- Offer Profile

-

Nilfisk is one of the world’s leading manufacturers of professional cleaning equipment

Our vision

At Nilfisk we have a clear vision. We want to lead intelligent cleaning to make our customers’ business smarter. See our vision film and learn more.

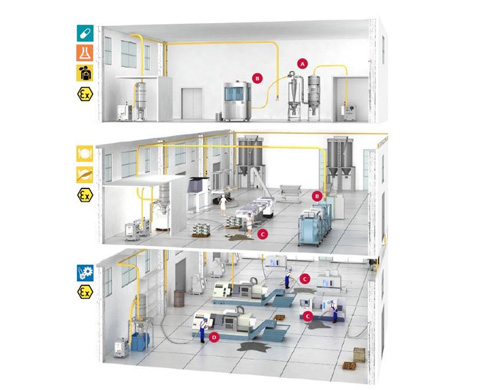

Industrial vacuum cleaners

- Nilfisk industrial vacuums are the optimal solution for maintenance, cleaning and production automation, and are helpful for cleaning in confined areas and for the removal of hazardous dust and fumes. Industrial vacums are also useful in places where no dust emissions are allowed, such as areas with dust-sensitive machinery, laboratories and clean room facilities.

Single-phase wet & dry

-

Single-phase industrial vacuum cleaners are mainly used for non-continuous cleaning of manufacturing areas or for overhead cleaning. Compact and flexible, they are easy to move. You can choose between models for the recovery of dry material only or models for both wet and dry applications.

Nilfisk blue line

- Our Blue line products are intended for cleaning in dirty, rugged and hot environments. This makes them ideal for cleaning within agriculture, building and construction, and industries where safety is of great importance.

AERO 21 / AERO 21 INOX

-

Compact wet&dry vacuum cleaner with filter cleaning and simple features

AERO 21 is the smallest model in the AERO series with compact design and easy to use features such as Push&Clean filter cleaning system and convenient accessory storage. The 20 liter machine has efficient suction performance and is found with optional INOX stainless steel container with robust trolley and lifting handle. Power socket with AutoOnOff is found on (-21) models, which activates the machine by the connected drilling, sanding or cutting tool. AERO 21 offers great help keeping both air and surroundings clean and reducing the overall sound level.

Being compact, light-weight and robust, the AERO wet and dry vacuum cleaners can easily be transported to any location, e.g. by car. After finishing your job, the container can nice and easily be emptied - either by dispose the standard fleece filter bag or by tipping the container by the lifting handle found on some models. The Push&Clean filter cleaning system prevents loss of performance and increase productivity during your cleaning task. Storage is made easy with several positions for suction hose, nozzles and power cord, and the built-in 2-points tube parking makes operation easy and flexible.

AERO 21 is compact and easy to use - the ideal choice for smaller cleaning jobs in workshops or at customer sites. It is a light-weight machine for workers within industry, automotive and building & construction featuring semi-automatic filter cleaning, ergonomic design and convenient storage.

- Washable PET fleece filter with minimum 99.9% filtration efficiency

- MultiFit accessory system for ultimate flexibility

- Convenient accessory and cable storage

- Exhaust air blow function

- Stabile wheels and ergonomic design for safe operation

AERO 26

-

Compact wet&dry vacuum cleaner with filter cleaning and ergonomic design

AERO 26 is the featuring model of the AERO series with high focus on application and end-user needs. Push&Clean filter cleaning system and exhaust air blow function is found on all models together with flexible and convenient accessory storage. The 25 liter machine has efficient suction performance and is available with optional cable rewind system. Power socket with AutoOnOff is found on (-21) models, which activates the machine by the connected drilling, sanding or cutting tool. The AERO 26 offers great help keeping both air and surroundings clean and reducing the overall sound level.

Being compact, light-weight and robust, the AERO wet and dry vacuum cleaner can easily be transported to any location, e.g. by car. After finishing your job, the container can nice and easily be emptied - either by dispose the standard fleece filter bag or tipping the container by the lifting handle. The Push&Clean filter cleaning system prevents loss of performance and increase productivity during the cleaning task. An innovative storage solution makes it easy to place suction hose, nozzles and power cord in several positions and the built-in 2-points tube parking makes operation easy and flexible.

AERO 26 is also available with L-class certification with extra suction power and safety features, practical tool compartment and variable speed control - the perfect choice for professionals working with power tools.

AERO 26 is compact and easy to use - the ideal choice for smaller cleaning jobs in workshops or at customer sites. It is a light-weight and robust machine for workers within industry, automotive and building & construction featuring ergonomic design, semi-automatic filter cleaning and convenient storage.

- Washable PET fleece filter with minimum 99.9% filtration efficiency

- MultiFit accessory system for ultimate flexibility

- Convenient accessory/cable storage and tool deposit

- Exhaust air blow function

- Flexible rubber strap for hose storage

- Optional cable rewind model

- L-class model with variable speed control

AERO 31 INOX

-

Stainless wet&dry vacuum cleaner with filter cleaning and big capacity

AERO 31 INOX is the big capacity model of the AERO series with high focus on application and end-user needs. Push&Clean filter cleaning system and exhaust air blow function is standard together with flexible and convenient accessory storage. The 30 liter machine has efficient suction performance and a durable stainless steel container with robust trolley. Power socket with AutoOnOff activates the machine by the connected drilling, sanding or cutting tool. The AERO 31 INOX offers great help keeping both air and surroundings clean and reducing the overall sound level.

Being compact, versatile and robust, the AERO 31 INOX wet and dry vacuum cleaner can easily be transported to any location, e.g. by car. After finishing your job, the container can nice and easily be emptied - either by dispose the standard fleece filter bag or tipping the container. The Push&Clean filter cleaning system prevents loss of performance and increase productivity during the cleaning task. An innovative storage solution makes it easy to place suction hose, nozzles and power cord in several positions and the built-in 2-points tube parking makes operation easy and flexible.

AERO 31 INOX with stainless steel container is compact and easy to use - the ideal choice for cleaning jobs in workshops or at customer sites. It is a robust and versatile machine for workers within industry, automotive and building & construction featuring semi-automatic filter cleaning and high mobility.

- Washable PET fleece filter with minimum 99.9% filtration efficiency

- MultiFit accessory system for ultimate flexibility

- Convenient accessory and cable storage and tool deposit

- Exhaust air blow function

- Stainless steel container

- Flexible rubber strap for hose storage

ATTIX 115 & 125

-

Superior suction power in a strong and flexible three-motor vacuum

ATTIX 115 & 125 are powered by 3x1000 Watt independent "by-pass" motors and offer 100 litres containers. The two models have an integrated durable polyester star-filter with big surface area, and the manual filter shaker on the top of the machine is easy-to-use and ensures a high efficiency of the filter.

ATTIX 115/125 are made of epoxy painted metal giving the vacuum cleaners a very robust and reliable design. The manual filter shaker ensures a good efficiency of the filter and the SitDown container system allows a convenient disposal without disassembling other parts of the vacuum cleaner.

- Three-motor industrial performance

- Comfortable grip and robust steel chassis for durability and easy mobility

- MultiFit adapter included for high flexibility in accessory choice

- Storage of accessories

ATTIX 30

-

Silent and mobile wet & dry industrial vacuum cleaners with superior suction power

ATTIX 30 series represent our compact and powerful range of all purpose Wet&Dry vacuum cleaners - a perfect solution for craftsmen on the move. The ergonomic design and low noise level emphasise our focus on real user benefits and longer working time.

The small size and big performance of the ATTIX 30, along with the wide range of available models, make it a perfect choice for people who move with their work from place to place. Operating costs are minimized with the washable PET fleece filter elements, and the low working noise level lets you work when others are nearby, without disturbing them. The excellent design offers you cable storage, accessory storage and a big tool deposit to keep all you need at hand.

