- Offer Profile

- STOKKERMILL Recycling Machinery designs and manufacture specific machinery and equipment for the recycling industry and for the recovery of materials and industrial wastes, for the development and implementation of circular economy and energy transition processes. The excellent performances of the Stokkermill machinery permit a rapid recovery of the initial investment and the high quality standard support the value of the investment over time. The wide and articulated range of equipments makes it possible to respond effectively and flexibly to the requirements of the most qualified recycling companies.

RECYCLING PLANTS AND SEPARATION LINES

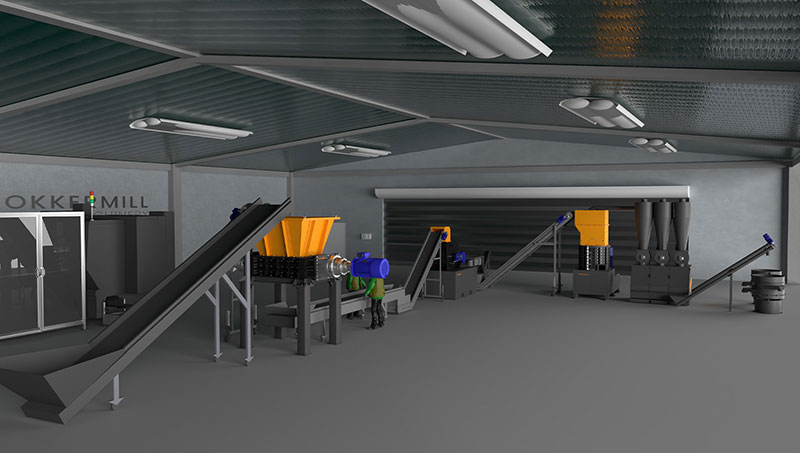

- Recycling plants and separation lines Stokkermill are designed and built for different types of materials. The recycling plants built by Stokkermill are turnkey solutions made on specific request of the end user and include customized solutions to achieve the customer's objectives. Stokkermill recycling plants are built according to criteria of rationality, efficiency and simplicity, however they contain modern and refined technological solutions. The recycling plants are equipped with a centralized control panel that allows the management of the individual machines to a single operator. The framework includes a system for diagnosing any anomalies and provision for remote assistance and connection to the company IT system.

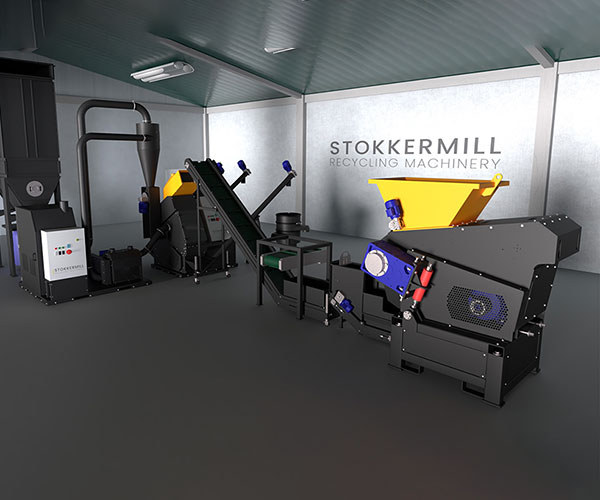

WEEE RECYCLING PLANTS - MINI LINE

-

WEEE recycling plants - Mini line designed for electrical and electronic e-waste and scrap WEEE

WEEE recycling plants, designed for E-waste and electrical scrap WEEE, allows the treatment of small and medium-sized electronic waste with a capacity of up to 300-500 kg/h at the inlet depending on the chosen configuration. MINI LINE WEEE allows the recovery of non-ferrous metals fraction, facilitating manual operations to make more profitable the operations of recycling of electrical and electronic waste. The MINI LINE WEEE has been designed for operators in the recycling industry who want to treat relatively small quantities of WEEE waste but understand the need to mechanize and automate some stages of the process. The MINI LINE WEEE allows to obtain a mix of metals separated from the ferrous fractions and from the plastic fractions. MINI LINE WEEE has been designed to allow the expansion of the system with additional refining and separating devices

WEEE SHREDDING PLANT FOR E-WASTE RECYCLING

-

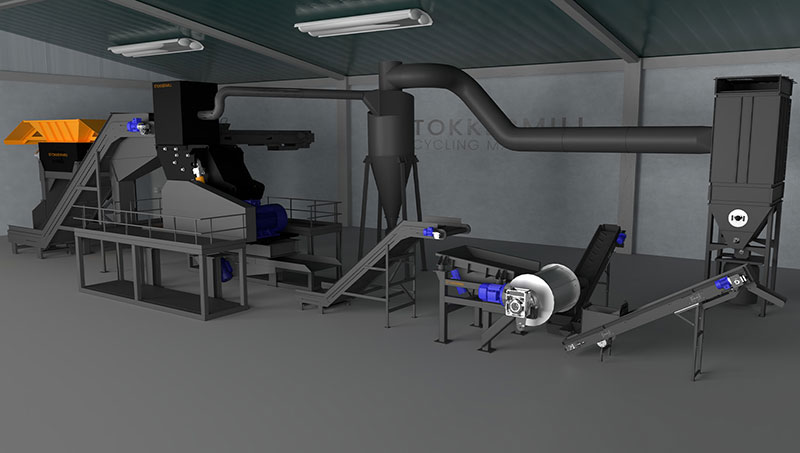

WEEE shredding plant for E-waste recycling allows the recovery and separation of metal fractions of electronic components of WEEE materials. WEEE separation line, able to treat the different parts of which the electronic materials are made with the aim of recovering the ferrous and non-ferrous metal fractions. Stokkermill’s well-established experience in refining and separating systems enables us to obtain homogeneous materials of high-quality purity. The production capacity of WEEE recycling lines varies according to the demands of the end user and the type of materials to be treated.

