- Offer Profile

-

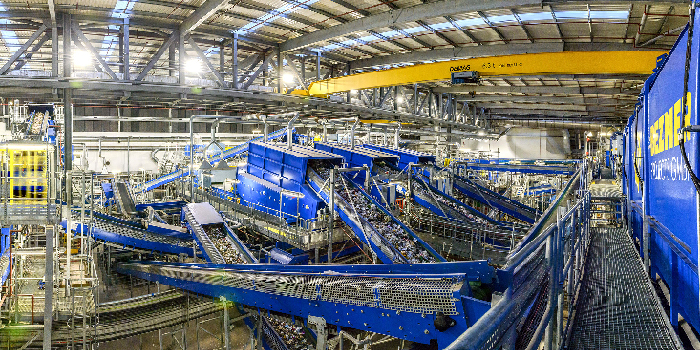

WASTE MANAGEMENT SOLUTIONS

CUSTOMIZED ENGINEERING OF RECYCLING AND WASTE MANAGEMENT MACHINERY

Bezner is a leading engineering and manufacturing company of recycling and waste management machinery. We supply our products to industries who turn waste to energy and extract valuable recyclables such as paper, metals, glass, and plastics that can be sustainably reprocessed.Operating internationally, we design and install both single machines and turn-key solutions for conveying, separating, sorting, and screening. With our in-house team of mechanical and electrical engineers and production facility, we supply customized components with a high throughput and excellent recovery and purity rates.

CUTTING-EDGE PRODUCTS

-

FOR RECYCLING AND WASTE MANAGEMENT INDUSTRY

At Bezner, we understand that your production or recycling process and/or waste treatment installation is unlike any other. Above all, your sorting facility requires specific equipment design to generate a high throughput and excellent recovery purity rates. We supply machinery to recover valuable commodities from the waste stream for:

- Waste recycling

- Waste processing

- Paper and cardboard recycling

- Plastic recycling

- Metal and scrap metal recycling

- Glass recycling

- Bottom Ash

We have the expertise and experience to offer specific components or a turnkey solution. We supply all required conveying, separation, sorting, classification and screening equipment. With our in-house electrical and software engineers, in cooperation with our sister company Beemster and the cooperation with first class suppliers, we come to turn-key processing solutions.

RECYCLING SOLUTIONS

-

INNOVATIVE RECYCLING SOLUTIONS RESULT IN HIGH-QUALITY RECYCLED MATERIALS

Thanks to the growing demand for recycling, also the need for innovative recycling plants increases. In the years to come, waste will be a definition from the past. A significant number of recycled materials have become resources over the past decades, and the varieties continue to grow.

For optimal waste recycling for our clients, Bezner engineers and builds waste management and recycling machinery according to customers recycling and sorting goals, dimensions and budget.

We build both conventional components and ingeniously tailored units. Specific equipment outside our range from secondary suppliers can be included. This way, our project management team offers a turnkey solution.

We operate in the following waste management and recycling industries:

- Bottom Ash recycling

- Commercial and industrial waste recycling

- Construction and demolition waste recycling

- Municipal solid waste recycling

- Glass recycling

- Paper and cardboard recycling

- Plastic recycling

- Single stream recycling

COMMERCIAL & INDUSTRIAL WASTE

-

COMMERCIAL AND INDUSTRIAL WASTE RECYCLING EQUIPMENT

Industrial and commercial operations create waste containing materials, such as paper and cardboard, metals, organic materials, glass, wood, and all types of plastics, among which HDPE, LDPE, PS, PP, etc.

By combining specific shredding, separating, and sorting technologies, Bezner realizes an installation with a high throughput to separate the materials into, for example, a high calorific fraction (RDF), residual components or recyclables such as metal, wood, and plastics.

CONSTRUCTION AND DEMOLITION

-

CONSTRUCTION AND DEMOLITION WASTE RECYCLING MACHINES AND PLANTS

Construction and demolition waste (C&D) mainly consist of debris collected during demolition, construction, and renovation of buildings. This type of waste, mostly in bulk and heavy materials, such as concrete, brick, wood, metals, glass, and salvaged building components, contains a mixture of mineral and non-mineral materials.

CONVERTING

To convert construction waste and demolition waste into reusables, Bezner has the experience in engineering customized installations that separate the profuse mixture of materials in recyclables and non-recyclables. It is our experience that the combination of our in-house developed conveyors, linear vibrating screen, air separators (or air classifiers), and many other devices builds an optimal functioning installation.