The -11 models are equiped with a convenience socket with no need for an extra extension cable, just plug your tool into the vacuum cleaner. Automatic On/Off models (-21) are the choice for people who use the machine with electric hand tool because starting or stopping the tool starts and stops the vacuum, as well. An accessory airbox is available which performs the same function when using pneumatic tools. While dealing with fine dust the Push&Clean filter cleaning system offers a comfortable and quick way to clean the filter. For even better performance the XtremeClean automatic filter cleaning system will clean the filter without any interruptions. The Multifit system allows the use of the complete range of accessories.

- Low working sound level

- SilentPower - high performance that is seen, but not heard

- MultiFit accessory system for the ultimate in task flexibility

- Washable PET fleece filter with minimum 99.9% filtration efficiency

- Accessory storage and tool deposit

ATTIX 33

-

Superior and powerful dust extractor

The ATTIX 33 dust extractor series sets a new standard for design and feature level of the Nilfisk wet & dry vacuum portfolio. With innovative filtration system, improved performance and robust design, this range represents a superior solution for professional customers looking for a safe and reliable machine. ATTIX 33 comes with more suction power, sealed dust system, automatic filter cleaning and several other user benefits - designed to meet the tough requirements in building & constructions and other industries.

ATTIX 33 offers a remarkable productivity thanks to the automatic filter cleaning system InfiniClean™. The InfiniClean™ system ensures continuously cleaning of the filter during operation using a reversed air-flow pulse, keeping suction performance on a high level. The downtime is reduced significantly, as the container can be filled up without filter maintenance – even in the most demanding fine dust applications. Also the washable PTFE long-life filter minimizes maintenance and reduces the overall service cost.

Easy handling and user-friendliness - also when it comes to transportation from one working site to another - are other valuable features for the ATTIX 33 dust extractor. All models offer flexible storage solutions for tools and accessories, so everything you need is at hand.

- InfiniClean™ - Automatic filter cleaning system with minimized performance loss

- PTFE long-life filter with non-stick membrane and minimum 99,9% filtration efficiency

- Dust class L certification

- Unique dual filter solution available with HEPA filtration.

- 30 liter container with steel castors and robust bumper.

- MultiFit accessory system for the ultimate in task flexibility

- Flexible rubber straps, tool box storage and optional trolley handle for convenient storage and transport

- Optional motor cooling filter, exhaust air collector and Long-Life filter bag

ATTIX 40 INOX

-

The perfect combination of high performance and robustness in moist applications

ATTIX 40 is the ideal Wet&Dry vacuum cleaner, if you need high performance in combination with a compact quality stainless steel container. The robust and easy to clean stainless steel container and the high suction power makes ATTIX 40 the perfect solution for commercial and industrial use.

ATTIX 40 represents a superior suction power in a compact and flexible solution. This vacuum cleaner is silent, small and mobile. A perfect solution for Commercial and Industrial use. The stainless steel container offers a robust and easy to clean container. While dealing with fine dust the Push&Clean or XtremeClean filter cleaning system offers a comfortable and quick way to clean the filter.

The size and big performance of the ATTIX 40, along with the wide range of available models, make it a perfect choice for people who needs to pick up any sort of wet or dry debris. The design offers you cable storage, accessorie storage and a big tool deposit to keep all you need at hand.

Operating costs are minimized with the washable PET Fleece filter elements, and the low working noise level lets you work when others are nearby, without disturbing them.

The -21 models are equiped with a convenience socket so no need for a extra extension cable, just plug your tool into the vacuum cleaner. Automatic On/Off models are the choice of people who use the machine with electric hand tools because starting or stopping the tool starts and stops the vacuum, as well. An optional Airbox is available which performs with the same function when using pneumatic tools.

- High quality stainless steel container

- Low working sound level - SilentPower - high performance that is seen, but not heard

- MultiFit accessory system for the ultimate in task flexibility

- Washable PET fleece filter with minimum 99.9% filtration effciency

- Accessory storage and tool deposit

ATTIX 44

-

Superior and large capacity dust extractor

The ATTIX 44 dust extractor series sets a new standard for design and feature level of the Nilfisk wet & dry vacuum portfolio. With innovative filtration system, improved performance and robust design, this range represents a superior solution for professional customers looking for a safe and reliable machine with large capacity. ATTIX 44 comes with more suction power, sealed dust system, automatic filter cleaning and several other user benefits - designed to meet the tough requirements in building & constructions and other industries when picking up bigger amounts of dust.

ATTIX 44 offers a remarkable productivity thanks to the automatic filter cleaning system InfiniClean™. The InfiniClean™ system ensures continuously cleaning of the filter during operation using a reversed air-flow pulse, keeping suction performance on a high level. The downtime is reduced significantly, as the container can be filled up without filter maintenance – even in the most demanding fine dust applications. Also the washable PTFE long-life filter minimizes maintenance and reduces the overall service cost.

Easy handling and user-friendliness - also when it comes to transportation from one working site to another - are other valuable features for the ATTIX 44 dust extractor. All models offer flexible storage solutions for tools and accessories, so everything you need is at hand.

- InfiniClean™ - Automatic filter cleaning system with minimized performance loss

- PTFE long-life filter with non-stick membrane and minimum 99.9% filtration efficiency

- Dust class L certification

- Unique dual filter solution available with HEPA filtration.

- 42 liter container with steel castors and robust bumper.

- MultiFit accessory system for the ultimate in task flexibility

- Flexible rubber straps, tool box storage and optional trolley handle for convenient storage and transport

- Optional motor cooling filter, exhaust air collector and Long-Life filter bag

ATTIX 50

-

Superior suction power for high-frequency cleaning and large container volume

ATTIX 50 combines high Wet&Dry performance with big container capacity - the ideal solution for demanding customers with high frequency cleaning. The improved ergonomic design ensures functional and user-friendly operation - all in all an effcient and reliable solution.

ATTIX 50 will solve all major tasks in your company, workshop, garage, production etc. The Push&Clean or XtremeClean offers an impressive cleaning performance and keeps the suction performance constantly high.

The design offers you cable storage, accessory storage and a big tool deposit to keep all you need at hand. The larger size of the ATTIX 50 allows you to work longer without emptying the container, and with the wide range of available models, it's difficult to imagine that you won't find a perfect match for your wetand dry vacuum cleaning tasks.

Operating costs are minimized with the washable PET fleece filter elements, and the low working noise level lets you work when others are nearby, without disturbing them.

The -21 models are equiped with a convenience socket so no need for a extra extension cable, just plug your tool into the vacuum cleaner. Automatic On/Off (-21) models are the choice of people who use the vacuum cleaner with electric hand tools because starting or stopping the tool starts and stops the vacuum, as well. An optional Airbox is available which performs with the same function when using pneumatic tools.

- Low working sound level - SilentPower - high performance that is seen, but not heard

- MultiFit accessory system for the ultimate in task flexibility

- Washable PET fleece filter with minimum 99.9% filtration efficiency

- Accessory storage and tool deposit

- AntiStatic System

ATTIX 7

-

Unheard performance in a big capacity Wet&Dry vacuum cleaner

ATTIX 7 is perfect for users who need a big capacity and highly efficient vacuum cleaner with a robust steel chassis. This model has a high suction power with a low noise level. ATTIX 7 is a genuine solution for professional use within wet and dry applications.

ATTIX 7 is designed with a 70 liter container which allows you to work for a very long time without emptying the container, and when it is necessary, you will find the Tilt or Lift-Off container system extremely convenient and time-saving. If your vacuum cleaning tasks are "high volume", you are sure to find a perfect match for your task in the ATTIX 7 range.

Operating costs are minimized with the washable PET fleece filter elements, and the low working noise level lets you work when others are nearby, without disturbing them.

Automatic On/Off models are the choice for people who use the vacuum cleaner with electric hand tools because starting or stopping the tool automatically starts and stops the vacuum, as well. An accessory Airbox is available which performs the same function when using pneumatic tools.

- High quality stainless steel container with tilt and lift-off option

- Low working sound level - SilentPower - high performance that is seen, but not heard

- MultiFit accessory system for the ultimate in task flexibility

- Washable PET fleece filter with minimum 99.9% filtration efficiency

- Accessory storage and tool deposit

- AntiStatic system and Softstart

ATTIX 7 LIQUID VACUUM

-

Big capacity with disposal pump for demanding wet applications

ATTIX 7 LIQUID VACUUM is specially designed for demanding wet applications like flood pickup, road spills and clean up after fires. Build for users who need easy liquid discharge, high suction power and robust construction combined with high mobility.

