- Offer Profile

-

Efficient processes are crucial to the success of a company. That is why we have made intralogistics our passion. We ensure that our customers benefit from the most cost-effective products, systems and services for their requirements, irrespective of their industry or business size.

START NOW WITH AUTOMATION

-

Autonomous Mobile Robots (AMR)

In the field of autonomous driving, intralogistics is setting the trends.

Autonomous Mobile Robots (AMR) navigate freely within a defined area, avoid obstacles and orient themselves to the position and orientation of a load carrier when picking it up. Bring these dynamics into your warehouse - with our versatile AMR arculee.

Intralogistics Highlights

Forklift

-

The right stacker for your warehouse

Whether electric or with combustion engine - with us you will find the optimal forklift for your warehouse.

Electric forklift

-

STRONG PERFORMANCE WITH THE LOWEST ENVIRONMENTAL IMPACT

Maximize your handling performance with our electric forklifts. They are particularly maneuverable and offer powerful performance with minimal consumption.

Electric high lift truck

-

Safe and easy to use for every need

Find out which of our electric high lift trucks best fits your warehouse's unique needs.

Electric low-lift pallet truck

-

Indispensable for the optimized transport of goods

Find the optimal electric low-lift pallet truck for your warehouse with us. We offer the right device for every requirement.

Lift truck

-

Powerful all-rounders

They are versatile and flexible, strong and maneuverable - our lift trucks are suitable for a wide range of requirements.

Shelves

-

Built from knowledge and steel

An optimally planned rack is the backbone of a warehouse. For over 65 years, we have relied on in-house developments, individual solutions and the highest quality.

Service around the vehicle

-

We get downtime out of the way.

Our forklift service and forklift and pallet truck repairs are always there for your fleet and storage equipment, chargers and batteries.

Conveyor systems

-

Automated components

The perfect combination of efficiency and cost-effectiveness: Material handling technology from Jungheinrich for customized intralogistics solutions.

Automated guided vehicles (AGVs)

-

THE HEART OF AN AUTOMATED WAREHOUSE

The automated guided vehicles (AGVs) solve any of your transport tasks safely and efficiently - controlled by intelligent software.

Pallet Trucks

-

Pallet trucks for short distances

With our user-friendly pallet trucks, you can transport your goods quickly and safely from rack to rack or directly to the required location. Our trucks represent a cost-effective, reliable solution for all applications, especially for short-distance operation.

Electric pallet trucks

EJE M electric pedestrian pallet truck

-

Trucks are not always subjected to high wear over one or more shifts. For light applications, we therefore offer electric pedestrian pallet truck starter models at a particularly attractive price. Nevertheless, you do not have to forego the renowned Jungheinrich reliability.

EJE electric pedestrian pallet truck

-

Easy to operate. Extremely manoeuvrable thanks to minimal front-end dimensions. Safe in every way. Energy consumption reduced by up to 25%. These are just four of the many quality features of our EJE electric low lift trucks. For goods transport over short distances from 1.4 to 3.5 tons.

ERE electric pedestrian pallet truck

-

The devices with hinged or fixed platform are ideal for transport over medium distances. Extremely robust, reliable, safe. Perfectly suited to your requirements: Innovative options for energy-efficient driving even in the toughest conditions or 15% more productivity at the push of a button. Also equipped for fully automated operations Intelligent automation components transform our field-tested serial trucks into Automated Guided Vehicles (AGVs). These combined with intelligent software keep your warehouse prepared for the future, streamline processes, and take efficiency to a new level. As an expert automation partner, we will plan and design an Automated Guided Vehicle System (AGVS) tailored to your needs, thereby enabling you to automatically increase the cost-effectiveness of your warehouse.

ESE electric stand-on and sideways seated Pallet Truck

-

There is nothing better for horizontal transport of loads up to 2.0 tons: The ESE electric pallet trucks are sideways seated, the driver's position is transverse to the direction of travel. Optimum visibility for the operator. Ergonomic workspace for relaxed operation over longer distances.

Electric pallet stackers

EJC M / EMC electric pedestrian controlled truck

-

The starter models are extremely easy to use in narrow warehouse environments — even for inexperienced operators. Efficient thanks to state-of-the-art 3-phase AC technology for drive and lift motors. Ideal for light use over short distances and occasional stacking and order picking.

