- Offer Profile

- The Doppstadt enterprise based in Velbert was founded in 1965.

While in the beginning, the company focused on the development of agricultural machines, Doppstadt is now a worldwide leading solution provider in all the fields of recycling and environmental technology and resource recovery.

"Best Solution. Smart Recycling." – with this motto we combine proven procedures to create individual complete solutions, which stand out for innovative processes, highest efficiency and profitability. With locations in Velbert, Wülfrath and Calbe we serve customers in more than 50 countries through our own dealer network and we offer various services regarding the unique Doppstadt portfolio.

SMART SHREDDING

- Powerful shredding

Mobile and stationary solutions for every shredding task - maximum performance and innovative technology always included. Multipurpose Recycling System

METHOR

-

METHOR - THE MULTITOOL - Versatility in a new dimension: MORE FLEXIBILITY. MORE EFFICIENCY.

Adaptable and versatile like no other of its class – Methor takes things as they come. As a multipurpose recycling system it is simply unstoppable. Whether opening (bags), dosing, charging, disintegrating, crushing or cutting – indestructible and resistant to contaminants, it covers the widest range of applications even under the most adverse conditions.

Our multitool Methor offers the widest variety of applications of its class. The shredding of industrial waste, construction and demolition waste, mattrasses, building rubble, biowaste or waste wood, for example, do not pose a problem, but even entangled waste from paper and plastic production, the shredding of rolls or roll goods or magnetic tape scrap and the opening of the yellow waste bags are easy with the Methor. For high-performance process chains, it can be optimally combined, e.g. with a drum screen or the Selector 400 with SWS spiral shaft screening deck.

THE FUTURE IS MOBILE-MODULAR

Doppstadt solutions are distinguished by innovative processes, great efficiency and high economic viability. This applies in particular to our

Benefits

mobile-modular processing concept, in which we are able connect standard machines in a smart and efficient manner. The METHOR is at the heart of this concept. The flexible, powerful multitool opens up new perspectives for you in a wide variety of applications. As carrier variation, you can combine it with additional processing technologies using an attachment, thus creating a compact treatment system.- a system that is designed for highest adaptability and versatility

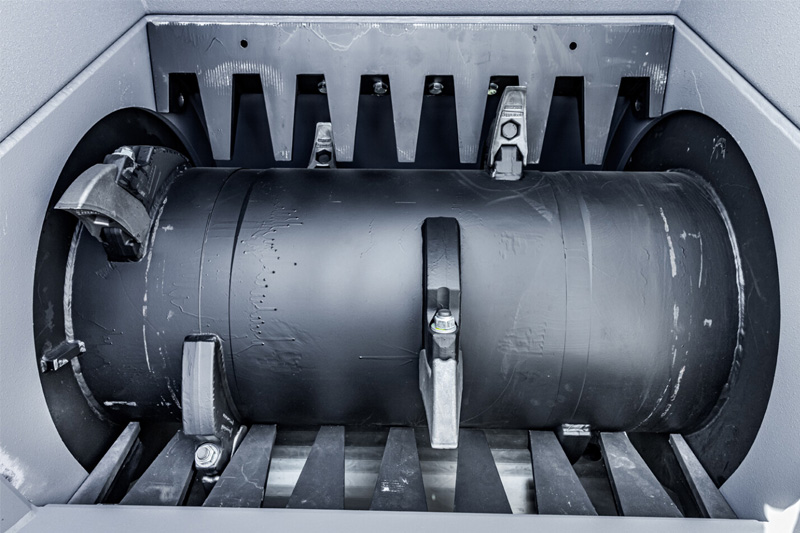

- single-shaft shredder with the widest range of applications in its class

- efficient multi-purpose shredding solution for smaller volume flows and special fractions

- unique quick tool replacement thanks to our patented Dopp-Lock® system

- largest selection of tools in its class, with roller tooth sizes S, M, and L

- the only single shaft shredder in its class with screwable tools and perfect accessibility

- HydraulicDirect Drive ensuring performance that meets your needs and contaminant-resistant operation

- selectable variants such as track-mounted chassis or mobile hook lift with yard chassis

- Smart handling – simple construction and impressive ease of maintenance and operation

Slow Speed Shredder Line

INVENTHOR TYPE 6.2

-

Breaks up more. Takes in more.

