- Offer Profile

-

Eriez Europe designs, develops and manufactures industry-leading magnetic separation, metal detection, fluid recycling and vibratory equipment for over 80 industries.

Established in 1942, Eriez is a global leader in separation technologies. Our commitment to innovation has positioned us as a driving market force in several key technology areas, including magnetic separation, flotation, metal detection and material handling equipment. The company’s 900+ employees are dedicated to providing trusted technical solutions to the mining, food, recycling, packaging, aggregate and other processing industries. Headquartered in Erie, Pennsylvania, USA, Eriez designs, manufactures, and markets on six continents through 12 wholly owned international subsidiaries and an extensive sales representative network.

Eriez Quick Ship Products

- Eriez' Quick Ship stocking program includes our most popular items from grate magnets to vibratory feeders and metal detectors, readily available for immediate needs. Many of these quick-ship items are available in three convenient designations: Next-Day, 5-Day, and 10-Day shipment.

Magnetic Separation

- Magnetic Separators are used in virtually all process industries, from removing fine metal contaminants in food processing to capturing damaging tramp metals in large mining operations. Providing dependable and economical solutions to problems associated with tramp iron contamination in processing lines, Eriez Magnetic Separation Equipment helps prevent costly shutdowns associated with machinery damage, prevent spark–caused fires and explosions, prevent product contamination and improve product purity.

Vibratory Feeders and Conveyors

- Whether your operation requires accurate, rugged performance in an underground mine or a sanitary rapid-cycling feeder to package snack foods, Eriez offers specific vibratory equipment and magnetic conveyors to meet your needs. Light to heavy-duty feeders and conveyors accurately feed and control material flows ranging from spoonfuls to 1,000 tons per hour.

Eriez Metal Detectors

- Made for industry applications including chemical, food processing, packaging, textiles, pharmaceuticals, plastics and rubber, Eriez Metal Detectors surpass previous units and competitive models alike with enhanced features, improved sensitivity, intuitive operation and exceptional reliability. The ultra-sleek Eriez Metal Detector blends simplicity and sophistication with its easy-to-navigate control with extra large color interface.

Fluid Recycling

- Our metalworking fluid management solutions are specifically geared to the type and brand of fluid in use in your facility. These heavy-duty industrial units clean virtually any machine tool sump, tank, or pit quickly and thoroughly, improving productivity and reducing disposal costs.

Eriez Solids Removal Equipment

- Eriez is a leading provider of comprehensive coolant and fluid management technology serving the metalworking industry. Our industrial filtration systems and fluid recycling equipment maximize coolant effectiveness and longevity enabling companies to improve productivity and reduce disposal costs.

Fluid filtering and recycling applications include parts washing, machining, grinding, honing, super finishing and EDM where fluids from water-based coolants to straight oil lubricants are required.

Eriez Sump Cleaners

- Eriez offers the widest selection of sump cleaners in the industry. Solutions range from inexpensive drum top cleaners to the industry’s widely recognized sump cleaner. Manufactured since 1974, these heavy-duty industrial wet/dry vacuum filtration units clean virtually any machine tool sump, tank, or pit quickly and thoroughly.

The sump cleaner removes the coolant, sludge and chips from the sump, filters the sludge and chips from the coolant and returns the filtered coolant to the sump, or transports the coolant to waste treatment for disposal or to an Eriez Recycling System.

The Sump Cleaner is fast! In a typical example, a cylindrical grinder sump with 120 U.S. gallons (454 liters) of coolant and 700 pounds (318 kilograms) of sludge was completely cleaned, the coolant filtered and returned to the sump in ten minutes.

Features:- Capacities from 65 U.S. gallons (246 liters) to 1,000 U.S. galllons (3780 liters) Single or twin compartment configuration Push around, tow around, or truck mounted units available Air, 120V single phase, 3-phase electric, or LP gas power sources Complete with hoses and cleaning tools

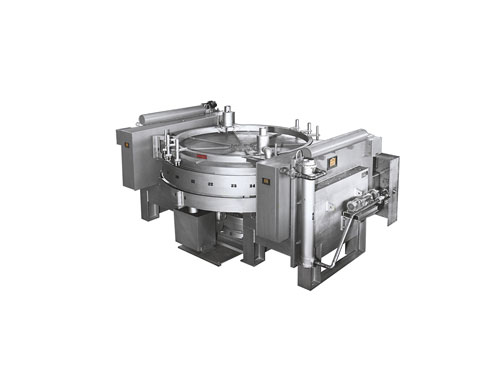

Solids-From-Liquid Centrifuges

- Solids-from-Liquid Centrifuges are very successful in reducing solids in numerous applications where ever the removal of fines is desired. Solids collect in individual machine tool sumps and in large central systems. It’s important to efficiently remove these chips and fines as they have detrimental effect on coolant performance and longevity as well as causing lost production and headaches during removal.

Eriez’ Solids-from-Liquids Centrifuges provide continuous MEDIA-FREE filtration of both metallic and non-metallic solids from industrial fluids. All Eriez’ Centrifuges are specifically engineered for heavy-duty industrial applications and will offer years of trouble-free operation. Solids-from-Liquid Centrifuges are available in either manually cleaned basket style (complete with reusable liner) or fully automatic self-cleaning designsto provide dependable, easy to maintain, media-free filtration solutions.

Whether used on a single machine, or as a component of or supplement to a complete paper media filtration/recycling system, the Solids-from-Liquid Centrifuge can remove solids typically missed by barrier filtration and reduces or eliminates costly filter paper, bags and cartridges, all of which require disposal.

Applications: Machining, grinding and sawing, high-speed centrifuge pre-filteration, rolling and tube mills, water jet cutting, de-scaling operations, wire drawing, parts washers, quench tanks, UF pre-filtration, precious metals recovery.

Magnetic Chip & Parts Conveyors

- Safely and reliably move and elevate ferrous materials such as chips, turnings, small parts and stampings from a sump to a discharge. These units are practically maintenance-free and innovatively designed to ensure the highest level of operator safety.

Most models feature Eriez’ unique internal Tuf-Trac track system with no moving external parts to jam or break like hinge belt conveyors. Tuf-Trac’s continuous series of powerful ceramic magnets pick up and glide material along the stainless steel slider plate. Material is then discharged over the head end.

Features:- Liquid-tight construction

- Conveyor can be completely submerged in the sump or tank

- Self-cleaning surface

- Excess fluids drain easily

Eriez Fluid Concentration Control

-

Maintaining tight fluid concentration control ensures that fluid never becomes too lean or too rich.

A "lean" concentrate often leads to rust, bacterial infection, and poor tool life, while a "rich" concentration often causes eye, nose and skin irritation for the operator and is a waste of product. Eriez mechanical mixers ensure consistent concentration under all types of conditions.

Eriez Tramp Oil Removal

-

Eriez offers a complete line of equipment to remove tramp oils from your metalworking fluids.

Removing tramp oils, any oil that leaks from a machine tool into the metalworking fluid, should be a high priority for all metalworking plants. Tramp oils cause a variety of problems with the metalworking fluids such as:

- Increased smoke and mist in the air

- Increased bacteria populations

- Decreased tool life

- Decreased coolant life

- Decreased parts washer bath life

- Skin irritations such as Dermatitis

Removing tramp oils from your fluids will improve all aspects of your metalworking fluids.

Eriez Magnetic Separation

Permanent Magnetic Separators

Eriez Magnetic Tubes

-

Powerful permanent magnetic tube magnets are designed to remove ferrous contamination from dry and liquid products

Eriez’ Xtreme Rare Earth Magnetic Tubes utilize the industry’s strongest magnet circuit available to recover more fine-iron contamination and reduce product wash off. They can be used as inspection tools or in areas where conventional Grate Magnets will not fit.

Features & Benefits:- 1" (25.4 mm) diameter tubes

- 316/316L stainless‑steel construction

- Custom made to any length Xtreme

- Rare‑earth circuits for up to 150°F, 250°F or 400°F

- Alnico circuits are available for temperatures up to 1200°F

Tube magnets can be manufactured with the following ends:- Stainless-steel end plugs with 1/4"-20 drilled and tapped ends

- Stainless-steel 1/4"-20 threaded studs, 1/2" long

- Stainless-steel plain end plugs with heliarc welds

- Stainless-steel sanitary end plugs

- Other ends available upon request

Eriez Permanent Plate Magnets

-

The workhorses of magnetic separation

Eriez Permanent Plate Magnets provide dependable and economical solutions to problems associated with tramp iron contamination in processing lines. Plate Magnets installed in chutes, spouts, ducts, pipes, or suspended over conveyors remove tramp iron to help prevent costly shutdowns associated with machinery damage, prevent spark– caused fires and explosions, prevent product contamination and improve product purity.

Features & Benefits:- All stainless-steel construction

- Welded Construction

- 1/2" high milled 400 series tapered step

- Hinge and latch Rare Earth and Xtreme

- Rare Earth units (sanitary design is standard)

Eriez PM Grate Magnets

- Eriez PM Grate Magnets are ideal for removing ferrous contamination from plastic pellets, flake and regrind prior to the injection moulding machine, extruder or compounding equipment to prevent damage and downtime in the process line, as well as improving product purity.

