- Offer Profile

- CMO Valves is a company that designs, manufactures and markets standard, and specialised knife gate valves. Its comprehensive range of manufacturing allows one to cover many industrial applications and the ability to control all kinds of fluids

VALVES FOR MULTIPLE INDUSTRIAL APPLICATIONS

-

Knife gate valves, Check valves, Dampers, Gates for Associated industry. Chemical Industry, Mining Valves, Solid pumping management, Food industry, Water treatment, Dams, Power plants, Thermal power stations, Energy generation.

Check Valves - Serie R

-

Check valves WAFER swing or tilting disc (can be manufactured with flanges on request). One‐piece cast body which provides easy evacuation of solid particles contained in the fluid. Face‐to‐face dimension in accordance with CMO standard. It has an arrow on the body indicating the flow direction. Can be supplied with auxiliary spring to obtain faster sealing. For high water loads or large valve diameters hydraulic damping systems can be incorporated which reduce the valve’s impact in the sealing. The R check valve allows the fluid to flow through in one direction, it is opened by the fluid passing through and it closes due to the weight of the disc and the return of the fluid.

Utilization

- This valve is suitable for liquids that contain a maximum of 5% suspended solids.

- Paper Industry. ‐ Chemical plants.

- Sewage treatment. ‐ Pumping.

Sizes

- DN50 a DN1200

- (Larger sizes on request).

Working pressures

- De DN 50 a DN 600: máximo PN 64.

- De DN 700 a DN 1.200: máximo PN 25

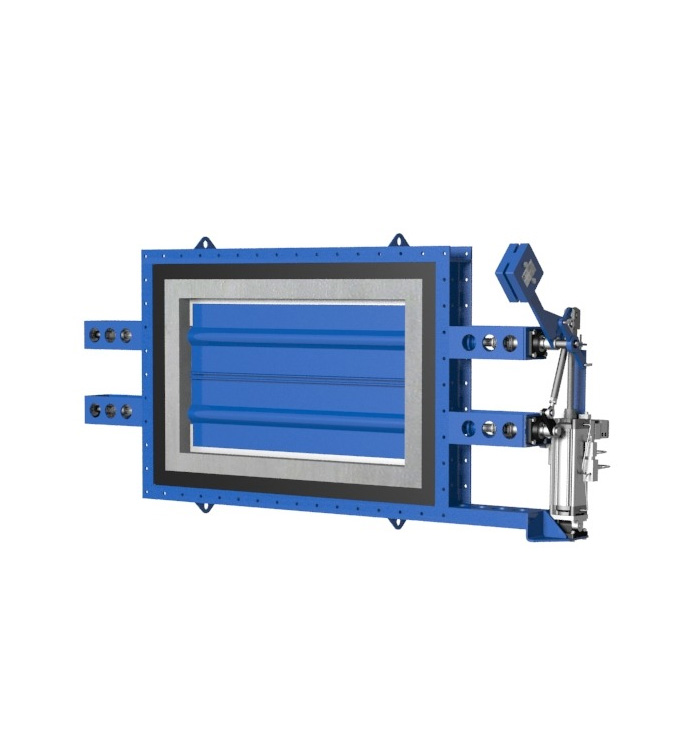

Damper - Serie GC

-

Gas valve, with square or rectangular damper design.

Unidirectional guillotine damper.

Various seat and packing materials available.

Face‐to‐face distance in accordance with CMO standard.Utilization

- This guillotine damper valve is suitable to work with a large range of airs and gases

- It is particularly suitable as an isolation element in order to allow inspections, maintenance and repairs in the ducts.

-

USED MAINLY IN:

- Cement factories.

- Steel mills.

- Electrical power stations.

- Chemical plants.

- Energy sector.

Sizes

- From 125 x 125 up to 3000 x 3000 (larger sizes on request). Check with CMO for the general dimensions of a specific damper.

Working pressures

- Maximum standard work pressure is 0.5 kg/cm 2 ; greater pressures upon request.