The Inventhor 6.2 combines the best of both worlds: All the experience from the DW 3060 series and all the technological innovations of the Inventhor series. The result: a machine concept designed for maximum efficiency with a high degree of suitability for practical use.

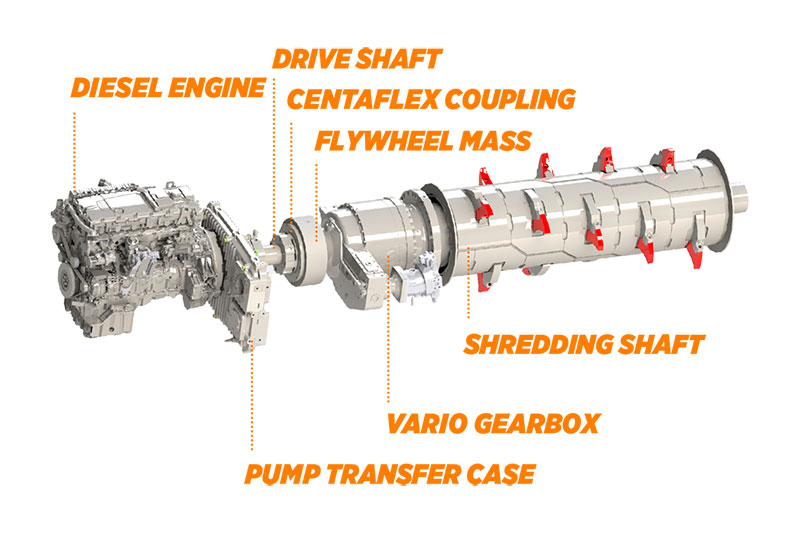

The Inventhor 6.2 sets shredding efficiency standards. Benefit from its unique VarioDirect Drive, highest uptime and simple, flexible operation, right from the first ton. Get to know the successor of the DW 3060 and take advantage of the latest Doppstadt shredder generation for your business!

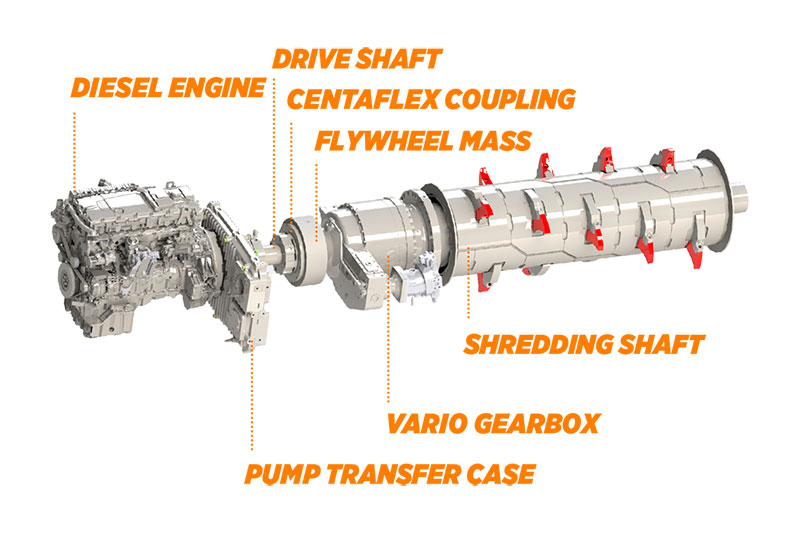

Benefits- variable, continuous power transmission thanks to our patented VarioDirect Drive concept

- high level of flexibility and quick retrofitting thanks to our patented Dopp-Lock® system with bolted tools

- operator-friendly loading with wheel loader or excavator possible as well as removable hopper extensions for a lower loading height

