- Offer Profile

-

Ammongas was founded in 2002 in Denmark, one of the world’s leading hubs for biogas innovation.

With more than 40 plants across Northern Europe and 7 across the United States, we specialize in engineering tailored solutions for CO₂ Separation, biomethane polishing for CH₄ liquefaction, CO₂ liquefaction, and carbon capture. Each plant is designed and built by our dedicated engineers, with a strong focus on sustainability, cost-effectiveness, efficiency, and reliable operation.

Ammongas aims to lead the global transition to a cleaner energy future by delivering smart, sustainable renewable gas treatment solutions that maximize resource recovery, minimize environmental impact, and empower circular energy systems worldwide.

Products

-

From Design to Delivery – We Make It Happen

Our project and service teams bring deep expertise in the engineering, procurement, and construction of environmental facilities, managing every phase from initial design to final commissioning. We deliver tailored solutions that meet diverse regulatory, geographic, and certification requirements, and we’re ready to support your next project with precision and purpose.

CO₂ Separation and expansions

- Experience Superior CO₂ Separation with Ammongas

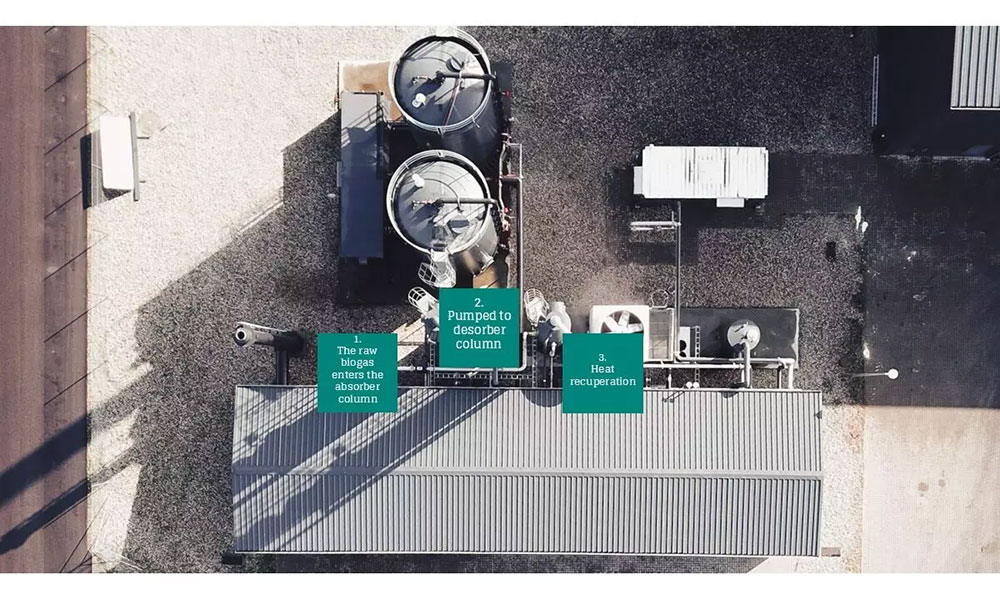

Ammongas uses the proven absorber stripper system with amines for upgrading biogas. The process has been used for many years in the oil and gas industry for removal of CO₂, H₂S other acidic gases, and is known for being a robust and reliable system.

By separating and removing the CO₂, raw biogas is efficiently upgraded to high-purity biomethane. Our advanced absorption process is exceptionally efficient, with the ability to limit methane slip below 0.05% – resulting in a methane recovery rate exceeding 99.95%.

Furthermore, Ammongas’ amine upgrading can remove down to less than 50 ppm of CO₂ in the biomethane stream, and thereby prepare the gas for liquefaction.

Our reliable technology ensures low operational costs and an average uptime of 99%, including comprehensive service support.Advantages:

- Designed to your needs

- Expensive pre-treatment of biogas is not necessary with an upgrading plant from Ammongas

- A pressureless upgrading process saves a lot of costs in the building phase and less expenses in maintenance.

- The parts in an upgrading plant from Ammongas are robust and of high quality, which ensures a long life.

- The share of biomethane in the Danish gas system is approximately 40%. More than half of that is processed by an Ammongas upgrade plant.

Biomethane polishing for CH4 Liquefaction

- Ammongas Polishing for Enhanced Gas Quality & Optimised Use

Biomethane polishing removes residual CO₂ from upgraded biogas or natural gas, enabling the methane to be liquefied. Without this polishing step, remaining CO₂ would freeze and crystallize during the CH₄ liquefaction, leading to operational issues and potential damage to equipment.