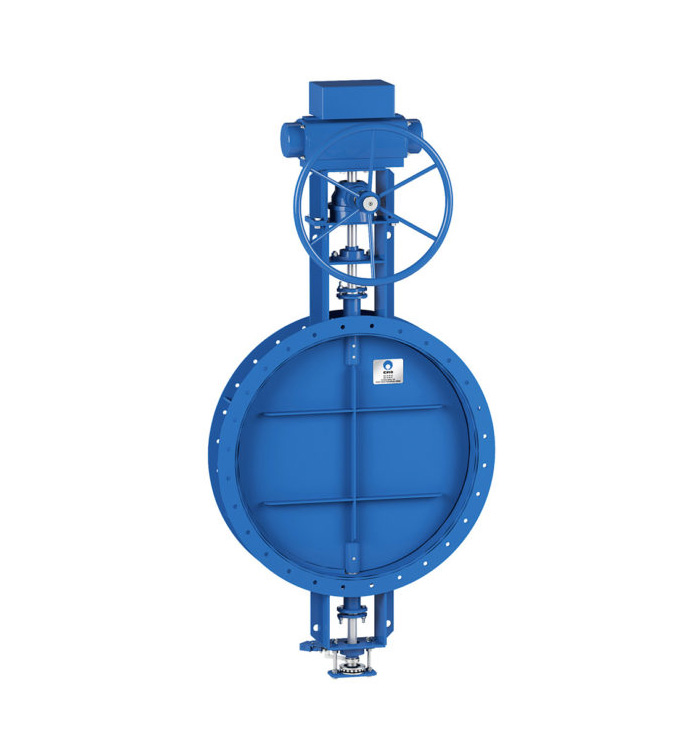

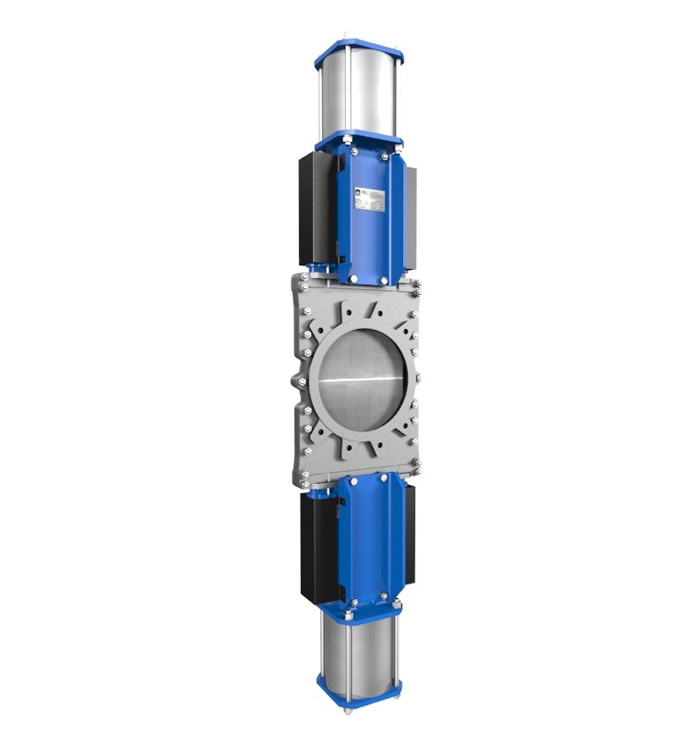

Damper - Serie GR

-

Gas valve, with round damper design.

Unidirectional guillotine damper.

Various seat and packing materials available.

Face‐to‐face distance in accordance with CMO standard.Utilization

This guillotine damper valve is suitable to work with a large range of airs and gases.

-

- It is particularly suitable as an isolation element in order to allow inspections, maintenance and repairs in the ducts.

- Cement factories.

- Steel mills.

- Electrical power stations.

- Chemical plants.

- Energy sector.

Sizes

- From DN 150 up to DN 3000 (larger sizes on request).

- Check with CMO for the general dimensions of a specific damper.

Working pressures

- Maximum standard work pressure is

-

Damper - Serie MD

-

Dámper mariposa distribuidor 3v para montaje entrebridas estanqueidad relativa.

Cuerpo y disco mecanosoldado en función del diámetro.

El grado de estanqueidad de esta válvula es del 99%.

Materiales de fabricación: acero S275JR, acero HII, acero 16MO3, diferentes gamas de aceros inoxidables (aisi 304, 316, 310 …).

En función de la aplicación.Utilization

- Diverting the fluid through one outlet or another, its most common uses are pneumatic conveying, stack gas regulation, exhaust gas regulation in combustion processes, exhaust gas control in gas turbines.

- Drives: Manual, pneumatic, electric

Sizes

- The sizes of construction of this type of gates are adapted according to the needs of each specific project.

Working pressures

- According to standard manufacturing these valves are designed to withstand 0.5 kg/cm2 at room temperature.

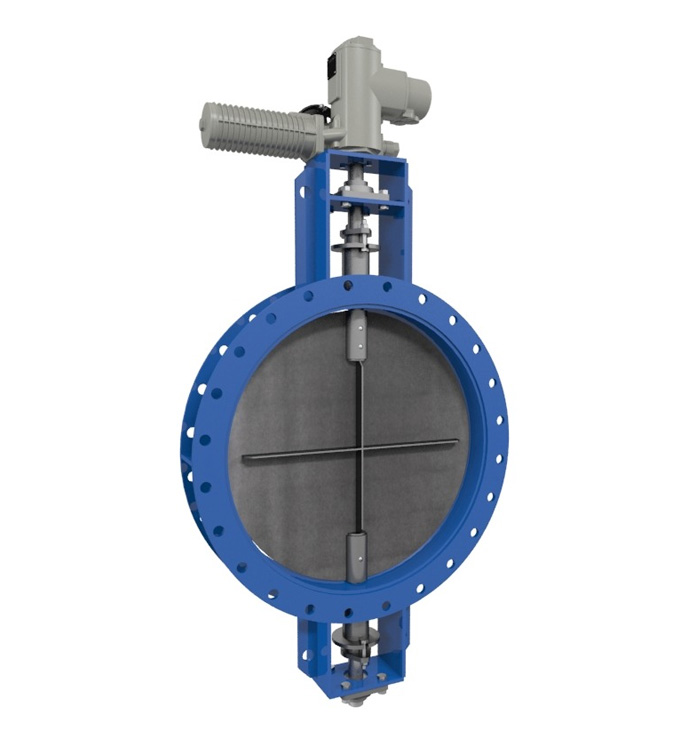

Damper - Serie MF

-

Round damper butterfly valve, with bidirectional design.

