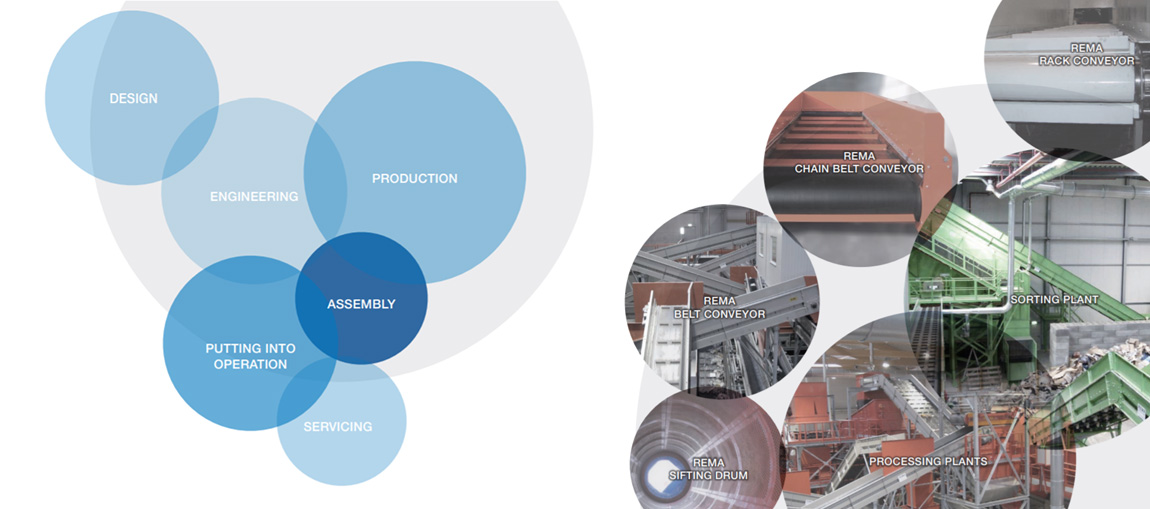

- Offer Profile

- We are specialized in the field of waste management. We focus on the design, production and installation of sorting- and treatment plants of various types of waste.

Our engineers design your individual plant solution with the highest level of expertise. These plans are then implemented by our experienced craftsmen and technicians. By permanent observation of the current market, we recognize additional development opportunities, so that your investment achieves the maximum return.

Conveyor technology for waste management

-

THE MORE VERSATILE YOUR REQUIREMENTS, THE MORE EXTENSIVE OUR RANGE IS

We provide our entire know-how, so that you get the best performance! Conveyor technology has a significant impact on the reliability and efficiency of the overall system. Therefore, we have specialized in this specific plant component. We offer very high quality and robust conveyor machinery such as belt conveyors, chain conveyors or rack conveyors designed to meet high demands.

Our extensive experience with these units guarantees you the following by means of appropriate design details

– long life-span

– resistance to faults

– optimal performance Plant Technologies

PREPARATION PLANTS FOR COMMERCIAL WASTE

-

Shortened disposal routes and rising disposal costs lead to high standards in the treatment of commercial waste. On the basis of the material composition and the quantities to be processed, we design plants where commercial waste is sorted for material recycling and / or processed for alternative fuels. In addition, we bring existing plant and preparation technology into the new concepts as often as possible.

Our goals are:

– high added value

– residue reduction

– high quality production of alternative fuels

MECHANICAL PREPARATION PLANTS

-

Due to the mechanical preparation of the most varied materials we are faced with constant new challenges. Depending on the physical characteristics or the different material composition, there is always a new task. The sensible combining of the fields of screening, sifting, selecting and compacting is part of our daily business.

Take advantage of our experience and talk to us! Specifically for your needs, we will develop a customized solution.