MUNICIPAL SOLID WASTE

-

MUNICIPAL SOLID WASTE RECYCLING EQUIPMENT

The composition of Municipal Solid Waste (MSW) varies per country, and in some cases even per region. In general, MSW, also referred to as household waste, consists of everyday items like glass, plastics, metals, textiles, organics, and paper discarded by the modern society. This composition contains a large portion of valuable products, compost and high calorific materials (refuse-derived fuel (RDF)) that, once extracted by mechanical treatment or degraded by biological treatment, offers a wide range of new resources.

Thanks to our vast experience as an engineer and operator for recycling installations, Bezner knows every requirement to provide the most profitable, efficient and sustainable solution for your situation.

PLASTIC RECYCLING

-

PLASTIC RECYCLING MACHINES AND PLANTS

Bezner delivers plastic recycling. Apart from the argument of sustainability, given the oil price as a raw material for plastics, the reduced need for energy required to produce recycled plastics is another reason, economic this time, to use recyclables.

The most common types of discarded plastics for a profitable recycling installation are PET, HDPE, and LDPE. Also found in plastic waste streams is PVC. Recovering this kind of plastic is a sustainable way to reduce air pollution.

Bezners innovative recycling process includes (color) sorting, cleaning, shredding, granulating, melting and molding. We have the knowledge and experience to provide the technology for engineering, building, and installing a cost-effective and reliable installation to produce high-grade recyclables for excellent products further down the production chain.

COOPERATION IN PLASTIC RECYCLING

Bezner supplies sorting equipment for the waste management of all types of plastic waste. Further down the production line, B+B Anlagenbau (also part of the Heilig group) offers equipment for washing, drying, color separating, and packing the recycled plastics to be used as a raw material for newly produced products.

BOTTOM ASH

-

FROM BOTTOM ASH OF INCINERATED WASTE TO RECYCLED MATERIALS

At Bezner we use bottom ash recycling equipment. Worldwide, collected municipal solid waste is incinerated to obtain energy and reduce the depletion of fossil fuels. The combustion of this waste in an incinerator results in a non-combustible residue which is called bottom ash.

Bottom ash contains a high quantity of valuable metals. With a particular combination of separating and conveying treatment, valuable metals such as gold, silver, tin, copper, and aluminium can be retrieved and re-used as raw materials. Also, bottom ash is processed as recycled aggregates in, for example, concrete and the foundation of roads and highways.

SINGLE STREAM RECYCLING

-

RECYCLING MACHINERY

Single stream recycling, or otherwise also referred to as mixed waste or commingled waste recycling, is an upcoming recycling process thanks to the innovation of recycling installation manufacturers.

Where in the past decade consumer pre-recycling was necessary to optimize the quality of recycled materials, nowadays, the installations have been further sophisticated with, for instance, infrared sensors and sorting systems that achieve high purity rates. Processing single streams of waste is no longer an obstacle to fully separate, sort, and transform valuable recovered materials into reusable materials and valuable commodities.

GLASS RECYCLING

-

GLASS RECYCLING INSTALLATIONS AND MACHINERY

The properties of glass vary from round to flat and from colorless glass to green and brown glass. Despite the difference, glass is a material that suffers little from quality loss during the recycling process. For all types, less energy is required for recycling than for producing it from raw materials, which is the main benefit.

With the combination of crushing, separating, sorting, and conveying technology, Bezner engineers a modern and profitable glass recycling installation for container glass, according to your requirements. For example, we consider the grain size which is important to sensor-based sorting of the cullets.

Our installations recover any remaining metals during recycling and convert any type or variation of glass into high-quality raw materials for glass processing industries such as new glass, fiberglass, and reinforcement of materials used in the construction industry.

PAPER AND CARDBOARD

-

RECYCLING INSTALLATIONS AND SORTING EQUIPMENT FOR PAPER AND CARDBOARD

Paper and cardboard are among the oldest materials in the history of recycling. In our home country, around 75% of the newly used paper is produced from recycled material. Also, approximately 75% of this materials are again recycled. Taking into account that producing recycled paper consumes 70% less energy than paper produced from new raw materials, the paper recycling industry, paper mills, or also called deinking industry, constitutes a nearly circular economy.

The reasons for these high percentages are the major awareness and the advanced infrastructure of this collection. The advantages of deinking include:

- waste reduction

- sustainable use of recycled materials

- reduction of newly produced materials

- reduced energy consumption

- reduced CO2 emission

With a clever combination of screens, air classifiers, separators, and balers, Bezner engineers paper & cardboard recycling installations with excellent sorting results and return on investment.