WEEE shredding plant for E-waste is generally divided into the following categories:

- large household appliances (refrigerators, freezers, washing machines, dishwashers, cooking appliances, electric heating/air-conditioning appliances)

- small household appliances (blenders, cleaning equipment, textile processing machines, time measuring equipment)

- computer and telecommunications equipment (computers, printers, copiers, telephones, and other equipment for transmitting sound, images, or other information)

- consumer equipment (video cameras, video recorders and musical instruments)

- lighting equipment and equipment

- electrical and electronic instruments (drills, saws, tools for screwing, nailing, painting, tools for gardening, etc.)

- toys and sports and leisure equipment (consoles, video games, sports equipment, etc.)

- medical devices

- monitoring and control instruments

- vending machines

PRINTED BOARDS RECYCLING PLANT

- Printed boards recycling plant, can reduce the size of the materials and to provide for the crushing of the materials aimed at separating the metal fraction from the plastic. The separation of the metal fraction allows to recover any ferrous parts, the aluminium fraction and a mix containing copper and other precious metals. The capacity of the recycling lines of the electronic cards varies according to the demands of the end user and the type of materials to be treated.

LCD SCREENS RECYCLING PLANT

- LCD screens recycling plant, allows you to recover the glass and TFT films present in LCD screens. Our system allows the aspiration of the fluorescent powders contained in the neon backlight lamps. To avoid dispersions in the environment or risks to the final operator caused by the dispersion of potentially hazardous substances, activities shall be carried out within isolated environments and, where necessary, connected to filtration systems generally of the type HELPA or ULPA. The LCD screen recycling line can handle up to 1,000 kg/h of LCD display.

SOLAR PANELS PV RECYCLING LINE

- Solar panels PV recycling line, allows you to recover the materials that make up the photovoltaic panel for scrapping. Photovoltaic panels recycling plants can recover about 97-98% of the total weight of a module. This is roughly equivalent to 15 kg of glass, about 1 kg of silicon powder, 2 kg of aluminium, 2,5 kg of plastic in addition to copper wiring. The Stokkermill photovoltaic panel recycling plant can separate the glass through delamination allowing the recovery of materials inside the panel. The recovered glass has a grain size between 1 and 3 mm. The production capacity of the photovoltaic panels recycling lines varies according to the demands of the end user and the type of materials to be treated.

ALUMINIUM SHREDDING PLANT

- Aluminium shredding plant is designed to refine the input material from inert fractions and ferrous metals. The recycling plants allow to obtain a high-quality aluminium proler allowing the delivery directly in the foundry avoiding further preparation activities. Aluminium scrap recycling plants improve economic performance. Aluminium scrap treatment plants are extremely flexible and versatile and allow to treat aluminium profiles, aluminium tins, and general aluminium scrap. Stokkermill can design and build turnkey plants according to the customer’s needs, carry out adjustments of existing plants or provide individual machinery for existing lines. Generally, the aluminium scrap refining lines consist of a primary shredder C or D series for the material reduction phases, a hammer mill to reach the desired size, from deferization systems and separation of inert fractions.

COPPER CABLE RECYCLING LINE

- Copper cable recycling line, for the treatment of copper and aluminium cables allow to treat high quantities of material obtaining an exceptional quality of the output product and the same technical and constructive excellence that characterizes the Stokkermill models. Specially designed to provide a complete recycling solution for the treatment of copper cables, aluminium cables, cables, and wiring, through a combination of technology: mill, air flow knives and vibrating table, and guarantee a high use of materials and a purity of 99.9%.

TONER CARTRIDGE RECYCLING PLANT

- Toner cartridge recycling plant allows you to recover plastics, metals and dust made up of pigments and plastic polymers. All components recovered during toner recycling activities are thus reused and regenerated. The recycling of toners requires attention and care regarding the handling of powders to avoid the risks of explosion caused by the particle size of the powders. The production capacity of the waste toner recycling lines varies according to the requests of the end user and the type of materials to be treated.

COFFEE CAPSULES RECYCLING PLANT

- Coffee capsules recycling plant, aims at the recovery of the plastic part, the metal fraction, generally consisting of aluminium foil and coffee powder reusable as fertilizer in agriculture. Coffee capsules are rapidly expanding in the markets requiring the recycling industry to adapt its production and recovery capacity. The production capacity of the coffee capsule recycling lines varies according to the requests of the end user and the type of materials to be treated.