Our goals are:

– cost-effective and profitable processing of materials

– high reliability

– flexibility

SEPARATION PLANTS FOR SPECIAL COMMODITIES

-

Ever-growing demands in the field of sorting lightweight packaging, PPK, mixed plastics, mixed metals and PET, for example, place high demands on the plant technology. Especially with regard to the efficiency and quality of the products generated, the highest level of performance is required. Through the combination of our own high quality products with advanced technology from the market, we develop concepts that will cope with these demands also in the future.

Our plant technology starts with the pre-treatment and dosing of the materials to be sorted and ends with the loading and compaction of the finished products.

Our goals are:

– high through-put

– high degree of purity

– wide sorting range

CONVEYOR TECHNOLOGY

-

The backbone of any system is the internal logistics!

The company REMA provides reliable and high-quality conveyor technology, which qualifies itself through a wide variety of usable conveyor belts. These include the troughed belt conveyor MGF and MGGF as a throughed sliding belt conveyor, the sliding belt conveyor GGF, the sturdy cross belt conveyor QGF, the chain belt conveyor KGF, the rack conveyor RF as well as the steep belt conveyor SGF.In order to design these conveyor belts so that they are safer, easier to maintain, more robust and more flexible, they are equipped by us with special accessories. Additional equipment such as winding protection, modular design and special side seals optimize our materials handling.

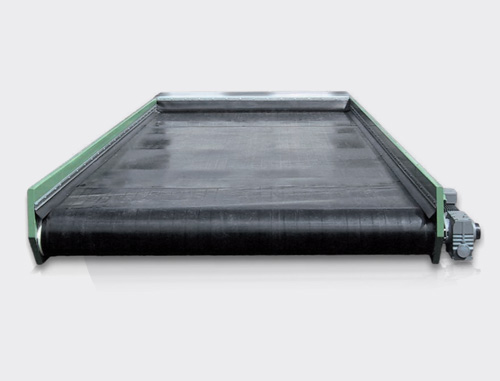

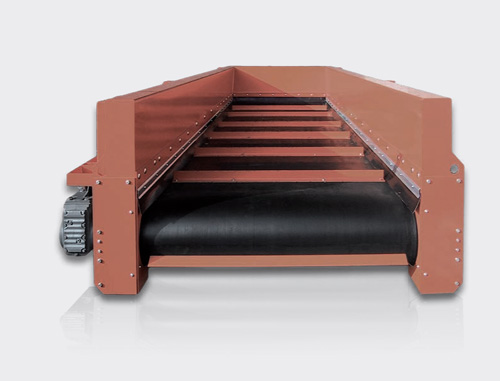

TROUGHED BELT CONVEYOR "MGF"

-

REMA troughed belt conveyors are based on a robust metal sheet edge design in segment construction. The side seals of the REMA troughed belt conveyor, a combination of sliding movement of the belt and additional labyrinth seals have proved their worth in use in recycling plants for decades. In particular these side seals are the basis for the high availability, the low maintenance requirement and the high service life of the REMA troughed belt conveyor.

Technical Data:

- Distance between axles: 1 - xx m

- Width of belt WB: 500 to 2.800 mm

- Effective width EB: 400 to 2.700 mm

- Effective height EH: 200 to 600 mm

- Speed: 0,1 – 3,0 m/s

- Belt quality: EP 400/3, 3:1, smooth or cleated

- Drive: Slip-on gear motor

- Special strengths

- Anti-wrap guard

- Robust edge design

- Closed structure

- Modular design

- Special side seal made from fabric rubber

Special Version:

- Reversible

- Manoeuvrable

- Load cells

- Flexible bend element, negative

- Stainless steel segment

- As dosing feeder

- As bunker

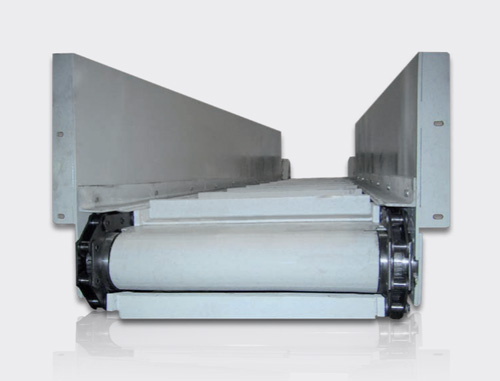

SLIDING BELT CONVEYOR "GGF"