Designed for pneumatic transport of air or gases at different temperatures.

Option of manufacturing “WAFER” type or with bored flanges.

Watertight integrity between 97% and 99%.Utilization

- The materials used for the fabrication of these Dampers MF depend on the temperatures and the working pressures.

- These butterfly damper valves are suitable to work with a wide range of air and gases. They are particularly suitable for controlling the flow of gas in pipelines.

Sizes

From DN 80 up to DN 3000 (larger sizes on request). Check with C.M.O. for the general dimensions of a specific damper butterfly.

Working pressures

- The most significant difference between the ML and MF series is the differential working pressure (ΔP). For lower pressures, choose the ML series (Light Butterfly); for higher pressures, choose the MF series.

- Maximum standard work pressure is 0.5 kg/cm2; greater pressures upon request.

Damper - Serie ML

-

Round damper butterfly valve, with bidirectional design.

Designed for pneumatic transport of air or gases at different temperatures.

Option of manufacturing “WAFER” type or with bored flanges.

Watertight integrity between 97% and 99%.Utilization

- The materials used for the fabrication of these Dampers MF depend on the temperatures and the working pressures.

- These butterfly damper valves are suitable to work with a wide range of air and gases. They are particularly suitable for controlling the flow of gas in pipelines.

Sizes

- From DN 80 up to DN 3000 (larger sizes on request). Check with C.M.O. for the general dimensions of a specific damper butterfly.

Working pressures

- The most significant difference between the ML and MF series is the differential working pressure (ΔP).

- For lower pressures, choose the ML series (Light Butterfly); for higher pressures, choose the MF series..

- Maximum standard work pressure is 0.5 kg/cm2; greater pressures upon request.

Damper - Serie MV

-

Damper de mariposa de doble clapeta con ventilador, puede ser con bridas o wafer.

Esta válvula está diseñada, con el fin de crear una cámara estanca en el interior de la doble clapeta, por medio de la presión del ventilador, consiguiendo así la estanqueidad del 100 % de lado a lado de la clapeta.

Cuerpo y disco en fundición o mecanosoldado en función del diámetro.

El grado de estanqueidad de esta válvula es del 100%.

Materiales de fabricación: acero S275JR, acero HII, acero 16MO3, diferentes gamas de aceros inoxidables (aisi 304, 316, 310 …). En función de la aplicación.Utilization

- Pneumatic conveying, stack gas regulation, exhaust gas regulation in combustion processes, exhaust gas control in gas turbines.

- Drives: Manual, pneumatic, electric.

Sizes

- DN200 to DN3000

- (Larger dimensions on request)

Working pressures

- These valves are manufactured according to pressure and temperature requirements, with the appropriate materials in each case.

Damper - Serie PL

-

The louver damper is composed of various blades which each turn on the central shaft. The ends are joined to the pipes via flanges. Normally, the louver damper is supplied as one piece, except in those applications in which the dimensions of the equipment require special transport.

Construction

The body of the PL damper is machine welded and can be made of different materials. The standard construction sizes range from 150×150 mm (minimum) to 3000×3000 mm although larger sizes are available on request. The blades are made flat, with reinforcing ribs and are supported on two semi‐shafts. The flat blade system is sufficiently rigid for the working pressures of these valves and they do not produce significant load losses.

Utilization

The PL dampers have two types of seals. Depending on the application you can choose between: Swing‐thru (97% seal), for environments with high dust concentrations, the metal/metal seal (99% seal) and the step‐seat joint for other applications that require greater watertight integrity, reaching 100% with air chamber sealing.

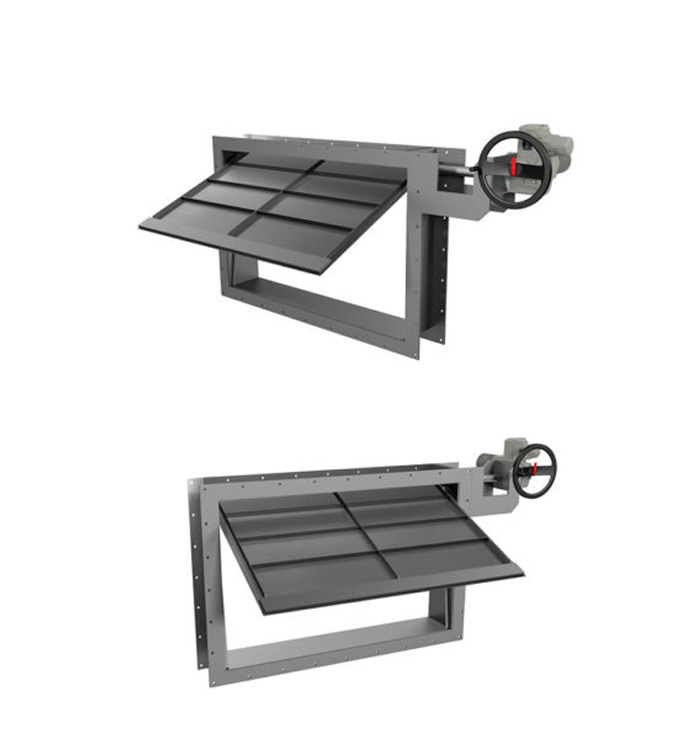

Damper - Serie SC

-

The SC damper is composed of a blade which turns on a shaft located on one side (like a gate). The ends are joined to the pipes via flanges. Normally, the SC damper is supplied as one piece, except in those applications in which the dimensions of the equipmentrequire special transport.