AUTOMOTIVE ELV’S PARTS RECYCLING LINE

- Automotive ELV’s parts recycling line for electric motors, recycling of starters, the recycling of alternators and, more generally, the recycling of electric motors is becoming, day after day, one of the most interesting activities for the recycling of end-of-life vehicles. The increase of electrical and electronic components in motor vehicles makes the recovery and recycling of metals, in particular copper and aluminium more and more important. The recycling lines and plants built by Stokkermill can facilitate the recycling of electric motors, the recycling of alternators and the recycling of starting engines. The recycling lines are generally composed of a hammer mill, a delamination mill and magnetic separation systems, eddy current separation systems - Eddy Current - and a battery of densimetric tables. Downstream of the process it is possible to insert optical sorter that can improve the separation of metals. The recycling plants made by Stokkermill are designed to allow maximum flexibility and versatility of use. In other words, these are recycling lines that can operate on different materials, allowing an extremely rapid return on investment. The electric motor recycling lines are designed specifically for the needs of the end customer. Capacity, versatility, and flexibility are important elements that are agreed directly by the end customer with the manufacturer. The recycling lines and plants for electrical and electronic components are equipped with highly advanced self-diagnosis and remote assistance systems to minimize any downtime. Stokkermill recycling plants are designed and produced in Italy with the best components available on the international market, like Schneider or Siemens electronics, SKF bearings, Linde hydraulic "Rossi gearbox" gear motors. The meticulousness of the realization and the use of premium components allow Stokkermill to offer a guarantee of 24 months from the date of delivery or start-up. The installation and commissioning are made by Stokkermill approved and certified technicians. Please contact us for more information.

SEPARATION PLANT FOR METAL RECOVERY

- Separation plant for metal recovery, refining line made by Stokkermill Recycling Machinery are extremely versatile and flexible systems that can operate in different fields with the aim of separating metals of different types from plastics and inert. Metal refining plants can separate ferrous metals using magnetic separators of various types and with different coercive forces. Separators with superior coercive capacity can separate stainless steel fractions and provide for the separation of paramagnetic metals in general.

RECYCLING MACHINERY AND PLANTS

- Recycling Machinery is an SME based in north-eastern Italy that for over thirty years has been designing and manufacturing specific machinery and equipment for the recycling industry and for the recovery of materials and industrial wastes, for the development and implementation of circular economy and energy transition processes. The excellent performances of the Stokkermill machinery permit a rapid recovery of the initial investment and the high quality standard support the value of the investment over time. The wide and articulated range of equipments makes it possible to respond effectively and flexibly to the requirements of the most qualified recycling companies. Innovation and research, optimisation of the product and after-sales service have always been the keys to Stokkermill Recycling Machinery's success.

SINGLE SHAFT SHREDDERS

-

Stokkermill’s range of single-shaft industrial shredder for reducing industrial waste, ferrous and non-ferrous scrap includes 17 models divided into 4 series. All single-shaft shredders are equipped with a classifier screen of variable measure that allows to define the output size. The special design of the single shaft shredders with classifier screen allows to obtain the expected output size in the first step saving time and energy consumption.

Single-shaft industrial preshredders are suitable for processing: non-ferrous metals, copper cables, aluminum cables, iron and metal coils, plastic bins, mixed containers, composite materials, wood, paper, cardboard, industrial packaging, tires, radiators with light iron parts and much more.

Single Shaft Pre Shredder - INDUSTRIAL SHREDDERS

- The single-shaft pre shredder of the Stokkermill PS range, with hydraulic pusher, are available in three models of variable dimension and power with capacity from 200 kg/h to over 2,000 kg/h. The rotating blades of the PS primary shredder are reversible and made of wear-resistant alloy. The industrial pre-shredders are equipped with classifier screens of different diameters allowing to vary the output size in accordance with the user requirements. The efficient hopper opening system allows a quick replacement of the screens, making easy and simple the maintenance activities, the replacement and adjustment of the blades.

Single Shaft Shredder - INDUSTRIAL SHREDDERS

- Single shaft shredders CSR allow the grinding and the volumetric reduction of tenacious materials and electronic industrial waste and can be driven by electric or hydraulic power units. Single shaft shredders - CSR series can be connected to granulators for recycling cables and radiators of the TURBO and Multi-Flex Turbo Zig-Zag series or, alternatively, they can perform the function of the primary roughing machine to increase the productivity of already existing lines. The selection grids, available in different sizes, allow to obtain the required size at the first step. The electronically controlled hydraulic power box and rotation inversion system allow to optimize the production parameters according to the material to be treated.

Industrial Shredders fast - INDUSTRIAL SHREDDERS

- Industrial shredders fast of MFS series are extremely versatile machines that allow to check the size of the material in output thanks to the presence of the sorting grid; however, MFS can also operate without grating for roughing activities. Industrial shredder fast MFS can therefore be used both as industrial primary fast shredder for the first reduction of material (reinforced copper and aluminum cables with the presence of ferrous parts, vehicle tires, scrap of electrical and electronic equipment, vehicle parts, etc.), or for further refining of materials already treated (crushing waste, ASR – car fluff – Zurik – Zorba) destined for valorization.