Features:- For suitable use up to 120ºC

- Available in 152mm (6") and 203mm (8") standard sizes

- Stainless steel housing

- Slide gate to shut off material flow

- Two banks of Rare Earth permanent magnets

Customers who want to check the strength of their current magnets can contact Eriez to arrange for a specialist to visit their facility for a free calibration visit, where a complete inspection of separation equipment will be undertaken and recommendations provided.

Eriez Grate Magnets

-

Powerful, permanent magnetic protection against fine and tramp iron contamination

Powerful, permanent magnetic protection against fine and tramp iron contamination. Designed for simple installation in steep-sloped hoppers, odd and irregular shaped hoppers, floor openings, vertical closed chutes and ducts.

Standard Grate Magnets

For many years Eriez permanent magnet grates have used ceramic or Alnico magnet materials as their energy source. When built with Eriez–designed circuits, these separators provide good magnetic fields for a nominal cost and satisfactorily remove both tramp and fine iron contaminants in most applications. They continue to be the magnets most frequently used to improve the product purity of dry bulk materials.

Xtreme® Rare Earth Grate Magnets

The Xtreme® RE separators available from Eriez remove weakly magnetic or very fine iron contaminants. They have more strength at a greater distance than conventional permanent magnets, higher gradients and increased holding force. This means they can reach out and attract weakly magnetic or very fine iron contaminants, and hold them so tightly that wipe-off by product flow is virtually eliminated.

Sanitary Grate Magnets

Both standard and Xtreme® grate magnets are available in sanitary construction. These units are stainless steel throughout and are carefully manufactured to contain no pits, cracks or crevices in accordance with accepted standards of sanitation for food processing.

Eriez Permanent Magnetic Traps

-

Provide magnetic protection for liquid lines and processing equipment.

Eriez’ line of powerful, permanent magnetic Ferrous Traps provide magnetic protection for liquid lines and processing equipment. They preserve product purity by removing small particles of magnetic scale, rust and fine iron contamination.

Protect your flow lines and products with the world’s finest liquid handling magnetic separators. Prevent abrasive wear, prevent pumps from jamming and assure yourself a product free of iron contamination... achieve the iron contamination protection your particular operation requires – whether it be a tiny 1/2–inch (13 mm) pipeline or a huge 30–inch (762 mm) diameter line, Eriez has a magnetic circuit to provide the protection that will serve you best.

All models of Ferrous Traps have a constant powerful magnetic circuit designed to attract and hold iron contamination. Clean, simple designs have no moving parts... powerful, permanent magnetic element will perform well handling materials with temperatures up to 150°F (65°C), with special models available for temperatures to 850°F (454°C).

Xtreme® Traps

The Xtreme® style Rare Earth (RE) separators available from Eriez remove weakly magnetic or very fine iron contaminants. Eriez Rare Earth develops a magnetic field up to 25 times the strength of conventional ceramic magnet material. All models of Eriez trap magnets are available with Xtreme elements.

Eriez Magnetic Humps and Round Pipe Separators

-

Powerful magnetic separator removes tramp iron from free flowing gravity or pneumatically conveyed materials

Eriez' Magnetic Hump and Round Pipe Separators provide a simple and effective way to remove tramp iron contamination from gravity or pneumatically conveyed dry, free flowing products such as feed, grain, wood ships, food stuffs, sand or plastic.

The housing is "dog-legged" on two sides at 45 degrees from a flat plane. Each leg contains a plate magnet hinged and latched to the housing, one on the up stream side and one on the downstream side.

Material enters the magnetic Hump and is forced abruptly to change direction against the face of the powerful plate magnet. As the material tumbles in the housing, it again changes direction and is forced against the face of the second powerful plate magnet. The Hump takes advantage of the ferrous material density because the heavier metallics are more likely to work their way to the face of the magnet, increasing the probability of capture.

The ferrous contamination remains on the face of the magnets until an operator swings the magnet out of the product flow and physically removes the metal.

Features & Benefits:- Quick release clamps for easy operation and maintenance

- Minimized overall height for difficult retrofit installations

- All welded construction

- Mild or stainless steel construction

- Available for gravity, horizontal or vertical pneumatic installations

Eriez Magnetic Drum and Drum In-Housing Separators

-

Eriez permanent magnetic drum separators offer automatic separation of ferromagnetic particles for higher levels of purity in food, grain, chemicals, plastics, metals, rock products, ores, etc.

Eriez’ Drum Separators remove both large and small pieces of iron contaminants from material processing lines. Powerful permanent magnets enable more efficient separation performance for a broader range of applications than ever before. The complete line includes standard models in diameters from 12 to 36 inches (305 to 915 mm), and widths from 12 to 60 inches (305 to 1525 mm). These units provide efficient separation on volumes up to 25,600 cubic feet (725 cubic meters) per hour. They provide years of trouble–free automatic removal of tramp iron from heavy flows of bulk materials, including large and highly abrasive materials.

Eriez Wet Drum Separators

-

For automatic, continuous recovery of magnetite or ferrosilicon in heavy media operations and concentration of ferrous and weakly magnetic ores

Eriez’ Drum Separators are setting industry standards. The newest advances in magnetic circuitry design, plus over a quarter of a century of experience with solid/liquid separation, are combined in Eriez Wet Magnetic Drum Separators.

Innovations in both magnetic circuit design and materials of construction are applied to Eriez wet drum magnetic separators. This results in maximum magnetite recovery while operating with a minimum amount of wear and maintenance. Refinements in the magnetic circuit, tank design, and drive system have resulted in further improvements in metallurgical performance and operation.

Features & Benefits:- Strongest, most effective magnetic elements in the industry

- Stainless steel encapsulated magnetic element

- One piece stainless steel drum shell

- Abrasion–resistant aluminum or stainless steel end flanges

- Double–row, self–aligning ball bearings easily accessible without drum disassembly

- Accurate drum positioning at factory eliminates field adjustments Modular tank for easy installation Full width overflow weirs High volume input Low initial cost Now available with high energy rare earth magnets

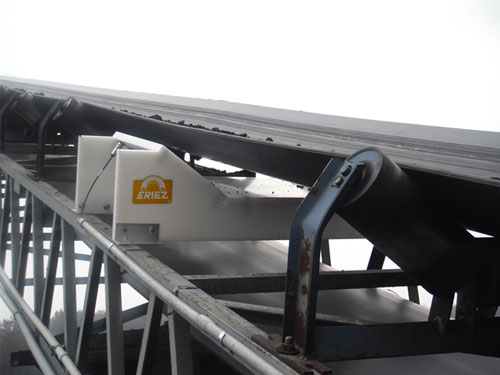

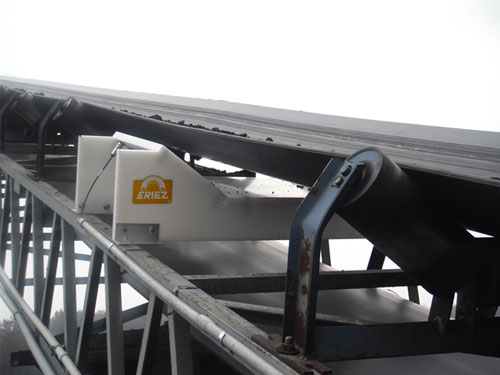

Eriez Magnetic Head Pulley Separators

-

Powerful magnetic pulleys for automatic separation of heavy tramp iron contaminants from conveyor transported materials

Eriez Magnetic Head Pulleys are an ideal compact solution for the magnetic treatment of conveyed materials.

Powerful magnets are used to automatically separate tramp iron and fine iron contaminants. These separators can be retro-fitted into existing conveyors or built in during conveyor design.

Features:- Simple to install

- Powerful uniform magnetic field across full belt width

- Robust fully-welded design with stainless steel shell

- Both Ferrite and Rare Earth element designs available

- Range of sizes available: 200-1200mm diameters, 500-2000mm widths (other sizes also available on request)

- Options for rubber lagging and crowning

- Suitable for variable belt speeds

For maximum ferrous metal recovery, magnetic head pulleys are ideally installed in conjunction with an Eriez Suspended Magnet. This enables maximum recovery of tramp iron throughout the product burden.

Eriez RF Cartridge Magnetic Separators

-

Powerful, radial-field magnet removes tramp iron from dry, free-flowing materials in gravity or 25 psi pneumatic conveying lines.

Eriez’ “RF” (Radial Field) Cartridge Magnet is ideal for removing tramp iron from dry, free flowing food or chemical products conveyed in pneumatic pipelines.

Material enters the housing, is distributed by a solid stainless steel cone and passes in close proximity to the magnetic cartridge.

Ferrous contamination is attracted and held by the magnet while the separated product continues past the magnet and out of the housing.The ferrous contamination remains on the magnet until the cartridge is removed and cleaned.

Compact overall dimensions alow the RF Cartridge Magnet to be installed in tight quarters. A section of pipe is removed and the magnetic separator put in its place.

Features & Benefits:- High-strength permanent tapered-step magnetic elements

- Available with ceramic or Xtreme strength Rare Earth magnet material

- Stainless steel housing construction

- Removable magnet element with built-in handles for easy cleaning

- Utilizes typical pneumatic conveyor couplings for easy operation and positive seal

- Independent magnet element for easy handling

- Standard units available for up to 25 psig (1.7 bar) operation

- High pressure units available

- Sanitary option available

Eriez Dry High Intensity Rare Earth Roll Magnetic Separator

-

Offers maximum efficiency in the separation of weak magnetic particles for product purification applications.

