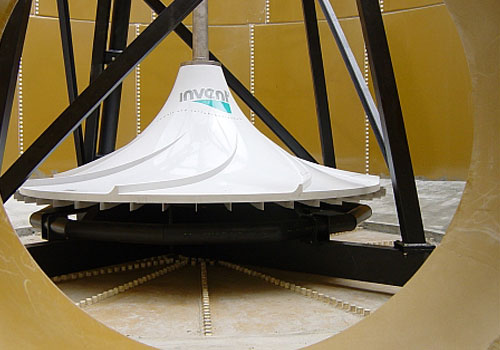

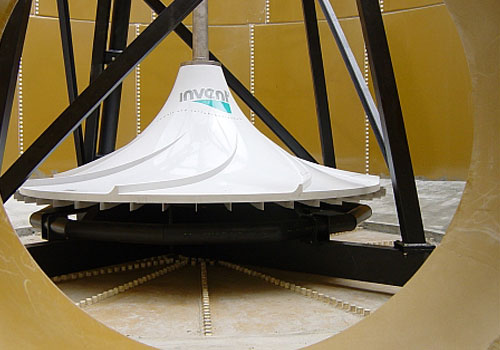

HYPERCLASSIC Mixer Evolution 6

- The INVENT HYPERCLASSIC®- Mixer is a vertical mixer with a hyperboloid-shaped mixer body, installed close to the bottom, and a drive mounted in dry position above the water level. Contrary to other products, it was developed and designed especially for applications in the area of water and wastewater treatment.

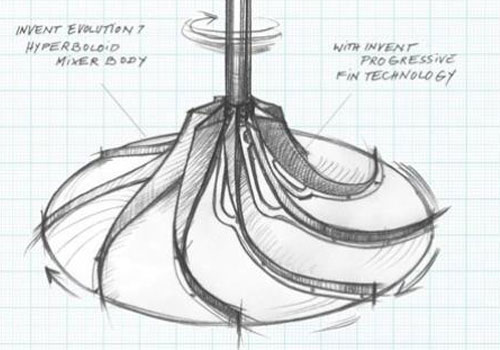

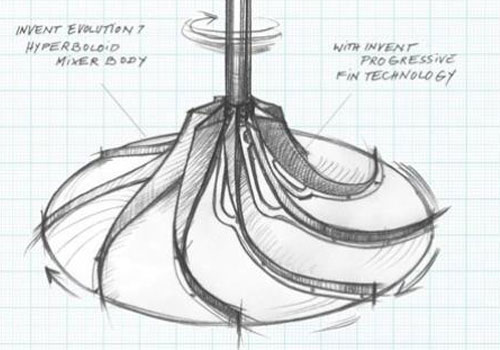

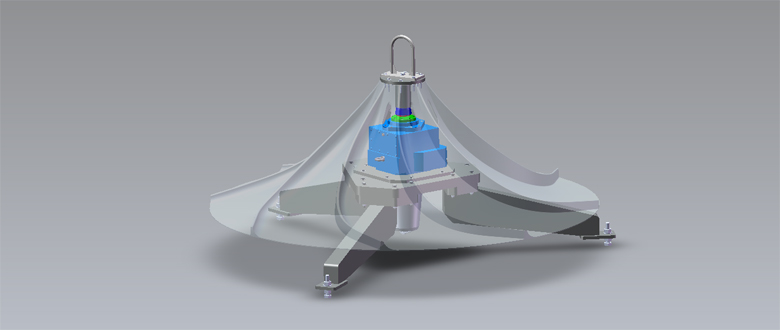

HYPERCLASSIC Mixer Evolution 7

- INVENT made a significant contribution to the efficiency and cost-effectiveness of such plants by introducing the hyperboloid mixing technology to the market for water and wastewater treatment over 20 years ago.

Since then, the hyperboloid mixing technology has been continuously developed and improved. Thousands of successful installations in municipal and industrial water and wastewater treatment plants world-wide impressively demonstrate that the hyperboloid mixing technology has already become the industrial standard in this field of application.

With the current version HYPERCLASSIC® evolution 7, the seventh, completely revised and revolutionary improved version of the classic hyperboloid mixer is now available.

HYPERDIVE Mixer

- The INVENT HYPERDIVE®- Mixer is a vertical mixer with a hyperboloid-shaped mixer body, installed close to the bottom, and a submersible drive. Contrary to other products, it was developed and designed especially for applications in the area of water and wastewater treatment.