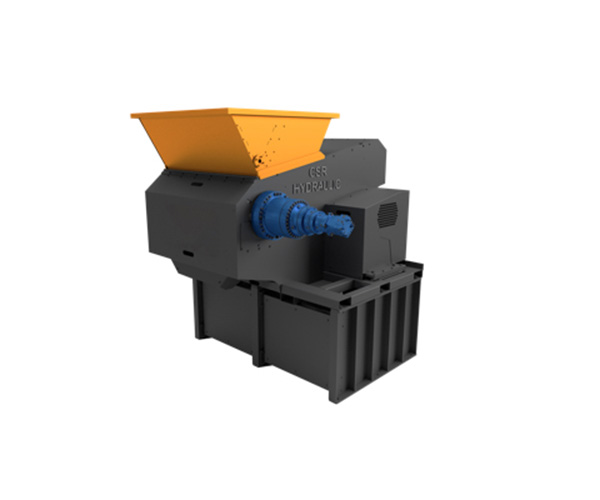

Single shaft shredder with hydraulic transmission - HYDRAULIC DRIVE

-

Single shaft shredder with hydraulic transmission, primary shredder of the Stokkermill "CSR Hydro" range do represent an excellent solution for the primary reduction and refining for industrial waste, electronic scrap, electric cables, bulky waste, ferrous scrap, and light metal scrap.

Technical characteristics:

• Rotor and pusher drawer driven by a hydraulic system

• Low rotor speed with automatic adjustment according to cutting force

• maximum energy efficiency and lower electricity consumption thanks to the ESEMS “E-Saving energy management system” that varies the electrical absorption according to the force required, drastically reducing energy consumption

• power control and management system

• PLC for the control of all plant peripherals

• Touch display for adjusting all machine parameters

• Remote control system via remote assistance

Primary shredders - HYDRAULIC DRIVE

-

Primary shredder single-shaft of the C series allow reducing of tough materials and are made with hydraulic transmission. The selection grids, available in different sizes, allow to obtain the desired size straightaway at the first step. The electronically controlled hydraulic power box and rotation inversion system allow to optimize the production parameters according to the material to be treated.

The field of use of the CS series hydraulic primary shredders is very wide:

metal profiles

tires (PFU)

aluminum waste of all types with ferrous parts

copper/aluminum radiators with ferrous parts

electric and electronic waste (WEEE) with the presence of ferrous parts

copper/aluminum electric cables with ferrous parts

armored cables in general

industrial waste

municipal solid waste (MSW)

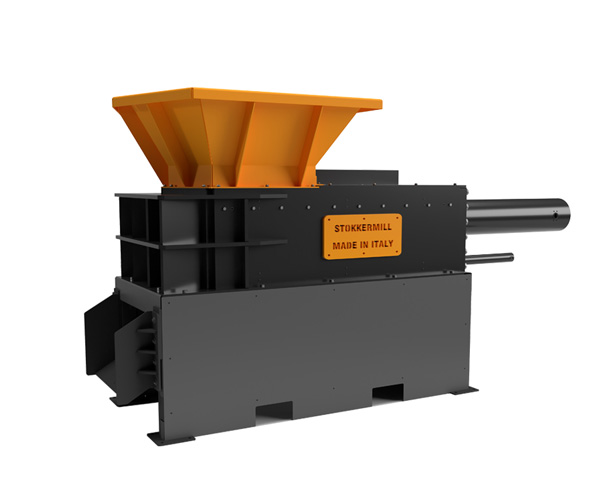

DOUBLE - TWO SHAFT SHREDDERS

-

Ferrous metal shredder, bulky scrap shredding of Stokkermill D series twin-shaft shredders with electric or hydraulic transmission are the ideal solution for the size reduction of bulky and tough waste materials such as industrial waste, electronic scrap, electrical cables, ferrous scrap and metal scrap. Double shaft industrial shredders is extremely varied with dimensions, capacities and powers suited to the different needs of the recycling industry. The twin-shaft primary shredders are made with the premium components available on the market to ensure the maximum reliability of the machines and the availability of spare parts in any country of use.

Metal scrap shredders double shaft equipped with SKF bearings, the gearbox of Rossi Spa and Reggiana Riduttori, Linde hydraulic components, Siemens electric motors, and Schneider Electric - Telemecanique automation. All the range of shredders is covered by 24 months warranty.

-

Industrial shredder primary

-

Industrial shredder twin shaft, electric or hydraulic shredders of the Stokkermill's range has been designed for proecessing many types of materials, in particular for the first volumetric reduction. The special design of the blades in the industrial shredder and the control of production parameters allow to control the size of the material in the output, although industrial double-shaft shredders are generally not equipped with a classifying grid. Extremely versatile and made for intensive use, the D series industrial primary shredders are the result of a cutting-edge project that aims to create efficient and versatile machines.

Metal scrap shredder

- Metal scrap shredder for ferrous scrap D-150 and D-200 metal shredders with hydraulic transmission are designed and manufactured for the primary reduction of ferrous scrap and metal scrap. These are extremely robust, versatile and high-performance machines characterised by a low rotation speed which allows to express exceptional torque values and guarantee high cutting capacity even in the presence of particularly tough materials.

FOUR SHAFT SHREDDERS

Four Shaft Shredders

- Industrial primary four shaft shredder, electric or hydraulic of the Stokkermill's range has been designed for the crushing of many types of materials and for the dimensional control at the exit thanks to the presence of interchangeable classifying grids. Industrial shredders are extremely versatile, made for intensive use, the shredders of the F series are the result of a cutting-edge project that aims to create efficient and versatile machines. The exclusive system of interchangeable shafts and the use of grids with anti-wear treatments has led to a drastic reduction of management costs and maintenance interventions.