With the ever increasing demand for high-purity feedstocks used in manufacturing, Eriez offers its Dry High Intensity Rare Earth Roll Magnetic Separators. These provide maximum efficiency in the separation of weak magnetic particles for product purification applications. Eriez applied sophisticated finite element analysis in magnetic circuit design to produce an energy-free separator capable of generating the exceptionally high field-strengths needed to remove unwanted fine iron contaminants.

Magnetic cleaning has been applied to the most basic industry foundations such as industrial minerals, metals recycling, glass batch and cullet, abrasives and refractories, chemicals, pharmaceuticals, and plastics.

Engineered for optimum performance- High-intensity magnetic roll assembled from rare earth permanent magnets

- Magnetic roll diameters of 4, 6, and 12 inches

- Magnetic roll widths up to 60 inches

- Continuous duty applications treating up to 12 TPH feed/separator

- All stainless steel construction

- Variable speed drive on each magnetic roll

- Mounted spread box/hopper and vibratory feeder

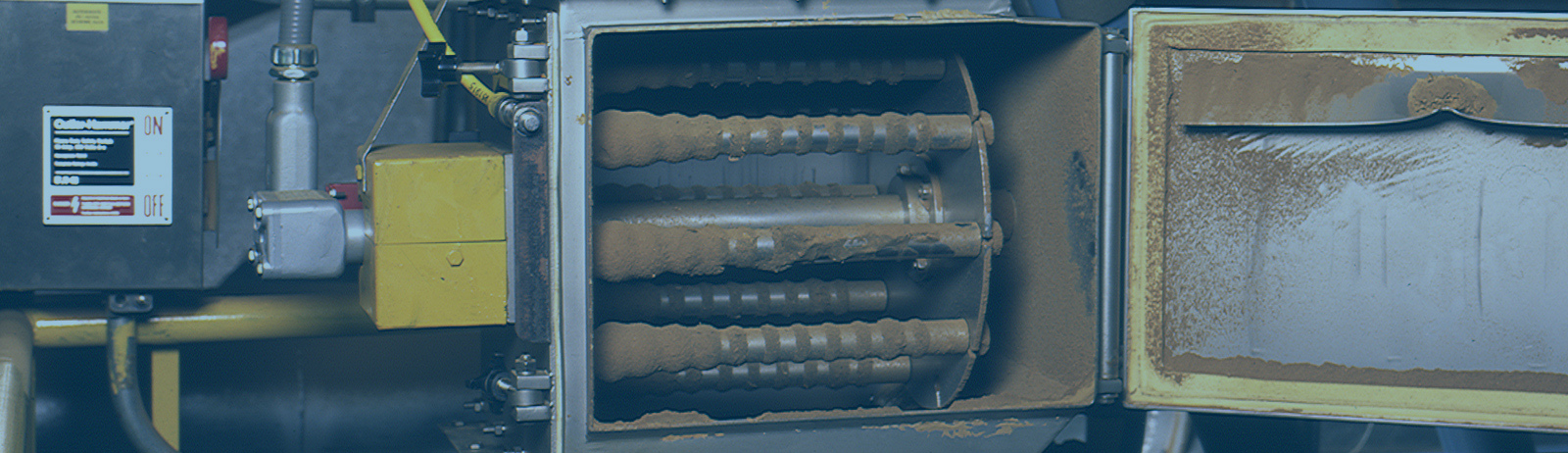

Eriez Magnetic Coolant Cleaners

-

Smooth-faced and extended-pole Coolant Cleaners extend the life of cutting tools, grinding wheels, pumps and coolant fluids.

Eriez Coolant Cleaners are designed for use with surface grinders, gear grinders, honing and lapping machines, broaches, milling and drilling machines face grinders, oil reclaiming machines - wherever clean coolant is needed. These cleaners keep machine tools running longer and more accurately with lower costs per unit produced.

Features & Benefits:- Cleaner coolant with a longer service life

- Lengthened tool life

- Machine accuracy maintained

- Reduced machine downtime

- Lower cost Reduced pump wear

- Easy installation in restricted space

- Can be used on new or existing machines

- Available in different capacities, different types

- Low initial cost

- Virtually no maintenance costs

Eriez Magnetic Flocculators

-

Compact, powerful units use magnets to speed settling of magnetic solids from slurries and liquids for easier recovery and separation.

Eriez Permanent Magnetic Flocculators aid in the separation of minute magnetic particles from liquids and slurries. Used widely in the iron and coal mining industries to speed settling of fine magnetic particles in ore slurries and heavy media slurries, they are finding new use in steel and other industries for agglomerating fine magnetic contaminants in quench water, cooling oils, etc.

Features:- 4” - 24” pipeline volumes accomodated Simple installation Floor, wall or ceiling mount Vertical or horizontal flow No operating costs No moving parts to wear out Minimum maintenance required

Eriez Handheld Inspection Magnet

- A simple handheld permanent inspection magnet for checking the quality of a product or removing loose tramp iron from a flow of materials.

Features:- Super-strong Rare Earth Magnets

- Deep-reach magnetic field

- All 304 stainless steel contact

- Detects ferrous contamination in nonferrous bales

- Avoid material rejections

Eriez Magnetic Sweepers

- For “clean sweep” removal of dangerous iron and steel debris from highways, airports, farms, orchards, parking lots, terminals, warehouses, quarries, machine shops, factory aisles and parks.

Eriez’ electromagnetic and permanent magnetic Road, Land and Floor Sweepers are the fast, efficient, practical way to rid large surface areas of hazardous pieces of iron. In one quick sweep they prevent costly tire damage, reduce equipment downtime and eliminate many safety hazards.

The Sweeper’s high–strength magnetic field picks up and holds nails, wire, welding rod ends, staples, tacks, bolts, ferrous chips—all kinds of potentially damaging tramp iron. Farms, vineyards, factories, storage houses, highways, airfields, parking lots, loading docks, city streets, parks and playgrounds are easily cleared of troublesome iron and steel debris.

Features:- Simple operation

- Exceptional performance

- Choose from a wide selection of models and sizes

- Magnetic Sweepers collect hazardous iron and steel debris and prevent tire punctures

Eriez Trunnion Magnet System

- Eriez has pioneered magnetic separation techniques to improve grinding circuit efficiency in mineral processing plants. The Trunnion Magnet System bolts directly to the ball mill discharge flange to provide continuous magnetic collection of the grinding ball fragments. A permanent magnetic circuit collects the grinding ball fragments and discharges them to a collection hopper.

Grinding ball fragments discharging from ball mills cause extreme wear to downstream processing equipment. These ball fragments, circulating in a milling circuit, will cause excessive wear to sumps, pumps, hydrocyclones and interconnecting piping. Grinding ball fragments contribute very little to the grinding process while consuming power.

Features:- Permanent magnetic circuit designed to provide maximum performance

- No energy consumption

- Rugged construction ensures long service life

- Minimum maintenance

- Continuous “Operator Free” process

Eriez Electromagnetic Separators

Dry Vibrating Magnetic Filters

-

High intensity electromagnetic filter to remove fine, ferrous contaminants from dry powder.

Eriez unique Vibrating Magnetic Filter incorporates vibrating filter elements to provide a high capacity material flow. As the material flows through the magnetized elements, the iron bearing contaminants are captured, resulting in a high‑purity product. Ferrous contaminants are typically reduced to the ppm level when treating materials such as alumina, talc, and silica and zircon flours. The exceptionally high intensity field generated by the electromagnet provides peak separation efficiency. Developed for the pharmaceutical, cosmetic, abrasives, specialty glass, specialty metallic powder and industrial minerals market.

Features:- High intensity, high gradient magnetic field

- High frequency, low amplitude vibration

- Two magnetic field strengths available

- Four sizes available, including a laboratory model

Eriez Force Cooled Suspended Electromagnets

-

Successfully removes damaging tramp from flows of coal, limestone, sand, gravel, municipal waste, wood products, recycled materials, and other non-ferrous materials

The Compact Forced Cooled Suspended Magnets provide the traditional quality, performance, reliability and value of Eriez separators, but at a smaller size which leads to increased productivity and profitability.

These separators are designed to capture tramp metal from both shallow or deep burden depths and are ideal for almost any application – wet, dry, fine, or coarse. As plants continue to increase in size to take advantage of economies of scale, the Eriez’ force cooled electromagnets have been engineered to achieve better performance at a smaller size than traditional magnets.

Manual–cleaning magnets are available for simple installations while self–cleaning units provide for continuous tramp metal removal.

Features:- Higher magnetic fields in a smaller footprint

- Wet-wound copper coils utilize Nomex insulation and fiberglass spacers to extend life

- Forced cooling allows the magnets to produce a higher field strength at lower temperatures

- Reduced suspended mass

- Exclusive oil expansion tank prevents condensation and keeps the coils submerged and cool

- Manganese bottom plate provides for superior durability in rugged applications

- 8 magnet sizes, 32 standard models and hundreds of special designs available for nearly every unique application

Special features available such as elevation derated coils, high fire point coolants, oil temperature sensors, flow switches for monitoring heat exchanger operation, conveyor speed switches, guards, controls, permanent retention, monitoring devices and many more

Eriez High Intensity Magnetic Filters

- Strong magnetic separators remove fine ferrous and paramagnetic contaminants from flowing liquids.

