- Offer Profile

-

TOMRA Recycling is a leading sensor-based sorting solutions provider with 50 years of experience in circular waste management. More than 8,200 of its sophisticated sorters are installed in more than 100 countries around the globe to recover high-purity fractions from the waste streams - from plastics, metals, wood and paper, we provide tailored sorting solutions for your bespoke needs, delivering significantly higher yields for your operation.

TOMRA Recycling is part of TOMRA Sorting, which develops sensor-based sorting and process control systems for the food, mining and recycling industries. TOMRA Sorting is owned by Norway's TOMRA Systems ASA, which is listed on the Oslo Stock Exchange. Founded in 1972, TOMRA Systems ASA reached sales of approximately € 1.1 billion in 2020 and employs more than 4,600 people.

Sorting systems for optimal resource recovery

-

Recover more - Recycle effectively.

We help you make the most of material recovery.

With sustainable production of new goods and construction at the forefront of climate action, secondary raw materials play an essential role in moving towards a circular economy. Our goal is straightforward: help our partners achieve their commercial objectives and meet climate-related targets.

As a trusted world leader in automated sorting systems, we partner with you long-term to ensure optimal performance and adapt to the demands of future legislation. No matter where your recycling site is in the world, TOMRA is there to enable your operations maximum potential.

Waste recycling

Plastics

- We help the world recycle plastics through sensor-based sorting systems that instantly detect and remove contaminants from all types of polymers.

Municipal Solid Waste

- By sorting recyclable and high-calorific materials from mixed waste streams, we transform waste into value while reducing landfill and incineration emissions.

Packaging

- We enable circularity with advanced sorting technologies that effectively recover post-consumer packaging waste for recycling.

Single Stream Recycling

- We make it easier for consumers and municipalities to recycle plastics, metals, paper and glass through our automated sorting technology.

Commercial and Industrial Waste

- We enable the cost-effective recovery of secondary raw materials from commercial, industrial and bulky waste.

Construction and Demolition Waste

- We help recyclers maximize the value of construction, demolition and excavation waste through automated sorting of materials for recycling.

Refuse-Derived Fuel

- We enable the sustainable energy transition through automated sorting systems to deliver high purity refuse-derived fuel.

Organic Waste

- We help reduce greenhouse gas emissions by sorting and purifying biodegradable waste to create feedstocks for compost and biogas.

Textiles

- We help recover recyclable fibers through sensor-based sorting technologies for industrial and post-consumer textile waste.

Wood

- We help industries conserve natural resources through sensor-based sorting systems that enable the recycling of waste wood.

Paper

- We optimize paper recovery and recycling through sensor-based sorting systems that deliver high-quality raw material for paper and board manufacturing.

Metal recycling

Aluminum

- We enable the production of green aluminum with high speed and high purity sorting of aluminum from heavy metals.

E-Scrap

- We help the world recover complex raw materials from electronic waste through advanced sensor-based sorting technology.

Post Shredder and Non-ferrous Metals

- We maximize yields for recyclers with automated systems that recover metals from residue and sort mixed metals into high quality monofractions.

Sensor-based sorting solutions

Waste and metal sorting products

AUTOSORT™

-

The most powerful multifunctional sorting system worldwide

- Multifunctional sensor configuration

- Optimized costs & performance

- Highly efficient FLYING BEAM™

- Future-proof system design

- Minimal maintenance

Maximize operational efficiency and profits with the ultimate all-rounder in sorting

The world-renowned AUTOSORT™ offers legendary sorting performance that stands the test of time, delivering unparalleled throughput and purity rates across numerous applications. Compact and ultra-flexible in design, the multifunctional sorting system integrates seamlessly into both new and existing plants.

AUTOSORT™ combines a variety of leading-edge features in one machine with a flexible sensor configuration for a future-proof sorting system that meets the challenges of a dynamic market landscape. The sorting unit delivers exceptional performance and operational efficiency thanks to its homogeneous light distribution for improved detection and monitoring across the entire belt width.

Optional add-on technologies expand material identification capabilities for traditionally undetectable fractions like black polymers. What’s more, AUTOSORT™ now comes with the option to connect to our secure, cloud-based data monitoring platform. TOMRA Insight is an add-on service that digitally connects sorting units to provide high-value data that helps you maximize plant throughput and boost output quality.