HYPERCLASSIC Flocculation System

- The INVENT HYPERCLASSIC® Flocculation System is based on the patented hyperboloid mixer, which has been specifically designed to minimize floc shear while providing excellent mixing and eliminating settling within flocculation basins.

The Flocculation System provides smooth mixing flow through the entire tank, maximizing floc-building interactions between particles.

Combined with the INVENT CYBERPITCH® flash mixer INVENT can provide a complete flash mix and flocculation process to optimize your potable water treatment facility.

HYPERPITCH Mixer add-on

- The INVENT HYPERPITCH®- Mixer add-on takes care about the reliable reduction of scum and floating sludge in anaerobic and anoxic basins.

The HYPERPITCH®- Mixer add-on can easily be installed on the shaft of an existing INVENT HYPERCLASSIC®- Mixer.

HYPERMIX Agitator

- Efficient mixing in drinking water reservoirs

Drinking water reservoirs play a central role in the implementation of safe access to drinking water in our cities and communities. The treatment and filtration processes to produce drinking water can be costly, and to ensure the final product to the consumers is of the highest standard, quality must be maintained within the storage facilities. Within the storage facilities the water can deteriorate through “stratification“ leading to undesirable odour and taste variations, as well as critical chemical concentration variations which can result on the delivered water being outside regulatory guidelines.

Stratification in drinking water reservoirs impacts water quality. During the stratification process, different water layers with different temperatures occur. There is no fluid exchange between these layers. This leads to longer dwell times for a part of the water and thus to algal formation, subsequent germination and/or uncontrolled chemical concentrations. All this can easily be prevented by the implementation of the INVENT HYPERMIX®-Agitator, a mixing element developed especially for complete volume movement. This mixing system helps to displace the water layers and to prevent them re-forming.

Aeration Technology

- In the purification of water and wastewater more and more process-technology steps for cleaning and purification are coming into use, which combine to form a complete installation. Processing can be divided into physical, physical/chemical and biological treatment. The biological phase represents the heart of the process. In this phase, carbon and nitrogen compounds are biologically broken down. The basis of this process is effective mixing and the efficient addition of oxygen, so that the biologically active bacteria can work effectively.

INVENT has specialised in exactly this area, and its innovative products make it one of the world’s leading concerns in the field of mixing and aeration technology for water and wastewater treatment.

