- Offer Profile

-

The head office of enkotherm GmbH, one of the leading manufacturers of custom-designed "Made in Germany" heat exchangers for CHP applications, is located in Merkendorf, Germany.

Our products are used in heat production and efficiency enhancement of modern gas-fired power plants, which play an important role in the current and future energy mix. They can also be used for gas processing, for example in biogas and sewage gas plants and for many other applications.

Using our heat exchangers avoids unnecessary resource consumption in energy generation processes and makes an important contribution to CO2 reduction and climate protection.

enkotherm supplies exhaust gas heat exchangers in the CHP output range of approx. 50 kW to 4500 kW and develops solutions for gas processing of approx. 50 Nm³/h to 10,000 Nm³/h.

Exhaust Gas Heat Exchangers

-

Our exhaust gas heat exchangers are primarily used in combined heat and power (CHP) plants. Combined heat and power plants produce both heat and electricity, making them particularly energy efficient in comparison to other technologies. Thus CHP plants also play an important role in the future energy mix.

In an exhaust gas heat exchanger, the hot exhaust gas from the CHP engines or CHP gas turbines is cooled, in the process heating water, a water-glycol mixture or thermal oil. This thermal energy can be used in a local or district heating system or for other industrial purposes.

The maximum possible cooling of the exhaust gas depends on the fuel gas used in the respective CHP plant. If it is possible to ensure a high fuel quality, then an additional efficiency increase can be realized by using condensing technology.

Since our exhaust gas heat exchangers are designed and constructed on a project-specific basis, we can offer highly customized solutions and thus an ideal match for the technical and structural framework conditions. The most common designs are shown below.

Applications:

- Natural gas

- Biogas

- Sewage gas

- Landfill gas

- Mine gas

- Wood gas

- Hydrogen

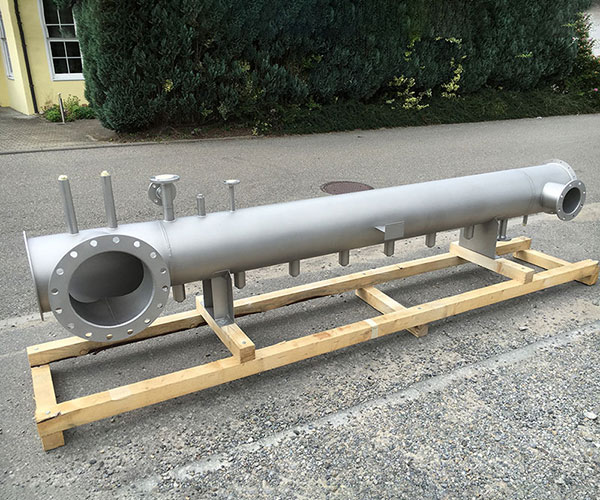

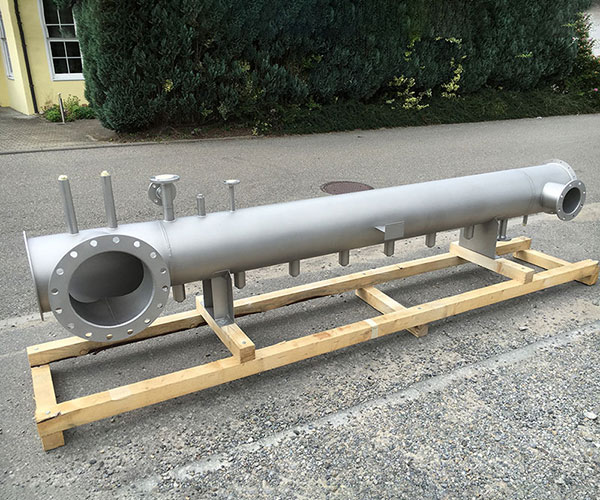

Horizontal

-

The standard design, which is used for most of our heat exchangers. The exhaust gas connections can be implemented radially or axially.

It is also possible to provide the heat exchanger without exhaust gas chambers or with flange-mounted exhaust gas chambers.