Features- SHARP EYE™ Technology

- GAIN TEX™

- DEEP LAISER™

- TOMRA Insight

- bulky waste

- commercial and industrial waste

- construction & demolition waste

- municipal solid waste

- organic waste

- packaging

- paper

- polymer recovery / mixed plastic

- refuse derived fuel

- metal recovery

- weee-electronic scrap

- wood

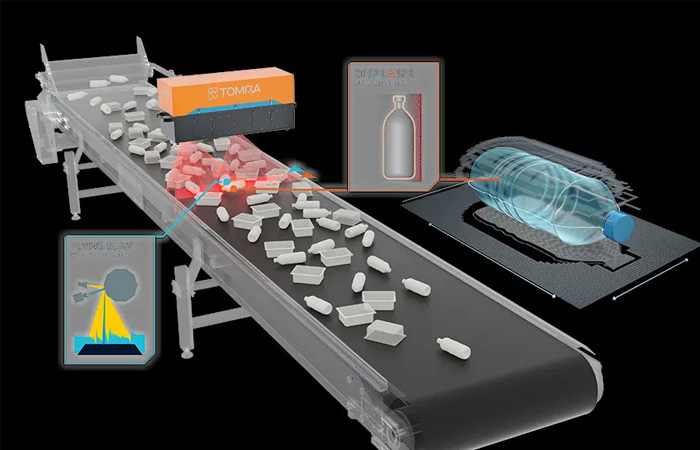

AUTOSORT™ FLAKE

-

Our highest performance and most versatile flake sorter

- Constant, ultra-high purity processing

- High sensitivity electromagnetic sensor

- Versatile sensor configuration

- Cost effective operation

- Bottle-to-bottle recycling solution

Achieve maximum purity yields for high-end applications such as bottle to bottle recycling.

With a combination of our most powerful sensor technologies, AUTOSORT™ FLAKE offers consistent and exceptional sorting performance. Its high-speed valves eject even the smallest contaminates with maximum precision to meet extremely high purity requirements.

The high performance flake sorter features an integrated light source, continuous signal correction and enhanced light distribution to ensure stable sorting performance and minimal downtime. Its high sensitivity electromagnetic sensor detects even the smallest non-ferrous metals and ferrous metals (as small as 1 mm) for maximum purity yields.

Setting new benchmarks worldwide, AUTOSORT™ FLAKE is the ideal sorting solution for high purity end products. What’s more, its operational efficiency is cost-effective and requires little maintenance.

Features- SHARP EYE™ Technology

- GAIN™

- DEEP LAISER™

- TOMRA Insight

- polymer recovery / mixed plastic

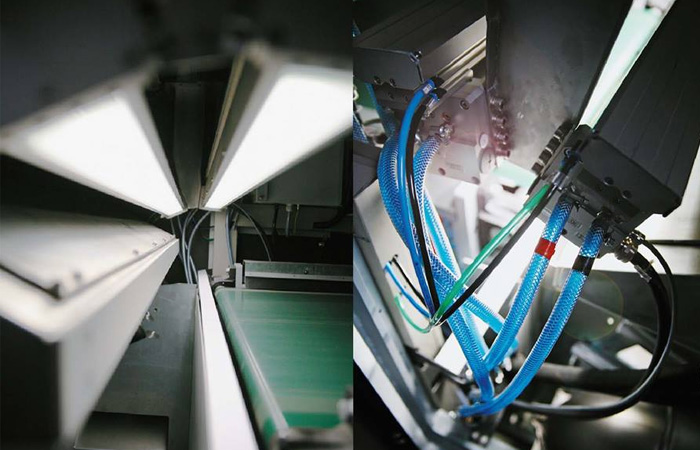

INNOSORT™ FLAKE

-

The world’s most flexible color and polymer flake sorter

- Sorts multiple contamination types

- Up to 6 t/h capacity

- Single or multi-step sorting

- Economical presorting solution

- User-friendly & easy maintenance

Achieve unparallel sorting performance in fractions with higher contamination levels.

With a unique combination of sensor technologies and dual full color camera, INNOSORT™ FLAKE effectively removes undesired colors, polymers, and metals. Its modular design with working widths up to 2 meters delivers a running capacity to 6 metric tons per hour. The flexible configuration allows for single or multiple step sorting to get the purest possible end products.

The high throughput flake sorting unit comes with an integrated light source, continuous signal correction and enhanced light distribution to ensure and minimal downtime. The dual full color camera can identify 16.8 million variations in color, while its near infrared (NIR) sensors identify impurities like undesired plastics.

Highly effective in removing significant amounts of contaminants after washing and before extrusion, INNOSORT™ FLAKE is the ideal sorting solution for upgrading plastics such as PET and PO applications. What’s more, this easy-to-maintain flake sorter with a low initial investment also reduces losses, making it an economical choice for your plastic recycling operations.

Features- FLYING BEAM™

- Dual full color camera

- Modular design

- NIR camera

- polymer recovery / mixed plastic

GAINnext™

-

AI-powered sorting system with deep learning technology

- AI waste sorting

- Identifies hard-to-classify objects

- Enables new material streams

- Automates manual sorting

- Wide application ecosystem

High accuracy sorting of multiple material streams with deep learning technology.

GAINnext™ maximizes the recovery and purity levels of valuable materials for recycling. Its AI-based visual classification identifies thousands of objects in milliseconds, offering high-throughput processing with up to 2000 ejections per minute, depending on the application.