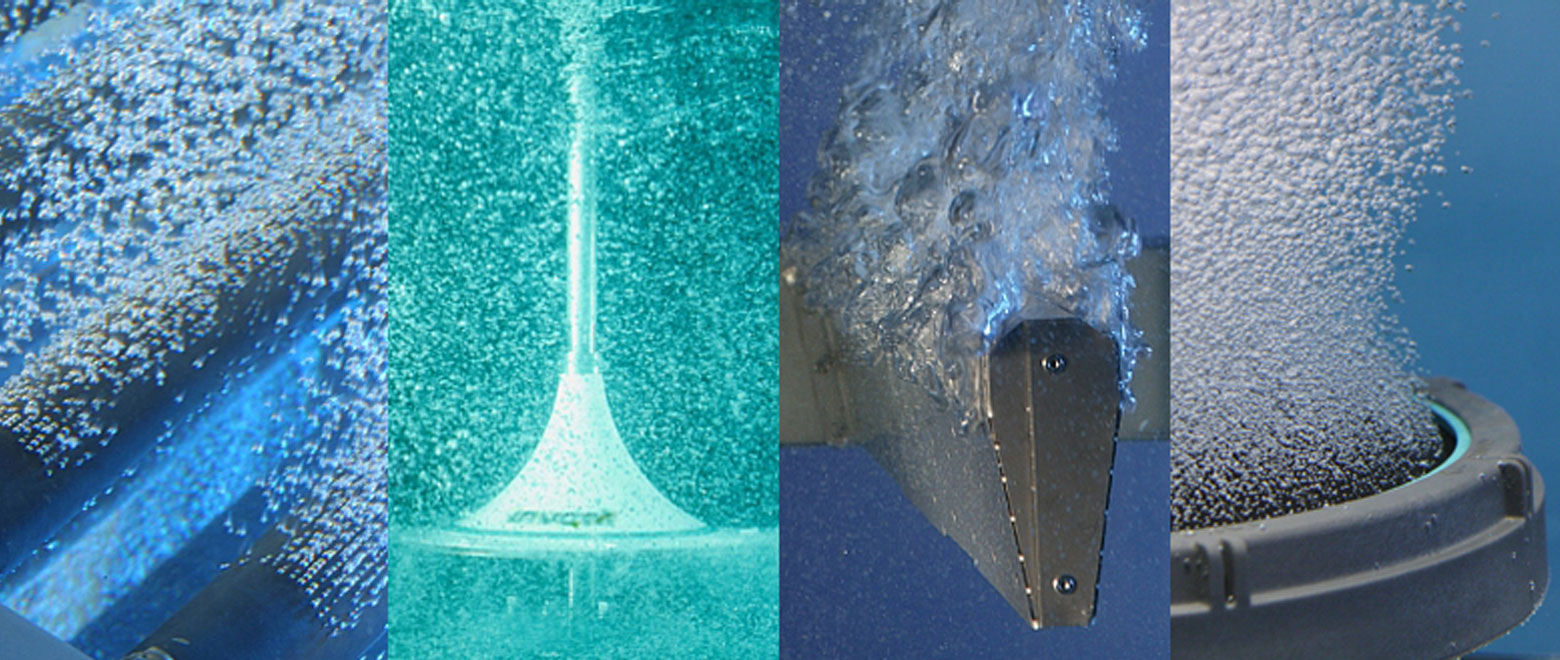

HYPERCLASSIC Mixer/Aerator

- The HYPERCLASSIC®- Mixing and Aeration System was developed and optimized especially for demanding applications in municipal and industrial wastewater treatment plants. It provides efficient oxygen transfer and optimal mixing during the biological stage.

In addition to the task of introducing oxygen, it also fulfils the important function of mixing and avoiding sedimentation. Due to the mechanical aeration method, the oxygen transfer performance is nearly as high in wastewater as it is in pure water. Even after many years, the aeration performance is not diminished. The system's pressure loss remains constantly low. The system can be installed simply and quickly, even in a filled tank.

HYPERDIVE Mixer/Aerator

- The HYPERDIVE®- Mixing and Aeration System was developed and optimized especially for demanding applications in municipal and industrial wastewater treatment plants. It provides efficient oxygen transfer and optimal mixing during the biological stage.

In addition to the task of introducing oxygen, it also fulfils the important function of mixing and avoiding sedimentation. Due to the mechanical aeration method, the oxygen transfer performance is nearly as high in wastewater as it is in pure water. Even after many years, the aeration performance is not diminished. The system's pressure loss remains constantly low. The system can be installed simply and quickly, even in a filled tank.

E-FLEX

- INVENT E-FLEX® is the ideal aerator for municipal and industrial treatment plants. It efficiently supplies the mixed liquor in the activated sludge tank with oxygen and is suitable for almost all variations of the activated sludge process.

E-FLEX®- Diffusers are used as modular components in an aeration system. Single modules are connected via separate air supply to the main air header. The modular design features trouble-free and quick installation and minimum effort for maintenance. The liftable version is part of our standard product range.

E-FLEX-Float

- E-FLEX®- FLOAT is the floating version of our proven E-FLEX®- Aaeration System. It is mainly used for aerated wastewater ponds or lagoon tanks with plastic liner, earthen basins with natural sealing, natural ponds and lakes and all aerated tanks, in which the levelling of conventional bottom aerators is only possible with considerable effort due to the unevenness of the bottom.

The E-FLEX®- FLOAT Aeration System is a so-called „chain aeration system" based on multiple aeration chains, which can move through the activated sludge tank at right angles to their longitudinal axis. One single „chain" consists of a floating air header, which simultaneously serves as a buoyancy body. Individual aeration modules are connected at regular intervals to this floating header via flexible downpipes.

iDISC

- The INVENT iDISC® has been developed and optimized for the use in municipal and industrial wastewater treatment plants. It efficiently supplies the mixed liquor in the activated sludge tank with oxygen and is suitable for almost all variations of the activated sludge process.

iDISC®- Diffuser systems are tailor-made to match the needs of every single plant. Its robust construction and high quality makes it ideal for most wastewater treatment applications.

iCBA

- The INVENT Coarse Bubble Aeration system (iCBA®) has been developed and optimised for special applications in industrial and municipal wastewater treatment plants. It provides oxygen supply and optimal mixing during the biological phase, in particular for use in processes that use carrier media for biomass detention, whether moving-bed or fixed-bed processing.