Utilization

The body of the SC damper is machine welded and can be made of different materials. The standard construction sizes range from 150×150 mm (minimum) to 3000×3000 mm although larger sizes are available on request. The blade is made flat, with reinforcing ribs and is supported on two semi‐shafts. The flat blade system is sufficiently rigid for the working pressures of these valves and they do not produce significant load losses.

Damper - Serie UL

-

Gas valve, with square or rectangular single-bladed tamper design.

Butterfly type tamper, unidirectional.

Multiple sealing and packing materials available.

Distance between faces according to CMO standard.Utilization

This butterfly valve is suitable for working with a wide range of air and gases.

It is especially indicated as an insulation element to allow inspections, maintenance and repairs of ducts.

MAINLY USED IN:Cement plants - Steel plants - Power plants.

Chemical plants - Energy sector.Sizes

From 125 x 125 to 3000 x 3000 (larger dimensions on request).

To find out the general dimensions of a specific pipe, please consult CMOWorking pressures

The standard maximum working pressure is 0.5 kg/cm 2 , for higher pressures on request.

Knife Gate Valve - A LUG

-

Lugged knife gate valve, manufactured with one piece monoblock body, supported gate with guides for back flows.

Utilization

- Light and medium services.

- Water, clean liquids or charged with solids in low concentrations.

- Pneumatic transport of powders.

- Medium concentration paper pulp.

Sizes

- Standard from DN 50 to DN 1200

- Bigger diameters under request.

Working pressures

- DN 50-250 = 10 bar

- DN 300-400 = 6 bar

- DN 450 = 5 bar

- DN 500-600 = 4 bar

- DN 700-1600 = 2 bar

Knife Gate Valve - Serie A

-

Knife gate valve unidirectional wafer design. One piece cast body with guides to support gate and seat wedges. Provides high flow rates with low pressure drop and include various seat and packing materials available. Face to face dimension in accordance with CMO standard. An arrow is marked on the body indicating the flow direction. This knife gate valve is suitable for liquids that contain a maximum of 5% suspended solids. If it is used for dry solids in gravity feed applications it should be installed with the arrow on the body pointing in the opposite direction to the flow.

Utilization

This knife gate valve is suitable for liquids that contain a maximum of 5% suspended solids. The valve it is used for dry solids in gravity feed applications it should be installed with the arrow on the body pointing in the opposite direction to the flow. Designed for applications such as:

Paper Industry, Mining, Silo emptying, Chemical plants, Bumping Food, Industry Sewage treatment.

Sizes

Standard manufacturing sizes: From DN50 up to DN1400

Working pressures

– DN 50-250 = 10 bar – DN 300-400 = 6 bar – DN 450 = 5 bar

– DN 500-600 = 4 bar – DN 700-1600 = 2 bar

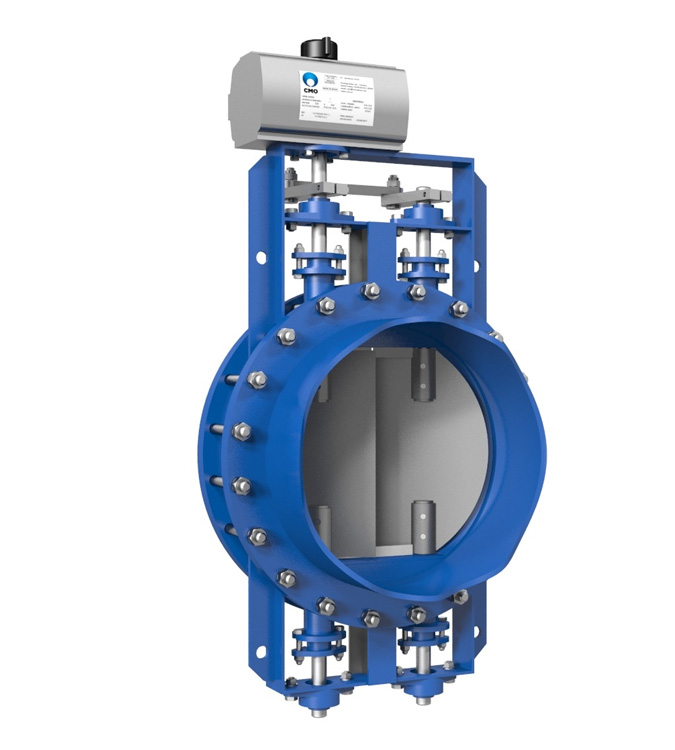

Knife Gate Valve - Serie AB

-

Slurry knife gate valve

Bidirectional wafer-design knife gate valve. One-piece cast body. Provides high flow rates with low pressure drop. Various seat and packing materials available. Face-to-face dimension in accordance with CMO standard.

Utilization

- Chemical plants

- Pumping

- Food Industry

- Sewage treatment

Sizes

- Standard manufacturing sizes: From DN50 up to DN2000

- Bigger sizes under request.

Working pressures

- DN 50-250 = 10 bar

- DN 300-400 = 6 bar

- DN 450 = 5 bar

- DN 500-600 = 4 bar

- DN 700-1600 = 2 bar

Knife Gate Valve - Serie AD

-

Knife Gate Valve uni-directional, Wafer style. One piece integral cast body with guides to support the gate and seating wedges. High flow rates with low pressure drops.