Thanks to its integrated deep learning software, GAINnext™ identifies hard-to-classify objects, reducing the need for manual sorting. The system automates complex tasks that cannot be achieved with traditional optical waste sorting. The intelligent system also classifies overlapping objects and calculates trajectory positioning for high-precision sorting.

GAINnext™ makes it possible to process multiple material streams on a single sorting line. The future-proof, adaptive technology can be easily optimized with network connectivity to continually improve performance and reduce downtime. Cloud-based monitoring and digital application services are optionally available with TOMRA Insight.Features

- Deep learning technology

- Multi-sensor integration

- High-resolution color camera

- Software upgradability

- TOMRA Insight (optional)

- Waste analyzer (optional)

Applications

- PE-silicone cartridges

- Food-grade plastic packaging

- Deinking

- PET cleaner

- Wood chips

More applications in development.

AUTOSORT™ RDF

-

Real-time quality analysis for refuse derived fuels

- Real-time online monitoring

- Calorific, water & chlorine analysis

- Reliable data accuracy

- Cost effective quality assurance

Maximum process control and uniform quality that meets the strictest requirements.

As a world-class technology utilized to prepare substitute fuels, AUTOSORT™ RDF combines built-in machine intelligence and high precision sensors to analyze the overall combustibility of various waste streams. The high throughput screening unit continuously monitors critical values such as calorific, chlorine and water content of the waste stream, providing real-time data and optimal process control.

Whether mixed municipal solid waste (MSW), industrial waste or commercial waste, AUTOSORT™ RDF enables operators to meet end-customer requirements with reliable quality assurance. The field-proven technology is significantly more consistent and cost-effective than traditional, random sample analysis. AUTOSORT™ RDF is used extensively throughout Europe for alternative fuel preparation.

Features- FLYING BEAM™

- Calorific analysis

- Chlorine analysis

- Water content analysis

- refuse derived fuel

AUTOSORT™ SPEEDAIR

-

High-speed, intelligent sorting of plastic films and lightweight packaging

- Closed-loop laminar airflow

- High throughput up to 6 m/s

- Low risk of material blockages

- Open conveyor system, no hood

- Highly efficient FLYING BEAM™

Accelerate recycling rates and purity levels for plastic films and lightweight packaging without unnecessary downtimes.

Utilizing laminar air flow to stabilize lightweight objects moving along a high-speed conveyor belt, AUTOSORT™ SPEEDAIR instantly identifies high-value materials and remove impurities. The closed-loop fan driven system delivers optimized air handling for lower installation and running costs.

Features

With belt speeds up to 6 m/s, the high throughput sorter features our newest integrated light source with continuous signal correction and intensified light distribution across the entire belt width. Moreover, its machine intelligence combines information to identify chemical properties and molecular differences in the materials for improved accuracy and sorting performance.

The machine’s advanced design allows for an open conveyor system reducing downtimes caused by material blockages in traditional conveyor belt covers. What’s more, it’s connected to the TOMRA Insight platform – a cloud-based service that enables your operations with secure remote status monitoring, process control and data validation.

AUTOSORT™ SPEEDAIR is available as solutions bundle (core device, conveyor belt and catcher hood) or as an add-on device to an existing AUTOSORT™ machine setup.- SHARP EYE™ Technology

- DEEP LAISER™

- TOMRA Insight

- Intelligent Object Recognition

- paper

- packaging

COMBISENSE™

-

Color sorting of mixed non-ferrous metals for maximum value

- Exceptional grey metal sorting

- Long-term yield stability

- High throughput processing

- Auto-adjusting ejection system

- Multiple sorting tasks & grain sizes

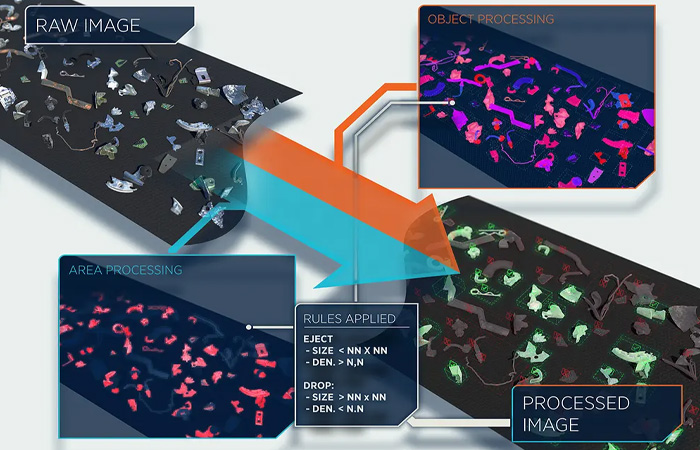

Effectively sort high value metals with unsurpassed color detection and image processing technology.

COMBISENSE™ offers exceptionally precise sorting of non-ferrous metals by color, extracting additional value from mixed waste streams. By combining in-house developed sensor and software technologies, the intelligent sorting solution detects, identifies and separates multiple materials regardless of grain size.