-

The REMA sliding belt conveyor shows its advantages particularly in application areas where an even distribution of the transported material on the belt is important. Therefore the REMA sliding belt conveyor is frequently used as an accelerator belt before sorting and separating units. The special side seals of the REMA sliding belt conveyor in combination with the standard anti-wrap guard on the drive drum make it the right choice even with difficult materials.

Technical Data:

- Distance between axles: 1 - xx m

- Width of belt WB: 500 to 2.800 mm

- Effective width EB: 400 to 2.700 mm

- Effective height EH: 200 to 600 mm

- Speed: 0,1 – 3,0 m/s

- Belt quality: EP 400/3, 3:0, smooth or cleated

- Drive: Slip-on gear motor

- Special strengths

- Anti-wrap guard

- Robust edge design

- Closed structure

- Modular design

- Side seal

Special Version:

- Reversible

- Manoeuvrable

- Load cells

- Flexible bend element, negative

- Stainless steel segment

LATERALLY STABLE BELT CONVEYOR "QGF"

-

The REMA laterally stable belt conveyor is based on a robust sheet edge design in segment construction. The special feature of the REMA laterally stable belt conveyor lies in the use of the laterally stable belt that in turn allows the design of a positive bend segment. Through this the REMA laterally stable belt conveyor lends itself especially as an extraction conveyor unit among the most varied machines and units. The combination of a horizontal conveyor segment for receiving the materials and direct connection of an ascending segment for transporting away make the REMA laterally stable belt conveyor into a space-saving alternative compared with traditional conveyor units.

Technical Data:

- Distance between axles: 4 - xx m

- Width of belt WB: 650 to 1.200 mm

- Effective width EB: 500 to 1.050 mm

- Effective height EH: 200 to 600 mm

- Speed: 0,1 – 1,5 m/s

- Belt quality: EP 400/3, 3:0, laterally stable, smooth or cleated

- Driver: Slip-on gear motor

- Special strengths - Anti-wrap guard

- Robust edge design

- Closed structure

- Modular design

- Labyrinth side seal

Special Version:

- Reversible

- Z-shape

- Stainless steel segment

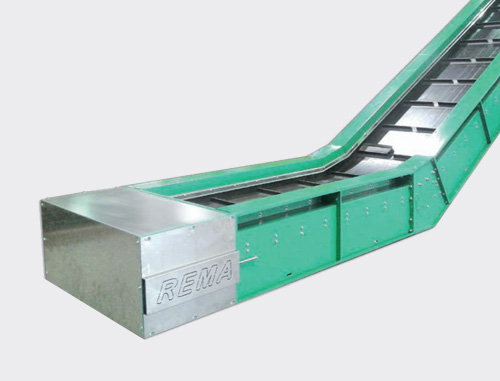

CHAIN BELT CONVEYOR "KGF"

-

REMA chain belt conveyors are specially designed for high demands with respect to the materials to be transported. Whether high bulk densities or large volumes, here the REMA chain belt conveyor shows all its advantages. Its basic design in segment construction made of robust sheet steel edge design holds advantages for a later modification and facilitates any servicing jobs. Various applications and special fittings enable the use of the REMA chain belt conveyor in many areas.

Technical Data:

- Distance between axles: 3 - xx m

- Width of belt WB: 800 to 2.000 mm

- Effective width EB: 750 to 1.950 mm

- Effective height EH: 400 to xx mm

- Speed: 0,1 – 0,5 m/s

- Belt quality: EP 400/3, 4:2, Glatt oder Stollen

- Drive: Slip-on gear motor

- Special strengths - Closed structure

- Robust design

- Modular design

- Labyrinth seal

Special Version:

- Reversible

- Load cells

- Bend element

- As dosing feeder

- As bunker belt

RACK CONVEYOR "RF"

-

The REMA rack conveyor is specially designed for use with the highest demands. The robust construction of the REMA rack conveyor makes it a reliable partner when it comes to dosing and transporting difficult and aggressive materials. Whether in the area of stone-earth, scrap metal or even in biowaste, the REMA rack conveyor is here the right choice.