EJC / EMD / EJD / EJG electric pedestrian controlled truck

-

Quality from top to bottom - the new Electric Pallet Stackers from Jungheinrich. Strive for the best and set new records for efficiency in your warehouse with the latest pedestrian controlled Pallet Stackers.

With numerous truck options for every purpose and every warehouse environment, Jungheinrich has got your short distance stacking covered. From the well-proven EJC universal stacker to the versatile EJD multifunctional truck - we have researched, developed and produced the perfect truck for your application, to bring unseen levels of efficiency, safety, robustness and flexibility to your everyday operations.

Electric pallet stacker ERC / ERD

-

The electric pedestrian controlled trucks with hinged or fixed stand-on platform combine the manoeuvrability of a pedestrian stacker with the comfort and speed of a ride-on truck. Loads can be gently raised and lowered, and the 3-phase AC drive motor ensures the best acceleration and efficiency.

ESC / ESD electric sideways seated stacker

-

Electric sideways seated stackers offer the ultimate driving and acceleration performance over long distances. Compact dimensions and minimal aisle widths make them unbeatable in narrower environments and block storage. Sideways seating position provides the operator with optimum visibility.

Hand pallet trucks

-

Hand pallet trucks: Agile helpers with high capacity

Our hand pallet trucks represent a cost-effective solution for many transport tasks involving short distances.

We have the right model for all requirements. Their high capacity of up to three tons and easy manoeuvrability in tight spaces make hand pallet trucks the perfect warehouse aid.

If you transport large quantities of goods and heavy loads across short distances on a daily basis, you will soon reap the benefits of using our manual hand pallet trucks. Thanks to their high capacity of up to three tons and excellent manoeuvrability in even the tightest of spaces, hand pallet trucks represent ideal warehouse aids. Chrome-plated axles and sliding bushings on the wheels and joints ensure smooth and effortless pulling and pushing with minimal noise.

Order pickers

-

Efficient order pickers

Order picking requires the human/machine interface to function flawlessly at all times. With our order pickers, you will not only increase your pick rates at reach heights of up to eleven metres, but will also benefit from enhanced travel safety and efficiency – even under the toughest conditions.

Height-adjustable steering units, PIN activation and individual travel programs for low to high speeds, not only raise the quality of your work, but also ensure a high level of comfort. The tougher the conditions, the more impressive the performance of our medium/high-level and low-level order pickers. Thanks to rapid battery replacement, even multiple consecutive shifts are no problem for the electric order pickers.

Low level order pickers

-

Durable, reliable and versatile

High-quality processing, robust design and the best performance values: These are the secrets that have transformed Jungheinrich into the market leader in this segment, thanks to significant sales figures and high customer satisfaction.

Our ECE Series 1, 2 and 3 low level order pickers are the 'workhorses' of the warehouse up to the second racking level. The transition to the medium/high level order pickers is represented by our EKS Series 1 with a picking height of up to 4.60 m.

Medium and high level order pickers

-

The new EKS range raises the game for medium and high level order pickers.

Productivity requirements in your warehouse are increasing. We can help you stay one step ahead. The versatile EKS demonstrates maximum picking performance and efficiency, from the first racking level up to heights in excess of 14 metres. Precise, fast and always by the shortest route possible.

From the entry-level truck to the flagship model, our adaptable medium/high-level order pickers deliver optimum results in narrow and wide aisles. Faster goods throughput, reduced costs and sophisticated technology are all hallmarks of Jungheinrich order pickers.

Reach Trucks

-

Our reach truck range – agile, powerful and efficient

For over sixty years, our reach trucks have been delivering reliable service and performance in warehouses across the globe. Particularly in confined conditions, our electric reach trucks set new benchmarks thanks to their compact construction and outstanding lifting capacity.

Jungheinrich is the outright leader in reach truck technology with the largest and most comprehensive range of reach trucks in the world. Our latest innovation, the ETV 216i, is the world’s first reach truck to have an integrated lithium-ion battery for maximum efficiency.

Very Narrow Aisle Truck

-

Efficient space utilisation with high rack VNA trucks

With our high rack stackers, you can stack pallets or pick individual articles with consummate ease. They impress with their throughput performance and space utilisation – both significant advantages in the face of growing costs and product variety in the world of logistics.