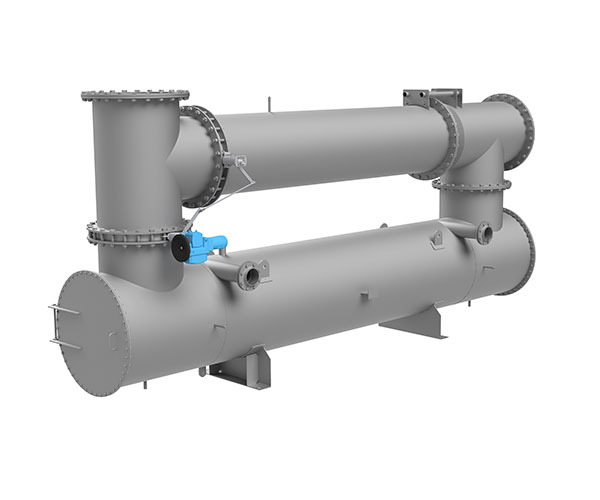

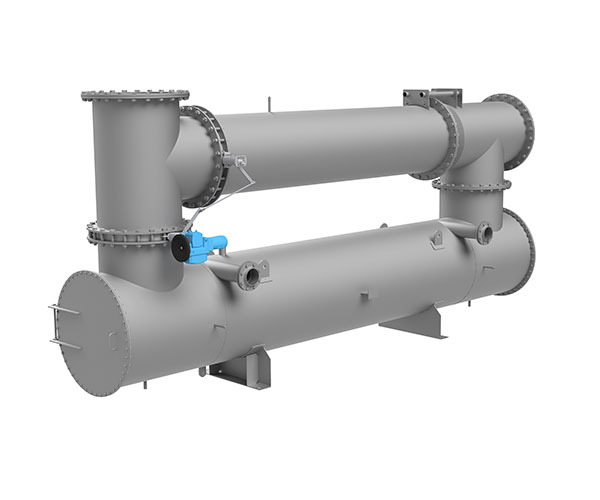

Bypass

-

A bypass can be used to decouple the heat exchanger whenever the thermal output isn't needed. The bypass is typically located above the heat exchanger, but can also be mounted on the side.

The bypass flaps can be equipped with electric or pneumatic actuators and/or can be operated manually. We also supply separate bypass T-connectors.

Catalyst Chamber

-

In this design a catalytic converter can be installed into the heat exchanger inlet chamber. This is often required for applications in which oxidisation catalysts are required for emissions reduction reasons.

The catalytic converter can be mounted either via the chamber cover or via a side inspection opening.

Safety Technology

-

The safety technology systems are designed in close cooperation with our customers, the planners and the operators in order to meet the respective project requirements and are fitted with the required controls and instruments.

The exact implementation can vary widely and depends on whether the application involves warm water, hot water or thermal oil.