WASTE HANDLING SYSTEMS IN LOGISTICS

-

WASTE MANAGEMENT LOGISTICS

In-house waste disposal is becoming increasingly important. Rapidly growing online purchases are causing the amount of packaging waste to explode, large volumes due to empty cardboard boxes or general waste make reliable and effective disposal of these items essential.

Bezner has been planning, manufacturing and installing these conveyor systems in the cardboard box and packaging industry for years.

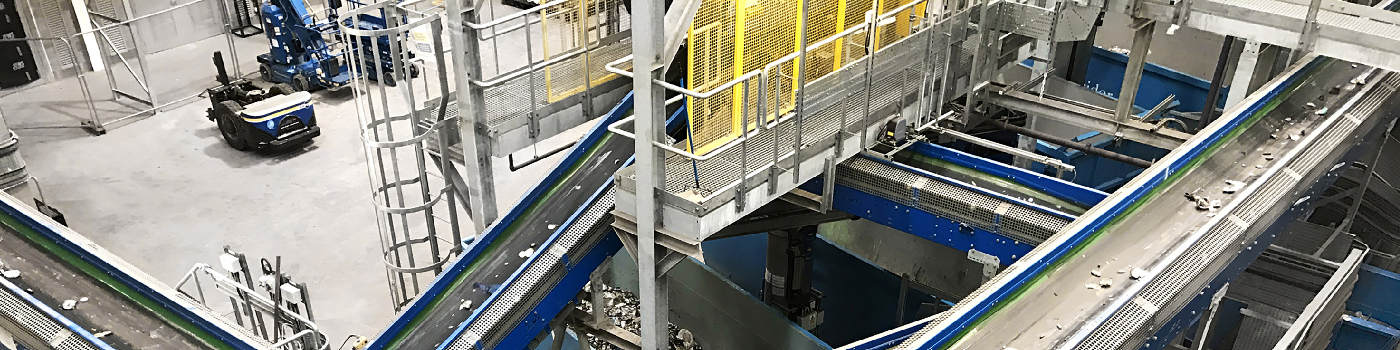

CONVEYOR SYSTEMS

-

CONVEYOR SYSTEMS FOR HIGH-VALUABLE RECYCLING MATERIALS

As a pioneer, Bezner started designing conveyor components and equipment for the recycling industry more than 3 decades ago. Today, conveyor systems are more sophisticated due to the demanding requirements for continuous operations (downtime reduction), safety, high throughput and less maintenance due to clogging damages.

For industries in waste treatment and recycling, we offer conveyors that include:

- Roller conveyors

- Sliding conveyors

- Speed conveyors

- Chain conveyors

- Transporting conveyors

- Spiral conveyors

- Bucket elevators

- Bunker conveyors

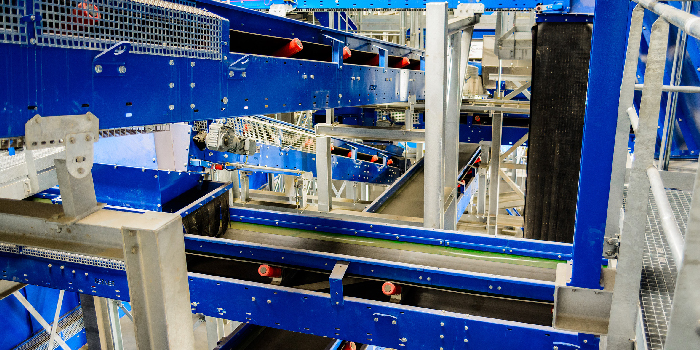

BELT CONVEYOR

-

DURABLE BELT CONVEYOR FOR CONTINUOUS TRANSPORT

Belt conveyor is one of the carrying or transporting mechanisms of a recycling or waste management installation. Depending on the complexity of the waste materials mixture, the looping belt requires robust and durable properties to resist impact, wear and leaking of oil and grease.

At Bezner, we are experienced in engineering customized turnkey solutions, including a belt conveyor system that feeds, discharges, distributes, doses, accelerates, or a combination of these. Our belt conveyors carry bulk waste mixtures for the recycling industry. Also, Bezner is experienced in engineering conveyor systems for among others bulk commodities, composting, and non-metallic minerals such as timber and glass.