To prevent these complications, Ammongas offers a polishing process -similar to a full CO₂ Separation plant- that reduces CO₂ levels to below 50 ppm. At this purity, the gas can be safely liquefied and is ready for use as a transport fuel or other energy applications.Our proven amine technology yields superior results for establishing a low CO₂ content, making it an ideal solution for gas polishing applications. The Ammongas polishing unit offers the same advantages as a CO₂ Separation unit:

Key Facts:

- Superior CO2 Removal Efficiency

- Proven Amine Technology

- High Methane Recovery

- Scalable and Modular Design

- Low Operating Costs

- Compatible with Existing Systems

- Robust Against Gas Composition Variability

- Environmentally Friendly

Carbon capture and CO2 Liquefaction

- Turn Emissions into Opportunity: Ammongas Carbon Capture and Liquefaction for the Net-Zero Era

As global momentum builds around climate action, CO₂ taxation is rapidly becoming a regulatory reality. For forward-looking companies, carbon capture is not just an environmental solution – it’s a smart financial strategy to significantly reduce CO₂-related costs.

By integrating carbon capture into your operations, Ammongas enables efficient processing and purification of CO₂ from flue gas or tail gas. With carbon capture now part of our core offering, AmgCarbonX delivers a cost-effective, high-performance path toward lower emissions and a stronger position in a net-zero future. Our high-efficiency system ensures that less than 1% CO₂ remains in the treated flue gas.With extensive experience in CO₂-separation, Ammongas has built deep expertise in carbon capture from biogas plants-expertise that has since been successfully adapted to flue gas capture. In 2021, Ammongas won the National District Heating Award in collaboration with Thisted and SEG A/S for their demonstration of carbon capture from waste-heat flue gas by using our proprietary technology.

- LCO₂: CO₂ liquefaction

- Carbon Capture (CCS & CCUS): AmgCarbonX

Feasibility Studies, pre-FEED, and FEED

- As part of our integrated project approach, we provide end-to-end project development support through Feasibility Studies, pre-FEED, and FEED.

Our Feasibility Studies evaluate technical, economic, and commercial viability to support early investment decisions.

Pre-FEED, advances the selected concept through detailed process definition, preliminary layouts, and equipment sizing, and identifies key risks and cost drivers.

FEED transforms the project into a defined, bankable scope with clear costs, schedules, and execution plans, minimizing risk and accelerating decision-making.

References

-

From Concept to Completion: Ammongas Plant Highlights

Discover how Ammongas delivers cutting-edge and sustainable solutions across a wide range of projects. From early design to final installation, explore key examples of our work in CO₂ Separation, CO₂ capture, and clean energy systems.

The references presented below are a small portion of our work. Contact us directly for our full reference list.

Vinkel: Upgrading one of Denmark’s biggest biogas producers with BioCirc and Lundsby

-

Biomethane for more than 25,000 households

- Type: Biogas plant with upgrade to biomethane

- Product: Upgrading Plant

- Capacity: 9,500 m³/hour

- Year: 2019

Upgrading Plant, Allen Farm, New York

-

Upgrading plant for compressed natural gas in Cayuga, New York

- Type: Biomethane for compressed natural gas

- Product: Upgrading Plant

- Capacity: 800 Nm³/hour

- Year: 2023

Upgrading Plant, Brande, Denmark

-

Project — Axel Månsson A/S: A full scale Ammongas upgrading plant, built in Brande

- Type: Upgrading of biogas to the natural gas network

- Product: Upgrading Plant

- Year: 2018

Upgrading Plant, Skive, Denmark

-

A full scale Ammongas upgrading plant, built on a farm in Skive, was one of the first plants in Denmark

- Type: Supply of green energy to the local area

- Product: Upgrading Plant

- Capacity: 1,300 m³/hour

- Year: 2014

Vaasa, Finland: Production of Gas for Buses in Vaasa

-

Vaasa, Finland: Production of Gas for Buses in Vaasa

- Type: Upgrading of gas for buses

- Product: Upgrading Plant

- Year: 2017

Holsted, Denmark — Active Carbon Filter: Pre-Purification of Gas Using Active Carbon Filter

- Type: Pre-cleansing of gas

- Product: Active Carbon Filter

Service and Maintenance

-

Optimal Performance and Long-Term Durability for Your Ammongas Plant

Expert Service & Maintenance for Peak PerformanceThe acquisition of an Ammongas plant marks the beginning of a new chapter, where daily operations evolve and priorities shift toward greater potential.

As a plant owner, it’s essential to not only plan for the future but to ensure the continuous, stable operation of your plant. Proper maintenance is the foundation for sustained success and performance.

At Ammongas, we are driven by a commitment to keep your plant running smoothly 24/7.

It is imperative to us that your Ammongas plants receive the highest level of care and attention after the transfer. That’s why we’ve crafted a service agreement designed to provide you with peace of mind, knowing that your plant will be meticulously maintained, fully functional, and ready to achieve its full potential.

An Ammongas service agreement offers:- Immediate troubleshooting of any operational problems.

- Coordination of service plan and planning of down-time in relation to maintenance.

- Continuous improvements: Every time our R&D department develops new technologies—whether to extend plant lifespan, boost uptime, or enhance efficiency—you are the first in line to have these advancements implemented.