- Offer Profile

- GEMÜ is a leading world-wide manufacturer of valves, automation components and other piping products. The company has been manufacturing innovative products and customized solutions in and around the field of process media control since 1964.

Our innovations

GEMÜ D40

-

The pneumatically operated GEMÜ D40 diaphragm valve is designed for use in sterile applications. The diaphragm hermetically separates the actuator from the working medium. All actuator parts (except the seals and design elements) are made from stainless steel. The "Normally closed", "Normally open" and "Double acting" control functions are available. The valve has an optical position indicator with a transparent cap as standard.

Features:

- For use in hygienic and aseptic applications (CIP/SIP capable and autoclavable)

- Valve can be configured for the respective process parameters

- Fast, safe and simple diaphragm and actuator mounting

- Low maintenance due to the firmly chambered diaphragm

- Very high Kv values thanks to the flow-optimized valve body

- Identification of the angle of rotation (hash mark), optical position indicator and transparent cap as standard

- Simple modular expansion possible thanks to state-of-the-art automation components

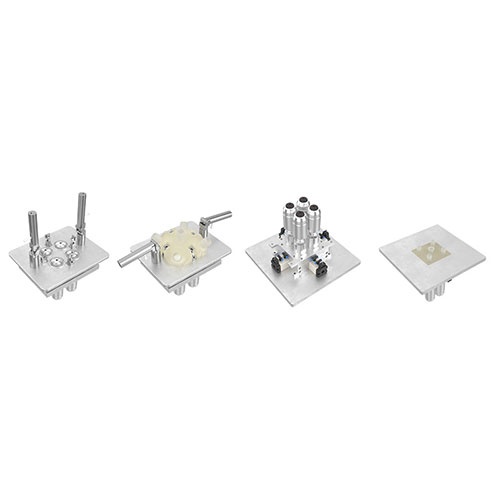

GEMÜ Multiport SUMONDO

-

If you are looking for Single-Use application components, GEMÜ is the right partner for you. We advise customers, design and produce our standard product range, as well as creating individual solutions on a case by case basis

GEMÜ Multiport SUMONDO – Single-Use diaphragm valves in the smallest of spacesCombine several Single-Use diaphragm valves in a Multiport-block and reduce deadlegs and space while also saving on installation work. When designing the GEMÜ Multiport SUMONDO solution, we take your individual process requirements into account.

GEMÜ Q50 eSyStep

-

The GEMÜ Q50 eSyStep 2/2-way pinch valve is motorized. The eSyStep electric actuator is available as ON/OFF or with integrated positioner. The valve guides a tube which is compressed from above by a compressor to control and regulate media. The compressor's specially developed contour and the tube holder's contour minimize the strain on the tube and thus increase the tubes' service life. Tubes can be safely inserted and removed in simple steps and without tools. An optical and electrical position indicator is integrated as standard.

Features:

- Open/close function or with integrated positioner

- Linear or modified equal-percentage control characteristics

- Parameterizable via IO-Link

- On-site or remote end position programming via programming input

- Fast, safe tube replacement

- Simple replacement of inserts and compressors for various tube sizes with the same actuator

- Minimized strain on the tube due to the optimized compressor

- Several installation options possible in the plant thanks to the mounting flange or female thread on the body

GEMÜ Q51

-

The GEMÜ Q51 2/2-way pinch valve is a electrically operated as a positioner. The valve guides a tube which is compressed from above by a compressor to control and regulate media. The compressor's specially developed contour and the tube holder's contour minimize the strain on the tube and thus increase the tubes' service life. Tubes can be safely inserted and removed in simple steps and without tools.

Features:

- Position indicator for precision control applications

- Fast, safe tube replacement

- Tube replacement about digital interface

- On-site end position programming

- Simple replacement of inserts and compressors for various tube sizes with the same actuator

- Minimized strain on the tube due to the optimized compressor

- Several installation options possible in the plant thanks to the mounting flange or female thread on the body

GEMÜ 1441 cPos-X

-

The GEMÜ 1441 cPos-X positioner can be paired with many pneumatically operated valves, thus expanding their range of functions. Discover the versatile GEMÜ solutions. We are sure that we have the right solution for your system.

Features:

- 2-wire-connection technology

- Quick commissioning using well-balanced preconfiguration

- HART communication available upon request

- "Fail safe" and "Fail freeze" safety function available

- BLE communication for remote access and configuration

- Almost no air consumption when idle

GEMÜ R480 Victoria

-

The GEMÜ R480 Victoria soft seated metal butterfly valve is equipped with a bare shaft with top flange in accordance with EN ISO 5211. The butterfly valve is available in nominal sizes DN 25 to 600 and in standard installation lengths ISO 5752/20 | EN 558-1/20 | API 609 category A (DIN 3202 K1) in wafer, lug and U section body versions.

Features:

- Low torques thanks to PTFE coated bushes

- Bubble tight sealing, in accordance with EN 12266-1/P12, leak rate A

- Liner material is easy to read when installed

- Sleek disc design for higher Kv values

- Robust body coating comparable to ISO 12944-6 C5

GEMÜ butterfly valves

-

Butterfly valves: Areas of application and industrial sectors

GEMÜ butterfly valves are primarily used in industrial applications and the chemical industry, as well as the fields of water supply and water/waste water treatment. The concentric and single-eccentric designs are available as standard. However, the double-eccentric and triple-eccentric shut-off valves are also available for projects on request. Use of matched control components such as position indicators, positioners and process controllers allows GEMÜ butterfly valves to also be used in control circuits.

GEMÜ 410

-

The GEMÜ 410 butterfly valve is motorized. Normally Closed and Normally Open control functions are available. The valve body is available in a plastic design.

- Media temperature: 0 to 60 °C

- Ambient temperature: -10 to 60 °C

- Operating pressure: 0 to 6 bar

- Nominal sizes: DN 15 to 50

- Connection types: Union end

- Connection standards: BS | DIN

- Housing materials: PVC-U, grey

- Liner materials: EPDM | FKM

- Disc materials: PVDF

- Conformities: EAC

Features:

- Low weight

- Corrosion resistant plastic body

- Simple installation with union nut

- Space-saving piston actuator made of plastic

GEMÜ 411

- The GEMÜ 411 soft seated butterfly valve made from stainless steel or brass has an ergonomically designed, corrosion-resistant plastic hand lever. It is protected against accidental operation by the integrated locking device. With its rounded and polished disc edges, the butterfly valve is optimized for frequent cycle duties. The surface of the butterfly valve can be further finished.

Technical specifications:- Connection: Spigot; Threaded socket

- Actuator: Manual

- Body material: 1.4581; CW617N (brass)

- Max. operating pressure: 10 bar

- Max. media temperature: 100 ° C

- Nominal sizes

Features:- Media temperature: -20 to 120 °C

- Ambient temperature: -10 to 60 °C

- Operating pressure: 0 to 10 bar

- Nominal sizes: DN 15 to 50

- Connection types: Clamp | Spigot | Threaded connection

- Connection standards: ASME | DIN | EN | ISO | SMS

- Housing materials: 1.4408, investment casting material | CW614N, brass | CW617N, brass

- Liner materials: EPDM | FKM | Silicone

- Disc materials: 1.4408, investment casting material | CW614N, brass | CW617N, brass

- Conformities: ATEX | EAC | FDA

GEMÜ 415

- The GEMÜ 415 soft seated butterfly valve made from stainless steel or brass is pneumatically operated by a space-saving piston actuator. The "Normally Closed", "Normally Open" and "Double Acting" control functions are available. A low-cost rack and pinion actuator can also be fitted. With its rounded and polished disc edges, the butterfly valve is optimized for frequent cycle duties. The surface of the butterfly valve can be further finished.

Technical specifications:- Media temperature: -20 to 120 °C

- Ambient temperature: 0 to 60 °C

- Operating pressure: 0 to 10 bar

- Nominal sizes: DN 15 to 50

- Connection types: Clamp | Spigot | Threaded connection

- Connection standards: ASME | DIN | EN | ISO | SMS

- Housing materials: 1.4408, investment casting material | CW614N, brass | CW617N, brass

- Liner materials: EPDM | FKM | Silicone

- Disc materials: 1.4408, investment casting material | CW614N, brass | CW617N, brass

- Conformities: ATEX | EAC | FDA

Features:- Suitable for vacuum applications and low temperatures

- High-quality butterfly valve made from stainless steel or brass

- Available in small nominal sizes

- Compact and robust body

- Corrosion-resistant and space-saving piston actuator made from plastic or metal

GEMÜ 417

-

The GEMÜ 417 butterfly valve has an ergonomically designed corrosion resistant plastic hand lever. It can be protected against accidental operation by the integrated locking device.

Technical specifications:- Connection: Union end

- Actuator: Manual

- Body material: PVC-U, grey

- Max. operating pressure: 6 bar

- Max. media temperature: 60 ° C

- Nominal sizes

Features:- Low weight

- Corrosion resistant plastic housing

- Integrated locking device

GEMÜ 423

-

The GEMÜ 423 butterfly valve has a low maintenance motorized quarter turn actuator. A manual override and an optical position indicator are integrated as standard.

Technical specifications:- Connection: Union end

- Actuator: Motorized

- Body material: PVC-U, grey

- Max. operating pressure: 6 bar

- Max. media temperature: 60 ° C

- Nominal sizes

Features:- Low weight

- Adjustable end positions by means of microswitches

- Simple installation

- Robust design

GEMÜ 428

- The GEMÜ 428 soft seated butterfly valve made from stainless steel or brass is motorized. A manual override and an optical position indicator are integrated as standard. With its rounded and polished disc edges, the butterfly valve is optimized for frequent cycle duties. The surface of the butterfly valve can be further finished.