The magnetic collection of fine particles requires a high-intensity, high-gradient magnetic field. An electromagnetic matrix-type separator, referred to as a magnet filter, has proven to be the most effective method of separation. This type of separator utilizes a high-intensity electromagnet and a flux-converging matrix. The matrix amplifies the magnetic field and provides high-gradient collection sites for the magnetic contaminants.

A line of permanent magnetic filters is also available.

Features:- Easy cleaning

- Various sizes and magnetic field strengths

- Increased magnetic strength

- Electro and

- Permanent models

- Custom designs available

Eriez Suspended Electromagnets

-

Removes damaging tramp metal from coal, limestone, sand, gravel, municipal waste, wood products, recycled materials, other ores and almost any conveyed nonferrous material

The Suspended Electromagnet provides tramp metal collection from conveyed materials. The electromagnet is typically mounted or suspended over a conveyor belt to remove large pieces of tramp metal that represent a hazard to downstream crushers, mills, pulverizers and grinders. Suspended electromagnets also remove sharp metal that can damage or tear expensive conveyor belts, especially at transfer points. Product purity is enhanced with the separation power of the suspended electromagnet.

Features & Benefits:- Exclusive oil expansion tank prevents condensation and protects against hot spots to extend coil life

- Aluminum or copper coils use Nomex insulation and fiberglass spacers to prevent shorts

- Five-year warranty on coil assembly

- New adjustable oil expansion tank design for any installation angle is mounted with slotted brackets, allowing the user to rotate the tank so the moisture drain is always on the low side

- Lift lugs now include two side-by-side holes to allow for simultaneous hoisting and installation of the suspension gear

- 23 magnet sizes, 69 standard models and hundreds of special designs available for unique applications

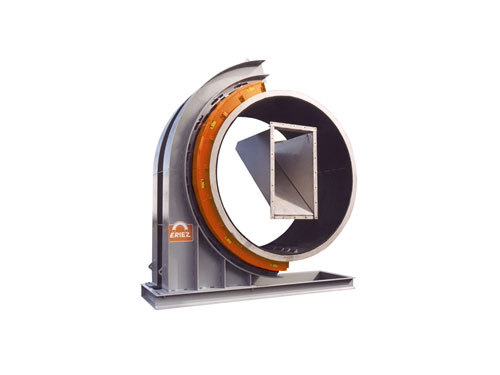

Eriez Wet High Intensity Magnetic Separator (WHIMS)

-

Wet High Intensity Magnetic Separators (WHIMS) are designed for high capacity, continuous removal or concentration of feebly magnetic materials.

WHIMS are designed for high capacity, continuous removal or concentration of feebly magnetic materials. Typical applications include hematitic iron, rare earth minerals, industrial minerals and more.

Features:- Excellent performance on even weakly magnetic materials: higher recovery (4-6% higher at the same grade) or higher grade.

- High capacity without clogging.

- Advanced design and durable construction with less maintenance (Matrix fabrication technology patented).

- Dual jigging washing for a higher separation efficiency (patented).

- Air assisted discharge for less water usage (patented).

- No ring step motion/indexing.

- No concentrate early drop off (patented).

- Many models and sizes to choose.

- Direct water cooling to make it a simple and reliable operation.

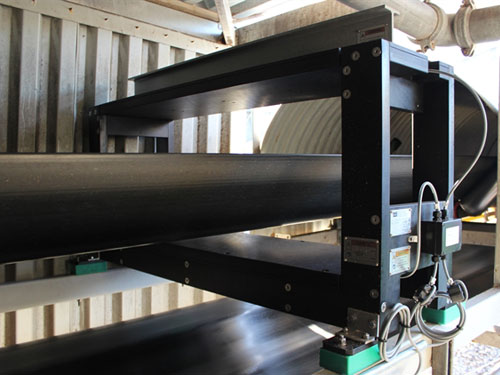

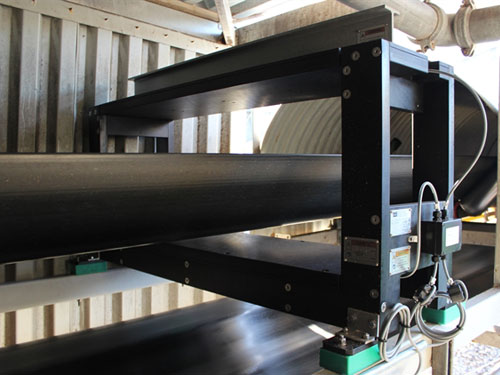

Eriez Industrial Metal Detection

Eriez MetAlarm Metal Detectors

-

Industrial metal detectors designed to protect a wide range of machinery from damaging tramp metals

Features & Benefits:- Easy to install

- Belt does not need to be cut to install Signal monitoring and self-check facility

- Mechanical relays to actuate reject devices and alarms

- High level immunity to radiated signals

- High density polyethylene encased search coils

- Detects ferrous and nonferrous metals

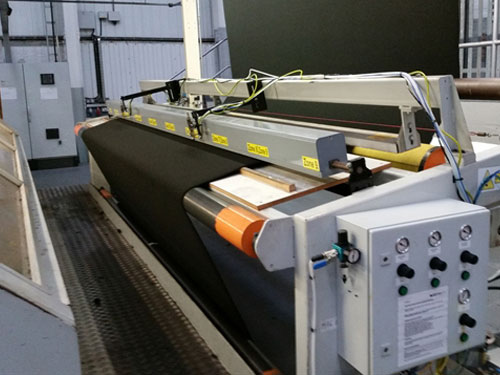

Eriez Xtreme Metal Detectors

-

Best-in-class performance, designed to detect small ferrous, non-ferrous and stainless steel metal contaminants

In its base package, the metal detector offers a huge 7” easy-to-use touchscreen interface, multiple preprogrammed languages, easy setup and reporting, multiple USB and interface ports, remote access and the standard high-pressure wash down design.

Xtreme software

In addition to its rugged construction, the Xtreme Metal Detector offers easy-to-use set up, operation and reporting from a large, well-designed graphical interface.

Setup and Operation

While the Xtreme Metal Detector ships with factory pre-set settings for your products (based on actual testing and provided application data), adding new products or changing parameters is simple. The following are a few standard features:- Four password protected levels of access

- Auto set-up and product learning

- Easily change product boundaries/rejection

- One touch log reporting

- Eight fields of data recorded on a large flash drive

- Multiple communication ports – USB and Ethernet

- Log/tracks/rejects, on/offs, faults, warnings, product and setting changes, operator changes and much more

ATEX Metalarm Metal Detectors

- Eriez MetAlarm Metal Detectors protect a wide range of machinery from costly damage caused by tramp metal in plants all around the world.

The MetAlarm EX range has been developed for use in hazardous environments, particularly in environments where potentially explosive dusts may be present. Eriez custom made sensor coils are configured to suit specific conveyor systems to optimise detection sensitivity performance and ensure systems offer a practical and efficient solution.

Features:- ATEX Zone 21 & 22 Dust compliant

- Detect all types of metals

- Fit all sizes of belt and vibratory conveyors

- Belt clip detector for use with metal repair clips or belt splices on EX2 and EX3600 models

- Signal monitoring and self-checking facility

E-Z Tec 9000 Metal Detectors

-

The E-Z Tec 9000 range of Metal Detectors incorporates high sensitivity, balanced coil technology for detecting and removing ferrous, non-ferrous and stainless steel metal contaminants,

ensuring product purity and machinery protection.

E-Z Tec 9000 metal detectors find applications in aggregates and mining, plastics and rubber, recycling, glass, chemicals, food, textile, and wood industries.

Features:- Easy operation

- High sensitivity - balanced coil technology

- Single printed circuit board for ease of servicing

- Surface Mount Technology (SMT) for increased reliability

- Self-monitoring

- Integral circuitry for remote operation and monitoring of reject devices

- Compliant with CE - EMC regulations Available in paint finish or stainless steel*

- Push button selection of controls via on-board micro-controller*

- Storage of up to 10 product settings*

- Password protected* 2 line LCD display of selected parameters*

- Product compensation*

Eriez MetAlarm 6600 Metal Detector

- The 6600 Metal Detector for installation on inclined conveyors provides a solution to many metal detection problems in any industry with conveyors used to feed granulators with tops and tails, sprues, etc.

Features:- Low cost Easy to install

- Small, lightweight control unit

- Directly attaches to lightweight conveyors

- Detects both ferrous and nonferrous metals

- Fail safe electronics

- Plug-in search coils

- Sensing height of detector covers whole belt width

- Complies with CE-EMC regulations

- Reduced susceptibility to electrical noise

- Surface Mount Technology (SMT) for improved reliability

- Fully removable PCB for easy maintenance

Eriez Metalarm 7000 Single Sider Metal Detectors

- The only detector of its kind that can fit into a machine process with moving metal in close proximity.

Features:- Minimum metal-free area requirement

- High sensitivity to both ferrous and non-ferrous metals

- Multiple sensing zones - 250 or 500mm wide

- Sensing widths up to 6 metres

- Easy to install search head

- Anti-static surface on face of the search coil

- Unique r.f. immunity circuitry

- Can be installed close to movingmetals without sensitivity loss or false tripping

- LED on control unit indicates position of metal detected

PolyMag® Additives

-

Add metal detectability, X-Ray contrast and magnetic susceptibility into plastic moldings to prevent plastic contaminated food products from reaching consumers.