Its robust stainless steel construction make it ideal for the most adverse conditions in industrial applications. The operational limits of conventional membrane aerators, such as high air temperatures or problematic wastewater ingredients, do not present a problem for the iCBA®- Aeration System.

TEX-FLEX

- The TEX-FLEX® -Aeration System has been specially developed and optimized for demanding applications in industrial and municipal wastewater treatment plants. For industrial applications in particular, the use of conventional membrane diffusrers is restricted or even impossible, or else they must be frequently replaced in order to guarantee trouble-free operation of the plant. In this situation, the TEX-FLEX®- System provides a reliable alternative. Its robust stainless steel construction and its textile membrane, which is both chemically and thermally highly resistant, make it ideal for the most aggressive applications.

The system is quick and simple to install, and can also be supplied as a removable module. The system can then be inserted into and removed from filled basins.

ALPHAMETER

- The INVENT ALPHAMETER® combines control and monitoring liquid phase and gas phase to produce real time measurement of key parameters for process and aeration control including:

- Aeration System Oxygen Transfer Efficiency (αOTE)

- Process Oxygen Uptake Rate (OUR)

- Mixed Liquor α Value

Accurate knowledge values of these parameters allows a new approach to understanding and control process and aeration system performance.

The INVENT ALPHAMETER® opens the door to a new world in aeration system control and achieves substantial energy saving.

iTURBO -Blower

- the high speed blower

The INVENT iTURBO®-Blower is specially suited for supplying air to aeration systems in activated sludge plants. The iTURBO® complements INVENT’s line of high efficiency aeration systems and aeration control products, maximizing system performance while minimizing energy costs. The iTURBO® is designed for peak efficiency and the perfect harmony of stability and reliability.

Overview of advantages of the iTURBO®-Blower- Compact, light weight package for quick and simple installation

- Integrated low noise design with motor, turbo, VFD¹ and control system in a single package

- Reduce operating cost by up to 30 % when compared to conventional blowers

- The only maintenance item is the changing of air filters

- User friendly HD touch screen HMI

- Customised turbo impellers to provide peak efficiencies over the desired flow range

- High speed PMSM² optimised for speed and torque control

¹ VFD: Variable Frequency Drive

² PMSM: Permanent Magnet Synchronous Motor

Solid-Liquid Separation

- INVENT is focussed on municipal and industrial water and wastewater treatment. We have used our many years of experience in this sector and our expertise in the fields of fluid mechanics, hydraulics and component design to develop innovative products for Solid-Liquid Separation, like iDEC®-SBR Decanting System and iFILT®-Diamond Filter.

iDEC - SBR Decanting System

- Before the INVENT-decanters were created, different types of effluent discharge constructions were used in the market with mixed results. This was the reason for INVENT to develop a new SBR-Decanting System for the discharge of clarified wastewater from SBRs.

The development of the iDEC®-SBR Decanting System was based on the well known features a decanting system which collects and discharges purified wastewater out of SB-reactors is expected to show.

The complete iDEC®-SBR Decanting System includes the decanter itself, all piping at the bottom of the tank with connection joints, stainless steel anchors and the INVENT application design for the system.

For technical details, please refer to the flyer on the left.

iFILT - Diamond Filter

- Compact stainless-steel filter with advanced hydraulic performance

This Diamond Filter was constructed especially for the separation of solids from fluids as a tertiary filtration step and was fluid-mechanically optimized with the help of CFD1. It is extraordinarily energy efficient and offers excellent separation performance using a minimum of space. Its advanced hydraulic performance is based on the principle of cross-flow-filtration.

The filter is entirely made of high-quality stainless steel. The design is simple and self contained, making the iFILT®-Diamond Filter easy to install and low-maintenance. During installation it is simply attached to the supply and drainage pipes and electrically connected – that’s it!

The iFILT®-Diamond Filter was constructed especially for the separation of solids from fluids as the next treatment phase after secondary sedimentation. It removes the smallest suspended solids that are still present in secondary effluent, for example- activated sludge particles

- precipitation particles after phosphorus reduction

- powdered activated carbon

- microplastics

In the area of industrial wastewater treatment the iFILT®-Diamond Filter is applied in the areas such as:- general reuse of processing water in the paper and textile industries

- flush water in the beverage industry

- water treatment in fisheries

- irrigation in agriculture

System Solutions

- A complete system solution from INVENT comprises, depending on the customer’s requirements, the basic and detailed engineering, project management, delivery of the mechanical components, installation of the plant, and training of plant personnel.