Long-term sorting and yield stability are ensured thanks to its FLUIDCOOL™ LED thermal management system that provides constant temperatures and uniform light distribution. Its Dual Processing Technology heightens the sorting performance by simultaneously processing object and area information to instantly identify select materials as they speed along the acceleration belt.

With a capacity of up to 5 metric tonnes per hour, COMBISENSE™ is the perfect high throughput sorting solution for separating zinc grey metals, copper, brass and printed circuit boards. The ultra-flexible, multi-sensor sorting unit can be programmed to create fractions for wires, coins, and non-metal materials like plastics. Offering a high return on investment across mixed waste, e-scrap and metal recycling, COMBISENSE™ is an excellent sorting solution to upgrade your operation and profits today.

Features- FLUIDCOOL™ LED technology

- Dual Processing Technology

- High resolution CRGB color camera

- Electromagnetic metal detection

- end of life vehicle scrap

- metal recovery

- weee / electronic scrap

- zorba

AUTOSORT™ PULSE

-

The dynamic LIBS solution for sorting aluminum scrap by alloy

- Dynamic LIBS technology

- High throughput alloy sorting

- 3D object scanning & shape recognition

- Single-point scan for sharper detection

- AI-based detection of overlapping objects

AUTOSORT™ PULSE redefines industry standards by enabling high-throughput production of alloy scrap fractions to create green aluminum. Our laser-induced breakdown spectroscopy (LIBS) technology is uniquely dynamic, offering you various scanning modes for higher precision sorting and long-term operational flexibility.

Thanks to the machine’s bulk infeed system and powerful combination of sensors, it offers high-capacity throughput that meets industrial production standards. What’s more, dynamic LIBS technology delivers high-quality aluminum scrap with less material preparation – even with painted, coated or dusty alloys. The high-purity fractions of series-based aluminum alloys allow direct remelting without downgrading valuable materials, providing a rapid return on investment.

The dynamic LIBS sorting system is ideal for processing large volumes of post-production and post-consumer aluminum scrap. Numerous material tests have demonstrated purity levels of 95 percent and higher . After sorting post-production scrap, the machine has consistently achieved these purity levels in both the 5xxx series and 6xxx streams.

Features- Dynamic laser system

- 3D object scanning

- Single-point focus mode

- AI-based object singulation

- TOMRA Insight (option)

- aluminium scrap sorting

FINDER™

-

Ultra-flexible, intelligent sorting of non-ferrous metals

- SUPPIXX™ spatial resolution

- Intelligent object recognition

- Multifunctional sorting

- Easy & intuitive interface

- High throughput for higher yield

High precision sorting and purification of metals from complex material streams.

FINDER™ is the ideal sorting solution to recover non-ferrous metals lost to eddy current separation. The sorting unit harnesses the power of electromagnetic sensors and built-in machine intelligence to instantly detect metals, regardless of material complexity or grain size.

Featuring groundbreaking software including SUPPIXX™, DEEP DATA™ and Intelligent Object Recognition (IOR) systems, FINDER™ delivers exceptionally high throughput and purity levels. Optional sensor technologies to sort copper wires, polymers, PCB, and clean non-metal fractions create additional value to complex materials streams such as e-scrap recycling.

Available in four configurations with high precision valve blocks, its modular and flexible design offers the optimal sorting solution metal and waste recycling. With belt speeds up to 3m/sec and reduced air consumption, FINDER™ delivers your operation high yield results across various sorting tasks.

Features- SUPPIXX™ technology

- DEEP DATA™ technology

- Intelligent object recognition

- High precision valves

- Adaptive belt calibration

- NIR sensor & FLYING BEAM™ option

- Laser object detection option

- endof life vehicle scrap

- ash

- metal recovery

- municipal solid waste

- weee / electronic scrap

- wire recovery

X-TRACT™ for wood

-

Powerful precision x-ray sorting of waste food

Exceptional speed and accuracy in removing impurities from waste wood.

X-TRACT™ is a high throughput sorting solution to separate waste wood from complex mixed streams with a capacity of up to 30 metric tons per hour, depending on the material input. Harnessing the power of dual energy x-ray transmission (XRT), the sorting system detects and separates wood from impurities like inert materials, metals, plastic and glass based on atomic density.Every aspect of the X-TRACT™ sorting system has been developed in-house by our engineers and wood processing experts. With its new generation DUOLINE™ XRT sensor and AI-based software, you benefit from precise detection and increased stability for long-term performance. The sorting system also comes with a 16000-hour warranty on the x-ray source and sensor.

Featuring a powerful combination of cutting-edge sensors and robust mechanics, X-TRACT™ delivers high-performance results – even in the harshest environments. The machine’s unique top-down design protects the x-ray source from dust and dirt to prevent costly maintenance. It effortlessly handles composite materials and overlapping objects with its Dual Processing Technology, enabling operators to prioritize sorting for either high recovery or high purity yields.