Technical specifications:- Media temperature: -20 to 120 °C

- Ambient temperature: -10 to 60 °C

- Operating pressure: 0 to 10 bar

- Nominal sizes: DN 15 to 50

- Connection types: Clamp | Spigot | Threaded connection

- Connection standards: ASME | DIN | EN | ISO | SMS

- Housing materials: 1.4408, investment casting material

- Liner materials: EPDM | FKM | Silicone

- Disc materials: 1.4408, investment casting material

- Supply voltage: 12 V AC, 50/60 Hz | 12 V DC | 24 V AC, 50/60 Hz | 24 V DC

- Operating time 90°: 4 to 100 s

- Protection class: IP 65, 66, 67, 68

- Conformities: EAC | FDA

Features:- Suitable for vacuum applications and low temperatures

- High-quality butterfly valve made from stainless steel or brass

- Available in small nominal sizes

- Compact and robust body

GEMÜ 480

- The GEMÜ C480 soft seated butterfly valve has a bare shaft. The butterfly valve is available in nominal sizes DN700 - 1600 and in standard installation lengths ISO 5752/20 | EN 558-1/20 | API 609 category A (DIN 3202 K1) in wafer and lug body versions.

Technical specifications:- Media temperature: -10 to 70 °C

- Ambient temperature: -20 to 95 °C

- Operating pressure: 3 to 16 bar

- Nominal sizes: DN 700 to 1600

- Body configurations: Lug | U section | Wafer

- Connection standards:

- Body materials: EN-GJS-400-15

- Liner materials:

- Disc materials:

- Conformities: ACS | EAC

Features:- Simple installation

- Low torques

- Modular construction

- Advanced seal design - even for larger diameters

GEMÜ C481 Victoria

- Die GEMÜ C481 soft seated butterfly valve has a metal actuator and is pneumatically operated. The butterfly valve is available in nominal sizes DN700 - 1600 and in standard installation lengths ISO 5752/20 | EN 558-1/20 | API 609 category A (DIN 3202 K1) in wafer and lug body versions.

Technical specifications:- Media temperature: -10 to 70 °C

- Ambient temperature: -20 to 95 °C

- Operating pressure*: 3 to 16 bar

- Nominal sizes*: DN 700 to 1600

- Installation lengths: ISO 5752/20 | EN 558-1/20 | API 609 category A

- Body configurations: Lug | U section | Wafer

- Connection types: Flange

- Connection standards:

- Housing materials: EN-GJS-400-15

- Liner materials:

- Disc materials:

- Conformities: ACS | EAC

Features:- Simple installation

- Low torques

- Modular construction

- Modular actuator concept

- Advanced seal design - even for larger diameters

GEMÜ 487

- The GEMÜ C487 soft seated butterfly valve is manually operated. It has a metal gearbox. The butterfly valve is available in nominal sizes DN700 - 1600 and in standard installation lengths ISO 5752/20 | EN 558-1/20 | API 609 category A (DIN 3202 K1) in wafer and lug body versions.

Technical specifications:- Media temperature: -10 to 70 °C

- Ambient temperature: -20 to 95 °C

- Operating pressure*: 3 to 16 bar

- Nominal sizes*: DN 700 to 1600

- Installation lengths: ISO 5752/20 | EN 558-1/20 | API 609 category A

- Body configurations: Lug | U section | Wafer

- Connection types: Flange

- Connection standards: not specified

- Housing materials: EN-GJS-400-15

- Liner materials: not specified

- Disc materials: not specified

- Conformities: ACS | EAC

Features:- Simple installation

- Low torques

- Modular construction

- Advanced seal design - even for larger diameters

GEMÜ 488

- The GEMÜ D488 Victoria soft-seated butterfly valve is motorized. Various metal or plastic on/off or control actuators are available. The butterfly valve is available in nominal sizes DN 25 to 1600, in the standardized installation lengths: ISO 5752/20 | EN 558-1/20 | API 609 category A (DIN 3202 K1) available in wafer, lug and U section body versions.

Technical specifications:- Media temperature: -60 to 210 °C

- Ambient temperature: -20 to 70 °C

- Operating pressure: 0 to 16 bar

- Nominal sizes: DN 25 to 1600

- Body configurations: Lug | U section | Wafer

- Connection standards: ANSI | AS | ASME | AWWA | BS | DIN | EN | ISO | JIS

- Body materials: ASTM | EN-AC-46100, aluminium casting material | EN-AC-47100, aluminium casting material | EN-GJL-250 | EN-GJS-400-15, SG iron material | EN-GJS-400-18-LT, SG iron material | S275JR, cast steel material with epoxy coating

- Body coating: Epoxy

- Liner materials: CR | CSM (Hypalon®) | ECO | EPDM | NBR | SBR, abrasion resistant | Silicone

- Disc materials: 1.4408, investment casting material | 1.4469, Duplex cast steel material | 1.4539, forged material | 2.0975, bronze casting material | 2.4602 (alloy 22), block material | EN-GJS-400-15, SG iron material

- Disc coating: EPDM | Epoxy | Halar® | NBR | Rilsan® | SBR

- Supply voltage: 100 - 120 V AC, 50/60 Hz | 12 - 24 V AC/DC | 220 - 240 V AC, 50/60 Hz | 380 - 480 V AC, 50/60 Hz

- Operating time 90°: 4 to 100 s

- Protection class: IP 65, 66, 67, 68

- Conformities: ACS | DNV GL | DVGW Drinking water | DVGW Gas | EAC | FDA | WRAS

Features:- Available in large nominal sizes

- Bubble tight sealing, in accordance with EN 12266-1/P12, leak rate A

- Special materials for disc, seal and valve body

- Vulcanizable liner

- Abrasion-resistant version possible

GEMÜ 490

-

The GEMÜ 490 Edessa PTFE-lined butterfly valve has a bare shaft. The disc and shaft are one piece; body and liner are available in different designs. The butterfly valve is available in nominal sizes DN 25 to 1200 (1"–48"), in the standardized installation lengths: ISO 5752/20 | EN 558-1/20 | API 609 category A (DIN 3202 K1) available in wafer and lug body versions.

Technical specifications:- Media temperature: -20 to 200 °C

- Ambient temperature: -20 to 95 °C

- Operating pressure: 0 to 10 bar

- Nominal sizes: DN 25 to 1200

- Body configurations: Lug | Wafer

- Connection standards: AS | ASME | DIN | EN | ISO | JIS

- Body materials: 1.4404, block material | EN-GJS-400-18-LT, SG iron material | S355J2 + N, cast steel material | VE Duroplast, reinforced

- Body coating: Epoxy

- Liner materials: PTFE/EPDM | PTFE/FKM | PTFE/silicone

- Disc materials: 1.4404 (316L), forged material | 1.4469, Duplex cast steel material | 2.4602 (alloy 22), block material | 3.7035, titan

- Disc coating: PFA

- Conformities: ATEX | EAC | FDA | FMEDA | TA Luft (German Clean Air Act)

Features:- Suitable for chemically corrosive media

- Bubble tight sealing, in accordance with EN 12266-1/P12, leak rate A

- High-quality selection of materials can be combined in different ways

- High level of plant reliability thanks to one-piece shaft and spring-washer-supported seal system

- Long service life thanks to shaft bearings and special disc and liner geometry

GEMÜ 491

- The GEMÜ 491 Edessa PTFE lined butterfly valve has a metal actuator and is pneumatically operated. The "Normally Closed", "Normally Open" and "Double Acting" control functions are available. Disc and shaft are one piece, body and liner are available in different designs. The butterfly valve is available in nominal sizes DN 25 to 600 and in standard installation lengths ISO 5752/20 | EN 558-1/20 | API 609 category A (DIN 3202 K1) in wafer and lug body versions.

Technical specifications:- Media temperature: -20 to 200 °C

- Ambient temperature: -20 to 95 °C

- Operating pressure: 0 to 10 bar

- Nominal sizes: DN 25 to 600

- Body configurations: Lug | Wafer

- Connection standards: AS | ASME | DIN | EN | ISO | JIS

- Body materials: 1.4404, block material | EN-GJS-400-18-LT, SG iron material | S355J2 + N, cast steel material | VE Duroplast, reinforced

- Body coating: Epoxy

- Liner materials: PTFE/EPDM | PTFE/FKM | PTFE/silicone

- Disc materials: 1.4404 (316L), forged material | 1.4469, Duplex cast steel material | 2.4602 (alloy 22), block material | 3.7035, titan

- Disc coating: PFA

- Conformities: ATEX | EAC | FDA | FMEDA | TA Luft (German Clean Air Act)

Features:- Suitable for chemically corrosive media

- Bubble tight sealing, in accordance with EN 12266-1/P12, leak rate A

- High-quality selection of materials can be combined in different ways

- High level of plant reliability thanks to one-piece shaft and spring-washer-supported seal system

- Long service life thanks to shaft bearings and special disc and liner geometry

- Optional accessories are installed, set and tested so they are ready for operation

GEMÜ 497

- The GEMÜ 497 Edessa PTFE seal butterfly valve is manually operated. It has a metal hand lever or gearbox depending on customer requirements. Disc and shaft are one piece, body and liner are available in different designs. The butterfly valve is available in nominal sizes DN 25 to 1200 and in standard installation lengths ISO 5752/20 | EN 558-1/20 | API 609 category A (DIN 3202 K1) in wafer and lug body versions.