Our VNA trucks (high rack stackers): Impressive performance and maximum safety

If you value powerful performance, you will definitely be impressed by our electric high rack stackers: Thanks to energy recovery and effective energy management, you can easily use the stackers for two shifts under normal operation without having to change the battery. In addition, the well arranged cab provides your employees with a generous workspace. Large storage facilities and a clear view make for light work, as does the 'height and tilt' adjustable control panel. The safety of your employees is also assured by our high rack stackers: All models feature an integrated personal protection system to satisfy the highest safety standards.

Forklift Trucks

-

The Perfect All-Round Counterbalance Forklift For Your Warehouse

Forklift trucks from Jungheinrich are the perfect all-rounders, they can be deployed in virtually any warehouse environment and routinely deliver quality, efficiency and reliability. Be it a compact electric model or a heavy duty counterbalance with a powerful combustion engine – you simply cannot go wrong with our ultra efficient forklift trucks.

Electric Forklifts

-

Powerful electric forklifts by Jungheinrich.

People and machines must work as one for effective transport and handling in production and storage facilities. Our electric forklifts step in where human muscle power leaves off: they can reach up to 7.5 metres and lift loads of up to 5,000kg, carrying them safely – even over long distances.

Our electric counterbalance forklifts deliver maximum efficiency with minimum energy consumption. Agile electric forklifts deliver top performance with the latest three-phase motors and our mature PureEnergy concept. This technology coordinates all forklift truck components, achieving optimum efficiency automatically. Efficiency meets economy in an electric forklift.

Diesel Forklifts

-

Stronger on balance - our latest diesel/LPG counterbalance trucks.

Our diesel forklift trucks offer the perfect combination of power and capacity. They can carry loads ranging from 1.6 to 5 tons, while ensuring rapid turnaround and the utmost efficiency in your warehouse or production facility.

The dynamic Series 3s and 4s forklifts are robust in every way: Unrivalled for manoeuvrability, whether making quick changes of direction, dynamic acceleration, rapid reversing or precise positioning - the modern drive technology guarantees maximum driving comfort and highest throughput.

Tow tractors

-

Electric tow tractors with superior 3-phase AC technology

Our electric tow tractors and tow trains enable efficient transport of loads weighing up to 28 tons in indoor and outdoor areas. The innovative 3-phase AC technology not only produces zero emissions and minimal noise, but also makes these trucks maintenance-free, powerful and very compact.

Whatever the job, whatever the location: With our electric tow tractors, you will be well equipped to tackle any logistical challenge. Loads weighing up to 28 tons are transported from goods receipt to distribution and production with utmost efficiency and flexibility. Unlike trucks with combustion engines, the tow tractors are suitable for both indoor and outdoor use. The robust construction, spring-loaded wheels and super-elastic drive wheel ensure optimum traction both on smooth industrial floors and in outside areas. This for example makes our electric tow tractors ideal for intralogistics applications in warehouses and production facilities.

Trailer

-

Tow train trailers to master any challenge

A tow train consists of a tow tractor and at least one, but usually multiple, trailers. Tow trains are ideal for transporting varying loads in warehouses or production facilities since they can be made up of very different trailers.

Particularly in just-in-time production, the perfectly timed supply and removal of materials to and from the production machinery is crucial. Traditional forklift trucks are of limited use for such applications since, in most cases, multiple trucks need to be used simultaneously. This would produce greater investment and ongoing costs, while the high traffic volume would also increase the risk of accidents. Tow train trailers represent an effective alternative as the train can service multiple machines consecutively and transport a wide range of goods on different trailers. They also incur lower costs and minimise the amount of traffic in warehouse and production facilities.

Shuttles

-

Shuttle channel racking for high throughput performance

Shuttle channel racking offers many advantages, ranging from the high throughput performance during complete filling and emptying of a pallet channel, to collision-free storage and retrieval of pallets as well as optimum space utilisation thanks to a low rack compartment height.

Our Shuttle channel racking systems – comprising a carrier, basic truck and channel rack – enable efficient use of your storage space. The racking offers sufficient height and width for multiple pallet channels. The low height utilisation per channel level allows effective use of the available storage height. Any Jungheinrich forklift truck with sufficient residual capacity can be used as a basic truck.

Forklift hire & Used forklifts

Forklift hire

-

Hire the right forklift for every transport need.