Utilization

Paper Industry

MiningChemical

BumpingFood

IndustryWater treatmentSizes

DN50 a DN2000

bigger diameters under request.Working pressures

- DN 50-250 = 10 bar

- DN 300-400 = 6 bar

- DN 450 = 5 bar

- DN 500-600 = 4 bar

- DN 700-1600 = 2 bar

Knife Gate Valve - Serie B

-

Knife Gate Valve, Wafer style, bidirectional knife gate valve. Cast body, composed by two bolted parts, with inside sliding guides to provide a smooth operation. High flow rates with low pressure drops. Several seat and packing materials available.

Utilization

- This knife gate valve is appropriate for liquids with a solids concentration of maximum 8%.

- Pulp and Paper – Mining – Effluent handling plants – Chemical plants.

- Food and beverage – Bulk conveying – Sewage applications – Chemical plants.

Sizes

- DN50 a DN2.000

- (Bigger sizes under request).

Working pressures

- From DN 50 to DN 125: 10 (kg/cm2)

- DN 150: 8 (kg/cm2)

- DN 200: 7 (kg/cm2)

- From DN 250 to DN 300: 5 (kg/cm2)

- From DN 350 to DN 400: 4 (kg/cm2)

- From DN 450 to DN 600: 3 (kg/cm2)

- From DN 700 to DN 1200: 2 (kg/cm2)

Knife Gate Valve - Serie C

-

Square or rectangular shaped knife gate valve.

Welded construction manufacturing.

Various seat and packing materials available.Utilization

- Designed for a wide range of applications such as:

- Mining, Bulk Transport, Chemical plants.

- Food Industry.

Sizes

- From 125×125 to 1400×1400.

- Also available in rectangular designs.

- Larger sizes on request.

Working pressures

- Standard: 0,5 Kg/cm2.

- For larger pressures, consult CMO.

Knife Gate Valve - Serie D

-

Unidirectional flanged knife gate valve (bidirectional option to order), designed for high pressure applications, with self‐cleaning seal.Single piece die‐cast body with screwed‐down bonnet and wedges to guarantee the seal. Provides high flow rates with low pressure drop. Various seal and packing materials available.

- Face‐to‐face distance in accordance with CMO standard.

- It has an arrow on the body indicating the flow direction.

Utilization

The gate valve is suitable for working with clean liquids or liquids with a concentration of solids:

Drying plants, Paper industry, Water Treatment, Chemical Plants

Food sector, Mining, Oil extraction, Sludge.Sizes

DN50 a DN2000

Larger sizes to order.Working pressures

PN 2,5 to PN 100

Each valve is designed according to work conditions

Knife Gate Valve - Serie E

-

Unidirectional knife gate valve with wafer design. With round input and square output. Body made up of two screwed‐down halves, with slides to provide smooth operation. Provides high flow rates with low pressure drop. Various seal and packing materials available.

Utilization

- The knife gate valve is suitable for working in very difficult conditions with fluids which contain a large amount of solids.

- It is very suitable for paper recycling pulp facilities and, in general, sites which work with hard particles such as metal pieces (staples, clips, etc) and stones.

- It is best placed horizontally. The output (square) is larger than the input (round), thus avoiding the accumulation of solids in the valve and preventing any interference when shutting the gate.

Sizes

- DN50 a DN1200

- (Larger sizes to order)

Working pressures

- DN50 to DN450 7 kg/cm2

- DN500 to DN1200 4 kg/cm2

Knife Gate Valve - Serie F

-

Unidirectional valve wafer design.

One‐piece cast body with guides to support gate and seat wedges. Provides high flow rates with low pressure drop. Various seat and packing materials available. Face‐to‐face dimension in accordance with CMO Valves standard. It has an arrow on the body indicating the flow direction. Usually mounted under a hopper, to prevent any kind of solids accumulating on the seat, has a special body design and it is assembled with the body arrow in the same direction as the fluid. When a knife gate valve remains open for long periods of time and the body’s internal walls are parallel a very large torque is usually required to close it. However, the inside of the body of model F is cone‐shaped, which provides greater space and, this way, when the valve is closed the solids stored inside it can be easily removed.

Utilization

This knife gate valve is suitable for working with dry products like powder and grain. It is generally used for gravity discharge of dry solids. Designed for the following applications: -Mining ‐Silo emptying ‐ Electrical power stations ‐ Chemical plants ‐ Food Industry

Sizes

- DN50 a DN1200

- (Larger sizes on request).

Working pressures

- DN50 a DN150 3 kg/cm2

- DN200 a DN300 2 kg/cm2

- DN350 a DN400 1,5 kg/cm2

- DN450 a DN1200 1 kg/cm2

Knife Gate Valve - Serie FK

-

Unidirectional wafer‐design knife gate valve.

Monobloc cast body with interior slides for optimum movement of the through conduit during operation and seal wedges.

Provides high flow rates with low pressure drop.

The lower part of the body has two holes for cleaning.

Various seal and packing materials available.Utilization

- This knife gate valve is suitable for working with dry products like powder and grain. It is completely sealtight, meaning it is recommended for toxic and hazardous fluids. It is generally used for gravity discharge of dry solids. D

Sizes

- DN50 a DN1200

- (Larger sizes on request).