Eriez PolyMag Additives impart metal detectability, X-Ray contrast, and magnetic susceptibility into plastic moldings to prevent plastic contamination from reaching the consumer.

Molders can satisfy varying levels of detectability at a cost substantially less than specialty compounds. This eliminates the need to buy minimum quantities of special resins and carry excess material inventory.

Major brand owners, retailers and restaurant chains insist that food processors utilize plastic and rubber articles that are Metal and X-Ray Detectable. This has become part of many company's HACCP (Hazard Analysis Critical Control Point) programs.

More recently, the Food Safety Modernization Act (FSMA) requires Agricultural Producers, Food Processors & Packers to implement Hazard Analysis & Risk-Based Preventative Controls (HARPC) to prevent physical contaminates like glass, metal, wood & plastic from entering the market. The FDA considers contaminates greater than .275” (7mm) in length to present a hazard. Growers, packers & food processors are using their existing metal detector and x-ray inspection system with detectable plastics to prevent plastic contaminated foods from reaching consumers.

Eriez Vibratory Feeders & Conveyors

Eriez Light and Medium Duty Electromagnetic Feeders

- A wide range of drive units for precision feeding of bulk materials

Eriez' unique Hi-Vi magnetic drive circuit provides a simple yet powerful solution to difficult material feeding applications.

These feeders, with their totally enclosed patented magnetic drive, can feed practically any bulk material from micron size to bulky chunks. Solid-state controls operate the feeders with “watch–like” precision. In addition, you get all the features that for years have made Eriez Feeders the leaders in quality and dependability.

Eriez has standard models for the majority of feeding applications. Special units such as multiple drives, enclosed trays or screens can be designed for the best solution to your application. In addition, a wide variety of standard and special trays are available.

Heavy Duty Vibratory Feeders

-

Rugged, efficient, high-capacity units for the controlled movement of large volumes of bulk material.

Our heavy duty line of Brute Force feeders provide a cost effective means to feed or screen large volumes of bulk material for applications where limited feed rate adjustability is required. Brute Force feeders are ideal for applications where limited feed rate adjustability is required. Brute Force feeders are ideal for applications such as coal or stone processing, recycling and scrap recovery. Eriez Brute Force feeders can be provided with unique tray designs for your specific applications.

Features:- Rugged, heavy duty construction

- Twin rotary motors for stability

- Unique tray designs available

- Quiet operation

- Easy access to rotary motors

- Available for hazardous environment applications

Feeder tray motion is provided by eccentric weights mounted on synchronized, counter-rotation, twin motors. The motors counteract each other to minimize the isolation problems associated with single centric drive systems. Feed rate can be varied by adjusting the weights. The twin motor drives operate on standard AC power.

Dust-tight construction and splash-proof design make the motors more suitable for dusty, dirty environments, as well as outdoors in rain or snow. Heavy-duty construction and long-life bearings ensure peak, long-term performance.

A variety of sizes and styles can be ordered to match specific application requirements. Tray options include screens, liners, covers and grizzlies.

Eriez Vibratory Conveyors

- Eriez mechanical feeders are simple, rugged, vibrating machines designed to handle a variety of bulk materials. The conveyors are available in single-mass and two-mass vibrating systems excited by a motor-driven eccentric shaft. Springs vary according to the type of application.

The remarkable compact, straight-line design of these conveyors presents an extremely low profile yet allows for ease of maintenance. Minimum headroom is required for installation.

Features & Benefits:- Adjustable angle rubber springs

- Low profile - minimum headroom

- Flow rates to 60 ft/minute (18mpm)

- Simple, stable, variable controller

Eriez Vibratory Screeners

-

Dependable units for efficient separation,dedusting, scalping and material sizing of a wide variety of materials

Eriez’ Vibratory Screeners provide solutions to industry’s demand for dependable material separation at an affordable price. The wide range of models available allows selection of units for specific and unique material application requirements. These ideal machines are available for processing slurries, waste water, minerals, chemicals and other dry or dewatering applications.

Features & Benefits:- Rugged construction

- Long life Simple controls

- Easy installation

- Low power consumption

Eriez has been providing high quality, creative screening solutions for more than 40 years. Both electromagnetic and mechanical designs are available to insure the optimal solution. Screeners ranging for 6” wide to over 4 foot wide are available for applications ranging from pharmaceutical to basic industries.

Material flow rates of screening feeders are easily adjusted. Each screener is available with an optional separate control that enables the vibration intensity to be varied for ideal screening.

Screeners for de-dusting, sizing and scalping can be designed for your specific application. Single deck or multiple deck screens, enclosed trays and tooless screen assembly are a few of the available options. Woven wire, perforated plate or grizzly bars are a few of the screening medias available.

These screeners, with their totally enclosed patented magnetic drive, can screen practically any bulk material from micron size to bulky chunks. Simple AC controls operate the screeners with “watch-like” precision. In addition, you get all the features that for years have made Eriez screeners the leaders in quality and dependability. Eriez has standard and heavy duty model for the majority of screening applications. Special units can be ordered with multiple drives for greater capacities.In addition, a wide variety of standard and special trays are available.

Eriez Vibratory Controls

-

Eriez offers a line of solid state Feeder Controls with state-of-the-art electronics at competitive prices.

The company’s line features three styles of controls:- UniCon, the standard “base model” control

- UniCon HC (High Current) control

- G Series controls

The UniCon series is designed to provide a precise amount of vibration for Eriez vibratory feeders as well as competitive electromagnetic feeders. These controls accommodate the vast majority of industry applications. Eriez’ full or half wave operation capability allows a plant to operate one control while competitive units provide half wave operation only. Eriez can modify or custom design an electromagnetic feeder control to suit your specific application.

Eriez Bin Vibrators

-

Twelve AC drive units to improve flow of hard-to-handle materials in bins, hoppers and chutes.

Eriez’ unique Hi-Vi magnetic drive circuit provides a simple yet powerful solution to difficult material flow applications.

These vibrators, with their totally enclosed patented magnetic drive, can be used for applications ranging from the tiniest hopper to huge bunkers with reinforced heavy steel plate and liners. Hi-Vi’s concentrated vibration, with its powerful positive drive in both directions, applies a superior action to bin walls, and results in a more economical, more efficient flow of hard-to-handle materials.

The basic simplicity of a drive powered by alternately opposing and attracting magnetic forces assures low maintenance. There are no sliding or rotating parts. Power consumption is low, installation is easy. The positive driving force of Eriez units provides stability, control and unexcelled dependability.

Features & Benefits:- Electro-permanent magnet drive

- AC operation

- Simple controls

- Encapsulated coils

- “Pinpoint” vibration

- Enclosed drive element

- Low power consumption

Vibratory Wet Sifting Machine

-

Incorporating stainless steel lawn screen cloth in aluminium frames, this machine has been developed principally for use in the ceramics industry for grading liquid slip used in the production of pottery and paper.

Multi-deck machines are used in two situations:- To provide a “scalping” effect when large throughputs are required, especially if a high degree of purity is desired.

- For removal of usable solids for further use (reclamation) or clarification of liquids.

The machine consists of a cast aluminium underbody (optional PVC coated body available) which performs three functions:- To support up to three screens, often termed “lawn frames”*.

- To provide mounting for the 500 watt “out-of-balance” rotary vibrator motor and suspension units.

- To accept the undersize from the screens and discharge via a single integral outlet pipe.

Eriez Pneumatic Vibrators

-

Oscillating piston type has displacement characteristics which result in high shock forces being generated on the forward stroke, within a frequency range of 30 to 68cps.

Suitable for air pressures of up to 6kg/cm² (80 psi).

Applications:- Small hoppers

- Grids

- Transfer chutes

- Moulding tables

- Compacting tables

Industries:- Foundries

- Agriculture

- Paper making

- Plastics

- Packaging

Eriez Metals Recycling Equipment

- Eriez' metal recycling equipment, either as individual units or complete systems, is designed for efficient and economical processing of automotive shredder residue (ASR), materials recovery facility (MRF), municipal solid waste (MSW), comingled recyclables, electronic scrap, glass cullet, plastic (PET), foundry sand and many other resource recovery operations.

End-to-End Metal Recovery

Eriez employs a range of separation technologies to efficiently recover valuable ferrous and nonferrous throughout the scrap metals process. Ballistic, gravity, magnetic and sensory equipment are specifically design to optimize the recovery of different metals and mixed metal fractions to maximize their value. Eriez Ferrous Recovery & Sorting Equipment

Eriez Magnetic Head Pulley Separators

-

Powerful magnetic pulleys for automatic separation of heavy tramp iron contaminants from conveyor transported materials

Eriez Magnetic Head Pulleys are an ideal compact solution for the magnetic treatment of conveyed materials.

Powerful magnets are used to automatically separate tramp iron and fine iron contaminants. These separators can be retro-fitted into existing conveyors or built in during conveyor design.