ATTIX 7 LIQUID VACUUM is designed with a 70 liters container and disposal pump, which allows you to work for very long time without emptying the container, and when necessary you will find the Tilt or Lift-Off container system convenient and easy to operate.

The built-in pump is able to pick up liquids at 200 L/min and discharge at 300 L/min up to 9 meter higher or 50 meters away from the cleaning position with a drain hose connected to the Storz C coupling or optional GEKA coupling. The double stainless steel filter sieve system protects the pump and turbine, and the low working noise level lets you work when others are nearby, without disturbing them.

The special MWF model (Mobile Wet vacuum for Firefighting services) is optimized for storage in fire trucks and includes ground fault circuit breaker (PRCD) and IP68 plug for additional safety when working in wet applications.

You are sure to find a perfect match for your demanding wet application cleaning task in the ATTIX 7 LIQUID VACUUM range.

- Built-in disposal pump for continously and automatic liquid discharge

- Double filter sieve system in stainless steel

- IP68 plug connection

- High quality stainless steel container with tilt and lift-off option

- Low working sound level - SilentPower - high performance that is seen, but not heard

- MultiFit accessory system for the ultimate in task flexibility

- AntiStatic system and Softstart

ATTIX 961-01

-

Two-motor driven industrial Wet&Dry vacuum cleaners for the toughest applications

The big capacity of 70 liter and stainless steel container keeps emptying to a minimum and ensures longer working time. High suction power and low sound enables ATTIX 961 to be used in a wide varity of conditions.

In your daily work the vacuum cleaner must be one that you can rely on. The essential requirement is a unit that will go on cleaning powerful and quickly, day-in and day-out. The ATTIX 961-01 is more than up to the task, for both spills and maintenance cleaning – even in the toughest conditions. Thanks to the 38 mm standard equipment the ATTIX 961-01 is a "Plug & Play" ready to use machine.

- Dual-motor industrial performance

- High quality stainless steel container with tilt and lift-off option

- Washable PET fleece filter with minimum 99.9% filtration efficiency

- MultiFit accessory system for the ultimate in task flexibility

- Accessory storage and tool deposit

ATTIX 965-21 SD XC

-

Two-motor performance for heavy-duty cleaning

The big capacity stainless steel container of the ATTIX 965-21 SD keeps emptying to a minimum and ensures longer working time. The practical SitDown container system makes emptying convenient for fast and productive cleaning.

ATTIX 965-21 SD offers the practical ‘SitDown’ system that makes emptying the container that much easier. ATTIX 965-21 SD also has the optional forklift device to help empty the container and save your back. A range of 38 mm and 50 mm accessories are available and makes it possible to handle all kind of jobs.

- Dual-motor industrial performance

- High quality stainless steel container with steel chassis

- Washable PET fleece filter with minimum 99.9% filtration efficiency

- MultiFit accessory system for the ultimate in task flexibility

- Accessory storage and tool deposit

SELF-SERVICE (SB) VACUUMS

-

Make a good profit with our made-to-measure solution

These coin-operated Self-Service vacuum cleaners fulfil all special requirements for filling stations and are built for outdoor use in all kinds of weather. Available with either single or twin motor operation and a simpel cloth filter system for quick and easy maintenance.

The SB Series are coin and/or token operated vacuum cleaners that are in compliance with all requirements needed for use in filling stations. These vacuum cleaners are specially designed for the rigors of outdoor use in all kinds of weather. Users/customers have been an inspiration throughout the development of the SB Series; therefore the users/customers will find these vacuum cleaners very easy-to-use.

We have not forgotten the owners of these vacuum cleaners. Maintenance is quick, simple and fast so that the machine is always ready to work for your users/customers with a minimum of effort on your part.

- Single or dual operation

- High performance and easy to use

- Washable cloth filter with high filtration

- Available in oil company colours and special coin or card reader versions

Nilfisk grey line

- Our Grey line products are perfectly suited for relatively clean surroundings like office spaces, retail environments, schools and warehouses as well as for cleaning where hygiene and safety is of great importance such as Food & Beverage, Healthcare, Pharma and Iron & Metal industries.

118

-

A real industrial vacuum in 95 cm height

Small and light, model 118 meets the different cleaning needs, even when absolute filtration is a must.

Model 118 is a singlephase industrial vacuum for dust and dry materials. One of the smallest industrial vacuum, it is powerful, reliable and can be customized according to the different needs. Available in stainless steel, with absolute filter for the collecting of asbestos or other toxic materials or with nomex filter to collect hot substances.

- Small

- Silent

- Absolute filter for asbestos or other toxic materials

- L class filter as a standard

- Nomex filter for hot substances

- Easy emptying of the container thanks to the practical release container system.

GM 80P

-

Lightweight and heavy-duty performance

Lightweight and portable, the Nilfisk GM 80P is the symbol of Nilfisk quality and provides durability, high performance and efficient cleaning - required by dust control professionals.

The sturdy aluminium container means that the vacuum cleaner is almost indestructable and therefore especially suitable for rough and heavy duty cleaning.

Mounted on a strong steel trolley with large rubber wheels, the machine is easy to manoeuvre. Ideal for e.g. production lines, chemi/pharma industries, hospitals and offices.

GM 80P is a versatile machine with high suction power and can be used for both industry cleaning and integrated into production facilities. The unique multi-stage filtration system allows for adaption to special applications where high filtration level and low emission is required. Choose between two types of dust bags (fleece or paper), four different washable sack filters (Polyester, Cotton, PTFE or Nomex) and special exhaust filters with HEPA or ULPA classication. GM 80P can handle every heavy duty cleaning task and has become a vacuum cleaner icon in variety of industries.

- Low noise operation

- Washable filter in Polyester or Cotton material

- PTFE (non-stick) and Nomex (heat resistant) filter optional

- 9 liters container capacity

- Lightweight aluminium construction - built for years of heavy duty cleaning

- Unique dual filter solution avalaible with HEPA or ULPA exhaust filters

- Bagless operation possible

- Dust class L-certification

S2

-

The first digital and fully modular 2kW industrial vacuum

Model S2 is equipped with 2 bypass motors, it is easy to use thanks to the electronic board supplying real-time data about the filter efficiency, it is easy to use but strong.

S2 is equipped with a control panel supplying real-time information about the vacuum efficiency. It is available with 40 liters containers, with gravity unload system (plastic bag or Longopac), in stainless steel, with absolute filter HEPA H14 (for the collection of very fine or toxic dust), with nomex filter (ideal in case of collecting of hot substances), with electric filter shaker: many versions for many different needs. From today it is easier working!

- Constant check of the vacuum efficiency

- Ergonomic Longopac disposal system ("endless bag") available

- High filtering efficiency

- Silent

- Modular and suitable for any industrial application

S2B-S3B

-

Power, simplified

Reliability, power and simplicity for this industrial vacuum designed for the mechanical sector, in particular for the collection of chips mixed with oil.

2 or 3 kW power, models S2B and S3B are powerful and reliable. Designed to collect wet and dry material they are used for the cleaning and manteinance of the machine tools. Th 50L or 100L container can be easily removed and emptied, the small size and the ergonomic design allow the operators to move very fast the vacuum.

- 2 or 3 kW power

- L or M class versions

- Small size

- Strong and reliable

- Easy to move

- Container release system for an easy and fast emptying

- Container with castors and handle

- Manual filter shaker

- Hepa absolute filter available

- Floater for the liquids collection

S3

-

The first digital and fully modular 3 kW industrial vacuum

Model S3 is equipped with 3 bypass motors. It is easy to use thanks to the control panel supplying real time data about the vacuum efficiency, it is easy to use but reliable.

