Saleplas

- Offer Profile

- The products and Systems

manufactured by Saleplas® are internationally recognized for their quality

and technology

Saleplas is a manufacturing company established in Madridejos (Toledo), which operates 2 production plants of around 20.000 m2. Nowadays we commercialize 4 product ranges for agriculture and industry:- Drip and sprinkling irrigation systems

- SF Filtration Systems

- High density PE100 polyethylene manifolds

- Geothermal energy collecting systems

Product Portfolio

WE REPLACE METAL WITH TECHNICAL PLASTICS

INDUSTRY

Particle separator

- The innovative design of the Saleplas' Particle Separators enables the separation of mixtures of water and solids, such as sand and slime, with a high efficiency. Its design exerts a rotational speed and centrifugal force in the water that makes possible the separation of the solids. Moreover, the design of its base prevents the separated particles coming back to the water flow.

Manifolds PE-100

-

In response to the increasing use of aggressive water in industrial and agricultural activities, Saleplas has developed a solution for handling this kind of fluids: Manifolds made of High Density Polyethylene PE-100.

These manifolds can be manufactured in diameters ranging from Ø50 up to Ø1000 mm. They have great versatility of design, allowing any type of configuration (swan necks, elbows, multiple outlets, etc..) and meeting the specific needs of each installation. On request, we can manufacture any design.

Pressure Pipes

-

Saleplas is a company devoted to the manufacture of polyethylene elements for the conduction of fluids.

Among those products, it is worth mentioning the Pressure Pipes and the Column Pipes for Submersible Pumps, both made of polyethylene and designed to be used in irrigation, industry or civil works.

FILTRATION

SF System: Seperation + Filtration

-

A NEW FILTRATION CONCEPT

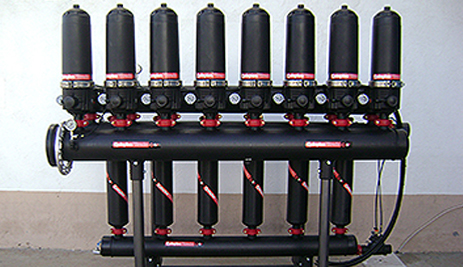

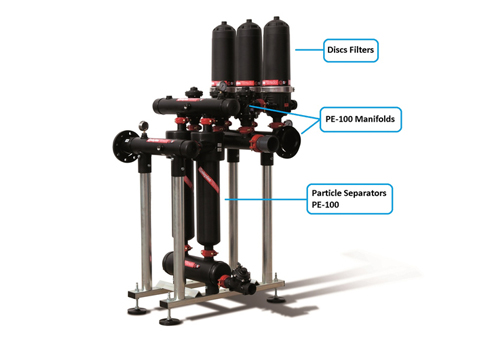

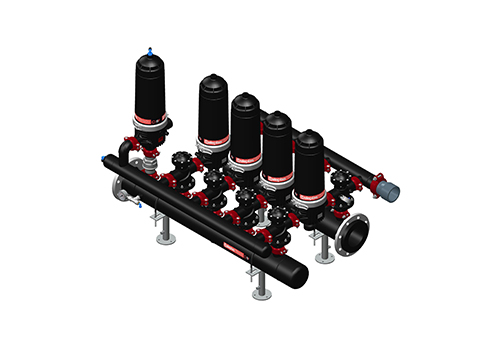

Filtration Systems assembled with PE-100 Particle Separators and Discs Filters.

First, we separate the solids, and then we filter the remaining particles, all in one, in order to get almost a 100% efficiency.

The aim of the SF System is to use as many pieces made of technical plastics as possible.- The separator removes the suspended particles, protecting and increasing the life of the discs filters.

- The PE-100 particle separators are able to separate mistures of water and solids such as sand and slime with a great efficiency up to 50 micron.

- The innovative design of the base prevents the separated particles from coming back to the water flow.

Automatic Cleaning

-

Characteristics

- Filtering element: grooved discs made of polypropylene with an enhanced uniormity.

- Bigger filtration surface, which helps delay the saturation.

- Easy to clean: the discs are separated during the backwash phase and cleaned with pressurized water jets thanks to the helical effect.

- Low frequency of cleaning: the cyclone effect keeps the particles away from the discs.

- Modularity and reduced space: we can manufacture any kind of equipment according to the customer requirements.

- Very simple automatisms for a user-friendly handling.

- High resistance: use of long lasting technical plastics.

- Models of automatic filters: 2", 3" and 4" double filters.