AUTOSORT™ BLACK

-

The ultimate solution for sorting carbon black plastics

- Sharp material detection

- Grain sizes from 25 to 120 mm

- High throughput and purity

- Easy installation

- Low maintenance effort

Uncover the hidden value of black plastic sorting

For many years, recycling black plastics was challenging due to plastics made with carbon black pigments. Thanks to our AUTOSORT™ BLACK sorting system, the future of black plastic recycling is very promising. This unit is the ultimate solution to separate carbon-filled black plastics by polymer types.

Using MIR spectroscopy with the modified FLYING BEAM™ technology, the sorting system differentiates between black plastics such as black PE, black PP and PS. Moreover, with its optional electromagnetic sensor, the sorting machine detects and extracts metals and other contamination from the input stream.

Thanks to its robust construction, the high-throughput system instantly sorts objects from 25 to 120 mm in size. An off-belt detection system and sturdy design ensure maintenance efforts and downtimes are kept at a minimum.

With its enhanced resolution, AUTOSORT™ BLACK delivers high-purity results and creates tremendous value for recyclers.Features

- MIR spectrometer

- Modified FLYING BEAM™

- Electromagnetic metal detection (option)

- TOMRA Insight (option)

Applications

- Black packaging

- Black plastics

- PS & ABS from Weee, ELV and C&I

Metal sorting products

X-TRACT™ for Metal

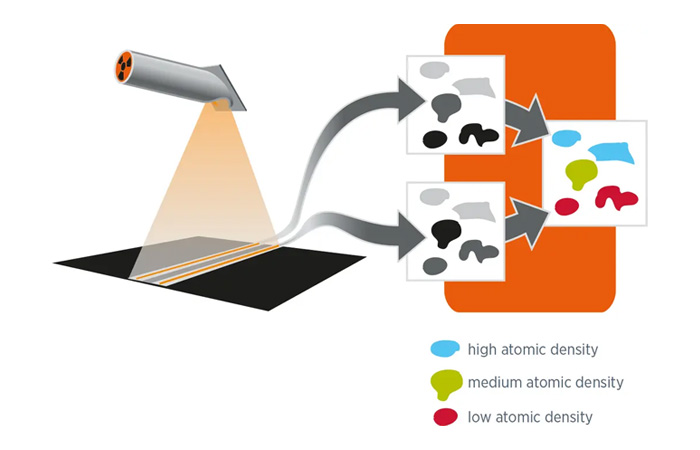

- Unrivaled speed and accuracy in separating low from high density objects from complex material streams.

X-TRACT™ is a high throughput sorting solution that harnesses the power of dual energy x-ray transmission (XRT) to detect and separate objects based on their atomic density. The machine’s top-down design protects the x-ray source from dust and dirt to prevent costly maintenance. It also comes with optimal source-to-sensor positioning providing more precise detection and higher throughput.

Every aspect of the XRT sorting system, including its robust mechanics, high precision sensors and software features was developed in-house by our experts and engineers. With x-ray power supply of up to 1000W, X-TRACT™ provides high-speed processing across multiple applications and grain sizes, including aluminum fines and copper wires.

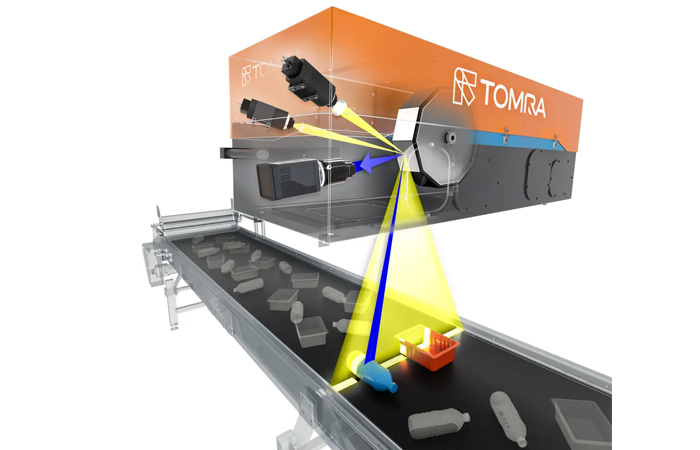

AUTOSORT™

-

Maximize operational efficiency and profits with the ultimate all-rounder in sorting

The world-renowned AUTOSORT™ offers legendary sorting performance that stands the test of time, delivering unparalleled throughput and purity rates across numerous applications. Compact and ultra-flexible in design, the multifunctional sorting system integrates seamlessly into both new and existing plants.AUTOSORT™ combines a variety of leading-edge features in one machine with a flexible sensor configuration for a future-proof sorting system that meets the challenges of a dynamic market landscape. The sorting unit delivers exceptional performance and operational efficiency thanks to its homogeneous light distribution for improved detection and monitoring across the entire belt width.