S3 is equipped with a control panel supplying real-time information about the vacuum efficiency. It is available with 50 or 100 liters containers, in stainless steel, with gravity unload system (plastic bag or Longopac), L-M-H certified or with absolute filter for the collection of toxic or fine dust, with nomex filter (ideal in case of collecting of hot substances), with electric filter shaker.: many versions for many different needs. From today it is easier working!

- 3 bypass motors

- Electric control panel

- Electric or manual filter shaker version

- Gravity unload system with plastic bag or Longopac (endless bag)

- Compact vacuum easy to move in the production area

- L or M class filter

- HEPA H14 absolute filter version

- Container release system

- Container with castors and handle accessory box, cable/pipe holder

VHS 40

-

The first digital and fully modular 3 kW industrial vacuum

The VHS 40 vacuum cleaner series sets a new standard for design and feature level of the Nilfisk wet & dry vacuum portfolio. With innovative filtration system, improved performance and robust design, this range represents a superior solution for professional customers looking for a safe and reliable machine. VHS 40 comes with more suction power, sealed dust system, automatic filter cleaning and several other user benefits - designed to meet the tough requirements within manufacturing and building and construction industries.

VHS 40 offers a remarkable productivity thanks to the semi-automatic Push&Clean™ or automatic filter cleaning system InfiniClean™. The InfiniClean™ system ensures continuously cleaning of the filter during operation using a reversed air-flow pulse, keeping suction performance on a high level. The downtime is reduced significantly, as the container can be filled up without filter maintenance – even in the most demanding fine dust applications. Also the washable PFTE long-life filter minimizes maintenance and reduces the overall service cost.

Easy handling and user-friendliness - also when it comes to transportation from one working site to another - are other valuable features for the VHS 40 vacuum cleaner. All models offer flexible storage solutions for tools and accessories, so everything you need is at hand.

- InfiniClean™ - Automatic filter cleaning system with minimized performance loss

- PTFE long-life filter with non-stick membrane and minimum 99,9% filtration efficiency

- Push&Clean™ - Semi-automatic filter cleaning system.

- Dust class L certification

- Unique dual filter solution available with HEPA filtration.

- Robust container with steel castors and bumper.

- MultiFit accessory system for the ultimate in task flexibility

- Flexible rubber straps, tool box storage and optional trolley handle for convenient storage and transport

- Optional motor cooling filter, exhaust air collector and Long-Life filter bag

VHS120

-

The most compact and powerful ever

The VHS120 is the ideal vacuum cleaner when there is need of high performances in compact dimensions for collecting any type of waste material.

The VHS120 is the compact mobile single phase vacuum cleaner equipped with n°2 by-pass motors and 37lt removable container to secure the highest performances and collection capacity when a limited space is available. The high filter surface, optional HEPA14 absolute filter and M-Class start filter with glued seams guarantee the highest filtering performances while manual filter shaker a quick cleaning of the main filter keeping the vacuuming efficiency high. Performances can be easily monitors thanks to the vacuum gauge on the motor head. The optional tool basket allows an easy and quick storage of accessories at the end of use

- Single phase, n°2 by-pass motors

- Compact dimensions

- Stainless steel version

- Absolute filtration version

- M Class star filter version

- High container capacity

- Container easy to remove and empty

VHS120 All-In-One #Bakery

-

Description

As efficient as simple, the right combination for your application: one specific model built according to each main specific segments and equipped with the best accessory kit.

Your task? Just plug and play… and continue doing your job without any thought.The #Bakery vacuum cleaner is the best ready to use solution for ovens, when the job is done and you need to clean inside.

The VHS120 is the modular machine par excellence.

In this specific configuration it is equipped with a NOMEX® filter (self-extinguishing material) and a specific accessory kit suitable for vacuuming hot substances.

You will get total hygiene, avoid any cross contamination

and ensure top product quality.We include a specific set of accessories designed for cleaning inside ovens. Consisting of a 3 meter hose, made up with glass fiber and silicone reinforced tissue with galvanized steel spiral and its metal tie, sleeves and all the fittings and reductions necessary, three 1m extensions with a sliding PTFE sleeve and a wheeled nozzle with two silicone lips.

- Single phase, n°2 by-pass motors

- Compact dimensions

- High container capacity

- Equipped with specific accessories developed for hot substances

- Glass fiber and silicone reinforced tissuec hose

- Wheeled nozzle with two silicone lips

- Container easy to remove and empty

- Suitable for hot material

- NOMEX® filter (self-extinguishing material)

- High filter surface

- Ergonomic manual filter shaker

- Vacuum gauge on the motor head

- Optimum balance among efficiency compactness and price

VHS120 All-In-One #General Cleaning

-

As efficient as simple, the right combination for your application: one specific model built according to each main specific segments and equipped with the best accessory kit.

Your task? Just plug and play… and continue doing your job without any thought.The #General Cleaning vacuum cleaner is the excellent balance among efficiency compactness and price.

Compact and powerful, it’s already equipped with an industrial cleaning accessories kit, ideal for cleaning spacious areas, both on floor and difficult spots. Consisting of a 5 meter polyurethane hose, and a complete set of single accessories, this kit lets you clean areas quickly and effectively.

Thanks to the numerous elements (handgrip, wheeled floor nozzle, cone, flat-tip crevice nozzle, etc.) it is extremely versatile.

Using this industrial vacuum means getting a cleaner working environment in few minutes.- Single phase, n°2 by-pass motors

- Compact dimensions

- High container capacity

- Equipped a wide range of specific accessories

- 5 meters polyurethane hose

- Handgrip, wheeled floor nozzle, cone, flat-tip crevice nozzle

- Container easy to remove and empty

- Suitable for spacious areas

- High filter surface

- Ergonomic manual filter shaker

- Vacuum gauge on the motor head

- Optimum balance among efficiency compactness and price

VHS120 All-In-One #Metal - Chips

-

As efficient as simple, the right combination for your application: one specific model built according to each main specific segments and equipped with the best accessory kit.

Your task? Just plug and play… and continue doing your job without any thought.The #Metal - Chips vacuum cleaner is ideal when the main need is cleaning the machine tools and the floors, and you have to recover more than 70% of metal chips and less than 30% of oil.

The VHS120 is the modular machine par excellence. In this specific configuration it is equipped with a grid and valve for

separating solids from liquids inside the container. The solid material deposits on the grill, whilst the liquids

can be drained via the manual valve fitted to the bottom of the container.

Thanks to the cyclone the primary filter doesn’t come in direct contact with incoming liquids or sharp objects.- Single phase, n°2 by-pass motors

- Compact dimensions

- High container capacity

- Equipped with specific accessories developed for metalworking environment

- 5 meters polyurethane hose

- Cone and Noozle for cleaning machine tools and around them

- Container easy to remove and empty

- Suitable for wet material (shavings mixed with traces of oil)

- Grid and Valve for separating oil from swarf and easily discharge.

- Cyclone to protect the filter from damages.

- High filter surface

- Ergonomic manual filter shaker

- Vacuum gauge on the motor head

- Optimum balance among efficiency compactness and price

Explosion-proof

- Examples of potentially combustible dust include cereals, flour, starch, sugar, animal feed, light metals, coal, plastics, and textiles. If there is a sufficient concentration of these substances, mixed with air, an ignition source can cause an explosion. Nilfisk vacuum cleaners prevent the triggering of potentially explosive mixtures.

VHS110 ATEX

-

More power. More safety. In only 400 mm diameter.

The single phase industrial vacuum cleaner for use in Atex Z22 locations.

The VHS110 Z22 is the innovative single phase industrial vacuum cleaner suitable for Atex Z22 locations. Thanks to the brushless motor, this machine ensures high performance. Moreover it needs less maintenance and is suitable for continuous use. The innovative PullClean system effectively cleans the antistatic star filter while the vacuum is running, without the need to stop working.The optional HEPA14/ULPA15 upstream filter is the perfect choice when collecting fine dusts. The modular design makes it extremely easy to service and upgrade in the field. With its 400 mm diameter the VHS110 ATEX is a compact in order to be easily used everywhere, but has a good capacity thanks to its 37 litre removable container. The simple design makes it easy to clean and sanitise.