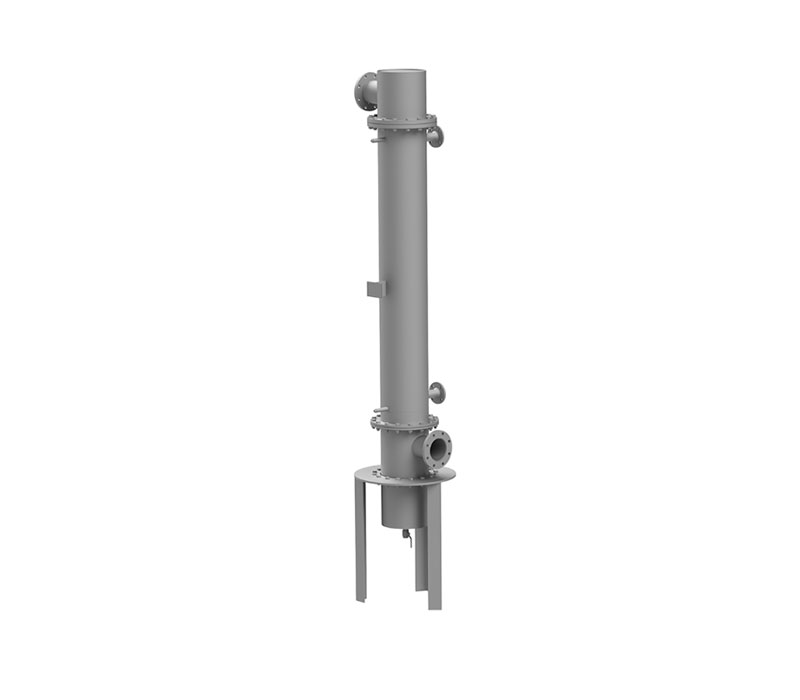

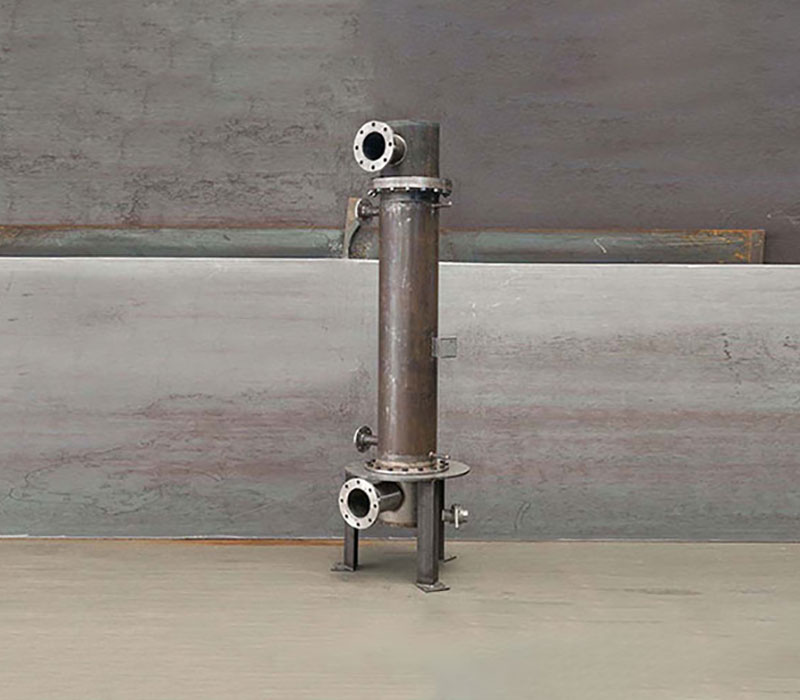

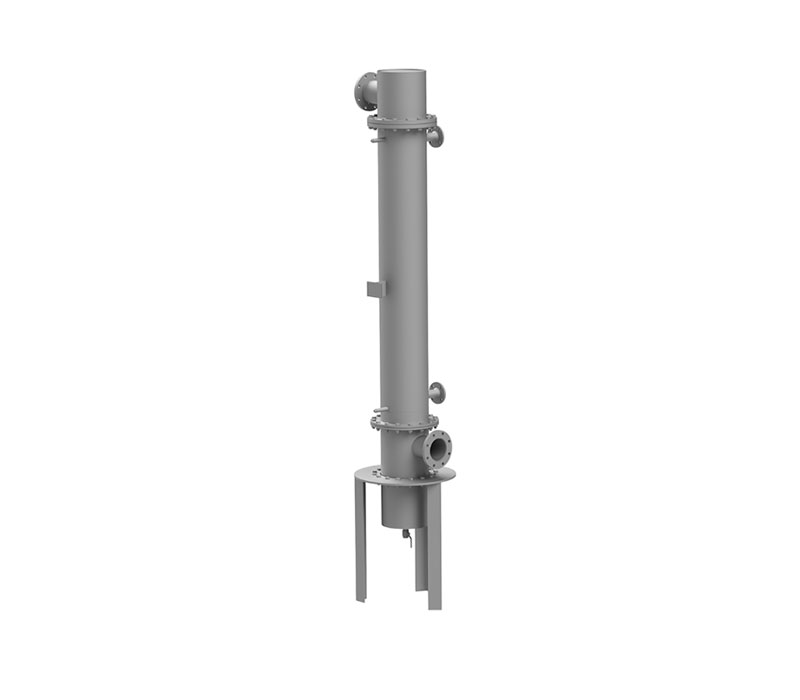

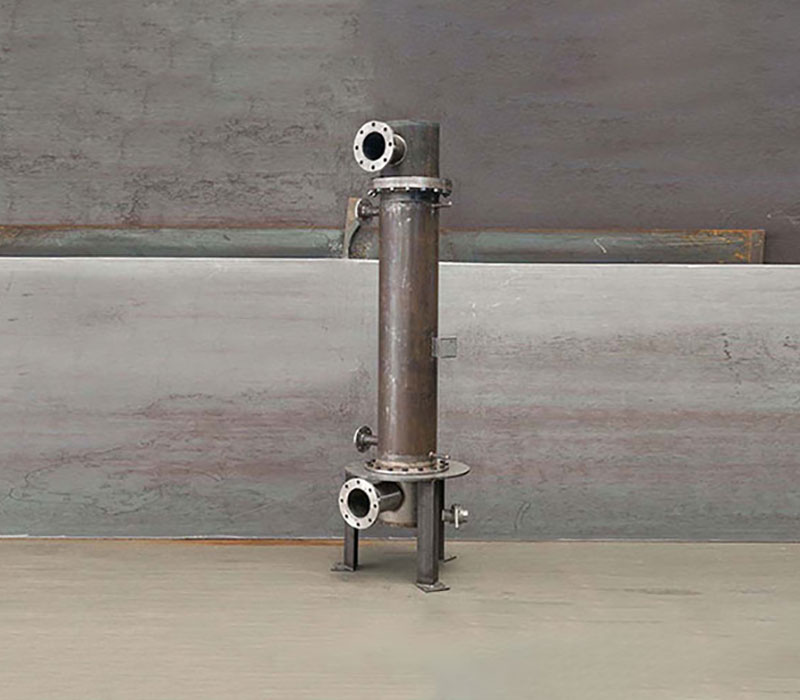

Vertical

-

A vertical design is also possible if this is necessitated by system space considerations. The heat exchanger can be equipped with a floor plate, side feet or with brackets.