We supply conveyor belts for the following industries:

- Waste management industry

- Recycling industry

- Wood processing

- Glass industry

- (scrap) Metal industry

- Paper and cardboard industry

- Plastics industry

The advantages of our conveyor belts include:

- Durable and high-quality materials

- Long-term maintenance free

CHAIN CONVEYOR

-

CHAIN CONVEYOR

Like belt conveyors, also a chain conveyor is engineered with the purpose of transporting materials. Transporting materials on this type of conveyor commonly proceeds in a horizontal way, but also vertically over a short distance to a higher level is possible.

The advantage of including this type of conveyor to your installation is that this conveyor is particularly suitable for moving heavy loads. In some cases, the belt and its infeed hopper are used for temporary storage of materials.

Of course, the high-quality, durable materials we utilize to engineer any part of your conveyor system also applies to building a chain conveyor. According to your requirements for dimensions and conveyed materials to for example a bailing press, a box feeder or a belt conveyor, Bezner engineers a chain conveyor that fits your installation perfectly.

We supply a variety of chain conveyor for both light and heavy loads for the following industries:

- Waste management industry

- Recycling industry

- Wood processing

- Glass industry

- Paper and cardboard industry

- Plastics industry

THE ADVANTAGES OF BEZNER CONVEYORS INCLUDE:

- Durable and high-quality materials

- Long-term maintenance-free

- Suitable for conveying heavy loads

- Optional vertical short distances

ELEVATOR CONVEYOR

-

LIFTS YOUR MATERIALS TO A HIGHER LEVEL

When your production or recycling process includes different levels in height or your facility is compact, implementing a state of the art elevator conveyor is an efficient solution.

Bezner offers a variety of conveyor lifts to convey materials vertically. We design smaller devices for finer materials such as glass cullets, heavy duty machinery for aggressive materials such as bottom ash, and everything in between.

THE ADVANTAGES OF IMPLEMENTING AN ELEVATOR CONVEYOR INCLUDE:

- Optimal plant process fits in compact facility

- Controlled flow over various levels

VIBRATING FEEDER

-

VIBRATING FEEDER

A vibrating dosing feeder is a conveying component that, by means of gravity and a vibrating motion, feeds the material further down the process. Other terms you may encounter are: dosing system, dosing feeder or grizzly feeder. Implementing this type of feeder as a dosing system is applicable for smaller granules or materials only.

BEZNER ENGINEERS, BUILDS AND SUPPLIES CUSTOMIZED A VIBRATING FEEDER FOR THE FOLLOWING INDUSTRIES:

- Bottom ash

- Glass industry

- Plastics industry

The advantage of implementing a dosing system in your installation includes the controlled flow or dosage of the single stream materials in your process.

BUNKER CONVEYOR

-

BUNKER CONVEYORS FOR CONTROLLED FLOW

A bunker conveyor, or also called metering bin or infeed bunker, allows the intermediate storage of a product to generate a controlled flow or batch in the production or recycling process. Bezner engineers and builds bunker conveyors in-house. We offer a variety of shapes and dimensions. If required, we equip our bunker conveyors with enhanced sensoric and control technology for a fully automated operation in the plant process.

THE ADVANTAGES OF IMPLEMENTING BUNK CONVEYORS INCLUDE:

- Temporary storage during plant process

- Controlled flow or dosage

SCREENS

-

SCREENING: A SIGNIFICANT PART OF WASTE RECYCLING

There are many techniques to separate waste. Bezner has developed screening machines for the recycling industry with linear, circular, rotating, and elliptical (ballistic) sieving motions. We offer in-house engineering and manufacturing of screening machinery with highly rated advantages:

- sorting based on size (fractions), shape, and weight

- high throughput and high purity rates

- low maintenance and shutdowns

LINEAR VIBRATING SCREEN

-

LINEAR VIBRATING SCREEN

To optimally separate waste by sort and size from a single stream or a complex mix of materials is a challenge. Part of the installation for sorting and screening waste is a linear motion vibrating screen, also called a horizontal screen.

Depending on the process, the throughput and screening quality may be improved by inclining the screen. Also, depending on the mixed material stream, the screen decks surfaces are manufactured from steel, polyurethane (PU) for washing material, wire mesh, grizzly screens or disc screens.

The horizontal method of screening provides a thorough and careful separation of a wide variety of materials such as demolition waste, bulk goods, paper and lighter packagings. Bezner engineers tailor-made components according to the sieving characteristics of the stream containing materials that differ in, for example, weight, shape (2D/3D, round or square) and density. For more information, please download our product leaflet Linear Vibrating Screen.