Technical specifications:- Media temperature: -20 to 200 °C

- Ambient temperature: -20 to 95 °C

- Operating pressure: 0 to 10 bar

- Nominal sizes: DN 25 to 1200

- Body configurations: Lug | Wafer

- Connection standards: AS | ASME | DIN | EN | ISO | JIS

- Body materials: 1.4404, block material | EN-GJS-400-18-LT, SG iron material | S355J2 + N, cast steel material | VE Duroplast, reinforced

- Body coating: Epoxy

- Liner materials: PTFE/EPDM | PTFE/FKM | PTFE/silicone

- Disc materials: 1.4404 (316L), forged material | 1.4469, Duplex cast steel material | 2.4602 (alloy 22), block material | 3.7035, titan

- Disc coating: PFA

- Conformities: ATEX | EAC | FDA | FMEDA | TA Luft (German Clean Air Act)

Features:- Suitable for chemically corrosive media

- Bubble tight sealing, in accordance with EN 12266-1/P12, leak rate A

- High-quality selection of materials can be combined in different ways

- High level of plant reliability thanks to one-piece shaft and spring-washer-supported seal system

- Long service life thanks to shaft bearings and special disc and liner geometry

- Lockable hand lever

- Optional stainless steel hand lever

GEMÜ 498

- The GEMÜ 498 Edessa PTFE-lined butterfly valve is motorized. Various metal or plastic on/off or control actuators are available. The disc and shaft are one piece; body and liner are available in different designs. The butterfly valve is available in nominal sizes DN 25 to 1200 (1½"–36"), in the standardized installation lengths: ISO 5752/20 | EN 558-1/20 | API 609 category A (DIN 3202 K1) available in wafer and lug body versions.

Technical specifications:- Media temperature: -20 to 200 °C

- Ambient temperature: -20 to 95 °C

- Operating pressure: 0 to 10 bar

- Nominal sizes: DN 25 to 1200

- Body configurations: Lug | Wafer

- Connection standards: AS | ASME | DIN | EN | ISO | JIS

- Body materials: 1.4404, block material | EN-GJS-400-18-LT, SG iron material | S355J2 + N, cast steel material | VE Duroplast, reinforced

- Body coating: Epoxy

- Liner materials: PTFE TFM™/EPDM | PTFE TFM™/FKM | PTFE TFM™/silicone | PTFE/EPDM | PTFE/FKM | PTFE/silicone

- Disc materials: 1.4404 (316L), forged material | 1.4469, Duplex cast steel material | 2.4602 (alloy 22), block material | 3.7035, titan

- Disc coating: PFA

- Supply voltage: 24 - 240 V AC/DC | 24 V AC, 50/60 Hz | 24 V DC

- Operating time 90°: 4 to 100 s

- Protection class: IP 65, 66, 67, 68

- Conformities: ATEX | EAC | FDA | FMEDA | TA Luft (German Clean Air Act)

Features:- Suitable for chemically corrosive media

- Bubble tight sealing, in accordance with EN 12266-1/P12, leak rate A

- High-quality selection of materials can be combined in different ways

- High level of plant reliability thanks to one-piece shaft and spring-washer-supported seal system

- Long service life thanks to shaft bearings and special disc and liner geometry

- Wide choice of motorized actuator types

GEMÜ C480

- The GEMÜ C480 soft seated butterfly valve has a bare shaft. The butterfly valve is available in nominal sizes DN700 - 1600 and in standard installation lengths ISO 5752/20 | EN 558-1/20 | API 609 category A (DIN 3202 K1) in wafer and lug body versions.

Technical specifications:- Media temperature: -10 to 70 °C

- Ambient temperature: -20 to 95 °C

- Operating pressure: 3 to 16 bar

- Nominal sizes: DN 700 to 1600

- Body configurations: Lug | U section | Wafer

- Connection standards: not specified

- Body materials: EN-GJS-400-15

- Liner materials: not specified

- Disc materials: not specified

- Conformities: ACS | EAC

Features:- Simple installation

- Low torques

- Modular construction

- Advanced seal design - even for larger diameters

GEMÜ C481

-

Die GEMÜ C481 soft seated butterfly valve has a metal actuator and is pneumatically operated. The butterfly valve is available in nominal sizes DN700 - 1600 and in standard installation lengths ISO 5752/20 | EN 558-1/20 | API 609 category A (DIN 3202 K1) in wafer and lug body versions.

Technical specifications:

- Media temperature: -10 to 70 °C

- Ambient temperature: -20 to 95 °C

- Operating pressure*: 3 to 16 bar

- Nominal sizes*: DN 700 to 1600

- Installation lengths: ISO 5752/20 | EN 558-1/20 | API 609 category A

- Body configurations: Lug | U section | Wafer

- Connection types: Flange

- Connection standards: not specified

- Housing materials: EN-GJS-400-15

- Liner materials: not specified

- Disc materials: not specified

- Conformities: ACS | EAC

Features:- Simple installation

- Low torques

- Modular construction

- Modular actuator concept

- Advanced seal design - even for larger diameters

GEMÜ C487

-

The GEMÜ C487 soft seated butterfly valve is manually operated. It has a metal gearbox. The butterfly valve is available in nominal sizes DN700 - 1600 and in standard installation lengths ISO 5752/20 | EN 558-1/20 | API 609 category A (DIN 3202 K1) in wafer and lug body versions.

Technical specifications:

- Media temperature: -10 to 70 °C

- Ambient temperature: -20 to 95 °C

- Operating pressure*: 3 to 16 bar

- Nominal sizes*: DN 700 to 1600

- Installation lengths: ISO 5752/20 | EN 558-1/20 | API 609 category A

- Body configurations: Lug | U section | Wafer

- Connection types: Flange

- Connection standards: not specified

- Housing materials: EN-GJS-400-15

- Liner materials: not specified

- Disc materials: not specified

- Conformities: ACS | EAC

Features:- Simple installation

- Low torques

- Modular construction

- Advanced seal design - even for larger diameters

GEMÜ D450

-

The GEMÜ D450 soft seated butterfly valve has a bare shaft. The butterfly valve is available in nominal sizes DN 50–300 and has a wafer body version.

Technical specifications:

- Media temperature: 5 to 90 °C

- Ambient temperature: -20 to 60 °C

- Operating pressure: 0 to 10 bar

- Nominal sizes: DN 50 to 300

- Body configurations: Wafer

- Connection standards: ANSI | EN | JIS

- Body materials: PP, reinforced

- Liner materials: EPDM | FKM

- Disc materials: PP-H | PVC-C | PVC-U

- Conformities: EAC

Features:- Simple installation

- Low pressure loss

- Low weight

- Excellent corrosion protection

- UV resistant

- Optimized for installation in plastic piping

- Low torque

GEMÜ D451

- The GEMÜ D451 soft seated butterfly valve has a metal actuator and is pneumatically operated. The "Normally Closed", "Normally Open" and "Double Acting" control functions are available. The butterfly valve is available in nominal sizes DN 50–300 and has a wafer body version.

Technical specifications:- Media temperature: 5 to 90 °C

- Ambient temperature: -20 to 60 °C

- Operating pressure: 0 to 10 bar

- Nominal sizes: DN 50 to 300

- Body configurations: Wafer

- Connection standards: ANSI | EN | JIS

- Body materials: PP, reinforced

- Liner materials: EPDM | FKM

- Disc materials: PP-H | PVC-C | PVC-U

- Conformities: EAC

Features:- Low weight

- Corrosion resistant plastic body

- Short operating times

- UV resistant

- Low torque

GEMÜ D457

- The GEMÜ D457 soft seated butterfly valve is manually operated. It has a metal hand lever or gearbox depending on customer requirements. The butterfly valve is available in nominal sizes DN 50–300 and has a wafer body version. The hand lever can be adjusted in seven positions (each at 55°) and is equipped with a hole for fitting a safety lock to prevent unwanted changes in position.

Technical specifications:- Media temperature: 5 to 90 °C

- Ambient temperature: -20 to 60 °C

- Operating pressure: 0 to 10 bar

- Nominal sizes: DN 50 to 300

- Body configurations: Wafer

- Connection standards: ANSI | EN | JIS

- Body materials: PP, reinforced

- Liner materials: EPDM | FKM

- Disc materials: PP-H | PVC-C | PVC-U

- Conformities: EAC

Features:- Low weight

- Corrosion resistant plastic body

- Disc outlet dimension designed on plastic piping

- Lockable hand lever made of plastic with latch positions

- UV resistant

- Low torque

GEMÜ D458

- The GEMÜ D458 butterfly valve is motorized. Various metal or plastic on/off or control actuators are available. A manual override and an optical position indicator are integrated as standard. The butterfly valve is available in nominal sizes DN 50–300 and has a wafer body version.

