- Offer Profile

-

MAKING MORE OF ENERGY.

As the leading manufacturer of the original equipment for exhaust heat exchangers and a specialist for industrial waste heating solutions BOMAT is your first point of contact in the topic of condensing technology. The unique, patented ceramic technology is the result of many years of pioneering work. Our success is based on continuous innovation.

BOMAT Profitherm Modular - CHP Industry Series

BOMAT Profitherm Modular

-

Flue gas heaters of the next generation in a modular design.

BOMAT invests in efficiency and quality.

Highlights- Suitable for operation with fuel oil, natural gas, biogas, sewer gas and landfill gas

- Up or down-sizing: exactly as you require

- Pipe sections individually selectable

- Easy to clean due to slide-in heater bank

- High heat recovery yield

- Low pressure drop on the flue gas side and fully corrosion-resistant

- Short payback periods

References - CHP (natural gas)

TETEC AG, Reutlingen

-

Utilisation of condensing technology in a Buderus natural gas CHP unit

The BOMAT 02-GG-1032-MT-4-9-3 exhaust gas heat exchanger is installed as a condensing heat exchanger downstream of a Buderus Loganova EN 70 CHP unit. The heat is supplied to the heating system for return temperature raising.

UTILISATION OF CONDENSING TECHNOLOGY IN A BUDERUS NATURAL GAS CHP UNIT

- Heat source: Buderus Loganova EN 70

- Fuel: Natural gas

- Exhaust gas heat exchanger: 02-GG-1032-MT-4-9-3 (year of manufacture: 2018)

- Exhaust gas temperature: approx. 110°C (upstream of HE) → approx. 56°C (downstream of HE)

- Coolant temperature: approx. 47°C (upstream of HE) → approx. 52°C (downstream of HE)

- Heat recovery per year: approx. 136,000 kWh

- CO2 reduction per year: approx. 27,200 kg

- Plant manufacturer: Wiegel Gebäudetechnik GmbH, Albert-Ruckdeschel-Straße 11, 95326 Kulmbach, Germany

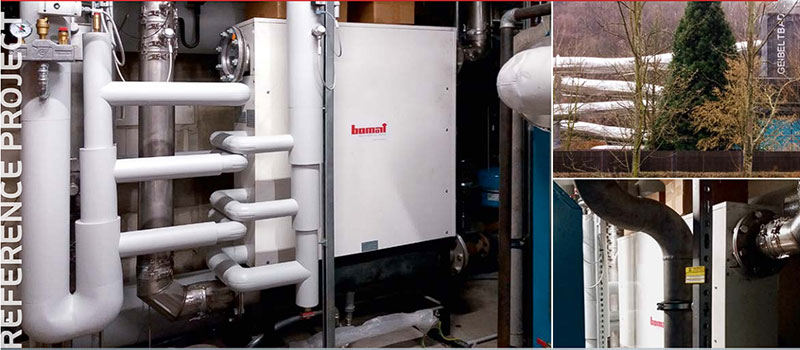

Geibeltbad Pirna, Pirna

-

Utilisation of condensing technology in a Buderus natural gas CHP unit

The BOMAT 03-GG-1032-MT-4-9-3 exhaust gas heat exchanger is installed as a condensing heat exchanger downstream of a Buderus Loganova EN 140 CHP unit. The heat is supplied to the heating system for return temperature raising.

- Heat source:Buderus Loganova EN 140

- Fuel: Natural gas

- Exhaust gas heat exchanger: 03-GG-1032-MT-4-9-3 (year of manufacture: 2017)

- Exhaust gas temperature: approx. 110°C (upstream of HE) → approx. 55°C (downstream of HE)

- Coolant temperature:approx. 43°C (upstream of HE) → approx. 48°C (downstream of HE)