Bezner has many years of experience in engineering and building linear vibrating screening machinery for many recycling industries. Whether you are looking for a particular variation or would like to know more about the number of screening elements, screening decks or the screen mesh, please feel free to contact us.

CIRCULATION VIBRATING SCREENS

-

CIRCULAR VIBRATING SCREEN

A circular vibrating screen (or rotary vibrating screen) offers a machinery component for the recycling industry with the purpose of classifying and sorting various types of waste. The vibrating screen in circular motion generates high purity rates.

Bezner is experienced in engineering both standard and customized designs for the following waste management industries:

- commercial waste

- industrial waste

- bulky waste

- scrap wood

- construction and demolition waste

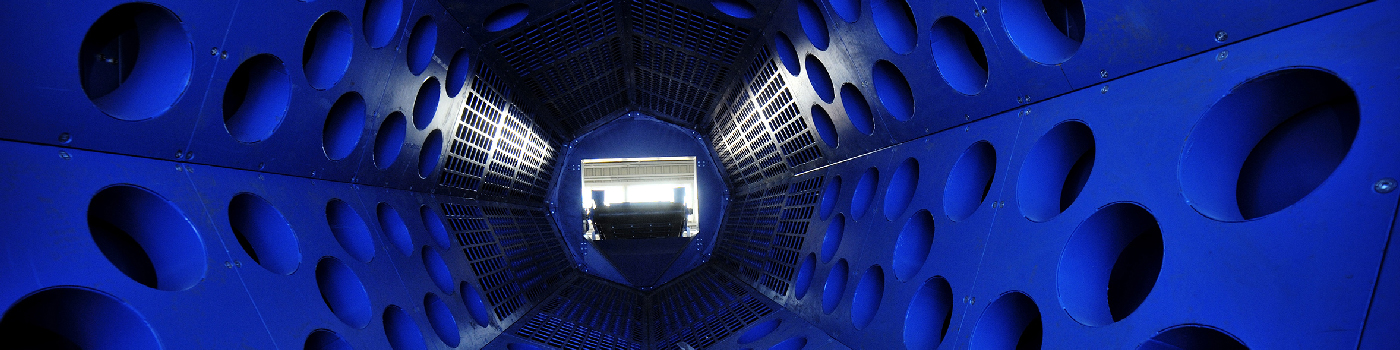

SCREENING DRUM

-

SCREENING DRUM

A screening drum, or also referred to as trommel screen or rotary drum screen, is a machine for classifying, size splitting, and pre-sorting waste in a waste management plant, recycling plant or compost plant.

Bezners designs vary in length and/ or diameter of the drum, and the shape and mesh of the holes in the drum. The sorting, or screening, of the materials, proceeds through the rotary motion of the different particle fractions. A screening drum is applicable to nearly all kinds of waste.

SCREENING BUCKET

-

SCREENING BUCKET

A screening bucket is commonly used for the primary selection, screening and separation of materials and consists of a number of screening blades with a variation in openings, depending on the process. The design requirements of the bucket screens have always had Bezners special attention. For instance, for the construction and demolition waste industry, a solid construction of the screening buckets is vital.

THE ADVANTAGES OF BEZNERS DESIGN OF SCREENING BUCKET INCLUDE:

- fully opening at the point of discharge

- no jamming of materials

- clog-free and continuous operation

- reduced downtime and fewer costly maintenance

AIR SEPARATOR

-

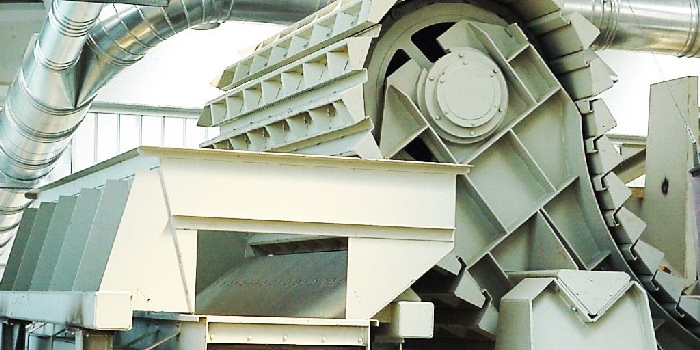

CUSTOMIZED AIR SEPARATOR

At Bezner, we engineer, build and supply a customized air separator as a component of your recycling installation. Other names you may come across for an air separator are wind sifter (otherwise spelled as windsifter), wind shifter or air classifier. The air separator is for the separation of light and heavy material. The wind sifter provides effective protection for following shredders and guarantees a high quality separation of heavy materials.