The mechanical components, such as mixers, aeration systems, pumps, blowers, armatures and instrumentation, control and automation systems, are carefully selected for an INVENT system solution, and co-ordinated with each other. INVENT takes responsibility for the entire scope of the delivery. This approach reduces the number of interfaces and potential sources of failure.

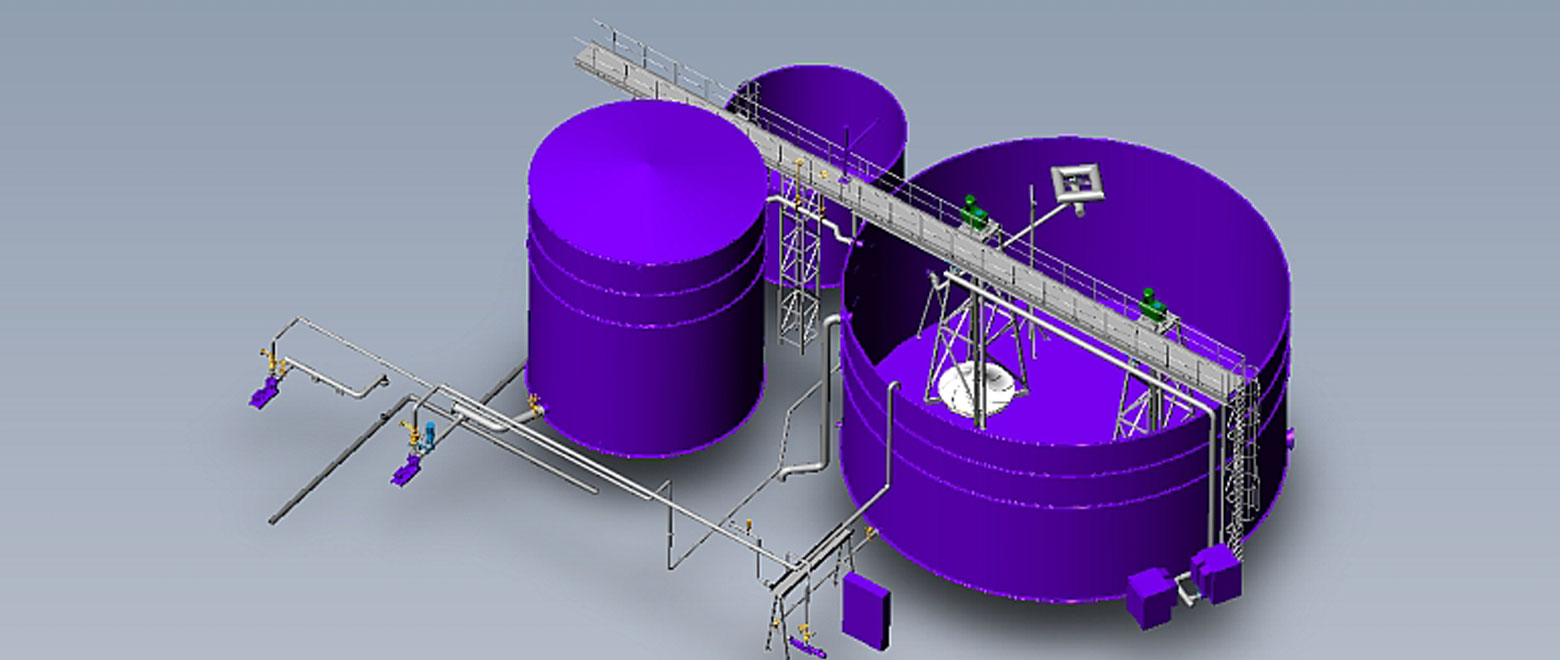

iSBR

- As a result of the exceptional suitability of the HYPERCLASSIC®- Mixing and aeration system for Sequencing Batch Reactor plants, we have more than 15 years of experience and considerable knowhow in this fjeld. For this reason, we offer SBR plants as an INVENT system solution. In this case, we also supply a special clean-water decanting system and a cycle strategy that is tailored to the individual application.