- moderate operating costs, high machine uptime

- outstanding capacity even with demanding applications and maximum throughput rates

- optionally available engine types (CAT / MTU) for different performance requirements

- excellent monitoring concept for shredding process

- maximum throughput rates

- quick uptime after maintenance and improved on-the-job safety during maintenance

- lower specific fuel consumption and reduced noise emissions

- optionally available as a wheeled semi-trailer (SA), with trailer chassis (A) or track-mounted chassis (K) with different discharge conveyor lengths (4.9 and 7 m)

INVENTHOR TYPE 9

-

DEVELOPED FOR MAJOR JOBS

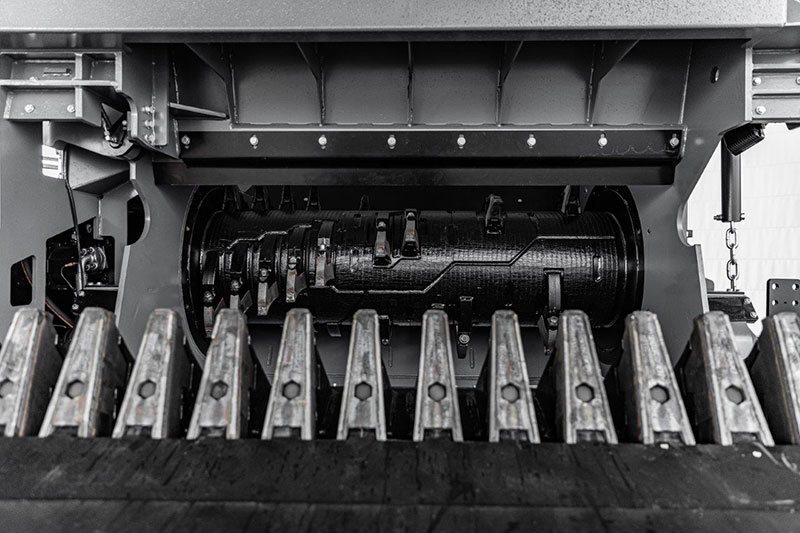

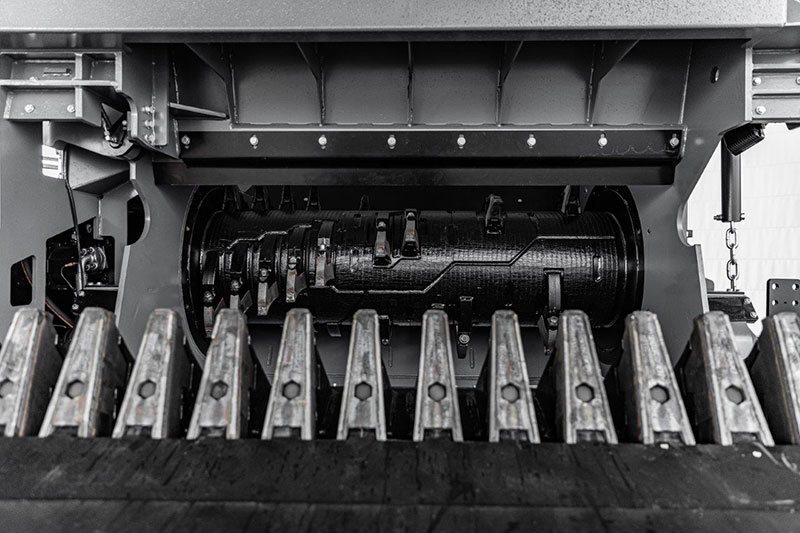

INVENTHOR TYPE 9 – Genuine heavyweight, full power and maximum flexibilityThe INVENTHOR TYPE 9 opens up completely new possibilities when it comes to effective shredding: From material feed to product removal, it stands out thanks to a whole number of innovations – for instance, the new VarioDirect Drive, which continuously transmits power to the shredding drum so that the engine always runs at the optimum operating point, or the new enclosure concept ensuring optimal accessibility from all sides. Regardless of whatever is to be shredded: The INVENTHOR TYPE 9 is the best new solution for every demanding job.