ELECTRIC WIRING GRANULATORS COMPACT

-

Wiring granulators and shredders compact for treatment or recycling and copper cables. Recycling and separation of large and small diameter cables. Plastic / copper separation to obtain fine copper.

Shredders for electrical cables, industrial and automotive cables are an important resource for the recovery of conductive metals, especially copper. Stokkermill has a solid track record in electrical cable recycling with a range of specific equipment capable of handling copper cables.

Wire shredder for electrical cables

-

Wire shredder for electric cables K750 is the last model of the manufacturer Stokkermill Recycling Machinery in the segment of small solutions for the recycling of electrical cables and wires. Thanks to the accurate engineering research Stokkermill is able to offer a "small but great" machine at an affordable purchasing price with the lowest maintenance cost.

The E-waste shredder K750 is a plug-and-play machine: easy to be installed and ready to operate.

Metal output close to 100% purity

High quality components

Recovering of metal dust directly from the densimetric table

Low investment and fast ROI

24 months warranty

Wire Granulators

-

Wire granulator with external filtration system

Wire, cable granulators in our range, however, we've designed K-S series keeping the same quality like other Stokkermill Cable granulators. We kept the same size of densimetric separation table and the blade length. Usually, a small size cable granulator has a small separation table, therefore, it's very unique that Stokkermill small granulators K-S series have the generous size of the densimetric separation table and the mill.Features of the compact granulators K-S series:

The new entry-level compact wire granulator for copper and aluminium cables with external filtration system

High-purity output materials

High-grade components: Siemens motors, SKF bearings, Schneider components for the control panel

Recover copper and aluminum powder directly from densimetric separation table

Affordable price and minimal maintenance / 24 months warranty

Copper shredder

-

Copper shredder, cable granulators are available in two models and suitable for productions from 100 to 250 kg/h. Copper shredder are particularly robust and reliable and allow the finest shredding of copper, aluminum and copper-aluminum radiators thanks to the robust grinding mills with three rotating blades.

Copper shredders - Flexi granulators have anti static bar for the completely recovery of dust.FLEXI series features:

easy to use

reliability and robustness

silent performance thanks to the Silent Technology system

reduced maintenance times

low operating costs

no need for cooling

mills obtained from the processing of a single steel block without welded parts

Wire Copper Granulator

-

Wire copper granulators of the Stokkermill TURBO series are equipped with a cell refiner downstream of the blade grinding mill and are available in three models with outputs from 170 to 400 kg/h. The presence of the TURBO cell refiner allows the processing of small-diameter cables (including telephone cables and data cables or capillaries), without the need of changing the processing grid or perform costly manual activities to separate the material to be treated.

Features of the TURBO series:

possibility of treating small-diameter cables without the need for expensive sorting operations of the material to be treated

easy to use

reliability and robustness

silent performance thanks to the Silent Technology system

reduced maintenance times

low operating costs

do not require forced cooling

RECYCLING PLANTS AND SEPARATION LINES

- Machines and granulators for the recycling of copper and aluminium cables equipped with turbo units capable of handling mixed and extremely thin diameter cables. Zigzag separators allow the recovery of the heaviest copper fraction from the larger diameter cables. Thanks to the large working surface of the densiometric separation tables, a of purity close to 100% of high quality of copper granulate can be guaranteed.

Cable Granulator

-

Cable granulators TURBOFLEX series are equipped with a cell refiner downstream of the grinding mill and are available in two models, with outputs from 170 to 350 kg/h. The presence of the turbo cell refiner allows the processing of small-diameter cables (including telephone cables and data cables or capillaries) without changing the screen, perform costly manual activities to separate the material to be treated.

Copper cable recycling plant

- Copper cable recycling plant Multi-Flex Turbo Zig-Zag series are composed of three units: the grinding mill, the refining turbine, the densimetric table. The separate mill significantly increases the performance and flexibility of the granulator and reduces vibration phenomena by improving dissipation of the heat produced by grinding and facilitating routine maintenance.

Copper recycling line

-

Aluminium radiator shredding lines for copper, cables and aluminum radiators of the Entryline series allow to treat medium quantities of material, obtaining an exceptional quality of the output product and the same technical and constructive excellence of superior capacity models. They are intended for all professional operators who are looking for equipment that is not too expensive but of high quality, to solve the needs of a discontinuous market such as the current one, allowing a quick return on investment.

Electric cable shredding plants can be implemented with optional equipment to increase their production capacity when customer needs increase.

Copper recycling plant | TURBOFLEX Line

- Copper recycling plant Turboflex series, treatment plants for copper and aluminum cable granulation. Stokkermill manuftures machinery and equipment that carry out the granulation of copper and aluminum cables and separate the insulating coating consisting of PVC or rubber. The cable recycling plant is designed to ensure the highest quality of the output material. The Turboflex cable shredding plant is a complete system, echnically advanced, yet simple in operation and extremely reliable. The pre-grinder, placed at the beginning of the recycling line, performs an initial roughing of the material going though an interchangeable classifier screen. The conveyor belt connecting the pre-grinder to the Turboflex cable shredder, thanks to the magnetic system, provides separation of any ferrous fractions. The Turboflex granulator, equipped with a turbo reduction unit and, upon request, a ZigZag air separator, finely crushes and pulverizes the material. The densimetric separation table, placed at the end of the process, generates the separation of the metal fraction, consisting of copper or aluminum, from the plastic fraction. Further classification of the recycled material can be carried out with the help of circular screens with two or more stages. Recycling copper and aluminum cables promotes circular economy processes and contributes to reducing the extraction of new, valuable, natural resources.