In the field of construction of SBR plants, INVENT has carried out projects for the most varied applications. These include municipal wastewater treatment, and numerous industrial applications in fields such as brewing, the chemical industry, the pharmaceutical industry, refineries, and the food and drinks industry.

In the municipal field, INVENT has numerous references round the world, starting from small and medium-sized plants all the way up to large municipal sewage treatment plants. We have special ist knowhow for the treatment of wastewater from the fermentation of biowaste.

iLAGOON

- There is a further INVENT standard solution for so-called pool purification plants. For that kind of wastewater treatment plant, we supply floating aeration systems, floating mixers, and a specially developed clarifier cleaning system. In this field too, INVENT has extensive know-how and many years of experience.

If you are working on a project of this type, or want to upgrade an existing plant, please contact us.

Engineering & Consulting

- Advanced fluid simulation for the water & process industry

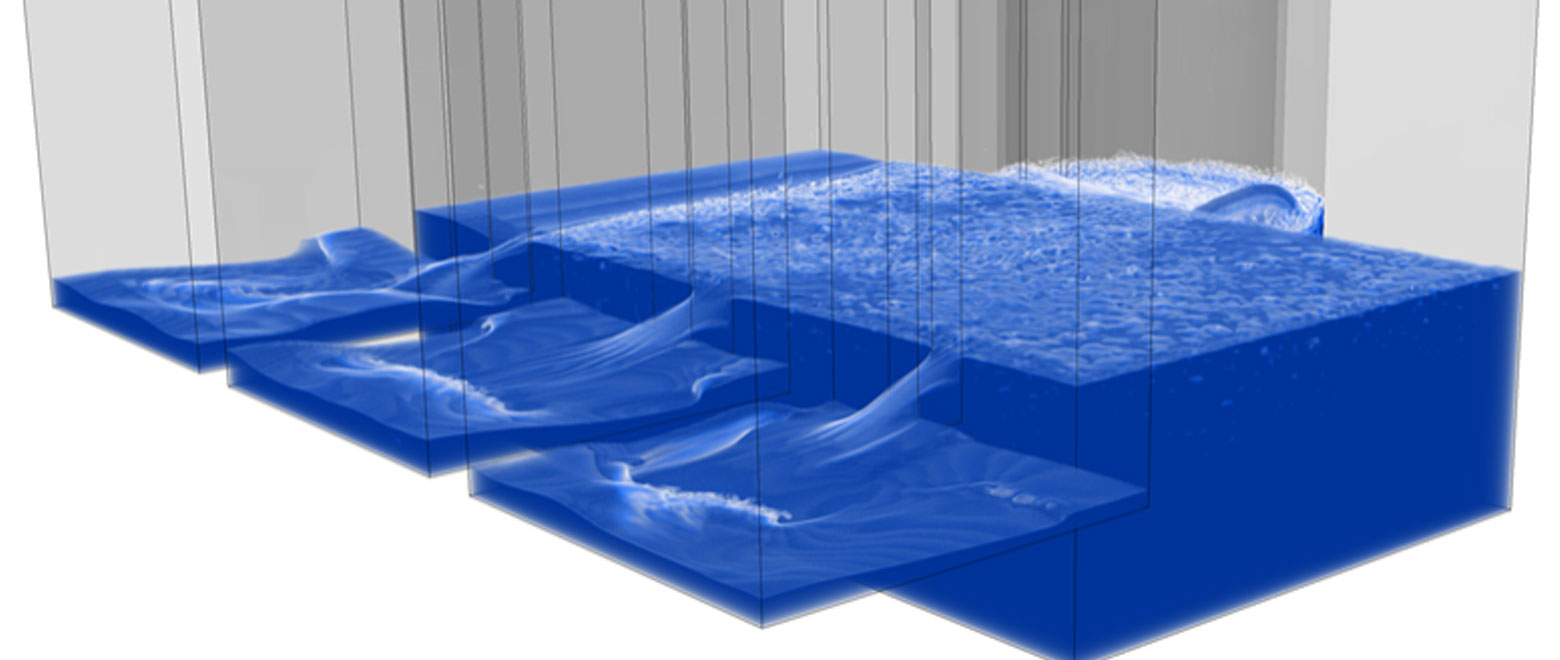

High resolution, realistic, real time fluid simulation opens a whole new world of possibilities. THINK Fluid Dynamix® is a consulting and engineering service department that specializes in advanced numerical technologies, such as computational fluid dynamics and automated optimization. Services