Features:- Simple to install

- Powerful uniform magnetic field across full belt width

- Robust fully-welded design with stainless steel shell

- Both Ferrite and Rare Earth element designs available

- Range of sizes available: 200-1200mm diameters, 500-2000mm widths (other sizes also available on request)

- Options for rubber lagging and crowning

- Suitable for variable belt speeds

For maximum ferrous metal recovery, magnetic head pulleys are ideally installed in conjunction with an Eriez Suspended Magnet. This enables maximum recovery of tramp iron throughout the product burden.

Eriez Magnetic Scrap Drum Separators

- Eriez magnetic drums have been used for many years in scrap metal yards to separate iron and steel from other materials.

Using our sophisticated design software and unique magnetic circuits, Eriez provides permanent and electromagnetic scrap drums with deeper magnetic fields to reclaim ferrous materials in automotive shredder residue (ASR), materials recovery facilities (MRF), municipal solid waste (MSW), scrap metal yards, wood waste, slag, incinerator bottom ash, foundry sand and minerals processing applications.

Eriez PokerSort Metal Separator

- The innovative PokerSort helps alleviate issues caused by long rod-like pieces typically over 24 inches in length, commonly referred to as pokers, that can damage downstream equipment in automobile and other metal scrap operations.

Utilizing a special magnetic drum positioned at the end of the shredder discharge belt, Eriez’ innovative PokerSort separates pokers as they catapult off the end of the belt with a different trajectory than the rest of the shredded material or “frag.”

Eriez Shred1™ Ballistic Metal Separator

- Automatically produces a premium low-copper shred using ballistics technology

Shred1 from Eriez uses ballistics to efficiently separate iron-rich ferrous from much of the mixed metals post-drum magnet flow. This separator delivers two distinct fractions: a premium low-copper ferrous product (in the range of 0.16-0.20% cu) and a traditional #2 shred.

The Shred1 ballistic separator combined with a PokerSort to extract long, troublesome pokers, and a P-Rex™ permanent rare earth magnetic drum improves the entire process. Not only does this new CleanStream™ process recover more ferrous and concentrate 75% of the post-drum magnet flow into a low-copper premium shred, but it also reduces the hand picking and helps increase recovery of copper bearing materials.- Produces a premium

- #1 low-copper shred

- #1 shred contains less than 0.2% copper

- Reduces picking labor

- No X-Ray scanning needed

- Removes concealed copper

Eriez Nonferrous & Metal Sorting

Eriez Eddy Current Separators

-

Removes non-ferrous metallics from plastics, glass cullet, electronic scrap, automobile shredder residue (ASR), boiler bottom ash, spent foundry core sand, municipal solid waste (MSW), co-mingled recyclables, urban wood waste and mixed metals

In 1969, Eriez Magnetics patented both permanent magnetic and electromagnetic eddy current separators. These powerful systems feature improved permanent magnetic circuits with Rare Earth magnetic material for stronger eddy currents and improved separation of non–ferrous materials.

In operation, the non–ferrous separator utilizes permanent rare earth magnets to induce eddy currents into metallic particles. This produces repelling forces which separate the metallics from non–metallics, providing a cleaner product for further processing. Removal of the metallics is selective and product loss is minimized.

The non–ferrous metallic separator consists of an external drum, an internal permanent magnetic rotor, a drive, and belt conveyor. The external drum shell of non–metallic composite material rotates at conventional belt conveyor speed. The internal Rare Earth alternating polarity rotor turns at much higher RPM than the external shell.

Through the induction of eddy currents and the resulting repelling forces, the alternating magnetic field selectively repels the non–ferrous metals and physically separates them from other materials with minimum product loss.

Eriez Stainless Steel Magnetic Separator

- Eriez' Stainless Steel Separator extracts stainless steel and weakly magnetic metals from Zurik and wire fractions sized 2" or smaller. In addition to being a valuable commodity, stainless steel can escape upstream separation and cause damage to wire chopping and processing equipment. Typically, stainless steel has been recovered using expensive sensor sorting technology. Using an Eriez Stainless Steel Separator, most stainless can now be effectively recovered much more economically.

The Stainless Separator is positioned as a magnetic head pulley on a 40" wide urethane belt to produce and extremely high surface gauss easily attracting and holding workharden stainless and other weakly magnetic material.

Optional equipment is available with the Stainless Steel Separator system, including:- Magnetic Drum-In-Housing installed upstream of the Stainless Steel Separator for ferrous recovery

- Electromagnetic Vibratory Feeder to provide even distribution of material across the width of the conveyor.

Features:- Powerful 6-inch Rare Earth Roll Magnetic Head Pulley

- High-strength Kevlar belt

- Heavy-duty frame structure

- Variable speed conveyor control

- Adjustable splitter

Sizes (widths) Offered:- 20" (.5 M)

- 40" (1 M)

- 60" (1.5 M)

Eriez FineSort®

-

Recover valuable metal "fines" from waste

Eriez’ FinesSort® Metals Recovery System uses powerful magnetic components to recover valuable ferrous and nonferrous metals from the fines waste stream in scrap yards.

This system not only reduces the amount of waste destined for landfill, but reclaims thousands of valuable pounds of metals per day.

FinesSort® Features:- Recover metals less than 1”

- Multi-stage separation process

- The most powerful magnetic circuits

- Constructed with heavy guage steel

- 60” machine width

- Payback in as little as six months

Multi-Stage Separation

Eriez’ FinesSort receives the "fines" material that has passed through the intial screening process. That material is evenly fed through the machine's magnetic separation system - recovering metals from the flow and dropping them onto a cross-belt material and into a recycling container.

The Value of Fines Recovery

Smaller sized materials or “fines” that have passed through the initial screening process, and are often discarded and sent to landfills, represent roughly 20% of the original total flow. Within the fines, generally less than 5% is recyclable metal, depending on the mix of product being scrapped. Recovery of just 1% additional metals from the total stream can be worth tens of thousands of annual revenue.

ProSortII® Airless Metal Recovery Separator

- Improved Zurik/Stainless Steel recovery and requires 70% less energy than air-driven sensor sorters.

Eriez' ProSort systems improve metal recovery from waste streams while operating at a fraction of the cost of air-powered metal separators.

Ideal for scrap processors, the new airless ProSortII doubles the number of metal sensors found on the original ProSort machine and positions them on one-inch centers. These high resolution sensors are aligned with a new inverted paddle mechanism to improve recovery of valuable metals. This new arrangement improves large and small metals recovery while producing a "cleaner" higher grade Zurik fraction.

ProSort advantages:- No air compressor plant required

- Low operating and maintenance costs

- Sensor activated paddles deflect detected metals

- Modular design up to 90" wide

- Reduced dust generation

- Excellent cold weather operation

Eriez Material Handling Equipment

Eriez Lifting Magnets

- Lift, move or position regardless of size, weight or shape — in fewer man hours — reliably and economically. Lifting magnets make quick work of difficult, time-consuming steel handling. Magnets possess a unique property of attraction which can be harnessed to ease and speed one’s work. The payoff is an immediate improvement in efficiency and operating economy.

Eriez’ SafeHold® Permanent Lift Magnets are ideal for carrying semi-finished products such as machined parts, castings, press molds, steel plates, bars, tubes and more. These magnets are available in ceramic and rare earth models, lift up to 7,500 pounds, need no outside power source and can be turned ON and OFF with ease.

Features & Benefits:- Available in capacities up to 7,500 lbs (3,402 kgs)

- Lift flat or round material

- Unique APL model for remote operation with no power supply required

Eriez SafeHold Permanent Lifting Magnets

- Lift, move or position regardless of size, weight or shape — in fewer man hours — reliably and economically. Lifting magnets make quick work of difficult, time-consuming steel handling. Magnets possess a unique property of attraction which can be harnessed to ease and speed one’s work. The payoff is an immediate improvement in efficiency and operating economy.

Eriez’ SafeHold® Permanent Lift Magnets are ideal for carrying semi-finished products such as machined parts, castings, press molds, steel plates, bars, tubes and more. These magnets are available in ceramic and rare earth models, lift up to 7,500 pounds, need no outside power source and can be turned ON and OFF with ease.

Features & Benefits:- Available in capacities up to 7,500 lbs (3,402 kgs)

- Lift flat or round material

- Unique APL model for remote operation with no power supply required

Selecto Electro Lifting Magnets

- Lightweight, power packed to provide reliable, fast lifts for hundreds of applications.

Electromagnets are formed by sending electricity through wire coiled around a steel core. These magnets are controlled by regulating the amount of electricity passed through its coils. Applications range from lifting thin steel sheets to unloading ships, containers and railcars. Lightweight, power packed to provide reliable, fast lifts for hundreds of applications.- Easy to install, easy to use

- Eliminate hooks, slings or grabs Use individually or in multiples 100-percent duty cycle

- Fully encapsulated moisture-proof coil Built-in solid-state rectifier and drop-control circuit (Model ST)

- Standard voltage of the SL Selecto Magnet is 115VDC; standard voltage of the ST Selecto Magnet is 115VAC; other voltages available upon request Copper-wound coil

Eriez Bi-Polar Lifting Magnets

- Eriez’ line of Square Bi-Polar Magnets provides for lifting of banded coils and miscellaneous bundled shapes.

Bi-Polar magnets can be used in either single-magnet or multiple magnet applications and with a variety of suspension systems. Eriez designs and builds complete systems including magnets, lift beams, power supplies, controls and battery back-up units. When the application is lifting bundles of pipe or re-bar, tapered pole shoes can be added.