Technical specifications:- Media temperature: 5 to 90 °C

- Ambient temperature: -10 to 60 °C

- Operating pressure: 0 to 10 bar

- Nominal sizes: DN 50 to 300

- Body configurations: Wafer

- Connection standards: ANSI | EN | JIS

- Body materials: PP, reinforced

- Liner materials: EPDM | FKM

- Disc materials: PP-H | PVC-C | PVC-U

- Supply voltage: 12 - 24 V AC/DC | 24 V AC/DC | 24 V DC | 85 - 240 V AC/DC

- Operating time 90°: 13 to 58 s

- Protection class: IP 65, 67

- Conformities: CSA | EAC

Features:- Low weight

- Corrosion-resistant materials

- Disc outlet dimension designed on plastic piping

GEMÜ D480

-

The GEMÜ D480 Victoria soft seated butterfly valve has a bare shaft. The butterfly valve is available in nominal sizes DN 25 to 1600 and in standard installation lengths ISO 5752/20 | EN 558-1/20 | API 609 category A (DIN 3202 K1) in wafer and lug body versions.

Technical specifications:

- Media temperature: -60 to 210 °C

- Ambient temperature: -40 to 70 °C

- Operating pressure: 0 to 16 bar

- Nominal sizes: DN 25 to 1600

- Body configurations: Lug | U section | Wafer

- Connection standards: ANSI | AS | ASME | AWWA | BS | DIN | EN | ISO | JIS

- Body materials: ASTM | EN-AC-46100, aluminium casting material | EN-AC-47100, aluminium casting material | EN-GJL-250 | EN-GJS-400-15, SG iron material | EN-GJS-400-18-LT, SG iron material | S275JR, cast steel material with epoxy coating

- Body coating: Epoxy

- Liner materials: CSM (Hypalon®) | ECO | EPDM | FKM | NBR | SBR, abrasion resistant | Silicone

- Disc materials: 1.4408, investment casting material | 1.4469, Duplex cast steel material | 1.4539 | 2.0975, bronze casting material | EN-GJS-400-15, SG iron material

- Disc coating: EPDM | Epoxy | Halar® | NBR | Rilsan® | SBR

- Conformities: ACS | ATEX | DNV GL | DVGW Drinking water | DVGW Gas | EAC | FDA | WRAS

Features:- Available in large nominal sizes

- Bubble tight sealing, in accordance with EN 12266-1/P12, leak rate A

- Special materials for disc, seal and valve body

- Vulcanizable liner

- Abrasion-resistant version possible

GEMÜ D481

-

The GEMÜ D481 Victoria soft seated butterfly valve has a metal actuator and is pneumatically operated. The "Normally Closed", "Normally Open" and "Double Acting" control functions are available. The butterfly valve is available in nominal sizes DN 25 to 1600 and in standard installation lengths ISO 5752/20 | EN 558-1/20 | API 609 category A (DIN 3202 K1) in wafer and lug body versions.

Technical specifications:

- Media temperature: -60 to 210 °C

- Ambient temperature: -20 to 70 °C

- Operating pressure: 0 to 16 bar

- Nominal sizes: DN 25 to 1600

- Body configurations: Lug | U section | Wafer

- Connection standards: ANSI | AS | ASME | AWWA | BS | DIN | EN | ISO | JIS

- Body materials: ASTM | EN-AC-46100, aluminium casting material | EN-AC-47100, aluminium casting material | EN-GJL-250 | EN-GJS-400-15, SG iron material | EN-GJS-400-18-LT, SG iron material | S275JR, cast steel material with epoxy coating

- Body coating: Epoxy

- Liner materials: CR | CSM (Hypalon®) | ECO | EPDM | NBR | SBR, abrasion resistant | Silicone

- Disc materials: 1.4408, investment casting material | 1.4469, Duplex cast steel material | 1.4539, forged material | 2.0975, bronze casting material | 2.4602 (alloy 22), block material | EN-GJS-400-15, SG iron material

- Disc coating: EPDM | Epoxy | Halar® | NBR | Rilsan® | SBR

- Conformities: ACS | DNV GL | DVGW Drinking water | DVGW Gas | EAC | FDA | WRAS

Features:- Available in large nominal sizes

- Bubble tight sealing, in accordance with EN 12266-1/P12, leak rate A

- Special materials for disc, seal and valve body

- Vulcanizable liner

- Abrasion-resistant version possible

GEMÜ D487

- The GEMÜ D487 Victoria soft-seated butterfly valve is manually operated. It has a metal hand lever or gearbox depending on customer requirements. The butterfly valve is available in nominal sizes DN 25 to 1600 and in standardized installation lengths ISO 5752/20 | EN 558-1/20 | API 609 category A (DIN 3202 K1) in wafer, lug and U section body versions.

Technical specifications:- Media temperature: -60 to 210 °C

- Ambient temperature: -20 to 70 °C

- Operating pressure: 0 to 16 bar

- Nominal sizes: DN 25 to 1600

- Body configurations: Lug | U section | Wafer

- Connection standards: ANSI | AS | ASME | AWWA | BS | DIN | EN | ISO | JIS

- Body materials: ASTM | EN-AC-46100, aluminium casting material | EN-AC-47100, aluminium casting material | EN-GJL-250 | EN-GJS-400-15, SG iron material | EN-GJS-400-18-LT, SG iron material | S275JR, cast steel material with epoxy coating

- Body coating: Epoxy

- Liner materials: CR | CSM (Hypalon®) | ECO | EPDM | NBR | SBR, abrasion resistant | Silicone

- Disc materials: 1.4408, investment casting material | 1.4469, Duplex cast steel material | 1.4539, forged material | 2.0975, bronze casting material | 2.4602 (alloy 22), block material | EN-GJS-400-15, SG iron material

- Disc coating: EPDM | Epoxy | Halar® | NBR | Rilsan® | SBR

- Conformities: ACS | DNV GL | DVGW Drinking water | DVGW Gas | EAC | FDA | WRAS

Features:- Available in large nominal sizes

- Bubble tight sealing, in accordance with EN 12266-1/P12, leak rate A

- Special materials for disc, seal and valve body

- Vulcanizable liner

- Abrasion-resistant version possible

GEMÜ D488

- The GEMÜ D488 Victoria soft-seated butterfly valve is motorized. Various metal or plastic on/off or control actuators are available. The butterfly valve is available in nominal sizes DN 25 to 1600, in the standardized installation lengths: ISO 5752/20 | EN 558-1/20 | API 609 category A (DIN 3202 K1) available in wafer, lug and U section body versions.

Technical specifications:- Media temperature: -60 to 210 °C

- Ambient temperature: -20 to 70 °C

- Operating pressure: 0 to 16 bar

- Nominal sizes: DN 25 to 1600

- Body configurations: Lug | U section | Wafer

- Connection standards: ANSI | AS | ASME | AWWA | BS | DIN | EN | ISO | JIS

- Body materials: ASTM | EN-AC-46100, aluminium casting material | EN-AC-47100, aluminium casting material | EN-GJL-250 | EN-GJS-400-15, SG iron material | EN-GJS-400-18-LT, SG iron material | S275JR, cast steel material with epoxy coating

- Body coating: Epoxy

- Liner materials: CR | CSM (Hypalon®) | ECO | EPDM | NBR | SBR, abrasion resistant | Silicone

- Disc materials: 1.4408, investment casting material | 1.4469, Duplex cast steel material | 1.4539, forged material | 2.0975, bronze casting material | 2.4602 (alloy 22), block material | EN-GJS-400-15, SG iron material

- Disc coating: EPDM | Epoxy | Halar® | NBR | Rilsan® | SBR

- Supply voltage: 100 - 120 V AC, 50/60 Hz | 12 - 24 V AC/DC | 220 - 240 V AC, 50/60 Hz | 380 - 480 V AC, 50/60 Hz

- Operating time 90°: 4 to 100 s

- Protection class: IP 65, 66, 67, 68

- Conformities: ACS | DNV GL | DVGW Drinking water | DVGW Gas | EAC | FDA | WRAS

Features:- Available in large nominal sizes

- Bubble tight sealing, in accordance with EN 12266-1/P12, leak rate A

- Special materials for disc, seal and valve body

- Vulcanizable liner

- Abrasion-resistant version possible

GEMÜ K410

-

The GEMÜ K410 butterfly valve has a bare shaft. The valve body is available in a plastic design.

Features- Low weight

- Corrosion resistant plastic body

- Simple installation with union nut

GEMÜ K415

-

The GEMÜ K415 soft seated butterfly valve made from stainless steel or brass has a bare shaft with standardized actuator flange in accordance with ISO 5211. With its rounded and polished disc edges, the butterfly valve is optimized for frequent cycle duties. The surface of the butterfly valve can still be further finished. The butterfly valve is optionally available with FDA or in an ATEX version. Thanks to its modular construction, it is also available with a manual, pneumatic or motorized actuator.

Features- High-quality butterfly valve made from stainless steel or brass

- Available in small nominal sizes

- Compact and robust body

- Suitable for vacuum applications and low temperatures

GEMÜ R470 Tugela

-

The GEMÜ R470 Tugela double-eccentric metal butterfly valve has a bare shaft with a top flange in accordance with EN ISO 5211. The butterfly valve is available in nominal sizes DN 50 Up to 600 and in standardized installation lengths API 609 category A (DIN 3202 K1).

Features:

High-performance butterfly valve with double-eccentric construction in order to separate the disc directly from the seat (gasket), thereby reducing friction and extending the service life Continuous shaft with temperature resistant graphite bearing and PTFE gland packing for readjustment in operation for minimized leakage, even at low pressures Antistatic fixture for ATEX area Bubble tight sealing, in accordance with EN 12266-1/P12, leak rate A

GEMÜ R471

-

The GEMÜ R471 Tugela double eccentric metal butterfly valve is operated by a pneumatic actuator. The butterfly valve is available in nominal sizes DN 50 to 400 and in standardized installation lengths API 609 category A (DIN 3202 K1).