Benefits- New, future-proof drive concept with variable, continuous power transmission thanks to our patented Vario drive unit: VarioDirect Drive

- Starting up the machine when loaded– the new drive concept delivers the necessary torque to start shredding from standstill

- The integrated cleaning system enables the automatic cleaning of any long materials that become wrapped around the shredding drum

- Flexible shredding concept with different shredder packages (sizes S to XL, consisting of drum/teeth + toothed bar + limiter) allows for a precise adaptation to the respective material requirements

- New door and enclosure concept with large comb hatch for optimum accessibility and on-the-job safety in the entire shredding area

- Plug and play: After lowing the conveyor belts to the working position, the machine is immediately ready for use at the press of a button

- Excellent monitoring concept for the entire shredding process

- Reduced noise emissions

- It is now possible to select a wheeled semi-trailer (SA) or track-mounted undercarriage (K) as chassis versions as well as different rear belt lengths (7 m, 8.5 m or fixed as 12 m) for maximum conical pile

Grinder Line

AK 565

-

INCREDIBLE THROUGHPUT WITH FUTURE-PROOF DRIVE SYSTEM

The powerful mobile shredder AK 565 is flexible and universally usable and is distinguished by a lowerable rear discharge conveyor, offering improved ease of maintenance. The new engine also complies the latest EU Stage V emissions standards.

Benefit

- Separate drive unit for scraper floor and floating infeed roller for optimum intake of materials and high output

- Impervious to obstructions due to freely oscillating flails, continuous shredding thanks to load-sensing material infeed

- Latest engine and emissions control technology, compliance with the EU StageV emissions standards, exhaust system made entirely of stainless steel, thermally shielded with highest quality integral insulation

- Lowerable rear conveyor* ensures very short set-up times and maximum accessibility and ease of maintenance for the flail drum, tools and rear basket (*optional)

- Rear conveyor 4 m or 6 m long* (*optional)

- Freely oscillating flails of the flail drum, with a flywheel mass of approx. 2.5 m. tons, have flail tips that can be replaced individually and adapted for specific materials (e.g. hard metal or armored tips)

- Easy-to-exchange fine-shredding basket*, the mesh size (30 – 400 mm) determines the grain size of the output material, (*optional)

- Special basket* with 3D technology for processing waste wood, for improving the structural composition of the end product (*optional)

AK 565 K

-

MAXIMUM MOBILITY – EVEN ON ROUGH TERRAIN

With its tracked chassis, which is also available as a an offroad version, the AK 565 K may also be used on rough terrain. The lowerable rear belt ensures that maintenance is easier.

Benefit

- Easy one-man operation (all functions can be controlled via remote control), machine moved using the tracked chassis, high mobility on rough terrain (*offroad version available as option with a clearance that is 200 mm higher)

- Continuous shredding thanks to load-sensing material infeed, impervious to obstructions due to freely oscillating flails

- Latest engine and emissions control technology, compliance with the EU StageV emissions standards

- Exhaust system made entirely of stainless steel

- Standard lowerable rear belt (7.5m long with a discharge height of more than 5m) ensures very short set-up times and maximum accessibility and ease of maintenance for the flail drum, tools and rear basket

- Separate drive unit for scraper floor and floating infeed roller for optimum intake of materials and high output

- Freely oscillating flails of the flail drum, with a flywheel mass of approx. 2.5 m. tons, have flail tips that can be replaced individually and adapted for specific materials (e.g. hard metal or armored tips)

- Special basket* with 3D technology for processing waste wood, for improving the structural composition of the end product (*optional)

AK 565 PLUS

-

THREE-PART REAR CONVEYOR FOR MAXIMUM FLEXIBILITY

As successor of the AK 560 EcoPower Plus, the mobile 3-axle AK 565 Plus is equipped with a new engine that complies with the EU Stage V emissions standards. The 6 m long rear conveyor offers immense flexibility when it comes to discharging.