Working pressures

- DN50 a DN150 3 kg/cm2

- DN200 a DN300 2 kg/cm2

- DN350 a DN400 1,5 kg/cm2

- DN450 a DN1200 1 kg/cm2

Knife Gate Valve - Serie GA

-

Slurry valves

Bidirectional knife gate valve. Valve suitable for use as end-of-line.The GA valve body is a single monobloc piece. Stainless steel through-conduit gate. Two rubber sleeves. The main characteristic of this slurry valves is that it provides a full continuous flow. This means that in open position it produces no cavities and there is no turbulence in the fluid. The stem protection hood is independent from the handwheel securing nut, this means the hood can be disassembled without the need to release the handwheel. This advantage allows regular maintenance operations to be carried out, such as lubricating the stem, etc. The CMO valve stem is made from stainless steel 18/8. This is another additional benefit, since some manufacturers supply it with 13% chrome, which quickly rusts. The operating wheel is manufactured in nodular cast GJS-500. Some manufacturers supply it in common cast-iron, which can lead to breakage in the event of very high operation torque or a bang. The yoke has a compact design with the bronze actuator nut protected in a sealed and lubricated box. This makes it possible to move the valve with a key, even without the handwheel (in other manufacturers’ products this is not possible). The pneumatic actuator’s upper and lower covers are made of GJS-400 nodular cast iron, making them highly shock resistant. This characteristic is essential in pneumatic actuators.

Utilization

Thats knife gate slurry valves are suitable for working in the mining industry, in loaded fluid transport lines such as water with stones, sludge, etc, and, in general, for abrasive fluids in the chemical industry and waste water.

Designed for the following applications:

Slurry valves for Mining, Sewage treatment, Electrical power stations

Chemical plants, Energy sector, Thermal power stationsSizes

DN50 a DN1500

Larger sizes to order.Working pressures

DN50 a DN600 10 kg/cm2

DN700 a DN1400 6 kg/cm2

DN1500 2 Kg/cm²

The pressures indicated in the table can be used in either of the valve’s two directions.

Knife Gate Valve - Serie GD

-

Slurry valves

Slurry valve for very loaded products with solids, used for suspended matter in mining. It does not present neither salient nor any split in the pipe. It is not needed any joint between the flanges as it is incorporated in the body.

Bidirectional wafer‐design knife gate valve.

Monoblock one‐piece cast iron body.

Stainless steel gate. Two rubber sleeves.

Provides high flow rates with low pressure drop.

Various seat materials available.This valve main characteristic is that it provides a full continuous flow.

The GD valve’s body is composed of one single “monoblock” piece.Utilization

If it is used for dry solids, slurry in gravity feed applications it should be installed with the arrow on the body pointing in the opposite direction to the flow.

This Slurry valve are designed for applications such as:

Paper Industry, Mining Slurry Valves, Silo emptying, Chemical plants, Bumping Food, Industry Sewage treatment, Slurry treatment.

Sizes

Standard manufacturing sizes:

From DN50 up to DN600

Bigger diameters under request.Working pressures

- DN 50-250 = 10 bar

- DN 300-400 = 6 bar

- DN 450 = 5 bar

- DN 500-600 = 4 bar

- DN 700-1600 = 2 bar

Knife Gate Valve - Serie GH

-

Slurry knife gate valve

Bidirectional wafer‐design knife gate valve. “Monoblock” one‐piece cast iron body. Stainless steel gate. Two rubber sleeves.Provides high flow rates with low pressure drop.

Utilization

This knife gate valve is suitable for working in the mining industry, in loaded fluid transport lines, such as: water with stones, sludge, etc.

Mining ‐ Sewage treatment ‐ Electrical power stations ‐ Chemical plants ‐ Energy Sector ‐ Thermal power stations

Sizes

ND80‐3″ to ND900‐36″

(Larger sizes on request).

Working pressures

The pressures indicated in the table, can be used in either of the valve’s two directions.

Maximum PN ND80‐3″ to ND900‐36″ 21 kg/cm2 = 300 psi

Knife Gate Valve - Serie K

-

Unidirectional knife gate valve. One‐piece cast body with guides to support gate and seat wedges. Provides high flow rates with low pressure drop. Various seat and packing materials available. Face‐to‐face dimension in accordance with CMO standard. It has an arrow on the body indicating the flow direction

Utilization

- This knife gate valve is suitable for liquids that contain a maximum of 5% suspended solids.

- Paper Industry, Mining, Silo emptying.

- Chemical plants, Pumping, Food Industry.

Sizes

- ND50 to ND2000

- (larger sizes on request).

Working pressures

- DN 50-250 = 10 bar

- DN 300-400 = 6 bar

- DN 450 = 5 bar

- DN 500-600 = 4 bar

- DN 700-1600 = 2 bar

Knife Gate Valve - Serie L

-

Bidirectional knife gate valve. Two‐piece cast body, joined by screws, with internal guides for smooth movement of gate during operation.

Provides high flow rates with low pressure drop. Various seat and packing materials available.

Face‐to‐face dimension in accordance with CMO standard.Utilization

- This knife gate valve is suitable for liquids that contain a maximum of 20% suspended solids.