Whether it is because of sudden breakdowns, seasonal fluctuations in capacity, or an unexpected large order, with Jungheinrich, you can stay flexible by renting the forklifts you need at any moment. Jungheinrich rental trucks are available to you worldwide in numerous variants. Additionally, we support you with detailed advice and on-site professional instruction to ensure that you rent exactly the right trucks and complete your projects safely.

Used forklifts

-

The Final Word in Used Forklift Trucks

At Jungheinrich our used forklifts really are all-star, so much so we named them accordingly. JUNGSTARS is the name we give to these immaculately refurbished used forklift trucks. The attention to detail lavished on every JUNGSTARS vehicle really sets them apart as some of the very best examples available on the market.

We are so convinced of the quality and performance of our JUNGSTARS, that every single vehicle is remanufactured and delivered with exactly the same 12-month warranty as a brand-new Jungheinrich forklift truck.

Automated components

-

The right automation components to take your intralogistics to the next level

With a wide range of intelligent, future-proof automation components, we can prepare your intralogistics for all future challenges. Enjoy maximum flexibility with a whole breadth of products covering everything from partial to full automation.

Automated guided vehicles

-

Automated Guided Vehicles (AGV)

Automatic truck solutions and fully automatic transport are the main focus of our automated guided vehicles (AGVs). We use intelligent automation components to automate our tried-and-tested standard production trucks and adapt them to your individual requirements.

Conveyor systems

-

Greater productivity for your warehouse is made possible by our conveyor systems. Jungheinrich offers intelligent solutions with innovative pallet and case conveyor systems for new or existing facilities. We configure efficient, fast, reliable systems tailored exactly to your needs.

Automated pallet warehouse

-

Short order cycles, smaller lot sizes, quicker delivery times: In the face of ever increasing market requirements, automated warehouses provide an effective solution. Your benefits: greater throughput, more speed and safety in your material flow and simple operation of different load carriers.

Stacker cranes for pallet warehouses

-

Rack servicing cranes for small parts

Maximum goods throughput due to high speed. In automated pallet racking warehouses, special high-speed rack operating systems provide 'speed' on the way to the order-picking station or to the affiliated materials handling technology.

Stacker cranes for miniload warehouses

-

Speed and precision with optimal energy efficiency determine productivity in automated miniload warehouses. The rack system, software, associated conveyor system and the core component, the stacker crane, interact perfectly.

The most powerful Miniload in its class

Jungheinrich developed the stacker cranes for miniload warehouses in-house using innovative technologies to deliver peak performance in throughput, space utilisation and energy efficiency. This is how we set efficiency in motion in your miniload warehouse.

Warehouse Racking and Storage

-

Racking is the key to optimum throughput efficiency. Our key offering is this: Integrated warehouse planning, where the racking and the forklift truck/rack operating equipment work "hand in hand" as a single, collaborative storage system.

We provide a comprehensive range of racking and storage systems, mezzanines and self-supporting stores (silos) for accommodating everything from pallets, containers and trays to boxes and long goods. The efficiency of your entire material flow is increased by our bespoke warehouse racking system design.

Static pallet storage

Drive in/drive through racking

-

Drive-in and drive-through racking are ideal for storing large quantities of heavy goods with a low variety of items. They combine the benefits of block storage for high utilisation of space with those of racking storage for pressure-free storage. The load units are placed one behind the other on two continuous depth supports (also called pallet rails), resulting in a fixed sequence for stacking and retrieval. A forklift truck can drive in only on one side of drive-in racking, but can drive in on both sides of drive-through racking. Drive-in racking is therefore suitable only for the LiFo method, while drive-through racking is suitable for the FiFo method. Operation is solely by industrial truck. Sideways-seated stackers are particularly suited to this system as they also give the operator a clear field of vision when in reverse.

Narrow-aisle multi-bay racking

-

Narrow-aisle multi-bay racking is a giant among racking systems. It is ideally suited to storing large quantities of individual, primarily palleted items. These systems show their strength in situations where high throughput is required in a small space. They offer all the performance features of multi-bay racking, such as direct access and flexible arrangement of beams, but require less space and enable extreme lift heights. These systems are characterised by their narrow aisle widths. The easy-to-adjust racking beams and optional double-depth storage enables an even more efficient use of the space available. They can be operated using rail or wire guidance, semi-automated or fully automated narrow-aisle trucks, sometimes also rack operating equipment.