Benefit

- Separate drive unit for scraper floor and floating infeed roller for optimum intake of materials and high output

- Impervious to obstructions due to freely oscillating flails, continuous shredding thanks to load-sensing material infeed

- Latest engine and emissions control technology, compliance with the EU StageV emissions standards

- Exhaust system made entirely of stainless steel, thermally shielded with highest quality integral insulation

- Lowerable rear conveyor ensures very short set-up times and maximum accessibility and ease of maintenance for the flail drum, tools and rear basket

- Rear conveyor 6 m long

- Freely oscillating flails of the flail drum, with a flywheel mass of approx. 2.5 m. tons, have flail tips that can be replaced individually and adapted for specific materials (e.g. hard metal or armored tips)

- Special basket* with 3D technology for processing waste wood, for improving the structural composition of the end product (*optional)

AK 315

-

FLEXIBLE AND UNIVERSALLY APPLICABLE

The smallest mobile shredder in the AK series, the AK 315 can be used for almost all shredding tasks, while its new 230 kW MTU engine meets the latest Stage V emission standards.

Benefit

- Load-sensing hydraulic infeed system

- Easy to start up with full shredding chamber

- Easy to change cutting tools thanks to bolt conections and inching mode

- Variable rotor speed from 100 to 350min-1

- Easy access thanks to the large service door

AK 640 K

-

MADE FOR BIG TASKS

The broadly applicable grinders of the AK series process green waste, garden and park waste, biowaste, pre-shredded logs and roots, waste wood and wooden pallets. For special applications, the AK grinders can be combined with other Doppstadt products, such as pre-shredders and screening machines

Benefit

- Easy one-man operation (remote control of all main functions),

- the machine can be moved easy via tracklaying chassis, high offroad mobility (* optional with 200 mm higher off-road chassis)

- Continuous grinding with maximum performance by means of

- load sensing material in-feed, contaminant resistant thanks to

- free-swinging flails

- Latest engine and exhaust reduction technology, fully compliant

- with stage V exhaust regulations

- Exhaust system completely made of stainless steel

- Standard lowerable rear discharge conveyor (7.5 m in length,

- drop height > 5 m) for minimum set-up time and perfect

- maitenance friendliness and accessibility to flail drum, tools and

- rear basket

- Separate power unit for feeder and free-movingly mounted

- infeed drum for perfect material intake and high through-put

- Free-swinging flails of the flail drum (gyrating mass appr. 2,5 t

- (5,512 lb) are provided with easily individual replaceable flail

- tips that can be adjusted to the materials to be grinded (e.g.

- hard metal or armoured tips)

- Special baskets* using 3D technology for the processing of

- waste wood, improving the structural quality of the final

- product. (*option)

AK 640 SA

-

PERFECT COMBINATION OF PERFORMANCE AND EFFICIENCY

The AK 640 SA is the flagship of the AK series and delivers maximum throughput thanks to its huge feed hopper and state-of-the-art engine technology. At the same time, it is just as easy to transport as the smaller models.

Benefit

- Continuous shredding thanks to load-sensing material infeed, impervious to obstructions due to freely oscillating flails

- Latest engine and emissions control technology, compliance with the EU StageV emissions standards

- Exhaust system made entirely of stainless steel

- 6 m feed hopper

- Standard lowerable rear conveyor (7.5m long with a discharge height of more than 5m) ensures very short set-up times and maximum accessibility and ease of maintenance for the flail drum, tools and rear basket

- Separate drive unit for scraper floor and floating infeed roller for optimum intake of materials and high output

- Freely oscillating flails of the flail drum, with a flywheel mass of approx. 2.5 m. tons, have flail tips that can be replaced individually and adapted for specific materials (e.g. hard metal or armored tips)

- Special basket* with 3D technology for processing waste wood, for improving the structural composition of the end product (*optional)

CORESHREDDING

CORESHRED 250

-

THE DOPPSTADT CORE SHREDDER LINE WITH TOP PRICE-PERFORMANCE RATIO.