Copper Cable Recycling Line - RECYCLING AND SEPARATION MACHINES

- Copper cable recycling line, for the treatment of copper and aluminium cables allow to treat high quantities of material obtaining an exceptional quality of the output product and the same technical and constructive excellence that characterizes the Stokkermill models. Specially designed to provide a complete recycling solution for the treatment of copper cables, aluminium cables, cables, and wiring, through a combination of technology: mill, air flow knives and vibrating table, and guarantee a high use of materials and a purity of 99.9%.

PCB, WEEE RECYCLING

PCB Boards recycling

- PCB Boards recycling Stokkermill has developed a series of compact machines (PCB Compact) and recycling lines (PCB LINE) which are easy to use and maintain, to enable the recycling of electrical cards, electronic boards, printed circuit boards and motherboards (PCB's – Printed Circuit Board).

HAMMER MILL SHREDDERS AND CRUSHERS

Hammer mill scrap shredder and crushers

- Hammer mill scrap shredder and crushers of HM series are designed for the volume reduction of heterogeneous scrap with the aim of dividing and recovering the ferrous and metallic fractions.

SOLUTIONS FOR SEPARATION

- Metal separation, scrap metal, stainless steel separation, solid urban waste, plastics. The separation of metals and the separation of scrap metal require different technologies depending on the composition of the incoming materials.

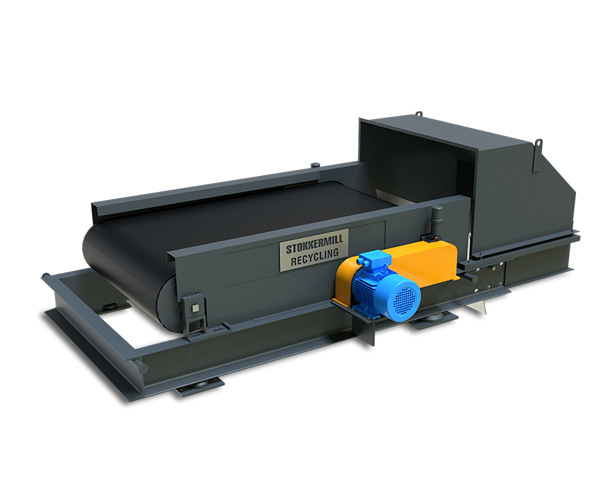

Separator non ferrous metal

-

Separator Non Ferrous Metals separation enable to recover the metal fraction (indicatively from 1 mm to 300 mm) sorting from the final stream in a recycling process. The Eddy Current separator have an extremely wide field of use and they can separate small non-ferrous metal particles. A magnetic rotor is placed inside a conveyor belt which, by turning at high speed, creates a considerable induced current field which moves the non-ferrous metal particles with low electrical conductivity away from the material flow.

Electrostatic separator

-

Electrostatic Separator for Separation Stokkermill E-Sorting provide the only known method of separating some important minerals and removing or recovering metals from certain recycled materials. Separation occurs by induced an electrostatic charge into a conductive dry-liberated particle. Electrostatic Separator Stokkermill E-soring are commonly used in conjunction with high-intensity magnetic separators.

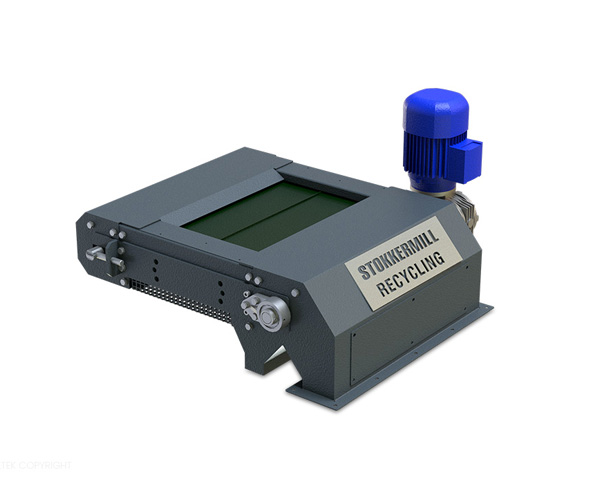

Densimetric separation table

- Densimetric separation tables the VT series allow the gravity dry separation of many materials with different relative specific weight. The densimetric sorting tables are equipped with systems for adjusting the vibration shaker frequency, table inclination, gravity and airflow pressure, guaranteeing high levels of purity of the separated materials. The Stokkermill shaker tables can be supplied with a pneumatic conveying system, cyclone and dosing starter valve and process dust suction filter.

Separator for Teck cable

- Separator for Teck cable shredding and separating of TECK series: Separation tables have been designed specifically for recycling TECK cables consisting of an internal section, made of copper, and an external protection generally made of aluminium. The separation tables of the TECK series allow extremely high levels of separation even between metals or materials with similar specific gravity thanks to the vibration frequency regulation systems, the angle of the table and the pressure of the air flow. TECK series separation tables can be used separately to improve the quality of the outgoing material of existing recycling plants or are the natural complement to the recycling plants and lines designed and built by Stokkermill.