Specifically designed to provide greater holding on coils, bundles of bar, re-bar, tubes or pipes.- Six sizes available

- For handling of various bundled materials

- Special-shaped pole shoes available

- Deep, two-pole field for maximum holding on irregular shapes

- Computer-designed coil

- Weather-tight welded construction 50-percent duty cycle: 15 minutes maximum “on” time

- 100-percent duty cycle available

Magnetic Chip and Parts Conveyors

Eriez Chip and Parts Conveyors

- Permanent magnets moving inside a liquid-tight, submersible housing attract, hold and convey ferrous chips, turnings, small parts and stampings.

Eriez’ Chip and Parts Conveyors provide a virtually maintenance-free way to move and elevate ferrous materials such as chips, turnings, small parts and stampings. Except for an externally mounted drive motor, the unit is self–contained, and the conveyor mechanism is completely enclosed. There are no moving external parts to jam, break or endanger personnel.

Our most popular models feature a unique internal track system called Tuf-Trac™, designed for low maintenance, quiet operation and long service life.

Features & Benefits:- One piece steel housing

- Submersible

- Self–cleaning

- Easily installed

- Continuous lubrication

- Virtually maintenance–free

Principle of Operation

Eriez’ permanent magnet conveyors use a continuous series of powerful ceramic magnets to pick up and glide material along the stainless steel slider plate. Material is then discharged over the head end. Because of their liquid-tight (submerged units) construction, lower conveyor sections can be completely submerged in coolant sumps or tanks. The working face is self-cleaning, and excess fluids drain easily back into the tank.

Construction

All conveyor models are of heavy duty construction to provide years of virtually maintenance-free use. High quality steel and non–magnetic stainless steel are used for the structure, slider plate and magnet assemblies. Conveyor housing construction is entirely liquid-tight (submerged units), and access panels are equipped with gaskets and seals.

Magna-Rails and Rolls

- Eriez Magna-Rails® and Magna-Rolls® have been the industry standard for nearly four decades.

An ever present need within many processing industries is the ability to hold steel parts firmly on moving belt conveyors. Such conveyors, fitted with Eriez Magna-Rails, ensure that parts do not fall off, even when being elevated or lowered.

Magna-Rolls are commonly used in direct contact with steel sheets and tubing. Their firm magnetic grip helps ensure that when the roll turns, the steel moves. Further, when the rollstops, the steel stops as well, thus eliminating the need for pinch rollers.

Features:- Rugged construction Standard and custom–designed sizes

- Magna-Rails available in permanent and electro-magnetic designs

- Magna-Rolls available with flat or contoured faces

Magna-Rails

- These magnetic elements, positioned under conveyor belts and secured by mounting brackets, provide a safe, positive hold for ferrous parts—cans, sheets, nails, stampings, finished parts, even scrap—at high speeds in any direction, even up inclines as steep as 90°.

Transition sections in various radii and matching holding strengths can be made to bolt to a straight section, providing a smooth carry–over from one direction to another.

Electro Magna-Rails are available for special applications where on/off power is required. Electro rails are built with a 3-3/4" (95 mm) face width in standard 12" (304 mm) as well as special lengths. They use a Class B insulated coil and can be furnished for operation on either 110V, DC or 220V, DC.

Magna-Rolls

- Magna-Rolls are constructed in several types with a flat surface or crowned. Contoured and special faces for specific jobs are available, as well as single and multiple gap units.

Virtually any diameter from 2-1/2" (63 mm) and up can be supplied in Magna-Rolls. The 2-1/2" (63 mm) and 4-3/8" (110 mm) rolls have a narrow air gap which provides maximum holding power and traction for a given diameter. When arranged side by side on a common shaft, these units are placed with like poles adjacent (N-S, S-N, N-S, etc.) resulting in deeper and stronger magnetic fields and minimum space.

Sheet Fanners

Eriez Sheet Fanners

- Eriez Sheet Fanners powerful magnetic circuit makes semi–sticky, oily, bent and heavy gauge sheet steel fan with ease and provide new efficiency to slow, costly, difficult sheet feeding to presses, brakes, shears, etc. No more prying, no more “doubles”, no more marring of polished and painted sheets. Three strengths are available in four functional heights. Eriez’ range of Sheet Fanner strengths and heights provides complete coverage for applications up to 1/8" (3 mm) thick steel sheets stacked up to 14" (355 mm) high.

Features & Benefits:- Magnetic circuit fans heavier gauges of steel with new efficiency.

- Completely enclosed magnetic circuit is rugged, tamperproof and will withstand severe usage.

- All units built with stainless steel “U” shaped frame with stainless anti–friction strips and back cover.

- Design provides hand cutouts for ease in carrying from one point to another...sturdy base for fast mounting to any flat surface.

Eriez Flotation

- Eriez Flotation provides novel and industry-changing flotation technologies that are changing the way mineral processing plants are designed. Our vision is to make mineral processing more efficient and less impactful on the environment.

Eriez Flotation provides game-changing innovations in process technology for the mining and mineral processing industries such as HydroFloat® for coarse particle recovery and the StackCell® mechanical flotation cell, as well as advanced testing and engineering services, column flotation and sparging equipment.

Applications for Eriez Flotation equipment and systems include metallic and non-metallic minerals, bitumen recovery, fine coal recovery, organic recovery (solvent extraction and electrowinning) and gold/silver cyanidation. Eriez Flotation has designed, supplied and commissioned more than 1,000 flotation systems worldwide for cleaning, roughing and scavenging applications in metallic and non-metallic processing operations, and we are a leading producer of modular column flotation systems for recovering bitumen from oil sands. Strengths in process engineering, equipment design and fabrication position Eriez Flotation as a global leader in minerals flotation systems.

Eriez Flotation (EF) is headquartered in Vancover, B.C., Canada and has offices around the world. EF is a wholly owned subsidiary of Eriez Manufacturing Co., a global leader in advanced separation technologies, which was founded in 1942.

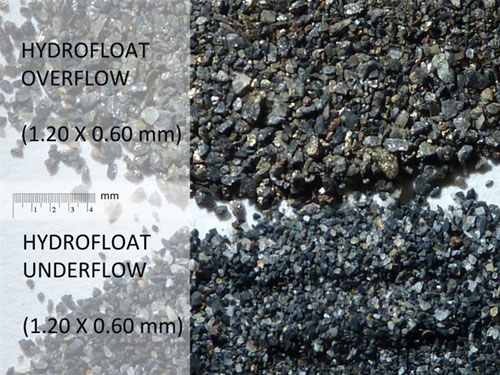

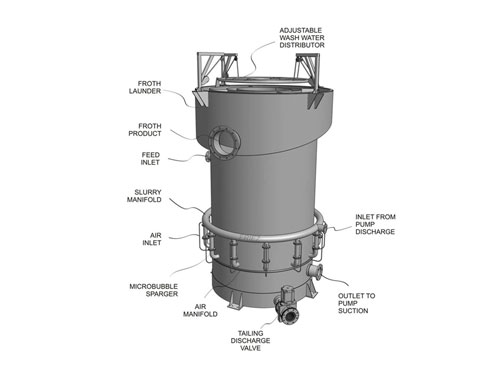

HydroFloat Coarse Particle Flotation

-

The HydroFloat recovers particles +2x coarser than conventional flotation cells, which allows for a shift in the economic optimum grind size, and in turn increases profitability and improves environmental sustainability of mining projects.

To meet society’s needs for critical mineral resources, the mining industry must develop projects that are socially accepted, environmentally sustainable, and economically profitable. One of the processes that have highest potential to overcome some of these challenges is Coarse Particle Flotation (CPF). Eriez has developed and patented the HydroFloat, an innovative fluidized-bed coarse particle flotation machine with demonstrated commercial success in base metals and industrial minerals applications for nearly 20 years.

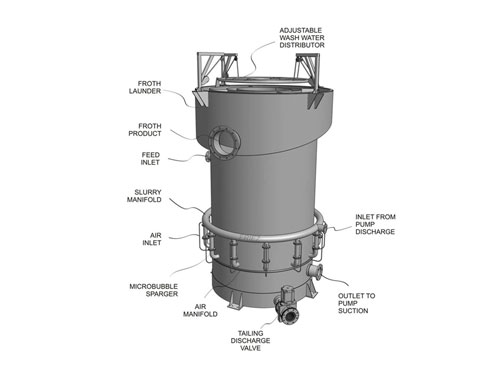

StackCell® High-Intensity Flotation

- Superior metallurgical performance contributing to a more profitable and sustainable mining operation.

StackCell flotation reduces conventional flotation residence time requirement by 75 to 85% and increases selective recovery of fine particles and slow floating minerals, which increases profitability and improves environmental sustainability of mining projects.

For mining companies that want to minimize environmental impacts of flotation circuits and maximize profitability, the StackCell offers reduced flotation circuit size and power consumption while delivering superior mineral recovery and concentrate grades.

Advantages

- Increase mill production and revenue

- Reduce carbon footprint and environmental impacts

- Increase project NPV

- Reduce CAPEX for greenfield projects and brownfield expansions

- Increase recovery of fine particles

- Increase concentrate grade

Eriez Column Flotation

-

Eriez has supplied more than 1,000 flotation columns throughout the world in mineral concentrating and purification applications that include iron ore, base-metals, gold, industrial minerals, fertilizers (phosphate and potash), energy, and specialty applications such as oil/water separation.