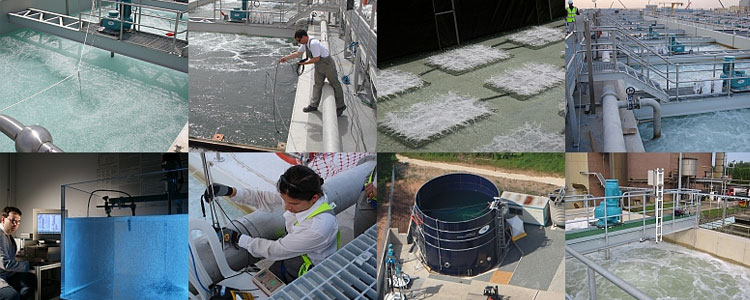

- INVENT offers part of its know-how and wealth of experience in the field of mixing and aeration technology as part of research, development and test projects.

The services on offer include (amongst other things):- Mixer development / optimisation

- Computational fluid dynamics

- Velocity profile measurements

- Oxygen transfer testing

Computational Fluid Dynamics

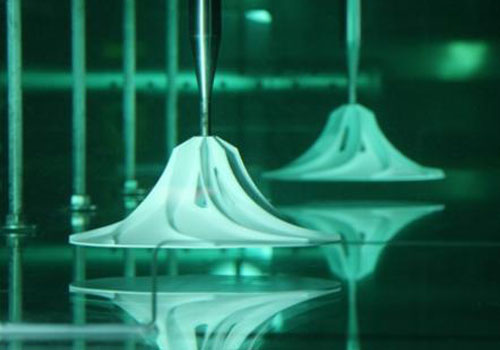

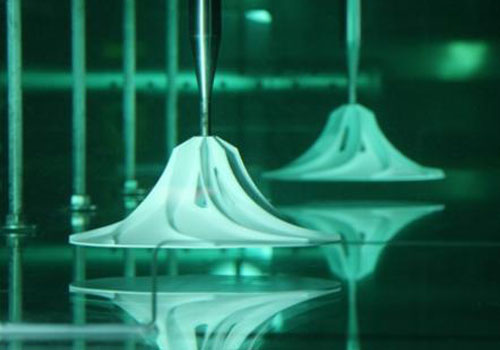

- Nowadays, it is primarily so-called CFD calculations that are mostly associated with fluid mechanical simulations. A usually more direct method is the construction of a true-to-scale model and a scale-up of the obtained results. These pieces of data can then be consulted in order to validate CFD calculations. Only in this manner can definitive results be obtained.

INVENT operates a fully-equipped fluid mechanical laboratory complete with test tanks in all imaginable sizes. Here, "State of Research" CFD programs with respective computing power are available in addition to the most modern and up-to-date fluid measuring techniques.

Mixer Optimization

- Mixers are developed and utilized for the most diverse of applications. However, the desired success is not always achieved. INVENT considers mixers and stirred vessels to be a complete unit and can help you to optimize your mixer application thanks to their experience and fluid mechanical simulation tools.

Velocity Profile Measurements

- Bottom flow velocity measurements are occasionally required for acceptance and as proof of performance of the mixers. The correct execution of such measurements in complex, three-dimensional flows requires expert knowledge of fluid mechanics as well as experience when it comes to preparation, execution and assessment.

We exclusively use ultrasound Doppler measurement devices for the measurement itself. These devices simultaneously collect all three velocity components. Only in such a manner can reliable and meaningful results be achieved.

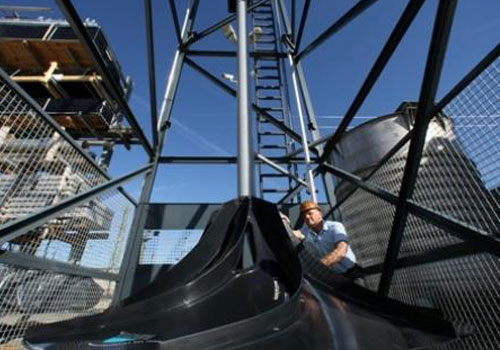

Oxygen Transfer Testing

- We have decade-long experience when it comes to executing oxygen transfer rate measurements in accordance with DWA or ASCE guidelines in the laboratory, on a large-scale and on large-scale installations. We would like to share this experience with you and offer such measurements as a service.