Metal densimetric separator

-

Metal densimetric separator with multiple tables are positioned at the end of a refining line to separate the metal streams with particle sizes smaller than 5 mm coming from blade mill granulators, turbo units, delamination mills or similar refining systems. Densimetric sorting tables can be loaded with conveyor belts, screw conveyors or pneumatic systems.

The metal densimetric sorters with multiple outputs are the natural evolution of VT series of separation tables. The system consists of a minimum of 4 outputs up to a maximum of 8 outputs. The dry sorters are manufactured in accordance with the end-user's requirements in terms of capacity and number of outputs.

Stainless Steel High Intensity Magnetic Sorter

- The Staniless Steel Sorters are used for the automatic separation of magnetic and paramagnetic materials inside fine and grainy products. The peculiar configuration of the machine integrated magnetic pulley allows to reach a high intensity magnetic field (11000 - 15000 Gauss) chosen according to the grain size of the material to treat. The conveyor belt equipped device has to be fed with vibrating tables to allow an homogeneous controlled-layer feeding of the product. The peculiar structure of the support frame simplify the replacement of the belt. The compact structure of the machine allows an easy installation as an independent unit in already working plants.

Magnetic belt separator

- Magnetic belt separator for separation of magnetic ferrous metals, Stokkermill Overbelt electromagnetic separator, placed on the conveyor belts, performs a precise and efficient separation of the magnetic ferrous metals present in the inerts and in the non-ferrous metals.

Stainless steel Separator inox

- Stailnless Steel Separator inox Stokkermill SS100 is able to separate stainless steel particles from pre-treated materials, particularly in the recycling and valorization of electrical and electronic materials (WEEE), car fluff (ASR), Zurik and Zorba and crushing residues. The SS100 Stailnless Steel Separator is also used in the field of plastic recycling and regeneration, where it is very important to eliminate metal and ferrous impurities to safeguard the extrusion and molding processes. The SS100 is available in different sizes and magnetic field strengths and can be cascade-configured where extremely high output purity standards are required.

Zig Zag Aeraulic Separators

- The Zig-Zag Air Separators of the Stokkermill ZZ series arise from the need to remove the light part of heterogeneous materials through a flow of air in countercurrent, inside a zig-zag duct. They are generally installed after a crushing or grinding process to improve the quality of the output product. They are particularly suitable for the cleaning of crushing residues (ASR, car fluff, Zurik, Zorba), for the separation of the heavy copper and aluminum fraction in the recycling processes of the cables and in all the activities that require the separation of light parts.

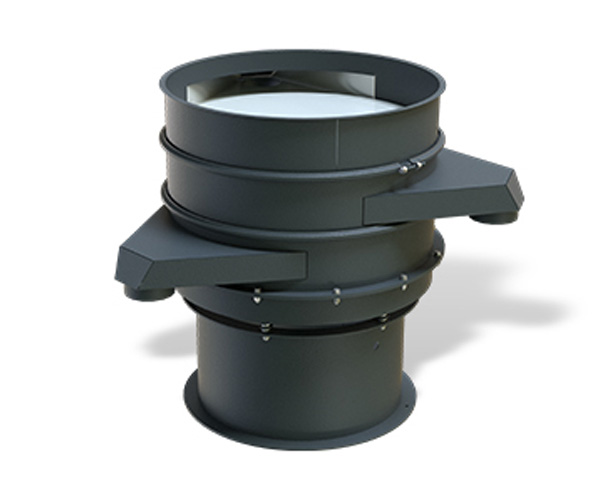

Circular vibrating sieve

- Circular vibrating sieve separators VB are created as a response to the need of improving the quality and homogeneity of the products involved in the recovery, recycling and separation operations. The VB circular vibrating separator allow to sieve, classify, de-dust and filter a vast range of materials.

AUXILIARY EQUIPMENT

Pneumatic wire cutters

-

Pneumatic wire cutters for quick and precise cuts of electric cables and wires. The pneumatic cutters Stokkermill CableChop is developed and tested for cutting electrical cables and allows quick and precise cuts of electrical cables in sections or hanks. CableChop is a professional, robust and reliable equipment, with reduced dimensions and weight to be easily and comfortably used by the operator, ensuring quick and easy cleaning and treatment of the cable. The CableChop blades are made of alloy steel, ensuring resistance to shocks and usury of the cutting profile and have the blade opening of 50 mm.

Dust filtration systems

-

Dust filtration systems, bag filters offer a complete range of solutions for the dedusting of industrial processes, helping to improve air quality and to increase the production efficiency of the plants.

They can be equipped with a continuously cleaning system based on the inversion of compressed air, whose operation is programmed by a control panel with logic units according to the characteristics of the process and the dust to be treated.

Refiner cell turbo

- Refiners turbo Stokkermill cell refiners allow to refine materials by impact and friction. The system is based on a system of blades that rotate at high speed, directing the materials towards the armored walls, crushing them in microparticles. The Turbo T Stokkermill line of refiners consists of 4 basic models, from two to five stages, with powers from 25 to over 200 kw and variable speed due to the inverter. Refiner systems with larger cells can be produced on specific customer request. Turbo refiners can be used effectively for the processing of a wide range of metallic and plastic materials, in the food industry, in the processing of chemical compounds, minerals, etc.