- Paper Industry ‐ Slurry Mining Service ‐ Chemical plants ‐ Food Industry

- Pumping ‐ Silo emptying ‐ Sewage treatmen

Sizes

- ND50 to ND2000

- (larger sizes on request).

Working pressures

- DN 50-250 = 10 bar

- DN 300-400 = 6 bar

- DN 450 = 5 bar

- DN 500-600 = 4 bar

- DN 700-1600 = 2 bar

Knife Gate Valve - Serie T

-

Slurry Knife Gate Valve

Unidirectional “LUG” guillotine slurry knife gate valve, designed in accordance with standards TAPPI TIS 405‐8 and MSS‐SP‐81.

Monobloc cast body with interior slides for optimum movement of the gate during operation.

Provides high flow rates with low pressure drop. Various seat and packing materials available.

Face‐to‐face dimension in accordance with TAPPI standard.Utilization

- This guillotine valve is suitable to work with liquids with a maximum concentration of solids of 6%.

- Bulk transport ‐ Draining plants ‐ Paper industry ‐ Water treatment.

- Chemical plants ‐ Food sector ‐ Mining

Sizes

- De DN50 ‐ 2″ a DN1200 ‐ 48″

- (larger sizes on request).

Working pressures

- DN50‐2″ a DN600‐24″ 10 kg/cm2

- DN700‐28″ a DN900‐36″ 8 kg/cm2

- DN1000‐40″ a DN1200‐48″ 4 kg/cm2

Knife Gate Valve - Serie UB

-

Slurry knife gate valve

Bidirectional Slurry knife gate valve with “wafer” design.

Two‐piece cast body, joined by screws, with internal guides for smooth movement of through conduit during operation.

Provides high flow rates with low pressure drop. Various seal and gasket materials available.

Distance between faces in accordance with Standard UNE‐EN 558 Basic Series 20.Utilization

This knife gate valve is suitable for working with clean liquids or liquids with a concentration of bland solids:

Drying plants ‐ Paper Industry ‐ Sewage treatment ‐ Chemical plants

Food industry ‐ Mining ‐ Oil extraction ‐ Sludge.Sizes

- DN50 a DN2.000

- (Other dimensions to order).

Working pressures

- DN 50-250 = 10 bar

- DN 300-400 = 6 bar

- DN 450 = 5 bar

- DN 500-600 = 4 bar

- DN 700-1600 = 2 bar

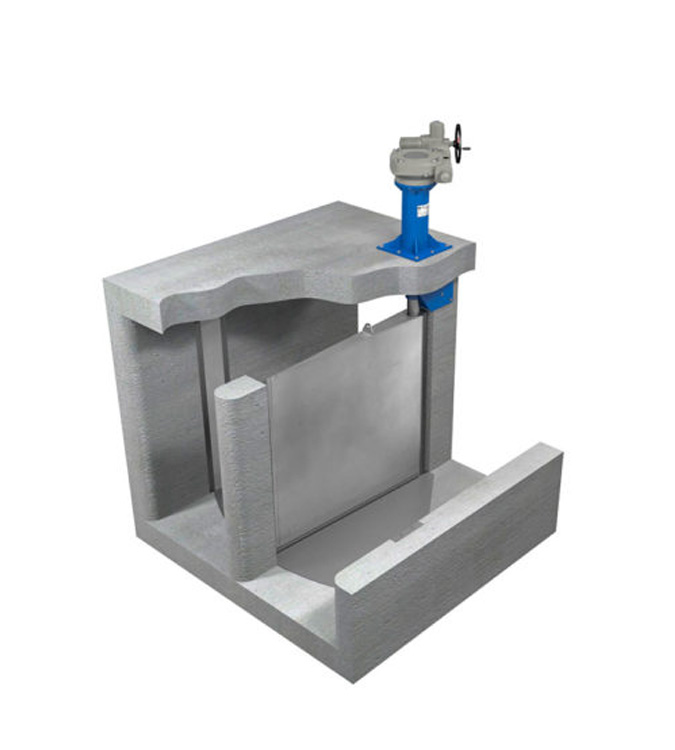

Penstock - Serie CB

-

Narrow groove sliding penstock for high‐speed fluids.

Mechanically welded body, comprising two screwed parts, with internal guides for smooth movement of the penstock during operation.

Penstock design carried out in accordance with “U.S. BUREAU OF RECLAMATION”.

Passage of the rectangular section penstock, although there is also the possibility of the inlet and outlet having a circular section.

Various construction materials available.

Face‐to‐face distance in accordance with CMO standard.Utilization

- This narrow groove sliding penstock is designed to work with fluids at high speeds. Its main application is in water deposit run‐offs.

Sizes

- The construction sizes for this type of penstocks are adapted to the needs of each particular project.

Working pressures

- As is the case with the dimensions of the penstock, the working ΔP is also adapted in accordance with the specific needs of each project.

Penstock - Serie CG

-

Swing gate which turns on a vertical shaft located at one end of the stopboard.

Gate designed to divert the flow..

Stopboard design with a support wheel, to reduce the lever effect on the rotation shaft.

Design of square or rectangular penstock.

Various sealing materials available.

Designed to install embedded in concrete or mounted on walls with chemical or expansion anchors.Utilization

The swing gate is designed for installation in channels. The channel can be rectangular or square in section, and this penstock can have a 3 or 4 side sealing, since it is designed to divert the flow.

It is suitable to work with clean liquids or loaded with solids.