Single-bay racking

-

Single-bay racking is ideal for ranges with large quantities per item and for heavy goods. The accessible configuration of the load units means that the use of single-bay racking is always advantageous when order picking is done directly from the pallet or pallet cage. Operation can be manual or automatic – using either forklift trucks or rack operating equipment. The depth supports ensure that the stacking process is particularly fast and reliable. Direct access to all load units and secure stacking up to high lift heights are advantages for block stacking. You also maintain flexibility when it comes to space: Angle profiles arranged in the depth direction take on the shelf function, permitting extra space heightwise.

Multi-bay racking broad aisle

-

Wide-aisle multi-bay racking is the most commonly used racking system. It is ideally suited to storing large quantities of individual, primarily palleted items. Its strength lies in its versatility: It can hold a great number of containers of various dimensions and weights and offers flexible expansion. In comparison with block storage, wide-aisle racking offers the advantages of pressure-free storage and direct access to all pallets. The possibilities are virtually limitless when it comes to height: With automatic operation, the racking can be increased from the standard 8 to 10 metres to more than 20 metres. The easy adjustment of the racking beams ensures optimum use of your warehouse space. Double-depth storage is also possible. Depending on the goods, storage takes place using forklift trucks or rack operating equipment.

Dynamic pallet storage

Drive-through storage - Pallet live storage

-

Our dynamic solutions are ideal when palleted goods need to be stacked and retrieved as quickly as possible. Drive-through racking is recommended when you operate using the FiFo method and want to move a large number of identical pallets. With this system, the stacked goods move forward automatically to the retrieval point. This goods-to-person method saves on unnecessary travel and the benefit is that the goods do not age. This makes drive-through racking ideal for transporting perishable goods with a short best-before date. The structure of the drive-through racking comprises racking uprights connected together to form a channel. One side is used for storing; the other side for retrieval. When a pallet is retrieved, the next one automatically moves along the slightly inclined roller conveyor. Brake rollers control the speed and an automatic separator makes sure that products don't get jammed.

Drive-through storage - Carton live storage

-

Drive-through racking is often used to increase efficiency when order picking small parts and packages. When using this system, your items are transported directly to the picking station using a roller system on a sloping level. This saves both time and travel distance. Because loading and removal are separate, items can be replenished without disruption. As a drive-through frame, this solution is suitable for installation in our versatile standard pallet racking. Drive-through racking is popular in the groceries sector, where strict compliance with a sequence focusing on best-before dates plays an important role (FiFo). It is also often the first choice in the mail order business, the automotive industry and in cold stores. The system is extremely flexible in both structure and operation. With operation possible by hand or by order picker, it is possible to implement multi-level systems to make full use of a room's height.

Push-back racking

-

Pushback racking is ideal when palleted goods of the same type are being put into compact storage in the warehouse. Unlike drive-through racking, goods are stored and retrieved from just one side. This reduces transport routes and also saves time and space. This type of dynamic storage is also often used for buffer channels. Pushback racking comprises racking uprights connected together to form a channel. The conveyors are tilted for particularly easy item retrieval, with the following unit moving up automatically. When stacking, units already stacked must be pushed up against the slope. There are usually three pallets in a rack, with the option of adding more. Stacking is typically done lengthways by forklift trucks or by using support arm stackers.

Static small parts storage

Automated miniload warehouse

-

Short cycle times, direct access to all articles as well as high throughput performance and optimum space utilisation: Our automatic small parts warehouses represent an ideal storage solution for large quantities of small parts and maximum goods turnover.

Modular racking system

-

If you need to store lots of different small parts, modular racking is the optimum solution. The popular, adaptable all-rounder is used in many industries, especially where access times need to be kept short for manual order picking. The comprehensive range of accessories and the simple components enable tailored adaptation to your storage space and your utilisation requirements. Modular racking is available as boltless racking with great flexibility in the height adjustment of shelving.

Order picking platforms

-

If you need to store lots of small parts, the warehouse space available is often insufficient. A modular racking floor system is recommended for this situation. It helps you make optimum use of the hall height and allows your employees to pick at multiple levels simultaneously. This increases your throughput. The multi-level system and the ability to pick at the upper levels saves you from having to use medium/high level order pickers. The steps make it easy to switch between levels. Hand pallet trucks and electric pallet trucks can be used to assist, and also forklift trucks for retrieving or removing palleted goods. The system has an extensive range of expansion and customisation options so that modular racking floor systems can be tailored to your industry, your site conditions and your performance requirements.