- Heat recovery per year:approx. 360,000 kWh

- CO2 reduction per year:approx. 72,000 kg

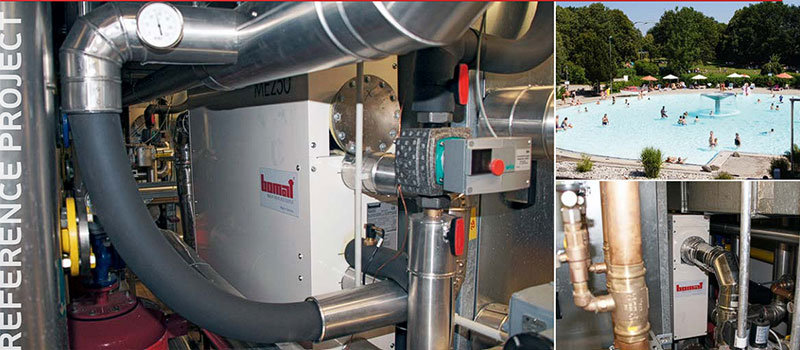

BADRIA, swimming pool, sports and leisure centre, Wasserburg am Inn

-

Natural gas CHP unit utilising condensing technology

Two Hereus ME250 exhaust gas heat exchangers (02-GG-1032-MT-4-9-3) are installed downstream of two Move MP250 CHP units to act as condensing heat exchangers. The heat recovered is used to preheat pool water.

- Heat generator: 2 x Move MP 250 CHP units

- Fuel: Natural gas

- Exhaust gas heat exchanger: 2 x Hereus ME 250 (02-GG-1032-MT-4-9-3) (year of manufacture: 2014)

- Exhaust gas temperature: approx. 120 °C (upstream of HE) → approx. 65 °C (downstream of HE)

- Coolant temperature: approx. 40 °C (upstream of HE) → approx. 50 °C (downstream of HE)

- Heat recovery per year: approx. 420,000 kWh (for both CHP units)

- CO2 reduction per year: approx. 84,000 kg (for both CHP units)

- Plant manufacturer: HAMO-KWK GmbH, Pfarrer-Huber-Ring 10, 83620 Feldkirchen-Westerham, Germany

Schlossbergkellerei GmbH, Althengstett, Germany

-

Sokratherm CHP unit utilising condensing technology

As a condensing heat exchanger, a BOMAT 01-GG-1522-NT-4-K-6 feeds the heat contained in the flue gas to the heating system, via a buffer cylinder system.

- Heat generator: Sokratherm GG50 CHP unit

- Fuel: Natural gas

- Exhaust gas heat exchanger: 01-GG-1522-NT-4-K-6 (year of manufacture: 2013)

- Exhaust gas temperature: approx. 160 °C (upstream of HE) → approx. 75 °C (downstream of HE)

- Coolant temperature: approx. 40 °C (upstream of HE) → approx. 55 °C (downstream of HE)

- Heat recovery per year: approx. 48,000 kWh

- CO2 reduction per year: approx. 9,600 kg

- Plant manufacturer: Messerschmid GmbH, Im Breitenfeld 20, 79848 Bonndorf im Schwarzwald, Germany

References - Biogas/Sewer gas

Götz Bioenergie GmbH & Co. KG, Markt Indersdorf

-

Biogas CHP unit utilising condensing technology

At the “Rieder Strasse” satellite site, the residual heat from the exhaust gas of a Hagl CHP unit is utilised by means of a BOMAT exhaust gas heat exchanger cascade. The two BOMAT 03-KK-1064-MT-4-9-6 exhaust gas heat exchangers from the modular Profitherm series are installed in the bypass on the exhaust gas side. The extracted heat is fed into the heating system via a return temperature raising facility.

- Heat generator: Hagl BIOGAS BHKW 400 kW

- Fuel: Biogas

- Exhaust gas heat exchanger: 2 x 03-KK-1064-MT-4-9-6 (year of manufacture: 2022)

- Exhaust gas temperature: approx. 180°C (upstream of HE) → approx. 75°C (downstream of HE)

- Coolant temperature: approx. 65°C (upstr. of HE) → approx. 73°C (downstr. of HE)

- Heat recovery per year: approx. 300,000 kWh

- CO2 reduction per year: approx. 60,000 kg

- Plant manufacturer: Edelstahl Huber, Gottlieb-Daimler-Straße 10-12, 86807 Buchloe