Doppstadt twin-shaft shredders are designed for a wide variety of applications and cover a wide range of areas and materials.

With the innovative quick-change system, the shredding unit can be easily adapted to your requirements. Depending on what you need to shred, our suitable shaft types, such as concrete shafts, paddle shafts, star shafts or metal shafts, offer you the ideal solution depending on the machine model:

- Construction & Demolition waste

- Commercial waste

- Rubber & Scrap tyres

- Natural & Waste wood

- Wooden rail sleepers

- Trunk wood

- Green waste

- Paper & Cardboard

- CFRP & GRP waste

- Automotive & Aluminium scrap

CORESHRED 800

-

THE DOPPSTADT CORE SHREDDER LINE WITH TOP PRICE-PERFORMANCE RATIO.

Doppstadt twin-shaft shredders are designed for a wide variety of applications and cover a wide range of areas and materials.

With the innovative quick-change system, the shredding unit can be easily adapted to your requirements. Depending on what you need to shred, our suitable shaft types, such as concrete shafts, paddle shafts, star shafts or metal shafts, offer you the ideal solution depending on the machine model:

- Construction & Demolition waste

- Commercial waste

- Rubber & Scrap tyres

- Natural & Waste wood

- Wooden rail sleepers

- Trunk wood

- Green waste

- Paper & Cardboard

- CFRP & GRP waste

- Automotive & Aluminium scrap

CORESHRED 900

-

THE DOPPSTADT CORE SHREDDER LINE WITH TOP PRICE-PERFORMANCE RATIO.

Doppstadt twin-shaft shredders are designed for a wide variety of applications and cover a wide range of areas and materials.

With the innovative quick-change system, the shredding unit can be easily adapted to your requirements. Depending on what you need to shred, our suitable shaft types, such as concrete shafts, paddle shafts, star shafts or metal shafts, offer you the ideal solution depending on the machine model:

- Construction & Demolition waste

- Commercial waste

- Rubber & Scrap tyres

- Natural & Waste wood

- Wooden rail sleepers

- Trunk wood

- Green waste

- Paper & Cardboard

- CFRP & GRP waste

- Automotive & Aluminium scrap

SMART SCREENING

- Reliable screening guaranteed

Even hard-to-screen material is neatly separated - simply get the best out of all recycling processes. Trommel Line

SM 620.2 K

-

FORWARD-LOOKING RECYCLING

Mobile power with large capacity

Thanks to its height-adjustable tracked chassis, the SM 620.2 K is always right on track, even on uneven and rough terrain – and is also able to handle demanding screening tasks very quickly and reliably.

Benefit- Heavy-duty tracklaying chassis

- Self-propelled via remote control unit

- Large feed hopper with a capacity of more than 7 m³

- Hopper width even suited for very large loader buckets, loading height only 2.9m

- Load sensing system allows, among other things, for moving and operating at the same time

- Track chassis with lifting kinematics for optimum levelling of machine on uneven terrain

- Fast changing system for trommel or star screen insert

- Diesel engine with low fuel consumption - exhaust standard stage V, low operation costs

- highest throughput capacity

- Extensive standard safety equipment (e.g. intrusion protection, emergency stop, machine monitoring)

- Complete machine control placed in the rear

- Additional hydraulic connections for using numerous optional equipment

SM 620.2 SA

-

HIGH OUTPUT AND CONVENIENT LOADING

High performance solution for continuous use

The large 7 m³ feed hopper makes the SM 620.2 SA especially easy to load for very large wheel loaders – be it with household waste, compost or building rubble. It is the perfect choice when it comes to high throughput in continuous operation.