Special Designs

-

In theory, there are countless possibilities for exactly how an exhaust gas heat exchanger is designed.

For example with two inlet connections in case of split exhaust gas routing after the CHP engine, as dual-stream version or with different fittings and measurement ports.

Gas Heat Exchangers

-

Before fuel gases can be used in CHP plant engines and converted into energy, they have to be cleaned and processed. This protects the engine and plant components and increases the service life significantly.

For these processes, we supply gas heat exchangers which cool the gas and precipitate condensate and additional heat exchangers which re-heat the gas for downstream processes in order to adjust the relative humidity.

Our gas heat exchangers can be used for a wide range of fuel gases.

Since our gas heat exchangers are designed and constructed on a project-specific basis, almost every one looks different and is suitable for a different application. The most common designs are shown below.

Applications:

- Biomethane

- Biogas

- Sewage gas

- Landfill gas

- Mine gas

- Wood gas

- Hydrogen

Tube Bundle

-

This is the simplest version of our gas heat exchanger. In this case only the tube bundle with connection flanges is supplied for installation in the pipe. Precipitating condensate must be drained separately in a different location. Gas heaters are typically shipped as tube bundles.

This design can be installed in the plant both horizontally and vertically.

Chambers

-

This version contains an outlet chamber with integrated demister and, if applicable, also an additional inlet chamber. The demister prevents precipitating condensate from being carried along into the downstream pipe. The condensate collects in the demister instead, drips down and can be removed via a condensate drain.

Upon request by the customer, a factory-installed siphon acting as a water and gas seal can also be integrated into the gas cooler condensate connection.

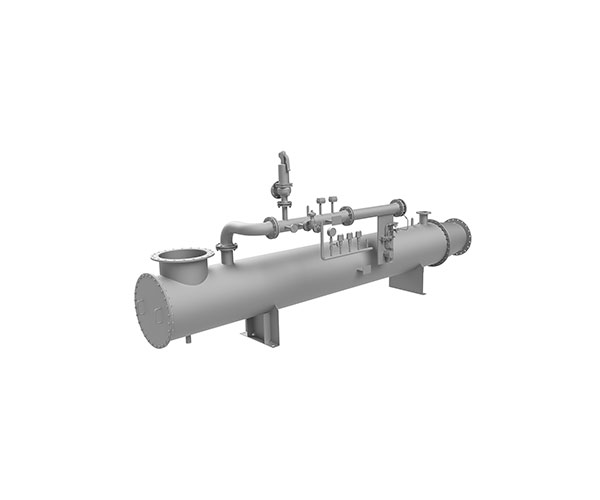

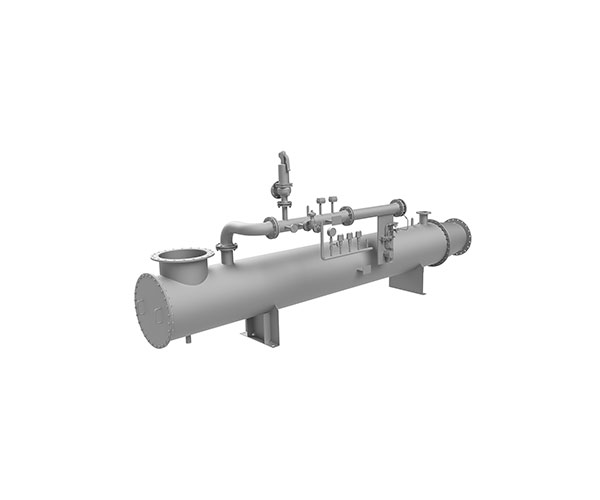

Gas Cooling Unit

-

In a gas cooling unit, the heat exchanger is equipped at the factory with a water chiller and mounted on a base frame and shipped as a closed, ready-to-connect system.

The system can be expanded with various options upon request, for example with a siphon or condensate collection container with electric trace heating. An additional heat exchanger can be installed directly at the gas cooler outlet for re-heating purposes.

Special Designs

-

There are many design options for gas heat exchangers.

The design can deviate a lot from the conventional construction, especially for applications outside the biogas and sewage gas field such as hydrogen or special gases.