Technical specifications:

- Media temperature: -60 to 230 °C

- Ambient temperature: -20 to 70 °C

- Operating pressure: 0 to 40 bar

- Nominal sizes: DN 50 to 400

- Body configurations: Wafer

- Connection standards: ASME | ISO

- Body materials: 1.0619 (WCB), cast steel material with CDP coating | 1.4408 (CF8M), investment casting material

- Liner materials: PTFE TFM™

- Disc materials: 1.4408

- Conformities: ATEX | EAC | FDA | TA Luft (German Clean Air Act)

Features:- High-performance butterfly valve with double eccentric construction in order to separate the disc directly from the seat (gasket), thereby reducing friction and extending the service life

- Continuous shaft with temperature resistant graphite bearing and PTFE gland packing for readjustment in operation for minimized leakage, even at low pressures

- Antistatic fixture for ATEX area

- Various actuator types can be selected

- Bubble tight sealing, in accordance with EN 12266-1/P12, leak rate A

GEMÜ R477

-

The GEMÜ R477 Tugela double eccentric metal butterfly valve is operated by a manual actuator. The butterfly valve is available in nominal sizes DN 50 to 400 and in standardized installation lengths API 609 category A (DIN 3202 K1).

Technical specifications:

- Media temperature: -60 to 230 °C

- Ambient temperature: -20 to 70 °C

- Operating pressure: 0 to 40 bar

- Nominal sizes: DN 50 to 400

- Body configurations: Wafer

- Connection standards: ASME | ISO

- Body materials: 1.0619 (WCB), cast steel material with CDP coating | 1.4408 (CF8M), investment casting material

- Liner materials: PTFE TFM™

- Disc materials: 1.4408

- Conformities: ATEX | EAC | FDA | TA Luft (German Clean Air Act)

Features:- High-performance butterfly valve with double eccentric construction in order to separate the disc directly from the seat (gasket), thereby reducing friction and extending the service life

- Continuous shaft with temperature resistant graphite bearing and PTFE gland packing for readjustment in operation for minimized leakage, even at low pressures

- Antistatic fixture for ATEX area

- Various actuator types can be selected

- Bubble tight sealing, in accordance with EN 12266-1/P12, leak rate A

GEMÜ R478

-

The GEMÜ R478 Tugela double eccentric metal butterfly valve is operated by a motorized actuator. The butterfly valve is available in nominal sizes DN 50 to 300 and in standardized installation lengths API 609 category A (DIN 3202 K1).

Technical specifications:

- Media temperature: -60 to 230 °C

- Ambient temperature: -20 to 70 °C

- Operating pressure: 0 to 40 bar

- Nominal sizes: DN 50 to 300

- Body configurations: Wafer

- Connection standards: ASME | ISO

- Body materials: 1.0619 (WCB), cast steel material with CDP coating | 1.4408 (CF8M), investment casting material

- Liner materials: PTFE TFM™

- Disc materials: 1.4408

- Supply voltage: 120 V AC, 50 Hz | 120 V AC, 60 Hz | 230 V AC, 50 Hz | 230 V AC, 60 Hz | 24 V DC | 380 V AC, 50 Hz | 400 V AC, 50 Hz | 440 V AC, 60 Hz | 460 V AC, 60 Hz | 480 V AC, 60 Hz

- Operating time 90°: 13 to 35 s

- Protection class: IP68

- Conformities: ATEX | EAC | FDA | TA Luft (German Clean Air Act)

Features:- High-performance butterfly valve with double eccentric construction in order to separate the disc directly from the seat (gasket), thereby reducing friction and extending the service life

- Continuous shaft with temperature resistant graphite bearing and PTFE gland packing for readjustment in operation for minimized leakage, even at low pressures

- Antistatic fixture for ATEX area

- Various actuator types can be selected

- Bubble tight sealing, in accordance with EN 12266-1/P12, leak rate A

GEMÜ R480

-

The GEMÜ R480 Victoria soft seated metal butterfly valve is equipped with a bare shaft with top flange in accordance with EN ISO 5211. The butterfly valve is available in nominal sizes DN 25 to 600 and in standard installation lengths ISO 5752/20 | EN 558-1/20 | API 609 category A (DIN 3202 K1) in wafer, lug and U section body versions.

Technical specifications:

- Media temperature: -10 to 160 °C

- Ambient temperature: -10 to 70 °C

- Operating pressure: 0 to 16 bar

- Nominal sizes: DN 25 to 600

- Body configurations: Lug | U section | Wafer

- Connection standards: ANSI | AS | BS | DIN | EN | ISO | JIS

- Body materials: EN-GJS-400-15, SG iron material | EN-GJS-400-18-LT, SG iron material

- Body coating: Epoxy

- Liner materials: EPDM | FKM | NBR | SBR, abrasion resistant | Silicone

- Disc materials: 1.4408, investment casting material | 1.4408, polished investment casting material | 1.4469, Duplex cast steel material | EN-GJS-400-15, SG iron material

- Disc coating: Epoxy | Halar® | Rilsan®

- Conformities: ACS | ASME GEMÜ B31.3 | ATEX | Belgaqua | DNV GL | DVGW Drinking water | DVGW Gas | FDA | FMEDA | NSF | Oxygen | Regulation (EC) No. 1935/2004 | TA Luft (German Clean Air Act) | WRAS

Features:- Low torques thanks to PTFE coated bushes

- Bubble tight sealing, in accordance with EN 12266-1/P12, leak rate A

- Liner material is easy to read when installed

- Sleek disc design for higher Kv values

- Robust body coating comparable to ISO 12944-6 C5

GEMÜ R481

-

The GEMÜ R481 Victoria soft seated metal butterfly valve has a metal actuator and is pneumatically operated. Normally Closed, Normally Open and Double Acting control functions are available. Various pneumatic actuators are available. The butterfly valve is available in nominal sizes DN 25 to 600 and in standard installation lengths ISO 5752/20 | EN 558-1/20 | API 609 category A (DIN 3202 K1) in wafer, lug and U section body versions.

Technical specifications:

- Media temperature: -10 to 160 °C

- Ambient temperature: -10 to 70 °C

- Operating pressure: 0 to 16 bar

- Nominal sizes: DN 25 to 600

- Body configurations: Lug | U section | Wafer

- Connection standards: ANSI | AS | BS | DIN | EN | ISO | JIS

- Body materials: EN-GJS-400-15, SG iron material | EN-GJS-400-18-LT, SG iron material

- Body coating: Epoxy

- Liner materials: EPDM | FKM | NBR | SBR, abrasion resistant | Silicone

- Disc materials: 1.4408, investment casting material | 1.4408, polished investment casting material | 1.4469, Duplex cast steel material | EN-GJS-400-15, SG iron material

- Disc coating: Epoxy | Halar® | Rilsan®

- Conformities: ACS | ASME GEMÜ B31.3 | ATEX | Belgaqua | DNV GL | DVGW Drinking water | DVGW Gas | EAC | FDA | Functional safety | NSF | Oxygen | Regulation (EC) No. 1935/2004 | TA Luft (German Clean Air Act) | WRAS

Features:- Low torques thanks to PTFE coated bushes

- Bubble tight sealing, in accordance with EN 12266-1/P12, leak rate A

- Liner material is easy to read when installed

- Sleek disc design for higher Kv values

- Robust body coating comparable to ISO 12944-6 C5

- Various actuator types can be selected

- Optional accessories are installed, set and tested so they are ready for operation

GEMÜ R487

-

The GEMÜ R487 Victoria soft seated metal butterfly valve is manually operated. It has a hand lever or gearbox depending on customer requirements. The butterfly valve is available in nominal sizes DN 25 to 600 and in standard installation lengths ISO 5752/20 | EN 558-1/20 | API 609 category A (DIN 3202 K1) in wafer, lug and U section body versions.

Technical specifications:

- Media temperature: -10 to 160 °C

- Ambient temperature: -10 to 70 °C

- Operating pressure: 0 to 16 bar

- Nominal sizes: DN 25 to 600

- Body configurations: Lug | U section | Wafer

- Connection standards: ANSI | AS | BS | DIN | EN | ISO | JIS

- Body materials: EN-GJS-400-15, SG iron material | EN-GJS-400-18-LT, SG iron material

- Body coating: Epoxy

- Liner materials: EPDM | FKM | NBR | SBR, abrasion resistant | Silicone

- Disc materials: 1.4408, investment casting material | 1.4408, polished investment casting material | 1.4469, Duplex cast steel material | EN-GJS-400-15, SG iron material

- Disc coating: Epoxy | Halar® | Rilsan®

- Conformities: ACS | ASME GEMÜ B31.3 | ATEX | Belgaqua | DNV GL | DVGW Drinking water | DVGW Gas | EAC | FDA | Functional safety | NSF | Oxygen | Regulation (EC) No. 1935/2004 | TA Luft (German Clean Air Act) | WRAS

Features:- Low torques thanks to PTFE coated bushes

- Bubble tight sealing, in accordance with EN 12266-1/P12, leak rate A

- Liner material is easy to read when installed

- Sleek disc design for higher Kv values

- Robust body coating comparable to ISO 12944-6 C5

- Various actuator types can be selected

- Optional accessories are installed, set and tested so they are ready for operation

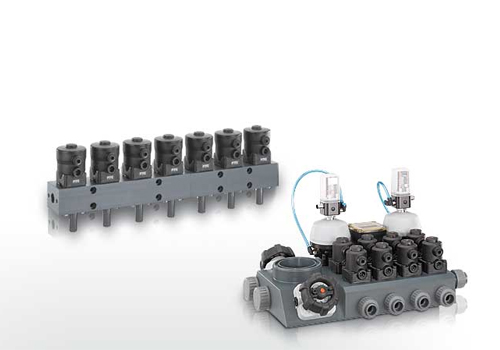

GEMÜ multi-port valve blocks

-

Stainless steel blocks comprise one or more diaphragm valve seats. It is possible to choose between manual, pneumatic and motorized actuator versions. The downstream media is isolated using a diaphragm.