Storage of long loads

Cantilever racking

-

When you need to store bars, pipes or panels, you want quick and easy access at all times. This is precisely what cantilever racking was developed for. It comprises racking uprights and cantilever arms (= that come forward) to safely accommodate long goods of all weight classes and lengths. Optional roll-away protection provides an additional safeguard for the goods. Each racking upright is equipped with multiple cantilever arms, the number and spacing of which is tailored to the weight of the goods stored. The ability to extend as required means you can stay flexible. Want to store goods of different lengths or even pallets on the same racking? There's the option of connecting the cantilever arms using galvanised mesh or shelving. Movable racking can also be used to create additional space.

Steel construction platform

-

A structural steel platform is a quick way to gain additional space at height without having to make costly structural changes to the floor plan. The self-supporting, walk-on and optional drive-on steel construction creates space at multiple levels: When new storage and work areas are provided, the lower level can also be used for production, for example. Compared with integral mezzanine floors, structural steel platforms offer many individual design options. They can be used as picking platforms, for instance. Structural steel platforms can be designed so that not only hand pallet trucks but also electric pallet trucks can operate on them. Forklift trucks or conveyor systems provide the of material flow from the ground floor to the platform; personnel gain access via steps or integrated lifts.

Batteries/charging technology

-

The efficient use of energy is a key priority of our products. For you, that translates into a drop in overall costs, greater range, and continuous availability of material handling equipment, no emissions, and a positive energy balance.

We can make this all happen, because we are the only supplier to develop and manufacture our own vehicles and control units, as well as the software, batteries, and charging technology, resulting in a comprehensive system from a single source. All components are matched and networked to each other, and ensure the best possible handling, safety and energy consumption.

Batteries

-

The battery is the beating heart of any electric forklift truck. Jungheinrich is a pioneer in the field of electric power and regularly sets the standards in this area. Discover the outstanding quality and top performance of our batteries for yourself.

Charging technology

-

Those who rely on the proper charging technology have the upper hand. An intelligently controlled charging process ensures a faster operational turn-around for the vehicles and extends the battery’s service life. Jungheinrich charging devices are generally developed and manufactured in-house to ensure the perfect interaction between the vehicle, its battery and the charging system. Whether you are using lead-acid or trendsetting lithium-ion batteries, or a charging station or a vehicle-integrated charging device, we have the ideal solution for your individual requirements.

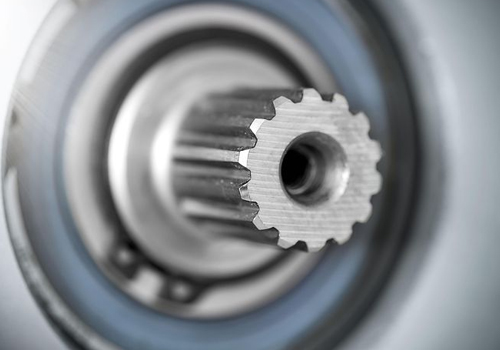

Electric drives and drivetrains

-

As one of the leading manufacturers in this segment, we develop individual solutions for you.

Controllers

-

Whether 3-phase AC or direct current controllers, whether combined control systems or individual components – we have a solution for you in store.

Electromechanic components, control pedals and displays

-

We take on the development and construction of the electromechanics needed for your project as well as displays and control pedals.

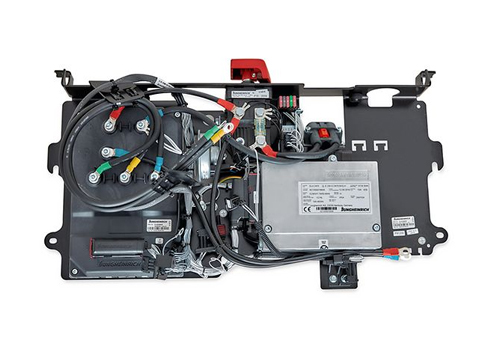

Electric mounting panels

-

Our electromechanical mounting plates are designed in such a way that they can be assembled in only a few steps.

Cable sets

-

We construct and produce cable sets of any kind and for any industry sector.

Software development

- Our software solutions are tailored to your individual needs.