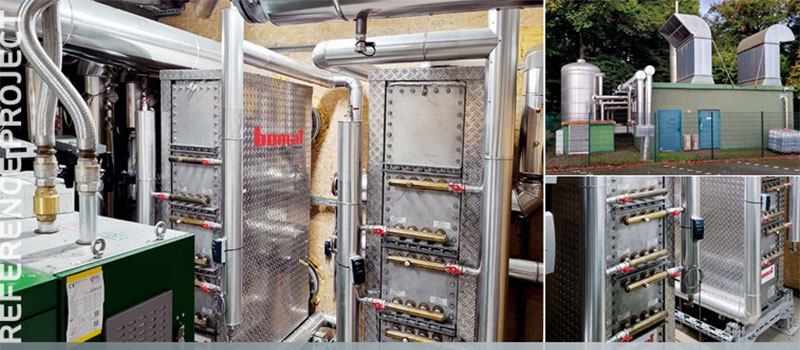

Bio-Strom-Kortenberken GmbH & Co. KG, Wietmarschen

-

Exhaust gas heat recovery in a biogas CHP unit

At the “Hauptstrasse 63” satellite site, the residual heat from the exhaust gas of a flexible CHP unit (Jenbacher JMS 412) is utilised by means of a BOMAT exhaust gas heat exchanger cascade. The three BOMAT 03-KK-1064- MT-4-9-6 exhaust gas heat exchangers from the modular Profitherm series are installed in the bypass on the exhaust gas side. An exhaust gas fan draws the exhaust gases from the chimney through the heat exchanger. The extracted heat is fed into the heating system via a return temperature raising facility.

- Heat generator: Jenbacher BHKW JMS 412 B25, 901 kWel.

- Fuel: Biogas

- Exhaust gas heat exchanger: 3 x 03-KK-1064-MT-4-9-6 (year of manufacture: 2022)

- Exhaust gas temperature: approx. 180°C (upstream of HE) → approx. 70°C (downstream of HE)

- Coolant temperature: approx. 60°C (upstream of HE) → approx. 66°C (downstream of HE)

- Heat recovery per year: approx. 390,000 kWh

- CO2 reduction per year: approx. 78,000 kg

- Plant manufacturer: BioBG GmbH, Webers Flach 1, 26655 Ocholt

Rottmar Agrartechnik GmbH, Leutkirch

-

Exhaust gas heat recovery in a biogas CHP unit

The BOMAT 03-KK-1064-MT-4-9-6 exhaust gas heat exchanger from the modular Profitherm series is installed in the bypass on the exhaust gas side. The extracted heat is fed into the heating system via a return temperature raising facility.

- Heat generator: Jenbacher BHKW JMS 412 GS, 889 kWel.

- Fuel: Biogas

- Exhaust gas heat exchanger: 03-KK-1064-MT-4-9-6 (year of manufacture: 2022)

- Exhaust gas temperature: approx. 200°C (upstream of HE) → approx. 66°C (downstream of HE)

- Coolant temperature: approx. 60°C (upstr. of HE) → approx. 64°C (downstr. of HE)

- Heat recovery per year: approx. 160,000 kWh

- CO2 reduction per year: approx. 32,000 kg

bioconstruct GmbH, Melle (Waldbach)

-

Exhaust gas heat recovery in a biogas CHP unit

At the "Waldbach - Riemsloh" satellite site, the residual heat from the exhaust gas of a Bayern CHP plant is utilised. The two BOMAT 03-KK-1064-MT-4-9-6 exhaust gas heat exchangers from the modular Profitherm series are installed in the bypass on the exhaust gas side. The extracted heat is fed into a buffer cylinder.

- Heat generator: Bayern-BHKW, 530 kW el.