COMBISENSE™

-

Color sorting of mixed non-ferrous metals for maximum value

- Exceptional grey metal sorting

- Long-term yield stability

- High throughput processing

- Auto-adjusting ejection system

- Multiple sorting tasks & grain sizes

Effectively sort high value metals with unsurpassed color detection and image processing technology.

COMBISENSE™ offers exceptionally precise sorting of non-ferrous metals by color, extracting additional value from mixed waste streams. By combining in-house developed sensor and software technologies, the intelligent sorting solution detects, identifies and separates multiple materials regardless of grain size.

Long-term sorting and yield stability are ensured thanks to its FLUIDCOOL™ LED thermal management system that provides constant temperatures and uniform light distribution. Its Dual Processing Technology heightens the sorting performance by simultaneously processing object and area information to instantly identify select materials as they speed along the acceleration belt.

With a capacity of up to 5 metric tonnes per hour, COMBISENSE™ is the perfect high throughput sorting solution for separating zinc grey metals, copper, brass and printed circuit boards. The ultra-flexible, multi-sensor sorting unit can be programmed to create fractions for wires, coins, and non-metal materials like plastics. Offering a high return on investment across mixed waste, e-scrap and metal recycling, COMBISENSE™ is an excellent sorting solution to upgrade your operation and profits today.

Features- FLUIDCOOL™ LED technology

- Dual Processing Technology

- High resolution CRGB color camera

- Electromagnetic metal detection

- end of life vehicle scrap

- metal recovery

- weee / electronic scrap

- zorba

AUTOSORT™ PULSE

-

The dynamic LIBS solution for sorting aluminum scrap by alloy

- Dynamic LIBS technology

- High throughput alloy sorting

- 3D object scanning & shape recognition

- Single-point scan for sharper detection

- AI-based detection of overlapping objects

AUTOSORT™ PULSE redefines industry standards by enabling high-throughput production of alloy scrap fractions to create green aluminum. Our laser-induced breakdown spectroscopy (LIBS) technology is uniquely dynamic, offering you various scanning modes for higher precision sorting and long-term operational flexibility.

Thanks to the machine’s bulk infeed system and powerful combination of sensors, it offers high-capacity throughput that meets industrial production standards. What’s more, dynamic LIBS technology delivers high-quality aluminum scrap with less material preparation – even with painted, coated or dusty alloys. The high-purity fractions of series-based aluminum alloys allow direct remelting without downgrading valuable materials, providing a rapid return on investment.

The dynamic LIBS sorting system is ideal for processing large volumes of post-production and post-consumer aluminum scrap. Numerous material tests have demonstrated purity levels of 95 percent and higher . After sorting post-production scrap, the machine has consistently achieved these purity levels in both the 5xxx series and 6xxx streams.

Features- Dynamic laser system

- 3D object scanning

- Single-point focus mode

- AI-based object singulation

- TOMRA Insight (option)

- aluminium scrap sorting

FINDER™

-

Ultra-flexible, intelligent sorting of non-ferrous metals

- SUPPIXX™ spatial resolution

- Intelligent object recognition

- Multifunctional sorting

- Easy & intuitive interface

- High throughput for higher yield

High precision sorting and purification of metals from complex material streams.

FINDER™ is the ideal sorting solution to recover non-ferrous metals lost to eddy current separation. The sorting unit harnesses the power of electromagnetic sensors and built-in machine intelligence to instantly detect metals, regardless of material complexity or grain size.

Featuring groundbreaking software including SUPPIXX™, DEEP DATA™ and Intelligent Object Recognition (IOR) systems, FINDER™ delivers exceptionally high throughput and purity levels. Optional sensor technologies to sort copper wires, polymers, PCB, and clean non-metal fractions create additional value to complex materials streams such as e-scrap recycling.

Available in four configurations with high precision valve blocks, its modular and flexible design offers the optimal sorting solution metal and waste recycling. With belt speeds up to 3m/sec and reduced air consumption, FINDER™ delivers your operation high yield results across various sorting tasks.

Features- SUPPIXX™ technology

- DEEP DATA™ technology

- Intelligent object recognition

- High precision valves

- Adaptive belt calibration

- NIR sensor & FLYING BEAM™ option

- Laser object detection option

- endof life vehicle scrap

- ash

- metal recovery

- municipal solid waste

- weee / electronic scrap

- wire recovery

RECYCLING TECHNOLOGY

-

The innovation behind the world's leading sorting systems

The technologies developed by our in-house team of engineers, application experts and machinists are designed and built to meet the most strenuous demands of recycling. Our sorting systems redefine machine capability and set new standards in performance thanks to our high-precision sensors, data-driven software and powerful processing techniques.

With our cutting-edge technology, you benefit from more flexibility and a dedicated team that knows exactly how to make the most of your sorting system. Our long-standing collaboration with waste and metal recyclers throughout the world is our constant source of inspiration – and the evolution of our technologies continue.