Technical Data:

- Distance between axles: 4 - xx m

- Width of belt WB: 800 to 2.000 mm

- Effective width EB: 700 to 1.900 mm

- Effective height EH: 400 to 800 mm

- Speed: 0,05 – 0,5 m/s

- Drive: Slip-on gear motor

- Special strengths

- Robust edge design

- Closed structure

- Modular design

- Suitable for the hardest tasks

Special Version:

- Reversible

- As dosing feeder

- As bunker

TROUGHED BELT CONVEYOR AS BIN BELT “BB”

-

The REMA bin belt is equipped with a pneumatic bin gate made of sheet steel and its design is based on the REMA MGF troughed belt conveyor. REMA bin belts and bin walls are constructed in segments to a robust sheet metal edge design. The side seal of the REMA bin belt, a combination of the sliding movement of the belt and an additional labyrinth seal, has proven itself over decades, especially in its use in recycling plants. In particular, this side seal is the basis for the high level of availability, low maintenance cost and long working life of the REMA bin belt. Suitable, for instance, for all waste fractions that can be compacted such as paper and plastics.

Technical Data:

- Installed length: XX - 20,000 mm

- Total length: XX up to 21,750 mm

- Total height: Up to about 2,800 mm

- Belt width: 1,000 to 2,000 mm

- Usable width: 1,025 to 2,025 mm

- Operating angle:

- Drive: Shaft-mounted geared motor

Special features:

- Bin wall made of robust sheet steel

- Pneumatic bin gate made of robust sheet steel

- Project-specific axle spacing

- Belt width as required

Special Version:

- Reversible

- Carbide external belt scraper - Plough scraper inside the belt

- Weighing cells

- Filling level monitor

- Light barrier

- Rotation speed monitor

- Emergency off cord

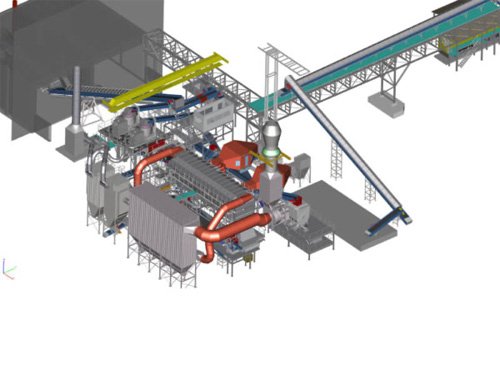

REFERENCES

-

Those who demand a lot may expect the best.

REMA offers comprehensive solutions and execution skills for all types of systems – starting with individual system components ranging to complete sorting plants, each for a variety of applications. Above all, our customers appreciate the intensive advice – from the application to the development of customised solutions – and of course the great experience of REMA in the planning, production and servicing of the equipment.

EGlog S.A.R.L. - Multi-Trenner

REMONDIS - Glasaufbereitung

REMEX - Rostascheaufbereitung

ALBA - Aufbereitung Ersatzbrennstoffe

MELOSCH - PPK-Anlage

Drekopf - Gewerbemüllaufbereitung

PKV - 3D-Modell-Aufbereitung Spuckstoffe

AFATEK - Rostascheaufbereitung

MEISTER - CVP

EZL - Gewerbemüllaufbereitung

SWEREC - Kunststoff-Rückgewinnung

TRG - LVP Anlage

URBASER - Hausmüll

AWG - Rostascheaufbereitung

B&A Metallaufbereitung - Shredder Schwerfraktion

B&R - LVP- und Gewerbemüllaufbereitung