Benefit- Quick exchange of screening unit, operates with trommel or star screen insert

- Many options to meet various requirements

- Electronic load sensing control for optimized screening results

- Large 7,0 m³ feeding hopper with low feeding height of 2,9 m

- Low operational costs and high throughput capacity

- Extensive standard safety equipment (e.g. intrusion protection, emergency stop, machine monitoring)

- European road approval

- Three additional hydraulic connections for simultaneous

operation of additional equipment

SM 518.2

-

MASTERING MANY REQUIREMENTS

SM 518.2 – The expert for many different recycling tasks

Our smallest highly flexible successor model to the tried and tested SM 518 Plus screening machine is now equipped with the latest engine technology complying with the EU’s Stage V emissions standards and delivers an end product of top quality in up to 5 fractions.

Benefit- Fast changing system for the screening unit, trommel, wire screen drum or star screen insert available

- Many options to meet various requirements

- Large 5,0 m³ feeding hopper with just 2,9 m loading height, 5,5 m long output conveyors with 3,5 m drop-off height

- Electronic load sensing control for perfect screening at optimized throughput

- Latest engine and exhaust reduction technology, fully compliant with stage V exhaust regulations

- Decentralized control for easy operation, exact adjustment and reading of the machine data by multifunctional display

- Extensive standard safety equipment (e.g. intrusion protection, emergency stop, machine monitoring)

- Compact transport dimensions for excellent mobility, worldwide road approval

SM 620.3

-

Simply efficient screening!

Made for big tasks - the new SM 620.3 universal screening machine now also with DualPower drive technology

The future starts now as we launch the SM 620.3, the new generation of our trommel screening machines. We have listened to the market and provide our customers with exactly the machine they need. The successor to the SM 620.2 offers the same performance with even greater efficiency at the most attractive price in its class. The new DualPower drive technology - teh samrter hybrid, enables operators to switch flexibly between diesel or electric drive and thus adapt perfectly to the existing infrastructure.

SM 720.2 SA

-

LARGE, POWERFUL, MOBILE

As the largest model with a screening drum spanning over 7 meters, the SM 720.2 SA is predestined for continuous operation during high-throughput screening tasks. In spite of its size, retrofitting and transporting is easy and convenient – and thus it is ideal for demanding recycling jobs at changing job sites.

Benefit- Maximum throughput capacity at high- quality screening results due to extra large screening area

- Many options to meet various requirements

- Large size feeding hopper and extra long output conveyors allow feeding of the machine with large front loaders

- Low operation costs due to powerful drive at low fuel consumption, short set-up time

- Unique load sensing feeder control makes sure that the capacity of the machine is used at the optimum in safe operation without interruption

- Extensive standard safety equipment (e.g. intrusion protection, emergency stop, machine monitoring)

- European road approval

SM 720.2 SA

-

Large, powerful, mobile

Maximum effectiveness on wheels: SM 720.2 SA

As the largest model with a screening drum spanning over 7 meters, the SM 720.2 SA is predestined for continuous operation during high-throughput screening tasks. In spite of its size, retrofitting and transporting is easy and convenient – and thus it is ideal for demanding recycling jobs at changing job sites.

Benefits- Maximum throughput capacity at high- quality screening results due to extra large screening area

- Many options to meet various requirements

- Large size feeding hopper and extra long output conveyors allow feeding of the machine with large front loaders

- Low operation costs due to powerful drive at low fuel consumption, short set-up time

- Unique load sensing feeder control makes sure that the capacity of the machine is used at the optimum in safe operation without interruption

- Extensive standard safety equipment (e.g. intrusion protection, emergency stop, machine monitoring)

- European road approval

Flatflex Line

SELECTOR 400

-

POWERHOUSE FOR EVERY SITUATION

Selector 400 – The perfect solution for separating difficult material streams

When it comes to mixed material streams, be it commercial waste, oversize bulky waste, or building rubble, a real expert is needed. Thanks to its spiral shaft technology, the Selector 400 is able to process even difficult-to-separate materials, breaking them up quickly, reliably and cleanly.