Customer benefits:

- Simplified documentation and validation (e.g. less radiographic inspection)

- Space savings due to compact design

- Optimization of production and operating procedures

- Expertise and copy protection

- Lower installation time, simplified commissioning and maintenance

- Reduced and/or simplified inventory (e.g. fittings)

- Greater flexibility and lower costs during simultaneous implementation of a modular plant design

- Increased product reliability

General product advantages:

- Produced from a single block of material → no internal welds, fewer fittings and fewer welds thanks to several valve seats in one unit

- Individual, customized and flexible design

- Integration of valves, measurement and control systems in a single unit; suitable for modular plant designs

- Certificate of compliance with the order, test certificate, inspection certificate 3.1, inspection certificate 3.2 available on request

- Design optimized for draining and dead space (low hold-up volume, small wetted area, minimal dead spaces)

- High-grade surface finish down to Ra 0.25 µm and EHEDG-certified diaphragm sealing system

GEMÜ P600M

-

The GEMÜ P600M M-block diaphragm valve in stainless steel comprises one or more diaphragm valve seats. It is possible to choose between manual, pneumatic and motorized actuator versions. The downstream media is isolated using a diaphragm.

- Compact design saves space

- Individual, customized and flexible design

- Reduced deadleg

- Fewer connection points and weld seams

- Huge variety of functions combined in the smallest of spaces

- Wide range of adaptation options from measurement and control systems, in addition to accessories

GEMÜ P500M

-

The GEMÜ P500M stainless steel valve block comprises two or more globe valves. These can be equipped with manual, pneumatic and motorized actuators. The downstream media is isolated using a valve plug.

- Space savings thanks to compact design

- Individual, customized and flexible design

- Fewer connection points and weld seams

- Huge variety of functions combined in the smallest of spaces

- Highly suitable for control applications

- Actuators, gland packing and automation components can be used from the tried and tested GEMÜ modular system

GEMÜ diaphragm valves

-

Diaphragm valve: Area of application and industrial sectors

As they are available with such a large number of body and seal materials, GEMÜ diaphragm valves are used successfully in many different applications.

GEMÜ metal aseptic diaphragm valves

- As a result of different diaphragm materials and due to the surface quality of the valve body being maintained down to 0.25 µm, GEMÜ valves can be used in numerous sterile applications. The EHEDG-certified GEMÜ sealing system ensures that there is hermetic separation between medium and actuator.

GEMÜ single-use diaphragm valves

- Single-use diaphragm valves comprise a stainless steel actuator and a gamma-sterilizable diaphragm valve body. The PP body with TPE diaphragm fulfils the purity requirements of the pharmaceutical industry as per USP 85 and USP 788.

GEMÜ metal industrial diaphragm valves

- GEMÜ metal diaphragm valves are available in a weir-type version and in a full bore version and, because they are insensitive to particulate media, they are suitable for numerous industrial processes. Coatings and plastic linings are optionally available.

GEMÜ plastic diaphragm valves

- Plastic GEMÜ diaphragm valves are suitable for use with both inert and corrosive media in a liquid or gaseous state. For these valves, all media-wetted parts are made of high-grade plastics and therefore possess high chemical resistance.

GEMÜ ultra pure plastic diaphragm valves

- For the GEMÜ plastic diaphragm valves manufactured under cleanroom conditions for sanitary/hygienic applications, all media-wetted parts and the housing are made of high-grade plastic (PFA/PTFE/PVDF/PP).

GEMÜ diaphragm globe valves

- Diaphragm globe valves from GEMÜ are available as 2/2-way valves and multi-port valve blocks. Body, actuator and diaphragm are manufactured from the high-performance plastics PTFE and PVDF. The valves are available for order as HPW (cleanroom manufacturing) or HPS (no cleanroom manufacturing).

GEMÜ diaphragm globe valves

-

GEMÜ has developed an innovative sealing concept for specific customer requirements. The unique feature of this concept is the PD technology seal (plug diaphragm technology), which ensures hermetic separation of the actuator from the medium flow. The concept was then further developed specifically for sterile and hygienic applications.

Aseptic control valve for sterile and hygienic processes

The sealing principle of the GEMÜ 567 BioStar Control 2/2-way control valve is based on GEMÜ PD technology. All actuator parts and the regulating cone or regulating needle are made of stainless steel, while the seal uses a diaphragm made of PTFE. The control valve was also nominated for the ACHEMA Innovation Award 2018 in the "Pharmaceutical engineering" category.

GEMÜ 567

-

The GEMÜ 567 BioStar Control 2/2-way diaphragm globe valve is an aseptic control valve and has been designed for demanding applications. Flow rates range from 80 l/h to 63,000 l/h, depending on the version. The sealing concept of the valve is based on the GEMÜ PD design. All actuator parts (except the seals) are made from stainless steel. Manual, pneumatic or motorized actuators are available.

The motorized actuators can be selected from two versions, GEMÜ eSyDrive and GEMÜ servoDrive, depending on the application. GEMÜ 567 eSyDrive can be used as a positioner or process controller. GEMÜ 567 servoDrive is suitable for real-time control processes.

Technical specifications:- Connection: Clamp; Spigot

- Actuator: Pneumatic

- Body material: 1.4435, block material

- Max. operating pressure: 10 bar

- Max. media temperature: 160 ° C

- Min. media temperature: -10 ° C

- Control valve

Features:- CIP/SIP capable

- Linear or equal-percentage control characteristic options

- Hermetic separation of the actuator from the medium using a PTFE seal

- Various valve body connections available

- Surface finishes down to 0.25 μm, electropolished

- ATEX version available as an option

- Actuator can be replaced under operating pressure without contaminating the medium

GEMÜ F40

- The GEMÜ F40 2/2-way filling valve is designed for filling processes in aseptic and hygienic applications. Flow rates of up to 18,500 l/h are possible, depending on the design. The sealing concept of the valve is based on the GEMÜ PD design, whereby the actuator is hermetically separated from the medium. All actuator parts (except the seals) are made from stainless steel. The "Normally closed" and "Normally open" control functions are available.

Technical specifications:- Media temperature: -10 to 140 °C

- Ambient temperature: -10 to 60 °C

- Operating pressure: 0 to 7 bar

- Nominal sizes: DN 8 to 25

- Body configurations: 2/2-way body | Multi-port body

- Connection types: Clamp | Spigot

- Connection standards: ASME | DIN | EN

- Body materials: 1.4435 (316L), block material | 1.4435, investment casting material

- Seat seal materials: PTFE

- Conformities: 3A | ATEX | EAC | FDA | Reg. (EU) No. 10/2011 | Regulation (EC) No. 1935/2004 | Regulation (EC) No. 2023/2006 | USP

Features:- Hermetic separation between medium and actuator due to PD sealing technology

- Long service life with over 10 million cycle duties

- Designed according to Hygienic Design guidelines

- FDA compliant as standard and suitable for contact with food according to Regulation (EC) No. 1935/2004

- Very fast and easy maintenance thanks to quick locking system and innovative cartridge spare parts system

- Suitable for vacuum up to 20 mbar (a)

GEMÜ F60

- The GEMÜ F60 motorized 2/2-way filling valve is designed for extremely precise and fast filling processes in aseptic and hygienic applications. GEMÜ F60 enables activation in real time, ultra-quick load cycles and high flow rates of up to 18.500 l/h. The sealing concept of the valve is based on the GEMÜ PD design, whereby the actuator is hermetically separated from the medium. All actuator parts (except the seals) are made from stainless steel.

Technical specifications:- Connection: Flare; Pillar

- Actuator: Manual

- Body material: PTFE

- Max. operating pressure: 6 bar

- Max. media temperature: 150 ° C

- Min. media temperature: -10 ° C

- Nominal sizes

Features:- Hermetic separation between medium and actuator due to PD sealing technology

- Long service life with over 10 million cycle duties

- Flexible and fast program changes thanks to freely programmable filling curves

- Fast filling cycles (less than 400 ms) possible

- Designed according to Hygienic Design guidelines and EHEDG certified

- FDA compliant as standard and suitable for contact with food according to Regulation (EC) No. 1935/2004

- Very fast and easy maintenance thanks to quick locking system and innovative cartridge spare parts system

GEMÜ C57

-

The GEMÜ C57 iComLine® ultra pure 2/2-way plastic diaphragm globe valve is manually operated via a handwheel. All media wetted parts are made of PTFE. The external operator parts are made of PVDF. An integral optical position indicator is standard. In addition to 2/2-way valve bodies customised multi-port valve block solutions can be produced.