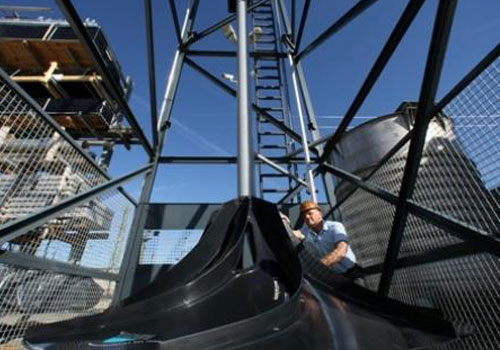

A fully-equipped test facility and a tank with a diameter of 10.24 m and a maximum filling height of 8 m is available for "shop tests" at our site in Erlangen, Germany.

Field measurements on purification facilities require individual planning and are therefore offered based upon the specific customer and facility requirements.

Markets

- INVENT Umwelt- und Verfahrenstechnik AG offer a wide range of products and services in the field of mixing and aeration for water and wastewater treatment. For more than 20 years INVENT have been offering both product and process expertise for industrial and municipal applications. Renowned for the hyperboloid mixing system, INVENT have a wide range of products ranging from dedicated mixers, combined mixer/aeration systems through to specific fine bubble aeration systems and tailored treatment process design

Municipal

- INVENT offers a whole range of products for the municipal water and wastewater treatment. Our Hyperboloid Mixers are used for precipitation and flocculation in drinking water treatment or are applied for the complete nitrogen elimination in anaerobic and anoxic tanks of wastewater treatment plants. The INVENT Aeration Systems are used in grit chambers, activated sludge tanks or in the sludge treatment process for oxygen transfer or mixing tasks. Using INVENT System Solutions, municipal wastewater is treated safely, efficiently and economically.

Food and Beverage Industry

- INVENT Umwelt- und Verfahrenstechnik AG offers numerous solutions for the food and beverage industry. Our products range from the simple mixer for mixing and equalization tanks, to mixing and aeration systems for the pretreatment of wastewater, up to complete wastewater treatment plants which, for example, operate using the SBR principle. Tailor- made solutions reply to the special demands of this industrial sector. Our customers include nationally and internationally known breweries as well as soft drink bottlers, fish processing companies, dairies or producers of ready-to-serve meals. The INVENT Membrane Aeration Systems are also used for the oxygen enrichment in fish farms.

Pulp and Paper Industry

- Wastewater out of the pulp and paper industry possesses different characteristics depending on the processed raw material and the applied production process. High temperatures, severe water hardness and abrasive materials are the rule. The "Heavy Duty" model of our INVENT Hyperboloid Mixing and Aeration System or the iCBA coarse bubble Aeration System have proven successful under these demanding conditions.

Pharmaceutical Industry

- The pharmaceutical industry shows specific demands in the field of wastewater treatment and partly extreme conditions such as high temperatures, aggressive media and severe salt contents. Hence robustness and reliability, apart from efficiency, are the mainly required features of any installed system. For that reason, the INVENT Hyperboloid Mixers and Hyperboloid Mixing and Aeration Systems are first choice for the pharmaceutical industry worldwide when it comes to fulfil demanding aeration tasks. Our vast experience in the pharmaceutical industry enables us to not only design and offer the ideal mixer or mixing and aeration system, but also to advise and support you in all aspects of the integration of such systems into your wastewater pre-treatment or treatment plant. Our Customers include renowned international pharmaceutical companies.

Chemical and Petrochemical Industry

- The chemical and petrochemical industry shows specific demands in the field of wastewater treatment and partly extreme conditions such as high water temperatures, aggressive media, and a severe salt content. Hence robustness and reliability, apart from efficiency, are the mainly required features of any installed system. For that reason, the INVENT Hyperboloid Mixers and Hyperboloid Mixing and Aeration Systems are first choice for the chemical and petrochemical industry worldwide when it comes to fulfil demanding aeration tasks. Our vast experience in the chemical and petrochemical industry enables us to not only design and offer the ideal mixer or mixing and aeration system, but also to advise and support you in all aspects of the integration of such systems into your wastewater pre-treatment plant or your wastewater treatment plant. Our Customers include big international chemical companies as well as international oil companies.