Benefit- Smooth processing of difficult-to-screen material streams that can easily wrap around the rotor and thus cause significant wear and tear

- Use of auxiliary hydraulic drive available on other Doppstadt products or even from other third-party machines or a separate hydraulic unit

- Mobile hook lift design, compact transport dimensions, short setup times

- Simple, rugged and compact design, no electronics and low-wear technology ensure a high level of process reliability

- Low energy consumption and very low operating costs

- Also suited for especially inhomogeneous materials without any pre-shredding

- Active screen openings prevent clogging or jamming of the screen surface – and thus ensure a consistent screening quality

Selector 800.2

-

FLEXIBLE, RUGGED AND EFFICIENT

SM 620 A – Thorough separation of difficult-to-screen materials

Right at home when it comes to materials that are difficult to screen and which easily wrap around the rotor, the Selector 800.2 thoroughly separates material streams with very little wear and tear. It is the ideal solution for separating complex materials downstream of a preshredding process thanks to its high throughput.

Benefit- Use of SWS screening deck for smooth processing of difficult-to-screen material streams that can easily wrap around the rotor and thus cause significant wear and tear

- No clogging of screen openings, thus ensuring a consistent screening quality

- Flexible setup depending on choice of spiral shaft or star screening decks on the base chassis; additional superstructures of different variations may be retrofitted (even for the previous model HS 800 with the aid of a retrofit kit)

- Use of auxiliary hydraulic drive available on other Doppstadt products or even from other third-party machines or a separate hydraulic unit

- Universal, broad range of possible uses. The separating cut can be individually adapted by changing the spiral shaft screening deck (SWS) or star screening deck (DST); individual decks are interchangeable between Selector 400 and 800.2

- Integrated, slewing return line allows for the automatic recirculation of oversized particles to pass through the shredding process again

- Mobile hook lift design, compact transport dimensions, short setup times

- Simple, rugged and compact design, no electronics and low-wear technology ensure a high level of process reliability

- Low energy consumption and very low operating costs

SMART TURNING

- Shift and ventilate optimally

Shifting layered and trapezoid windrows flexibly and reliably - this speeds up the biological conversion process. Side Turner Line

DU 265

-

EFFECTIVELY TURNING COMPOST

DU 265 – Ideal for creating precise and individual windrows

Flexible and absolutely reliable for every task: essentially describing how the DU 265 laterally turns flat and trapezoidal windrows in compost. At the same time, the material is aerated and the biological conversion process in the compost is effectively homogenized and accelerated.

Benefit- Great flexibility thanks to compact design

- Easy to transport on roads* and quick set-up due to hydraulically folding elements

- Blade-like milling tools with high wear resistance

- Easy to maintain and replace cutting elements as a result of freely accessible milling discs

- Good adaptability due to variety of tools

- Discharge drum* for variable control of windrow heights

- Long grass wedge for processing cut crops

DU 320

-

FOR ALL TYPES OF MATERIAL WINDROWS

DU 320 – Efficient turning in any direction

The DU 320 is the ideal addition for any company that wants to better utilize the capacity of its large tractors. The windrow turner with reversing unit laterally turns flat and trapezoidal windrows, effectively accelerating the biological conversion process by means of aeration.

Benefit- Use of SWS screening deck for smooth processing of difficult-to-screen material streams that can easily wrap around the rotor and thus cause significant wear and tear

- No clogging of screen openings, thus ensuring a consistent screening quality

- Flexible setup depending on choice of spiral shaft or star screening decks on the base chassis; additional superstructures of different variations may be retrofitted (even for the previous model HS 800 with the aid of a retrofit kit)

- Use of auxiliary hydraulic drive available on other Doppstadt products or even from other third-party machines or a separate hydraulic unit

- Universal, broad range of possible uses. The separating cut can be individually adapted by changing the spiral shaft screening deck (SWS) or star screening deck (DST); individual decks are interchangeable between Selector 400 and 800.2

- Integrated, slewing return line allows for the automatic recirculation of oversized particles to pass through the shredding process again

- Mobile hook lift design, compact transport dimensions, short setup times

- Simple, rugged and compact design, no electronics and low-wear technology ensure a high level of process reliability

- Low energy consumption and very low operating costs