Technical specifications:- Connection: Flare; Pillar

- Actuator: Manual

- Body material: PTFE

- Max. operating pressure: 6 bar

- Max. media temperature: 150 ° C

- Min. media temperature: -10 ° C

- Nominal sizes

Features:- Low space requirement due to compact design

- Ideally suited for corrosive media

- High purity due to cleanroom manufacturing

- Manifolds are a space-saving design solution

GEMÜ C58

-

GEMÜ C58 is an ultra-pure 3/2-way process valve in order to change over between a supply and two outlets, whereby it can also be operated in the other flow direction. The switch position can be detected using an optical position indicator. The 3/2-way process valve is suitable for ultra-pure and corrosive media. All media wetted parts are made of pure and highly resistant PTFE. The 3/2-way process valve is therefore particularly suitable for applications in media supply or in the process area of semiconductor production.

Technical specifications:- Media temperature: -10 to 130 °C

- Ambient temperature: 0 to 60 °C

- Operating pressure: 0 to 5,5 bar

- Nominal sizes: DN 4 to 10

- Body configurations: Multi-port body

- Connection types: Flare | PrimeLock® | Super 300 Type Pillar®

- Body materials: PTFE TFM™

- Seal materials: PTFE

Features:- High Kv value

- Ideally suited for corrosive media

- High purity due to cleanroom manufacturing

- Low space requirement due to compact design

GEMÜ 567 BioStar control

-

The GEMÜ 567 BioStar Control 2/2-way diaphragm globe valve is an aseptic control valve and has been designed for demanding applications. Flow rates range from 80 l/h to 63,000 l/h, depending on the version. The sealing concept of the valve is based on the GEMÜ PD design. All actuator parts (except the seals) are made from stainless steel. Manual, pneumatic or motorized actuators are available.

The motorized actuators can be selected from two versions, GEMÜ eSyDrive and GEMÜ servoDrive, depending on the application. GEMÜ 567 eSyDrive can be used as a positioner or process controller. GEMÜ 567 servoDrive is suitable for real-time control processes.

Technical specifications:

- Media temperature: -10 to 160 °C

- Ambient temperature: -10 to 60 °C

- Operating pressure: 0 to 10 bar

- Nominal sizes: DN 8 to 65

- Body materials: 1.4435 (316L), block material

- Conformities: 3A | BSE/TSE | EAC | FDA | Oxygen | Reg. (EU) No. 10/2011 | Regulation (EC) No. 1935/2004 | Regulation (EC) No. 2023/2006 | USP

Features:- CIP/SIP capable

- Linear or equal-percentage control characteristic options

- Hermetic separation of the actuator from the medium using a PTFE seal

- Various valve body connections available

- Surface finishes down to 0.25 μm, electropolished

- ATEX version available as an option

- Actuator can be replaced under operating pressure without contaminating the medium

GEMÜ C50 iComLine

-

The GEMÜ C50 iComLine ultra-pure 2/2-way plastic diaphragm globe valve has a pneumatic actuator. All media wetted parts are made of PFA or PTFE. The external actuator parts are made of PVDF. An integral optical position indicator is standard. In addition to 2/2-way valve bodies, customized multi-port valve block solutions can be produced.

Technical specifications:

- Media temperature: -10 to 150 °C

- Ambient temperature: 0 to 60 °C

- Operating pressure: 0 to 6 bar

- Nominal sizes: DN 4 to 25

- Body configurations: 2/2-way body | Multi-port body

- Connection types: Flare | Nexus Connect® | PrimeLock® | Super 300 Type Pillar®

- Body materials: PFA | PTFE

- Seal materials: PTFE

Features:- Low space requirement due to compact design

- Ideally suited for corrosive media

- High purity due to cleanroom manufacturing

- Manifolds are a space-saving design solution

GEMÜ C51 iComLine

-

The GEMÜ C51 iComLine ultra-pure 2/2-way plastic diaphragm globe valve is manually operated using a hand lever (quarter turn). All media wetted parts are made of PFA or PTFE. The external actuator parts are made of PVDF. In addition to 2/2-way valve bodies, customized multi-port valve block solutions can be produced.

Technical specifications:

- Media temperature: -10 to 150 °C

- Ambient temperature: 0 to 60 °C

- Operating pressure: 0 to 6 bar

- Nominal sizes: DN 4 to 12

- Body configurations: 2/2-way body | Multi-port body

- Connection types: Flare | Nexus Connect® | PrimeLock® | Super 300 Type Pillar®

- Body materials: PFA | PTFE

- Seal materials: PTFE

Features:- Low space requirement due to compact design

- Ideally suited for corrosive media

- High purity due to cleanroom manufacturing

- Manifolds are a space-saving design solution

- Choice of design with PTFE-coated screws and compression springs

GEMÜ globe valves

-

Globe valves: Areas of application and industrial sectors

Globe valves are ideal for fast cycle duties, higher temperatures and control applications. Although they are often used for steam control and in the field of water/waste water treatment, they can handle the most diverse of applications in industrial processes, yet also in sterile and hygienic applications in the pharmaceutical, food and biotechnology industries.

GEMÜ 312

-

The GEMÜ 312 3/2-way globe valve has a rugged low maintenance aluminium piston actuator and is pneumatically operated. The double sided valve plug is connected to the actuator via a spindle. The valve spindle is sealed by a self-adjusting gland packing providing low maintenance and reliable valve spindle sealing even after a long service life. A wiper ring fitted in front of the gland packing protects the seal against contamination and damage.

Technical specifications:- Connection: Flange

- Actuator: Pneumatic

- Body material: EN-GJL-250

- Max. operating pressure: 16 bar

- Max. media temperature: 180 ° C

- Min. media temperature: -10 ° C

- Nominal sizes

- Control valve

Features:- Simple adaptation for use as a control valve

- Extensive range of accessories

- Robust aluminium actuator

- Seat seal made of PTFE or PTFE/fibreglass

- Design with flanged connections

GEMÜ 314

-

The GEMÜ 314 3/2-way globe valve has a rugged low maintenance aluminium piston actuator and is pneumatically operated. The double sided valve plug is connected to the actuator via a spindle. The valve spindle is sealed by a self-adjusting gland packing providing low maintenance and reliable valve spindle sealing even after a long service life. A wiper ring fitted in front of the gland packing protects the seal against contamination and damage.

Technical specifications:- Connection: Threaded socket

- Actuator: Pneumatic

- Body material: (Rg 5) CC499K

- Max. operating pressure: 16 bar

- Max. media temperature: 180 ° C

- Min. media temperature: -10 ° C

- Nominal sizes

- Control valve

Features:- Simple adaptation for use as a control valve

- Extensive range of accessories

- Robust aluminium actuator

- Seat seal made of PTFE or PTFE/fibreglass

- Design with threaded sockets

GEMÜ 519

-

- Motorized linear actuator for Open/Close applications

- Self-locking spindle actuator

- Safety shut-down integrated

- Standard optical position indicator and manual override

- Integrated emergency power supply module (optional)

- Electrical position indicator GEMÜ 1215 (optional)

GEMÜ 529

- The GEMÜ 529 eSyLite 2/2-way angle seat globe valve is motorized. It is available as an OPEN/CLOSE version. An integral optical position indicator is standard. The self-locking actuator holds its position in a stable manner in the event of power supply failure.

Features:- Motorized linear actuator for Open/Close applications

- Self-locking spindle actuator

- Safety shut-down integrated

- Standard optical position indicator and manual override

- Integrated emergency power supply module (optional)

- Electrical position indicator GEMÜ 1215 (optional)

GEMÜ 352

-

The GEMÜ 352 3/2-way globe valve has a rugged low maintenance plastic piston actuator and is pneumatically operated. The valve body is designed with flanged connections. The connection for the control medium can be rotated through 360°. The double sided valve plug is connected to the actuator via a spindle. The valve spindle is sealed by a self-adjusting gland packing providing low maintenance and reliable valve spindle sealing even after a long service life. A wiper ring fitted in front of the gland packing protects the seal against contamination and damage.

Technical specifications:- Connection: Flange

- Actuator: Pneumatic

- ATEX

- Explosion protection

- Body material: EN-GJL-250

- Max. operating pressure: 16 bar

- Max. media temperature: 180 ° C

- Min. media temperature: -10 ° C

- Nominal sizes

Features:- Extensive range of accessories

- Simple adaptation for use as a control valve

- Seat seal made of PTFE or PTFE/fibreglass

- ATEX version available as an option

- Design with flanged connections

GEMÜ 354

-

The GEMÜ 352 3/2-way globe valve has a rugged low maintenance plastic piston actuator and is pneumatically operated. The valve body is designed with flanged connections. The connection for the control medium can be rotated through 360°. The double sided valve plug is connected to the actuator via a spindle. The valve spindle is sealed by a self-adjusting gland packing providing low maintenance and reliable valve spindle sealing even after a long service life. A wiper ring fitted in front of the gland packing protects the seal against contamination and damage.

Technical specifications:- Connection: Flange

- Actuator: Pneumatic

- ATEX

- Explosion protection

- Body material: EN-GJL-250

- Max. operating pressure: 16 bar

- Max. media temperature: 180 ° C

- Min. media temperature: -10 ° C

- Nominal sizes

Features:- Extensive range of accessories

- Simple adaptation for use as a control valve

- Seat seal made of PTFE or PTFE/fibreglass

- ATEX version available as an option

- Design with flanged connections

GEMÜ 505

-

The GEMÜ 505 2/2-way angle seat globe valve has a high temperature rated plastic handwheel and is manually operated. The angle seat globe valve is particularly designed for isolating pure steam. The valve has a PTFE seat for tight shut off. The valve spindle is sealed by a stainless steel bellows. Valve plug and valve spindle are welded to prevent contamination areas.