Specific versions for additive manufacturing available

- Single Phase Atex Z22

- High performance

- HEPA14/ULPA15 absolute filtration for very fine dust

- 37L stainless steel removable container

- Stainless steel version

- Compact dimensions

- Easy to use

- Easy to service

- Specific versions for additive manufacturing available

VHS110 CIID2

-

Single-phase ClassIIDiv2 certified industrial vacuum cleaner

TThe single phase ClassIIDiv2 certified industrial vacuum cleaner.

The VHS110 CIID2 is the innovative single phase industrial vacuum cleaner ClassIIDiv2 certified for North America. Thanks to the brushless motor and the certification issued by a third party notified body, this machine secures the highest performances and safety in compact dimensions.

The innovative PullClean system allows an effectively cleaning of the star filter while the vacuum is running, without need to stop it.

The HEPA14 or ULPA15 upstream filter is the perfect choice when collecting fine dust.

The modular design makes it extremely easy to service and upgrade on the field.- Single Phase ClassIIDiv2 certified

- High performances

- Absolute filtration for very fine dust

- 37L stainless steel removable container

- Stainless steel version

- Compact dimensions

- Easy to use

- Easy to service

3707-3707/10 ATEX

-

Endless power for endless possibilities

The series 3707 / 10 ATEX are the right I-Vacs for the industries who have to work in potentially explosive atmospheres.

This vac offers high performances while still being extremely manoeuvrable and versatile. It mounts a Threephase Side Channel Blower that guarantees a silent and continuous running. The suction unit is controlled by an electrical equipment with a star-triangle starting as standard, housed in the rear casing. It gets a large Stainless Steel container and an Antistatic Star filter in "L" class as standard.

- Reliable 3 Phase

- aluminium casting

- induction motor directly driven to the fan

- Maintenance-free

- Continuous use

- Very high performance levels

- Large Primary Antistatic

- L Class Star Filter

- Efficient filter cleaning system

- Vacuum gauge

- Removable and very capacious stainless steel bin

- Watertight

- Control panel with Star-Triangle starting

- Higlhly manoeuvrable

- ATEX Versions (Directives 94/9/EC and 99/92/EC)

3907/18 ATEX

-

18 HP power and reliability, for heavy industries

The series 3907 / 18 ATEX are the right I-Vacs for the industries who have to work in potentially explosive atmospheres as the Directive 94/9/EC and 99/92/EC state.

This vac offers high performances while still being extremely manoeuvrable and versatile. It mounts a Threephase Side Channel Blower that guarantees a silent and continuous running. The suction unit is controlled by an electrical equipment with a star-triangle starting as standard, housed in the rear casing. It gets a large Stainless Steel container and an Antistatic Star filter in "L" class as standard.

- Reliable

- 3 Phase aluminium casting induction motor directly driven to the fan

- Maintenance-free

- Continuous use

- Very high performance levels

- Large Primary Antistatic L Class Star Filter

- Efficient

- electrical filter cleaning system

- Vacuum gauge

- Removable and very capacious stainless steel bin

- Watertight Control panel with Star-Triangle starting

- Higlhly manoeuvrable

- ATEX Versions (Directives 94/9/EC and 99/92/EC)

3907-3907W ATEX

-

15 HP power and reliability, for heavy industries

The series 3907 / W ATEX are the right I-Vacs for the industries who have to work in potentially explosive atmospheres as the Directive 94/9/EC and 99/92/EC state.

This vac offers high performances while still being extremely manoeuvrable and versatile. It mounts a Threephase Side Channel Blower that guarantees a silent and continuous running. The suction unit is controlled by an electrical equipment with a star-triangle starting as standard, housed in the rear casing. It gets a large Stainless Steel container and an Antistatic Star filter in "L" class as standard.

- Reliable

- 3 Phase aluminium casting induction motor directly driven to the fan

- Maintenance-free

- Continuous use

- Very high performance levels

- Large Primary Antistatic L Class Star Filter

- Efficient filter cleaning system

- Vacuum gauge

- Removable and very capacious stainless steel bin

- Watertight

- Control panel with Star-Triangle starting

- Higlhly manoeuvrable

- ATEX Versions (Directives 94/9/EC and 99/92/EC)

CTS-CTT ATEX

-

The most compact and fully configurable, ATEX certified threephase

Threephase explosion-proof industrial vacuums, compact, steady and ATEX certified and with infiniClean system.

This range is composed by threephase explosion-proof industrial vacuums that can be customized. Two models: CTS with side channel blower for a greater vacuum or CTT with a turbine for a greater airflow. 2,2 or 4 kW power available. This series has a compact design making the vacuum really easy to move into the working area. Top filtering efficiency thanks to the L, M, H class filters that can be chosen by the customer according to the toxicity of the material to recover.

The innovative InfiniClean system make it the perfect solution for automated applications. The main filter is automatically and periodically cleaned with the exhaust air without any action required by the operator, keeping the highest level of efficiency and productivity.

- Ideal for continuous use (24/7)

- Silent

- Removable container

- Small, short but steady

- Highly configurable

- ATEX zone 22 version (CTS), zone 1-2 and 21-22 (CTT)

- InfiniClean version: the innovative automatic cartridge filter cleaning system featuring conical cartridges, for every kind of dust on CTS40 Z22 series.

- Download the catalogue to have a look to the complete range of accessories.

CTT40 IECEx

-

Compact, configurable and IECEx certified!

The high performing threephase IECEx vacuum

The CTT40 IECEx is the new threephase explosion-proof industrial vacuum IECEx (International explosive atmosphere standards) certified.

The 4kW motor with turbine secures excellent performances while the compact design makes it really easy to move into the working area.Filtration is also top quality: the star filter of 1,9 m2 grants high filter efficiency and the manual filter shaker allows to clean fastly and easily the filter. Available also absolute filter HEPA H14 to collect very fine dust.

- IECEx certified

- Ideal for continuous use (24/7)

- Silent

- Removable container

- Small but steady

T22PLUS ATEX

-

Health and safety as standard in a 2,2 kW industrial vacuum

TPlus range is TuV certified: these models can hold efficiently every kind of dust, even the finest. The ATEX certification grants the highest technological standard against the explosion risk in the working environment.

Silent and light but offering excellent performances, model T22Plus is available in many different configurations: with M class filter or cartridge filter, with HEPA or ULPA absolute filter for the collection of very fine or hazardous dust, with 50 or 100 liters container, with solid cut-off system. The ATEX versions for Z21 and 2 are equipped with a stainless steel container and antistatic star filter. Mod. T22Plus is easy to use and is very ergonomic to meet the different requirements of the industries: cable holder, accessory box and vacuometer (to check the filtering efficiency).

- Manual or electric filter shaker version

- Pulse jet cartridge filter cleaning version

- Vacuometer

- L or H class versions

- ATEX versions for Zone 21 and Zone 2 plug with inverter

- Solid cut-off system

- Extractible container with castors and wheels

- Accessory box, cable holder and support for the hoses

T40PLUS ATEX

-

Health and safety as standard with high vacuum in 4 kW

4,3 kw suction power. It is M and H certified for hazardous dust and ATEX certified for explosion-proof environments. Version T40Plus HE is equipped with an high efficiency motor for low consumption: top power, low consumption

The great suction power of model T40Plus is given by the vacuum it creates: it can collect very heavy materials or wet dust, it is ideal to solve any waste problem that were unsolvable till today. Several versions are available: with M class or with HEPA or ULPA filters for the collection of very fine or hazardous dust, with cartridges filter, with 50 or 100 l container, with solid cut-off system and so on. The ATEX versions are certified for zone 22-21 and 2 in compliance with the 94/9/EC and the 99/92/EC directives.

- L, M, H certified for operators' safety

- ATEX certified for explosion proof environments

- Top filtering efficiency

- Powerful

- Silent

- Modular

T40WPLUS ATEX

-

Health and safety as standard with great airflow in 4 kW

T40W generates a great airflow and is the ideal tool to collect high quantities of very fine dust. The M and H class filters grant a safe dust containment. The ATEX certification allows to work safely in explosion- proof areas.