- Fuel: Biogas

- Exhaust gas heat exchanger: 2x 03-KK-1064-MT-4-9-6 (year of manufacture: 2021)

- Exhaust gas temperature: approx. 180°C (upstream of HE) → approx. 70°C (downstream of HE)

- Coolant temperature: approx. 60°C (upstr. of HE) → approx. 72°C (downstr. of HE)

- Heat recovery per year: approx. 470,000 kWh

- CO2 reduction per year: approx. 94,000 kg

- Plant manufacturer: bioconstruct GmbH

References - Industry

puren GmbH, Obermarchtal

-

Waste heat utilization on a thermal oil boiler

The Bomat AWR 03M1064 is installed in the bypass on the flue gas side. The flue gases from the chimney are fed to the Bomat flue gas heat exchanger via a fan. The thermal energy it contains is made available to the heating system via a large buffer tank.

- Heat generator: Thermal oil boiler 1250 kW

- Fuel: Natural gas

- Exhaust gas heat exchanger: : AWR 03M1064 (year of manufacture: 2024)

- Exhaust gas temperature: approx. 170°C (upstream of HE) → approx. 75°C (downstream of HE)

- Coolant temperature: approx. 55°C (upstream of HE) → approx. 70°C (downstream of HE)

- Heat recovery per year: approx. 180,000 kWh

- CO2 reduction per year: approx. 36,000 kg

Aluminium melting furnaces, Metallguss Brinschwitz GmbH, Rastatt

-

Utilising waste heat from aluminium melting furnaces

Exhaust gas generated by the aluminium melting furnaces is fed into a BOMAT 02-VG-1072-HT-8-9-3 high temperature exhaust gas heat exchanger via an exhaust gas fan. The heat contained therein is then supplied to the heating system via a 25,000 litre buffer cylinder.

- Heat generator: 6 melting furnaces with a total output of approx. 300 kW

- Fuel: Natural gas

- Exhaust gas heat exchanger: 02-VG-1072-HT-8-9-3 (year of manufacture: 2016)

- Exhaust gas temperature: approx. 500 °C (upstream of HE) → approx. 75 °C (downstream of HE)

- Coolant temperature: approx. 50 °C (upstream of HE) → approx. 70 °C (downstream of HE)

- Heat recovery per year: approx. 170,000 kWh

- CO2 reduction per year: approx. 34,000 kg

- Plant manufacturer: Gerold Weber Solartechnik GmbH, Gerberstrasse 11, 77855 Achern, Germany

Qualitätstrocknung Nordbayern e.G, Wechingen

-

Combustion air preheating in a drying system

The heat generated by a biogas CHP unit is routed to the combustion air via a BOMAT special heat exchanger. The installed fan takes in the air to be used for drying and routes this to the burner as combustion air via the Bomat heat exchanger. The heat exchanger is designed so that it can be opened fully on one side for cleaning purposes.

- Heat generator: heating water – produced by a biogas CHP unit

- Fuel: Biogas

- Exhaust gas heat exchanger: special unit (year of manufacture: 2015)

- Exhaust gas temperature: approx. 95 °C (upstream of HE) → approx. 65 °C (downstream of HE)

- Coolant temperature: approx. 45 °C (upstream of HE) → approx. 70 °C (downstream of HE)

- Heat recovery per year: approx. 250,000 kWh

- CO2 reduction per year: approx. 50,000 kg

Thannhauser Asphalt GmbH & Co. KG, Fremdingen

-

Utilising waste heat from an asphalt mixing plant

A Bomat 02-GG-1064-MT-4-9-3 is installed in the bypass on the exhaust gas side. A fan is used to route the exhaust gas from the chimney at the asphalt mixing plant to the Bomat exhaust gas heat exchanger. The thermal energy it contains is supplied to the underfloor heating system to preheat the mix.

- Heat generator: Asphalt mixing plant

- Fuel: Natural gas

- Exhaust gas heat exchanger: 02-GG-1064-MT-4-9-3 (year of manufacture: 2015)

- Exhaust gas temperature: approx. 110 °C (upstream of HE) → approx. 45 °C (downstream of HE)

- Coolant temperature: approx. 25 °C (upstream of HE) → approx. 35 °C (downstream of HE)

- Heat recovery per year: approx. 80,000 kWh

- CO2 reduction per year: approx. 40,000 kg

- Plant manufacturer: FRANK Energie- und Gebäudetechnik, Emil-Eigner-Str. 7, 86720 Nördlingen, Germany