Technical specifications:- Connection: Clamp; Spigot

- Actuator: Manual

- ATEX

- Explosion protection

- Body material: 1.4435, block material; 1.4435, investment casting

- Max. operating pressure: 10 bar

- Max. media temperature: 180 ° C

- Min. media temperature: -10 ° C

- Nominal sizes

Features:- Free from non-ferrous metals

- Welded valve plug/valve spindle design to remove possible contamination areas

- Low maintenance, fixed seat plug (without threads)

- Standard integral optical position indicator

- Traceability of all media wetted parts

GEMÜ 507

-

The GEMÜ 507 2/2-way angle seat globe valve has an ergonomically designed plastic handwheel and is manually operated. The valve spindle is sealed by a self-adjusting gland packing providing low maintenance and reliable valve spindle sealing even after a long service life. A wiper ring fitted in front of the gland packing protects the seal against contamination and damage. A stainless steel bellows and a handwheel extension are available as options (not for operator size 0).

Technical specifications:- Connection: Clamp; Flange; Spigot; Threaded socket; Threaded spigot

- Actuator: Manual

- ATEX

- Explosion protection

- Body material: 1.4408, cast stainless steel; 1.4435, forged body; 1.4435, investment casting

- Max. operating pressure: 25 bar

- Max. media temperature: 180 ° C

- Min. media temperature: -10 ° C

- Nominal sizes

Features:- Various valve body connections (threaded sockets, threaded spigots, butt weld spigots) available

- High flow rates due to angle seat design

- Optionally for contact with foodstuffs as per directive (EC) No. 1935/2004 (K-no. 1935)

- Standard gland packing suitable for vacuum up to 20 mbar (abs.)

GEMÜ 514

-

The GEMÜ 514 2/2-way angle seat globe valve has a low maintenance aluminium piston actuator and is pneumatically operated. The valve spindle is sealed by a self-adjusting gland packing providing low maintenance and reliable valve spindle sealing even after a long service life. A wiper ring fitted in front of the gland packing protects the seal against contamination and damage.

Technical specifications:- Connection: Flange; Spigot; Threaded socket; Threaded spigot

- Actuator: Pneumatic

- Body material: (Rg 5) CC499K; 1.4408, cast stainless steel; 1.4435, investment casting

- Max. operating pressure: 25 bar

- Max. media temperature: 180 ° C

- Min. media temperature: -10 ° C

- Nominal sizes

- Control valve

Features:- Various valve body connections (threaded sockets, threaded spigots, butt weld spigots) available

- High flow rates due to angle seat design

- Extensive range of accessories

- Versions with bellows available

- Special connections and materials on request

- Optionally for contact with foodstuffs as per directive (EC) No. 1935/2004 (K-no. 1935)

- Standard gland packing suitable for vacuum up to 20 mbar (abs.)

GEMÜ 530

-

The GEMÜ 530 2/2-way globe valve has a rugged low maintenance stainless steel piston actuator and is pneumatically operated. The valve spindle is sealed by a self-adjusting gland packing providing low maintenance and reliable valve spindle sealing even after a long service life. A wiper ring fitted in front of the gland packing protects the seal against contamination and damage.

Technical specifications:- Connection: Flange

- Actuator: Pneumatic

- ATEX

- Explosion protection

- Body material: 1.4408, cast stainless steel; EN-GJS-400-18-LT

- Max. operating pressure: 25 bar

- Max. media temperature: 180 ° C

- Min. media temperature: -10 ° C

- Nominal sizes

- Control valve

Features:- Suitable for inert, corrosive, liquid and gaseous media

- Easily cleanable

- Actuator and valve body are free from non-ferrous metals

- High flow rates and compact design

- ATEX version available as an option

GEMÜ 532

-

The GEMÜ 532 2/2-way globe valve has a rugged low maintenance aluminium piston actuator and is pneumatically operated. The valve spindle is sealed by a self-adjusting gland packing providing low maintenance and reliable valve spindle sealing even after a long service life. A wiper ring fitted in front of the gland packing protects the seal against contamination and damage. The actuator does not require an actuator flange (as used in the GEMÜ 512).

Technical specifications:- Connection: Flange

- Actuator: Pneumatic

- Body material: 1.4408, cast stainless steel; EN-GJS-400-18-LT

- Max. operating pressure: 36 bar

- Max. media temperature: 180 ° C

- Min. media temperature: -10 ° C

- Nominal sizes

- Control valve

GEMÜ 534

-

The GEMÜ 534 2/2-way globe valve has a plastic piston actuator and is pneumatically operated. The valve spindle is sealed by a self-adjusting gland packing providing low maintenance and reliable valve spindle sealing even after a long service life. A wiper ring fitted in front of the gland packing protects the seal against contamination and damage.

Technical specifications:- Connection: Flange

- Actuator: Pneumatic

- ATEX

- Explosion protection

- Body material: 1.4408, cast stainless steel; EN-GJS-400-18-LT

- Max. operating pressure: 36 bar

- Max. media temperature: 180 ° C

- Min. media temperature: -10 ° C

- Nominal sizes

- Control valve

Features:- High flow rates and compact design

- Extensive range of accessories

- Lightweight plastic actuator

- ATEX version available as an option

- Free from non-ferrous metals

GEMÜ 536

-

The GEMÜ 536 2/2-way globe valve has a rugged low maintenance membrane actuator and is pneumatically operated. The valve is particularly suitable for use as a control valve. The valve plug is fixed to the spindle in such a way as to allow flexing during closure in order to ensure tight shut off. The valve spindle is sealed by a self-adjusting gland packing providing low maintenance and reliable valve spindle sealing even after a long service life. A wiper ring fitted in front of the gland packing protects the seal against contamination and damage.

Technical specifications:- Connection: Flange

- Actuator: Pneumatic

- Body material: 1.4408, cast stainless steel; EN-GJS-400-18-LT

- Max. operating pressure: 16 bar

- Max. media temperature: 180 ° C

- Min. media temperature: -10 ° C

- Nominal sizes

- Control valve

Features:- High flow rates

- Broad range of operating temperatures and pressures

- Extensive range of accessories

- ATEX version available as an option

- Seat seal made of PTFE, PTFE/fibreglass or steel

GEMÜ 537

-

The GEMÜ 537 2/2-way globe valve has an ergonomically designed plastic handwheel and is manually operated. The valve spindle is sealed by a self-adjusting gland packing providing low maintenance and reliable valve spindle sealing even after a long service life. A wiper ring fitted in front of the gland packing protects the seal against contamination and damage. A handwheel extension available as an option enables installation of the valve in insulated pipelines.

Technical specifications:- Connection: Flange

- Actuator: Manual

- ATEX

- Explosion protection

- Body material: 1.4408, cast stainless steel; EN-GJS-400-18-LT

- Max. operating pressure: 25 bar

- Max. media temperature: 180 ° C

- Min. media temperature: -10 ° C

- Nominal sizes

Features:- High flow rates and compact design

- ATEX version available as an option

- Optionally for contact with foodstuffs as per directive (EC) No. 1935/2004 (K-no. 1935)

- Can be retrofitted with a pneumatic actuator

- Seat seal made of PTFE or PTFE/fibreglass

GEMÜ 539

-

The GEMÜ 539 2/2-way globe valve has a hollow shaft actuator and is electrically operated. The eSyDrive hollow shaft actuator can be operated as an OPEN/CLOSE actuator or as an actuator with integrated positioner or process controller. The valve spindle is sealed by a self-adjusting gland packing providing low maintenance and reliable valve spindle sealing even after a long service life. A wiper ring fitted in front of the gland packing protects the seal against contamination and damage. An integral optical and electrical position indicator is standard.

Technical specifications:- Connection: Flange

- Actuator: Motorized

- Body material: 1.4408; EN-GJS-400-18-LT

- Max. operating pressure: 10 bar

- Max. media temperature: 180 ° C

- Min. media temperature: -10 ° C

- Nominal sizes

Features:- Linear or modified equal-percentage control characteristics

- Kv values from approx. 25 - 200 m³/h, depending on nominal size, valve seat and regulating cone design

- High flow rates

- Force and speed are variably adjustable

- Extensive diagnostic facilities

- Operable via web interface eSy-Web

- Integral optical position indicator and LED high visibility display

- Standard gland packing suitable for vacuum up to 20 mbar (abs.)

GEMÜ 543

- The GEMÜ 543 eSyStep is an electrically operated 2/2-way angle seat globe valve. The eSyStep electric actuator is available as On/Off actuator or with integrated positioner. The valve spindle is sealed by a self-adjusting gland packing providing low-maintenance and reliable valve spindle sealing even after a long service life. A wiper ring fitted in front of the gland packing protects the seal against contamination and damage. An integral optical and electrical position indicator is standard. The self-locking actuator holds its position in a stable manner when idle and in the event of power supply failure.

Technical specifications:- Media temperature: -40 to 180 °C

- Ambient temperature: 0 to 60 °C

- Operating pressure: 0 to 25 bar

- Nominal sizes: DN 6 to 50

- Body configurations: 2/2-way body | Angle valve body

- Connection types: Clamp | Flange | Spigot | Threaded connection

- Connection standards: ANSI | ASME | BS | DIN | EN | ISO | NPT | SMS

- Body materials: 1.4408, investment casting material | 1.4435 (316L), forged material | 1.4435, investment casting material | CC499K, cast bronze material