Sizes

- Water treatment plants.

- Irrigation.

- Hydroelectric power stations.

- Conduits

Working pressures

- From 500 x 500 up to 3000 x 3000 (larger sizes to order).

- Check with CMO for the general dimensions of a specific swing gate.

Penstock - Serie TE

-

The valve will be installed in vertical position perfectly aligned with the actuator.

Must be avoid stresses in the body of the valve, because of an incorrect aligned with the discharge pipe.

Is not necessary any specific instructions for the operation of the valve. The valve will be opened an closed,

Slowly or quickly. Obviously, must be avoid any excessive effort.

The valves are appropriated for regulation as the stroke can be regulated in any intermediate positionUtilization

- La válvula telescópica, tal y como la compuerta de rebose, se utiliza para controlar el nivel de fluidos almacenados.

- También se utiliza para evacuar mediante rebose las posible espumas y solidos que se acumulen en la parte superior de los liquidos.

Sizes

From DN50 up to DN1500 (larger sizes on request). Check with C.M.O. for the general dimensions of a TE telescopic valve.

Working pressures

Maximum working pressure depends on the valve stroke and is equal to the difference between the maximum and minimum level required for the pond.These units adapt to the customer’s requirements in each project, and are designed to meet the working conditions in the final location.

Penstock - Serie VM

-

Penstock design for covering big surfaces and high water columns.

Design of the gate with lateral wheels, it helps on the manoeuvrability of the penstock at high water columns.

Square or rectangular designs available.

Unidirectional and bidirectional versions available.

Multiple seat materials available.

Designed for installing embedded on concrete or fitted on wall by mechanical/chemical anchors.Utilization

- Wagon type penstock is designed for installing in channels or for covering wall holes.

- The channel or hole can be rectangular, round or square and the seat tightness can be made in 3 or 4 sides.

- It is suitable for working with clean fluids or fluids charged with solids.

- Mainly used in: Water treatment plants – Irrigations – Hydro-power plants – Conductions

Sizes

- From 150×150 mm to 3000×3000 mm (bigger dimensions under request)

- For overall dimensions of the wagon type penstock, please check it with CMO.

Damper - Serie LR

-

Air, Gas Damper

Round multilouvre damper butterfly valve, shutter type, with bidirectional design.

Designed for pneumatic transport of air or gases at different temperatures.

Option of manufacturing “WAFER” type or with bored flanges.

Watertight integrity between 97% and 99%.Utilization

These multilouvre damper butterfly valves are suitable to work with a wide range of air and gases. They are particularly suitable for controlling the flow of gas in pipelines. Used mainly in:

Cogeneration plants, Thermal power stations, Electrical power stations, Chemical plants, Energy sector.

Sizes

From DN 400 up to DN 3000 (larger sizes on request). Check with C.M.O. for the general dimensions of a specific round multilouvre damper butterfly.

Working pressures

Maximum standard work pressure is 0.5 kg/cm2; greater pressures upon request.

Serie CM

-

MULTIPLE FIXED CONE VALVES

Standard construction with body and sleeve in carbon steel with stainless steel sliding side.

Utilization

- Regulation valve.

- It is not needed any joint between the flanges as it is incorporated in the body.

- Main application: flow regulation in pipe.

Sizes

DN150 a DN2000 (Larger sizes on request)

Serie SD

-

Specially designed to be fitted in installations for the transport of fine‐grained solid fluid like cement, ash, sand, etc.

Utilization

- In all kinds of industries in which pneumatic transport is performed, either by pipe with flanges or at inlet and outlet of silos.

Sizes

- The construction sizes for this type of valves are adapted to the needs of each particular project.

Working pressures

- The regular pressures in this type or work, where normal pressures are between 0 and 2 Kg/cm².

- For other pressures or applications please ask CMO.

Serie TD

-

Unidirectional knife gate valve, with wafer design and quick opening and closing. Body made up of two screwed‐down halves, with slides to provide smooth operation. It has two opposing gates which come together in the centre of the mouth, and all the components which are liable to deteriorate can be easily replaced.

Utilization

This knife gate valve is designed to work in the most demanding conditions, it being commonly used in the paper industry in pulp facilities and purification plants, rejecting soft lightweight materials such as plastic.

Sizes

DN50 to DN1200 (larger sizes to order).

Working pressures

DN50 to DN250 10 kg/cm2

DN300 to DN400 6 kg/cm2

DN450 5 Kg/cm

DN500 to DN600 4 Kg/cm

DN700 3 Kg/cm

DN800 to DN1200 2 Kg/cm

Serie TM

-

Cone seated sampling valve. One piece integral cast body with bolted flange to be welded to the main pipeline.

The TM sampling valve is manufactured fully in AISI316 stainless steel. It is composed by three main parts: welding flange with neck, valve body and operating system.Utilization

- The CMO sampling valve is used to take samples of the working fluid inside of the pipelines.

- Designed for a wide range of markets such us:

- Pulp and Paper.

- Effluent handling plants.

- Chemical plants.

- Food and beverage.

Sizes

- DN4

Working pressures

- 10 (kg/cm2)

Serie VF

-

Seat valve with opening or closing by spring.

Utilization

- Pressure circuits or vacuum lines as a safety valve rated at different pressures.

Sizes

- Sizes on request.

Working pressures

- N/D