Wire Cable Stripper

- Wire, cable stripper of Stokkermill systems quickly remove the insulation from the metal part in copper or aluminum cables. Versatile cable stripper with double cutting system

- The ST33100 cable stripper is an extremely versatile model. Combine a double cutting system. The first with blade-drive for non-rigid cables and diameters from 5 to 30 mm where the double incision of the insulation is not necessary; the second consists of two blades which allow making a double incision on copper cables and aluminium cables with rigid insulation and diameters between 30 and 60 mm.

Industrial dosing system

-

Industrial dosing system Stokkermill FD doser-series are used to improve the integration between two pieces of equipment serially connected by one or more conveyor bands. The hopper, made in variable sizes, depending on the capacity of the production line, retains the possible surplus material coming from the upstream process, and release it at the right time according to times and methods managed by the electronic control system.The dosers allow the line to work with linearity, always providing the downstream equipment the right amount of material.

Industrial conveyor belts

- Industrial conveyor belts for material handling, Stokkermill produces different types of conveyor belts in various sizes and configurations. The standard tapes are made by using aluminum profiles that allow to create light, still rigid and robust structures. Generally, the main structure is equipped with a horizontal part that functions as a container for the materials. The system rests on a pilot rotating frame that allows easy movement of the unit and a height adjustment of about 30-40 cm (depending on the model), in order to perfectly adapt to the needs of the final user.

E-MOTORCHOP FOR ELECTRIC MOTORS RECYCLING

Electric motors shredders

- E-scrap Hammer Mill industrial shredder HM of Stokkermill's range are systems for reducing the size of incoming materials, in order to allow subsequent separation and cleaning operations with the aim of maximizing the commercial value of the output materials. E-scrap Hammer Mills are especially suitable for processing electric motors, refrigerator compressors, meatballs, alternators and metals refining. Stokkermill designs and manufactures small and medium sized hammer mills that are characterized by their robustness and simplicity during maintenance operations thanks to the hydraulic opening system of the crushing and rotor lifting chamber or the replacement of the grading grid. The simple construction and the use of high quality materials guarantee the durability and reliability of the Stokkermill hammer mills for electric motor recycling. E-scrap Hammer Mill industrial electric shredders can be equipped with an inverter to optimize the rotation speed according to the material to be processed; a particular system for anchoring the crusher to the base allows vibration reduction. A safety system allows the automatic ejection of any foreign bodies, avoiding damage to the rotor and the crushing chamber.

AUTOMOTIVE ENGINE PRESS

Engines crusher

- Engine crusher for aluminium engines and gearboxes: The P01 automotive engines crushing machine is designed and manufactured by Stokkermill Recycling, for the recovery of ferrous metals and the aluminium fraction of gearboxes, engines, and transmissions coming from the end-of-life vehicles (ELVs). Crushing and subsequent separation, carried out with a magnetic drum separator, allow to obtain ready materials for the downstream processes. The robustness and reliability of the crushing presses P01 are guaranteed by a steel structure with a thickness of 60 mm with an anti-wear coating in Hardox. Welding of the P01 endothermic motor press is performed automatically with a robotic arm. The total weight of the crushing press P01 exceeds 10Ton.

SHREDDING ELECTRICS VERTICAL MILL

Shredder electric scrap

- Shredder electronic scrap, vertical delamination turbine is designed to reduce the size of the materials in particle sizes by a few mm in order to be treated into the final separation which is dry densimetric separation tables or equivalent separation systems. The delamination mill can be used as an alternative to the traditional blade mill where the volumes of the incoming material influenced and it in terms of quantity and physical characteristics. The vertical mill introduces some advantages over the blade mill: it can also operate in the presence of residues of ferrous or stainless steel materials and requires less adjustment of the blades.

REFINING GRANULATORS

Blade granulators

- Blade granulators, secondary shredders of the Stokkermill ML series are used for the treatment of plastic waste, non-ferrous metals, heterogeneous materials and allow to obtain a high refinement in the recycling processes of materials with the use of interchangeable classifying grids. The Stokkermill ML mills are made from solid processing, avoiding the use of welds. Stokkermill granulators can be supplied with a dust extraction and filtration system produced during the grinding phase, a pneumatic conveying system, a cyclone and metering valve.

OPTICAL SELECTOR

- Optical selector for mixed materials, completes the range of recycling machines and equipment, Stokkermill has developed a series of optical separators that allow you to select the metal fractions according to the color and size of the materials involved in the recovery and recycling activity. Optical separators can be integrated into electrical and electronic waste recycling lines - WEEE or wherever high quality is required in the separation process. The OS optical separators are able to distinguish millions of color shades, allowing the separation of metals of different types with dimensions between 2 mm and 8 mm. The optical sorters are built with detection systems from one to six channels according to the separation needs of the customer and the material to be treated.

OS100 - Optical sorter

OS200 - Optical selector

OS300 - Optical separator

OS400 - Optical separator

COMPACTING PRESSES

Vertical Bailing Presses

- Stokkermill VP vertical baling press compactors are ideal for the recycling industry, transformation and service activities. They are solutions to reduce the volume of waste material such as paper, cardboard, plastics, various packaging, PE and PET bottles. Stokkermill VP vertical bailing press compactors are equipped with a bale binding and ejection system and can be equipped with an automatic machining cycle.