Ideal to be used in companies producing high quantities of very fine dust, model T40WPlus is available in several configurations: with M class filter or with HEPA upstream or ULPA downstream absolute filter for the collection of very fine or hazardous dust, with cartridges filter and jet pulse cleaning system, with 50 or 100 liters container, with solid cut-off system and so on. ATEX versions can work in zone 22-21-2 in compliance with directives 94/9/EC and 99/92/EC.

Specific versions for additive manufacturing available

- manual or electric filter shaker version

- jet pulse catridge filter cleaning system version

- vacuometer

- L and H class versions

- ATEX version for zone 22-21 and 2 plug with inverter

- Specific versions for additive manufacturing available

Hazardous dust

- When it comes to workplace safety and the potential danger level of dusts, three classes of dusts considered a risk to health have been identified: L (low risk), M (medium risk) and H (high risk). Nilfisk can provide both filters and machines with L, M or H certification in accordance with the above-mentioned European standard. Nilfisk has also developed a dust containment system for total safety.

ATTIX 33 M-H

-

Powerful and safe dust extractor for hazardous dust

The ATTIX 33 M/H dust extractor series sets a new standard for design and feature level of the Nilfisk wet & dry vacuum portfolio. With innovative filtration system, improved performance, robust design and dust class M/H certification, this range represents a superior solution for professional customers looking for a reliable machine to protect workers health and safety. ATTIX 33 M/H comes with more suction power, sealed dust system, automatic filter cleaning and several other user benefits - designed to meet the tough requirements in building & constructions and other industries when picking up hazardous dust.

ATTIX 33 M/H offers a remarkable productivity thanks to the automatic filter cleaning system InfiniClean™. The InfiniClean™ system ensures continuously cleaning of the filter during operation using a reversed air-flow pulse, keeping suction performance on a high level. Downtime is reduced significantly, as the container can be filled up without filter maintenance. To minimize dust exposure during disposal several dust bag options are available to match the specific need in the hazardous dust application. Also the washable PTFE long-life filter and the dual HEPA filter option minimizes maintenance and reduces the overall service cost. A flow sensor with combined acoustic and LED warning monitors the filter and air flow to secure performance and filtration on the highest and most safe level.

Easy handling and user-friendliness - also when it comes to transportation from one working site to another - are other valuable features for the ATTIX 33 M/H dust extractor. All models offer flexible storage solutions for tools and accessories, so everything you need is at hand.

- InfiniClean™ - Automatic filter cleaning system with minimized performance loss

- PTFE long-life filter with non-stick membrane and minimum 99.9% filtration efficiency

- Push&Clean™ - Semi-automatic filter cleaning system on selected models.

- Dust class M and H certification including Asbestos

- Unique dual filter solution available for H-class/HEPA - including 3-stage filtration

- Flow sensor with combined acoustic and LED warning

- 30 liter container with steel castors and robust bumper.

- MultiFit accessory system for the ultimate in task flexibility

- Flexible rubber straps, tool box storage and optional trolley handle for convenient storage and transport

- Optional motor cooling filter, exhaust air collector and Long-Life filter bag

ATTIX 44 M-H

-

Powerful and large capacity dust extractor for hazardous dust

The ATTIX 44 M/H dust extractor series sets a new standard for design and feature level of the Nilfisk wet & dry vacuum portfolio. With innovative filtration system, improved performance, robust design and dust class M/H certification, this range represents a superior solution for professional customers looking for a reliable machine with large capacity to protect workers health and safety. ATTIX 44 M/H comes with more suction power, sealed dust system, automatic filter cleaning and several other user benefits - designed to meet the tough requirements in building & constructions and other industries when picking up bigger amounts of hazardous dust.

ATTIX 44 M/H offers a remarkable productivity thanks to the automatic filter cleaning system InfiniClean™. The InfiniClean™ system ensures continuously cleaning of the filter during operation using a reversed air-flow pulse, keeping suction performance on a high level. Downtime is reduced significantly, as the container can be filled up without filter maintenance. To minimize dust exposure during disposal several dust bag options are available to match the specific need in the hazardous dust application. Also the washable PTFE long-life filter and the dual HEPA filter option minimizes maintenance and reduces the overall service cost. A flow sensor with combined acoustic and LED warning monitors the filter and air flow to secure performance and filtration on the highest and most safe level.

Easy handling and user-friendliness - also when it comes to transportation from one working site to another - are other valuable features for the ATTIX 44 M/H dust extractor. All models offer flexible storage solutions for tools and accessories, so everything you need is at hand.

- InfiniClean™ - Automatic filter cleaning system with minimized performance loss

- PTFE long-life filter with non-stick membrane and minimum 99.9% filtration efficiency

- Push&Clean™ - Semi-automatic filter cleaning system on selected models.

- Dust class M and H certification including Asbestos

- Unique dual filter solution available for H-class/HEPA - including 3-stage filtration

- Flow sensor with combined acoustic and LED warning

- 42 liter container with steel castors and robust bumper.

- MultiFit accessory system for the ultimate in task flexibility

- Flexible rubber straps, tool box storage and optional trolley handle for convenient storage and transport

- Optional motor cooling filter, exhaust air collector and Long-Life filter bag

118 L-M-H

-

A real L-M-H industrial vacuum in 95 cm

Small and light, model 118 meets the different cleaning applications, even when absolute filtration is a must.

Model 118 is a singlephase industrial vacuum for dust and dry materials. One of the smallest industrial vacuum, it is powerful, reliable and can be customized according to the different needs. Available in stainless steel, with absolute filter for the collecting of asbestos or other toxic materials, with nomex filter to collect hot substances. You can choose this model in L, M or H class version to collect hazardous dust.

- L, M, H version for hazardous dust

- Small

- Silent

- Absolute filter or nomex filter

- Easy emptying of the container thanks to the release container system

S2 L-M-H

-

The first digital and fully modular 2kW L-M-H industrial vacuum

Model S2 is equipped with 2 bypass motors, it is easy to use thanks to the electronic board supplying real-time data about the filter efficiency, it is easy but strong. L-M-H certified for the collection of hazardous dust.

S2 is equipped with a control panel supplying real-time information about the vacuum efficiency. It is available with 40 liters containers, L-M-H certified, in stainless steel, with absolute filter HEPA H14 (for the collection of very fine or toxic dust), with nomex filter (ideal in case of collecting of hot substances), with electric filter shaker: many versions for many different needs. From today it is easier working!

- L, M, H certified to collect safely hazardous material

- Constant check of the vacuum efficiency

- eEgonomic

- High filtering efficiency

- Silent

- Modular and suitable for any industrial application

S3 L-M-H

-

The first digital and fully modular 3Kw L-M-H Industrial vacuum

Model S3 is equipped with 3 bypass motors. It is easy to use thanks to the control panel supplying real time data about the vacuum efficiency, it is light but strong. L, M, H certified for the collection of hazardous dust.

S3 is equipped with a control panel supplying real-time information about the vacuum efficiency. It is available with 50 or 100 liters containers, in stainless steel, with gravity unload system (plastic bag or Longopac), L-M-H certified or with absolute filter for the collection of toxic or fine dust, with nomex filter (ideal in case of collecting of hot substances), with electric filter shaker: many versions for many different needs. From today it is easier working!

- 3 bypass motors

- L, M, H certified for the safe collection of hazardous dust

- Electric control panel

- Electric or manual filter shaker version

- Compact vacuum easy to move in the production area

- HEPA H14 absolute filter version

- Container release system

- Container with castors and handle accessory box, cable/pipe holder

VHS 42 M-H

-

Powerful and safe dust extractor for hazardous dust

The VHS 42 M/H dust extractor series sets a new standard for design and feature level of the Nilfisk wet & dry vacuum portfolio. With innovative filtration system, improved performance, robust design and dust class M/H certification, this range represents a superior solution for professional customers looking for a reliable machine to protect workers health and safety. VHS 42 M/H comes with more suction power, sealed dust system, automatic filter cleaning and several other user benefits - designed to meet the tough requirements in building & constructions and other industries when picking up hazardous dust.