- Compact units that can be also equipped with particle separators in order to improve the performance.

Filtration Application for Industry

-

WASTE WATER AND ULTRAVIOLET TREATMENT (UV)

Improvement of the effectiveness of the treatment, as we reduce the suspended solids content, as well as the chemical products.

RECIRCULATION & REUSE OF WATER

Direct saving, as less volume of water is consumed. Reduction of the clogging risk and maintenance costs, because we minimize the accumulation of particles.

OTHER APPLICATIONS- Meat processing, agri-food industries, etc.

- Steel industry, plastic processing industries, etc.

- Fish farming.

- Golf courses, gardens.

IRRIGATION AND AGRICULTURE

Particle Separator

- The innovative design of the Saleplas' Particle Separators enables the separation of mixtures of water and solids, such as sand and slime, with a high efficiency. Its design exerts a rotational speed and centrifugal force in the water that makes possible the separation of the solids. Moreover, the design of its base prevents the separated particles coming back to the water flow.

Drip Irrigation

-

Dripline with Integral Drippers (Turbulent and Pressure Compensating)

- Drippers integrated during the manufacturing process.

- High resistance to obstruction, long life and high uniformity.

- Recommended filtration degree: ≤130 micron.

- Maximum pressure: 4 bar.

Automation and Hydraulic Command Kits

-

Time and labor savings: Once programmed, the control unit switches itself on an off automatically.

Water saving: Possibility of programming the system during the off-peak hours or when the resources are better used, such us nocturnal irrigation.

Exhaustive irrigation control: Easy programming control unit that makes possible to adjust the irrigation by hours, days, etc.

Uniform water distribution: These kits facilitate the sectorization of the isntallation, in such a way that every area of the crop receives the same quantity of water.

Manifolds PE-100

-

In response to the increasing use of aggressive water in industrial and agricultural activities, Saleplas has developed a solution for handling this kind of fluids: Manifolds made of High Density Polyethylene PE-100.

These manifolds can be manufactured in diameters ranging from Ø50 up to Ø1000 mm. They have great versatility of design, allowing any type of configuration (swan necks, elbows, multiple outlets, etc..) and meeting the specific needs of each installation. On request, we can manufacture any design.

Sprinkler irrigation - COVERLINE®

-

Coverline is a modular system that combines the aluminium couplings with the high density polyethylene pipes, offering you the best of each product.

The Coverline modular system made by Saleplas has successfully passed the following tests:

Pipes for Submersible Pumps

-

Saleplas is a company devoted to the manufacture of polyethylene elements for the conduction of fluids.

Among those products, it is worth mentioning the Pressure Pipes and the Column Pipes for Submersible Pumps, both made of polyethylene and designed to be used in agriculture or industrie.

GEOTHERMAL ENERGY

The Energy from the Earth

-

The Earth is a great solid mass that stores energy from its inside. The earth’s crust receives daily a great quantity of heat from the action of the sun and the atmospheric agents, such as rain and wind. This energy is kept underground.

The best conditions to collect the energy take place at not very deep subsurface levels, allowing us to transform it into heat or cold according to the needs of each housing or installation. What Saleplas does is to take advantage of the energy stored at few meters beneath the surface. It is a renewable and clean energy, which is available almost in any place.

Geothermal Probes

-

Probes for the collection of geothermal energy made of high density polyethylene PE-100. Moreover, these probes are HTC (High Thermal Conductivity), which means that they are more efficient than normal PE-100 polyethylene for the use in geothermal systems.

The geothermal probes manufactured by Saleplas are in accordance with all the tests referred to in DIN 8075/199 Norm (equivalent to UNE-EN 12201) and also in the VDI 4640 Norm, as proved by the tests made by the College of Industrial Engineering (Polytechnic University of Madrid).

Geothermal Manifolds

-

Saleplas has been manufacturing manifolds for water treatment applications (desalination plants, waste water treatment, reuse, irrigation, etc.) for more than 14 years, using the newest technologies in order to give a quick answer and efficient service.

We manufacture both standard manifolds and made-to-measure models.

Our manifolds are characterized by their high quality standards thanks to the use of technical plastics in the manufacturing process. The excellent properties of these materials make them perfect for the water treatment and air conditioning sectors.

Pressure Pipes

-

High density polyethylene PE100 pipes manufactured according to UNE-EN 12201 Norm and especially suitable for the transport of pressure water, for agriculture, industry or civil works.

In the field of geothermal energy, this kind of pipe is used for the injection of concrete at the drilling site.