DEEP LEARNING

- Utilizing the expansive power of TOMRA’s neural networks, Deep Learning technology extracts numerous material characteristics of individual objects to classify them for sorting. Our deep learning-based applications for waste wood, PE-silicone cartridges and other materials set new performance standards for objects once considered difficult to sort.

Deep Learning technology brings groundbreaking solutions to challenges that cannot be solved with conventional sorting methods. Our artificial neural networks are trained with thousands of images to create a pool of information that drives performance. Delivering high-purity and user-defined fractions, this innovation can upgrade material output and create new revenue streams.

DEEP LAISER™

- Through artificial intelligence and laser line scanning, DEEP LAISER™ creates a digital copy of objects that can be used for advanced data-driven decision making. It enables 3D object recognition and enhanced classification of materials that can be combined with other sensor data to provide the high accuracy sorting across numerous applications.

The trailblazing technology boosts image sharpness and delivers unrivaled object-based recognition – even with overlapping materials and high-throughput processing. Utilizing sorting algorithms to prioritize targeted materials, DEEP LAISER™ enables operators to flexibly adapt sorting tasks while simultaneously maximizing yields and purity levels.

FLUIDCOOL™

- Our illuminating FLUID COOL™ technology is an advanced liquid-based cooling system to extend the lifetime and achieve maximum stability in LED lighting systems. Unlike conventional air cooling, this technology enables higher light intensity, enhanced color quality and outstanding efficiency thanks to a consistently lower LED temperature.

The technology utilizes liquid silicone to remove heat from LEDs through a highly efficient convection process. Delivering outstanding performance for thousands of hours, it is an ideal solution for sorting in harsh operating environments with extreme temperatures. FLUID COOL™ enables unsurpassed light distribution for maximum yield stability.

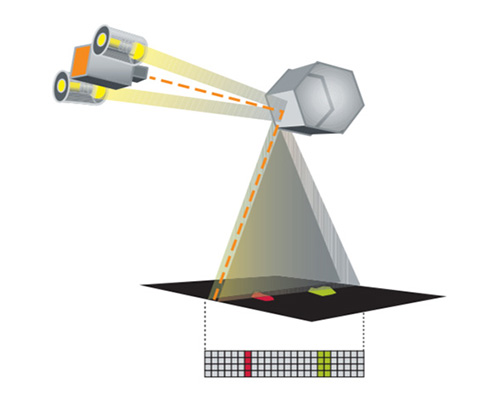

FLYING BEAM™

- Our world-class lighting technology guarantees a stable and homogenous light distribution that is beamed across the entire working width to ensure that all materials passing the sensors can be instantly classified. With continuous signal correction offering simultaneous light beam calibration, you benefit from long-lasting sorting performance.

Protected from dust and dirt thanks to its encased setup, the technology utilizes an innovative point scanning principle to focus exclusively on the area being scanned. This extends the temperature range, enabling flammable materials to be safely processed, and saves up to 80% energy consumption compared to conventional lighting methods.

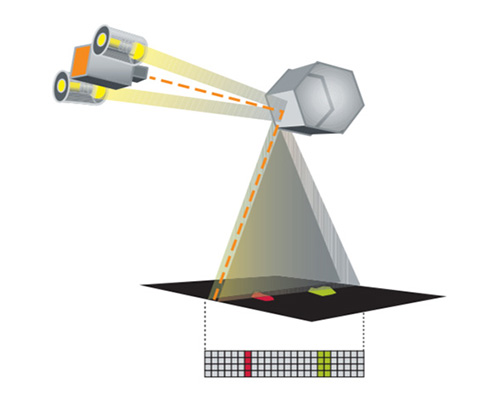

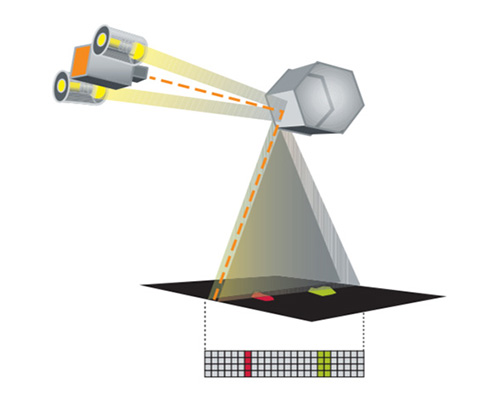

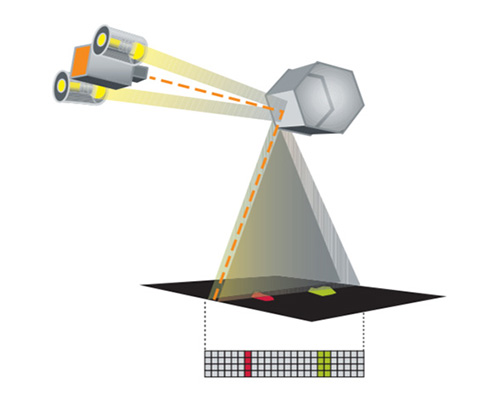

SUPPIXX™

- Accelerating the detection of objects for high throughput sorting tasks, our SUPPIXX™ technology enhances resolution levels, scaling up images to eight times their size to reduce product loss. Thanks to the significantly improved detection accuracy, including small and thin objects, operators benefit from maximum yields and higher purity levels.