VHS 42 M/H offers a remarkable productivity thanks to the semi-automatic Push&Clean™ or automatic filter cleaning system InfiniClean™. The InfiniClean™ system ensures continuously cleaning of the filter during operation using a reversed air-flow pulse, keeping suction performance on a high level. Downtime is reduced significantly, as the container can be filled up without filter maintenance. To minimize dust exposure during disposal several dust bag options are available to match the specific need in the hazardous dust application. Also the washable PFTE long-life filter and the dual HEPA filter option minimizes maintenance and reduces the overall service cost. A flow sensor with combined acoustic and LED warning monitors the filter and air flow to secure performance and filtration on the highest and most safe level.

Easy handling and user-friendliness - also when it comes to transportation from one working site to another - are other valuable features for the VHS 42 M/H dust extractor. All models offer flexible storage solutions for tools and accessories, so everything you need is at hand.

- InfiniClean™ - Automatic filter cleaning system with minimized performance loss

- PTFE long-life filter with non-stick membrane and minimum 99,9% filtration efficiency

- Push&Clean™ - Semi-automatic filter cleaning system on selected models.

- Dust class M and H certification including Asbestos

- Unique dual filter solution available for H-class/HEPA - including 3-stage filtration

- Flow sensor with combined acoustic and LED warning

- Robust container with steel castors and bumper.

- MultiFit accessory system for the ultimate in task flexibility

- Flexible rubber straps, tool box storage and optional trolley handle for convenient storage and transport

- Optional motor cooling filter, exhaust air collector and Long-Life filter bag

VHS120 All-In-One #B&C

-

As efficient as simple, the right combination for your application: one specific model built according to each main specific segments and equipped with the best accessory kit.

Your task? Just plug and play… and continue doing your job without any thought.The #Building&Construction vacuum cleaner is the VHS120 H Class third party certified machine, which represents the state-of-art of industrial vacuum cleaner suitable for collecting hazardous materials.

The absolute HEPA14 filter, standard on this H Class variant, retains the finest dust, M-Class start filter with glued seams get the highest filtration efficiency, while the Longopac® system allows the easiest and safest discharge of the collected material, without coming into contact with the vacuumed hazardous dust.The new anti-shock accessories kit, which this machine is equipped with, has been created specifically for the Building & Construction Sector, where there is the need to dissipate any static charges caused by the passage of dust.

It includes a conductive hose, a conductive cone, an antistatic round brush and a specific anti-shok nozzle with silicone lips, that can also be stored in the tool basket.Focus on total safety!

- Single phase, n°2 by-pass motors

- H Class third party certified machines

- Compact dimensions

- M Class star filter with glued seams

- Absolute filtration as a standard

- Longopac system for easy and safe material discharge

- Accessories tool basket

- Equipped with a full chain of conductive or antistatic accessories

- 5 meters flexible conductive hose

- High filter surface

- Ergonomic manual filter shaker

- Vacuum gauge on the motor head

- Optimum balance among efficiency compactness and price

VHS120 L-M-H

-

The most compact and powerful ever, even for hazardous materials

The VHS120 is the ideal single phase vacuum cleaner when there is need of high performances in compact dimensions for collecting any type of hazardous material.

The VHS120 L-M-H Class third party certified series represents the state-of-art of industrial vacuum cleaner suitable for collecting hazardous materials.

The M and H Class machines are equipped with M-Class start filter with glued seams to get the highest filtration efficiency and the Longopac system for an easy and safe discharge of the collected material. The absolute HEPA14 filter, standard on the H Class variant, retains the finest dust. The 2 by pass motors secure the highest performances in very compact dimensions being the machine only 630x628x1.300. The manual filter shaker allows an easy and effective cleaning of the main filter so as to keep always the best performances which can be monitored thanks to the vacuum gauge on the motor head. Accessories can be stored in the tool basket which is standard on the M and H Class machines while optional on the L Class ones.

- Single phase, n°2 by-pass motors

- L-M-H Class third party certified machines

- Compact dimensions

- Stainless steel version

- Absolute filtration version

- M Class star filter with glued seams version

- L Class machine, 37lt container easy to remove and empty

- M-H Class machines, Longopac system for easy and safe material discharge

- Accessories tool basket

3707 - 3707/10 L-M-H

-

Endless power for endless possibililties

Models 3707 and 3707/10 are really powerful and can collect high quantities of heavy materials.

Excellent suction performances, wide filtering area, metal construction, 175 liters container, accessory box, mobile and ergonomic: what else would you need in an i-vac? Thanks to its 5,5 kW power, model 3707 is perfect for heavy duty tasks, moreover model 3707/10 supplies 7,5 kW power, the most powerful of its category!

- M and H class filters

- Big container easy to empty

- Electric filter shaker as option

3907 - 3907W L-M-H

-

15 HP power and reliability, for heavy industries

15 HP power and ATEX certified for use in explosion-proof areas, that is 3907 series by Nilfisk-CFM

Powerful and strong industrial vacuums suitable for heavy duty and continuous use thanks also to the wide filtering area and the great container capacity. No need for manteinance and excellent performances in collecting high quantities of heavy material they are perfect for heavy industries such as foundries, cement or steel plants and so on. Special filters for the recovery of toxic dust or of hot substances available. What else can you request to an I-Vac?

- Manual or electric filter shaker

- Extractible container

- Easy to move

- No need for manteinance

3907/18 L-M-H

-

18 HP power and reliability, for heavy industries

18 HP power and ATEX certified for use in explosion-proof areas, that is 3907 series by Nilfisk-CFM

Powerful and strong industrial vacuums suitable for heavy duty and continuous use thanks also to the wide filtering area and the great container capacity. No need for manteinance and excellent performances in collecting high quantities of heavy material they are perfect for heavy industries such as foundries, cement or steel plants and so on. Special filters for the recovery of toxic dust or of hot substances available. What else can you request to an I-Vac?

- Manual or electric filter shaker

- Extractible container

- Easy to move

- No need for manteinance

CTS22 L-M-H

-

The most compact, certified and fully configurable threephase 2,2 kW I-Vac

Thanks to the small size and the high performance, CTS threephase range is chosen by companies with tiny environments but need high power. Compact, stable and easy to move, model CTS is really appreciated.

CTS range is equipped with a side channel blower placed on the bottom of the chassis, making the vacuums stable and easy to manoeuver. Many details featuring this range: the magnetothermal on/off switch, the vacuometer to monitor the filter efficiency, the small size, moreover they can work continuously 24/7! Filtration is also top quality: L class star filter of 19500 cm2 grants high filter efficiency and the manual filter shaker allows to clean fastly and easily the filter. Available also upstream absolute filter HEPA H14 and downstream absolute filter ULPA15 to collect very fine dust.

- For continuous use

- small size

- silent

- vacuometer to monitor filter efficiency

- removable container

- L, M, H class to collect hazardous dust

CTS40 L-M-H

-

The most compact, certified and fully configurable threephase 4 kW I-Vac

Thanks to the small size and the high performance, CTS threephase range is chosen by companies with tiny environments but need high power. Compact, stable and easy to move, model CTS is really appreciated.

CTS range is equipped with a side channel blower placed on the bottom of the chassis, making the vacuums stable and easy to manoeuver. Many details featuring this range: the magnetothermal on/off switch, the vacuometer to monitor the filter efficiency, the small size, moreover they can work continuously 24/7! Filtration is also top quality: L class star filter of 19500 cm2 grants high filter efficiency and the manual filter shaker allows to clean fastly and easily the filter. Available also upstream absolute filter HEPA H14 and downstream absolute filter ULPA15 to collect very fine or hazardous dust. L,M, H and ATEX (for Zone 1 and 2 Gas and 21-22 Dust) versions.

- for continuous use

- small size

- silent

- L, M, H and ATEX versions

- vacuometer to monitor filter efficiency

- removable container

CTT40 L-M-H

-

For maximum airflow in hazardous environments

With its small but powerful turbine motor, model CTT is the right union between quantity of collected air and number of possible applications.