Eriez Flotation's Advantages in Columns include:- A large group of knowledgeable engineers throughout the world to design and support your application. This includes some with more than 30 years of experience in supplying column applications.

- Offering test-services. We operate a central test lab and test columns that can be brought to site that can be used to predict metallurgical performance and de-risk the installation.

- Provides a variety of column and sparging technologies so we can recommend and design the most appropriate equipment for the application. In some cases, we have optimized columns for particular mineral systems such as the PhosPro™ for phosphate, the K-Pro™ for potash, and the BitPro™ for bitumen.

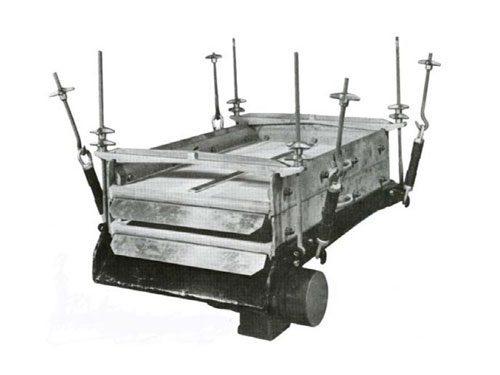

CrossFlow® Separator

-

Eriez CrossFlow Separator is a highly efficient hydraulic classifier for the separation of material based on particle size, shape and/or density. This technology can also be used for desliming, counter-current washing and acid neutralization of minerals.

The CrossFlow separates particles based on hindered-settling principles providing an economical and efficient means of classifying material such as silica and frac sands, mineral sands and industrial minerals.

Ores containing a mixture of high- and low-density components can also be upgraded based on their difference in specific gravity. Examples include iron ore, and heavy mineral with silica contamination and run-of-mine coal containing various ash-forming components such as rock and pyrite.

The hindered-settling environment creates the optimum conditions for efficient counter-current washing to rinse, clean, and neutralize ore prior to secondary unit operations.

Applications include:

- Sizing and Classification

- Density Separation and Concentration

- Washing and Neutralization of Minerals

RSP Distributor™

- The Rotating Slurry Powered Distributor provides reliable slurry distribution to multiple processing stages.

Slurry Distribution

The requirement to split a slurry stream to feed two or more parallel units - and to do it uniformly and reliably - has been a problem throughout the history of milling. A variety of gravity, pressurized and motorized distributors have tackled this problem with limited success. Gravity and pressure cans are notoriously unreliable - the accuracy of the feed split is always in question. And the distribution gets even worse when one or more outlets are taken off line. Motorized rotating distributors get the job done, but at the cost of high maintenance.

Benefits of the RSP include- Modest capital cost

- Very low maintenance cost VERY accurate feed split

- Reliable, trouble-free operation

- Slurry driven - no motors

- Unique internal launder provides

- Improved distribution when one or more outlets are off line

SlamJet™ Spargers

-

The Sparging Factor - Improving the operating efficiency of flotation columns, leach tanks and other processes that depend on the generation of fine gas bubbles

In mineral flotation applications, Eriez Flotation SlamJet sparging systems promote the attachment and recovery of hydrophobic particles through the generation of a fine bubble dispersion that is evenly distributed across the flotation column. Eriez Flotation sparging systems are designed to generate a large amount of bubbles at the optimum size for the given application. Specifically, they are designed to generate high rates of bubble surface area which guarantees a high probability of attachment and improved recoveries. In leaching and other hydrometallurgical applications, SlamJet; spargers improve the process kinetics of the vessel contents by ensuring a high rate of gas dissolution.

CavTube® Sparging

- The CavTube® design is based on hydrodynamic cavitation. This occurs when the pressure in a moving liquid is momentarily reduced below its vapor pressure, creating ultra-fine air or vapor-filled bubbles. These fine bubbles are carried by the flow to a region of higher pressure resulting in a bubble dispersion that resembles fine smoke. Cavitation and the shearing of additional gas ensure the generation of fine bubbles suitable for the recovery of both ultra-fine and coarser particles.

CavTubes are offered in a variety of materials-of-construction to provide a long wear life. Material selection is based on application specifics and includes polyurethane, ceramic, tungsten carbide and hardened steel.

Benefits:- Ensure a higher attachment probability... higher recovery of hydrophobic particles

- Produce higher recoveries for ultra-fine material... greater concentrate production Improve bubble/particle collision rates... lower reagent costs

- Have no direct impediments to flow... longer wear life with better materials of construction

Laboratory Testing

- Eriez Flotation can provide a complete and detailed analysis of most mineral processing applications. With laboratory equipment ranging from grinding mills to benchtop and column flotation cells, complex plant circuitry can be simulated and tested. Typical tests range from exploratory batch testing to the evaluation of multi-stage flotation circuits. With analytical capabilities, including a glass fluxer and an XRF (x-ray fluorescence), Eriez Flotation can quickly conduct in-house assays and improve turn-around time on testing.

Testing and Analysis includes:- Bench-top batch testing

- Batch milling (ball, rod)

- Continuous milling (ball, rod)

- Steady-state column flotation testing

- High and low gradient magnetic separation

- HydroFloat

- CrossFlow

- StackCell

Field Services

- These services include pilot-scale and production-scale demonstration testing of Eriez's flotation technologies, commissioning and start-up assistance, and optimization of existing flotation circuits. The key to successful on-site collaboration with customers is Eriez Flotation's team of over 25 degreed metallurgists and mineral processing engineers distributed strategically in key mining jurisdictions, including Australia, Brazil, Canada, Chile, China, Mexico, Peru, South Africa, and USA. Each local team specializes in flotation of key metals and minerals, and is supported by a team of corporate flotation experts providing additional field support to strategic customers and projects

On-site pilot-scale testing is often conducted by Eriez Flotation to assist customers with business case confirmation and risk mitigation for flotation expansion projects, particularly when considering new or innovative flotation technologies. The specific objectives of these test programs are generally to confirm metallurgical performance and design criteria for the proposed full-scale circuit, to investigate equipment operation and maintenance over an extended trial period, and to familiarize the customer with the technology. Eriez Flotationhas an extensive in-house inventory of modular pilot-scale flotation cells and auxiliary equipment designed for ease of transport, installation, and operation at customer sites. In addition, Eriez Flotation provides custom pilot-scale flotation equipment and complete pilot-scale flotation circuits to meet specific customer objectives and specifications

Industries

Equipment for the Aggregates Industry

- Eriez manufactures a range of quality products to meet the rugged demands of the aggregates industry. To reliably move materials and protect expensive equipment from costly damage caused by tramp metal, look no further than Eriez.

Metal Removal

Metal in your product can tear belts, damage crushers, and cause unnecessary downtime to processing equipment at your site.- Magnetic Pulleys

- Suspended Electromagnets

- Suspended Permanent Magnets - European Models

Metal Detection

Non-magnetic metals such as stainless steel, cobalt, aluminum and other materials found in mining bits must be removed to protect processing equipment. With Eriez Metalarm and 1200 Series Metal Detectors, you will be able to detect unwanted non-magnetic metals before they become a problem.- MetAlarm Metal Detectors

Vibratory Feeders, Conveyors & Screeners

Eriez' Heavy Duty electromagnetic and mechanical vibratory feeders are built to perform in the toughest applications. With the broadest feeder line in the industry, Eriez can help select the ideal feeder for your application.- Bin Vibrators

- Heavy Duty Feeders

- Light and Medium Duty Feeders

- Vibratory Controls

Equipment for the Chemical Industry

- Eriez provides a range of products to assist the chemical industry with its unique processing challenges, including protecting product purity and handling materials in the most efficient, economical and safe manner.

Magnetic Separation

Our line of magnetic separators effectively draw out fine tramp metal along critical points of production lines - both wet and dry.- Dry High Intensity Magnet

- Grate Magnets

- Magnetic Humps

- Plate Magnets

- Tube Magnets

Metal Detection

Our line of incredibly powerful Metal Detectors offer sensitivity and dependability in a design rugged enough to meet the harsh demands of the industry. They expertly detect ferrous and nonferrous metallics in a variety of bulk materials.- E-Z Tec 9000 Metal Detectors

- Xtreme Metal Detectors

Vibratory Screeners & Conveyors

Eriez offers a wide variety of vibratory feeders and conveyors designed to safely and efficiently move both chemical ingredients and finished products.- Bin Vibrators

- Heavy Duty Feeders

- Light and Medium Duty Feeders

- Vibratory Controls

- Vibratory Conveyors

- Vibratory Screeners

PolyMag® Additives

Eriez' PolyMag additives impart Metal Detectability, X-Ray Contrast and Magnetic Susceptibility into plastic moldings to prevent plastic contaminated food products from reaching the consumer.- PolyMag Plastic Additives

Equipment for the Coal Industry

-

Eriez is truly a one–stop resource with our wide range of products to assist in the processing of coal. No other source designs, manufactures and locally supports such an assortment of equipment to convey, clean and analyze coal.

Metal Removal & Magnetite Recovery

Metal in your product can tear belts, damage crushers, and cause unnecessary downtime to processing equipment at your site. Maximize magnetite recovery while operating with a minimum amount of wear and maintenance.- Magnetic Pulleys

- Wet Drum Separators

Metal Detection