Our SUPPIXX™ imaging processing technology creates clear and specific material characteristic information to identify objects instantly. The technology’s software algorithms also improve the signal-to-noise ratio, eliminating noise caused by mechanical and electrical influences for sharper imaging and improved sorting performance.

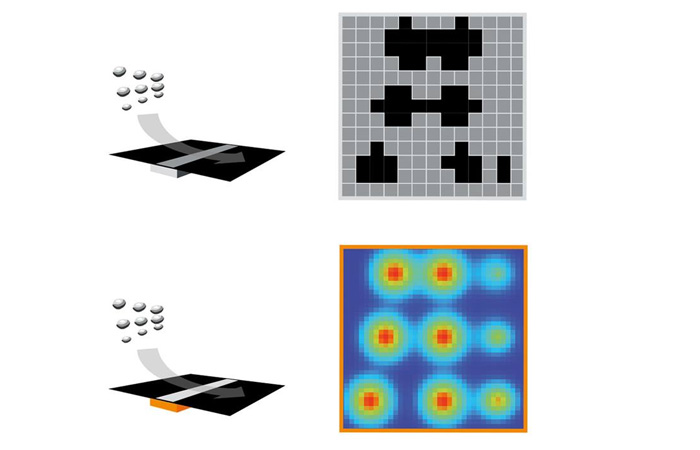

DUAL PROCESSING TECHNOLOGY™

- Simultaneous object and area processing is at the core of our Dual Processing Technology, which combines optical information to make data-driven decisions based on the targeted material. Ideal for maximizing yields with complex material streams, the technology gives operators the flexibility to choose high purity and/or high recovery sorting.

Dual Processing Technology enables superior detection of targeted materials on high throughput sorting lines. It instantly identifies overlapping object and composite materials for sorting to increase purity and reduce product loss. The intelligent software also optimizes ejection efficiency for reduced air consumption, lowering operational costs.

DUOLINE™

- Leveraging the power of two independent scan lines, our DUOLINE™ technology delivers outstanding precision in high throughput x-ray transmission (XRT) sorting. The dual line scan offers significant advancements in separating low from high density objects across multiple applications, regardless of the relative thickness of materials.

DUOLINE™ technology enables the sorting of materials with even the slightest differentiation in density. Operators achieve even greater results thanks to the choice of high resolution or high sensitivity sensor units, depending on the targeted sorting task. Our newest dual line sensor offers even sharper detection and faster processing of complex material streams.

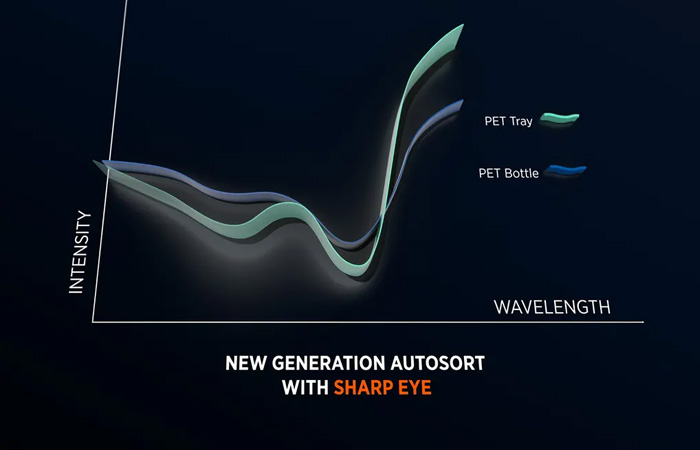

SHARP EYE™

- Our SHARP EYE™ technology identifies materials down to the molecular level to ensure superior detection and the highest sorting accuracy. Even with complex material streams, its multi-point scanning system enables the detection of individual objects based on their specific chemical properties and classifies them according to the assigned sorting task.

Utilizing breakthrough techniques with broadband wavelength illumination, SHARP EYE™ provides intelligent, automated image analysis. The innovative optical solution also facilitates ultra-efficient, high density light to increase the sharpness of images. Operators profit from outstanding energy efficiency and subsequent.

TOMRA Insight

- Connect. Anywhere. Anytime.

One of the most valuable assets for recycling operation is the data captured by sensor-based sorting units. Near-live monitoring of material streams offers the ultimate control for quick and strategic decision-making, giving you a competitive edge in today’s dynamic marketplace for secondary raw materials.

As waste and metal recycling enter the digital era to maximize resources, it begins with connected sorting units and data optimization solutions.

Our cloud-based sorting data platform offers you valuable support from our team of specialists, an easy-to-use dashboard and customizable reporting tools. Now you can have full access to critical sorting data anytime, anywhere.