Thanks to the high airflow produced by the turbine. CTT range is suitable for the collection of big quantities of fine dust. Low noise levels, compactness, high filtering efficiency and the L-M-H certification, make CTT the ideal model for the recovery of hazardous dust.

- For continuous use

- High filtering efficiency

- L, M, H versions for hazardous dust

- Removable container

- TuV approved

T22PLUS L-M-H

-

Health and safety as standard in a 2,2 kW industrial vacuum

TPlus range is TuV certified: these models can hold efficiently every kind of dust, even the finest. The ATEX certification grants the highest technological standard against the explosion risk in the working environment.

Silent and light but offering excellent performances, model T22Plus is available in many different configurations: with M class filter or cartridge filter, with HEPA or ULPA absolute filter for the collection of very fine or hazardous dust, with 50 or 100 liters container, with solid cut-off system. The ATEX versions for Z21 and 2 are equipped with a stainless steel container and antistatic star filter. Mod. T22Plus is easy to use and is very ergonomic to meet the different requirements of the industries: cable holder, accessory box and vacuometer (to check the filtering efficiency).

Specific versions for additive manufacturing available.

- Manual or electric filter shaker version

- Pulse jet cartridge filter cleaning version

- Vacuometer

- L or H class versions

- ATEX versions for Zone 21 and Zone 2

- Plug with inverter

- Solid cut-off system

- Extractible container with castors and wheels

- Accessory box, cable holder and support for the hoses

- Specific versions for additive manufacturing available.

T40PLUS L-M-H

-

Health and safety as standard with high vacuum in 4 kW

4,3 kw suction power. It is M and H certified for hazardous dust and ATEX certified for explosion-proof environments. Version T40Plus HE is equipped with an high efficiency motor for low consumption: top power, low consumption.

The great suction power of model T40Plus is given by the vacuum it creates: it can collect very heavy materials or wet dust, it is ideal to solve any waste problem that were unsolvable till today. Several versions are available: with M class or with HEPA or ULPA filters for the collection of very fine or hazardous dust, with cartridges filter, with 50 or 100 l container, with solid cut-off system and so on. The ATEX versions are certified for zone 22-21 and 2 in compliance with the 94/9/EC and the 99/92/EC directives. Model T40Plus HE has been designed thinking to the respect of the environment, it is in fact equipped with an high efficiency motor offering great performances but with low energy consumption.

- L, M, H certified for operators' safety

- ATEX certified for explosion proof environments

- Top filtering efficiency

- Powerful

- Silent

- Modular

- "Green motor" for great performance with low energy consumption

T40WPLUS L-M-H

-

Health and safety as standard with great airflow in 4 kW

T40W generates a great airflow and is the ideal tool to collect high quantities of very fine dust. The M and H class filters grant a safe dust containment. The ATEX certification allows to work safely in explosion- proof areas.

Ideal to be used in companies producing high quantities of very fine dust, model T40WPlus is available in several configurations: with M class filter or with HEPA upstream or ULPA downstream absolute filter for the collection of very fine or hazardous dust, with cartridges filter and jet pulse cleaning system, with 50 or 100 liters container, with solid cut-off system and so on. ATEX versions can work in zone 22-21-2 in compliance with directives 94/9/EC and 99/92/EC.

- Manual or electric filter shaker version

- Jet pulse catridge filter cleaning system version

- Vacuometer

- L and H class versions

- ATEX version for zone 22-21 and 2

- Plug with inverter

Three-phase wet & dry

- Three-phase industrial vacuum cleaners are designed for continuous use. They are ideal for integration into process machines, for use in fixed installations and for heavy-duty use in general. The three-phase industrial vacuums can be equipped with side-channel blowers that offer higher vacuum rates and reduced airflow, or with turbines that release higher airflow and reduced vacuum rates. You can choose between the models for the recovery of dry material only and models for both wet and dry applications.

ATTIX 145 & 155

-

Ideal for heavy industrial vacuum cleaning

Thanks to its high performances, ATTIX 145 & 155 are the ideal industrial three phase vacuum cleaners for the general cleaning in all kind of industry, especially when large quantity of dust have to be collected. The 100 liters steel container is ideal for collecting big amount of solid (e.g. metal chips) or liquids (e.g. oil and lubricants). The practical SitDown container system makes emptying convenient for fast and productive cleaning.

ATTIX 145 & 155 can run for many hours without requiring maintenance thanks to the very silent and reliable double stage side-channel blower. The lower position of the blower gives it a great stability even when moving on rough floors. A handle all around the machine allows pulling or pushing it from a working place to another one. L-class filter is fitted as standard, but M-class filter and HEPA-filter is available as option when fine dust has to be removed. Furthermore the manual filter shaker guarantees a perfect efficiency of the filtration. An accessory box, a cable and hose/tube holder makes ATTIX 145 & 155 very ergonomic and simplifies the daily work of the operator. From its protected position, the manometer shows to the operator when the filtration efficiency decreases, inviting him to shake the filter. The ON/OFF switch is placed on the rear of the chassis inside the carter in order to protect it against shock.

- Powerful and reliable double side channel blower - needing no maintenance

- Comfortable grip and robust steel chassis for durability and easy mobility

- MultiFit adapter included for high flexibility in accessory choice

- Storage of accessories

3707-3707/10

-

Endless power for endless possibilities

Models 3707 and 3707/10 are really powerful and can collect high quantities of heavy materials.

Excellent suction performances, wide filtering area, metal construction, 175 liters container, accessory box, mobile and ergonomic: what else would you need from an i-vac? Thanks to its 5,5 kW power, model 3707 is perfect for heavy duty tasks, moreover model 3707/10 supplies 7,5 kW power, the most powerful of its category!

- M class and H class filters

- Big container easy to empty

- Electric filter shaker as option

3907 - 3907W

-

15 HP power and reliability, for heavy industries

15 HP power and ATEX certified for use in explosion-proof areas, that is 3907 series by Nilfisk-CFM.

Powerful and strong industrial vacuums suitable for heavy duty and continuous use thanks also to the wide filtering area and the great container capacity. No need for maintenance and excellent performances in collecting high quantities of heavy materials, they are perfect for heavy industries such as foundries, cement or steel plants and so on. Special filters for the recovery of toxic dust or of hot substances available. What else can you request to an I-Vac?

- Manual or electric filter shaker

- Extractible container

- Easy to move

- No need for manteinance

3907/18

-

18 HP power and reliability, for heavy industries

18 HP power and ATEX certified for use in explosion-proof areas, that is 3907 series by Nilfisk-CFM

Powerful and strong industrial vacuums suitable for heavy duty and continuous use thanks also to the wide filtering area and the great container capacity. No need for manteinance and excellent performances in collecting high quantities of heavy material they are perfect for heavy industries such as foundries, cement or steel plants and so on. Special filters for the recovery of toxic dust or of hot substances available. What else can you request to an I-Vac?

- Manual or electric filter shaker

- Extractible container

- Easy to move

- No need for manteinance

3997 - 3997W

-

First class power

The most powerful "mobile" Nilfisk-CFM industrial vacuum, featuring 30 HP and up to 36000 l/m airflow

Designed for heavy duty and continuous use, it doesn't need any maintenance and grants an excellent filtering efficiency thanks also to the electric filter shaker. Despite its size, it is very easy to move and to use: the vacuometer monitors the filter, the container is easily extractible, the control panel includes on-off switches, timer and manometer. This vacuum is also equipped with lifting brackets or clamp and brackets and it mounts a comfortable accessory box.

- High suction power

- Excellent filtering efficiency

- Maintenance free

- Easy to use

- Absolute filter version

- “L”, “M”,“H”, or PTFE filter Stainless steel version

CTS 22

-

The most compact, certified and fully configurable threephase 2,2 kW industrial vacuum

Thanks to the small size and the high performance, CTS threephase range is chosen by companies with tiny environments but need high power. Compact, stable and easy to move, model CTS is really appreciated.