- Offer Profile

-

Carbon Twister – Engineering Sustainable Biochar Solutions

Carbon Twister, a division of Prodana GmbH based in Neumarkt, Germany, designs and manufactures advanced pyrolysis systems for the production of high-quality biochar. Our technology transforms biomass and organic residues into valuable carbon while generating renewable heat energy in the process.

Each Carbon Twister plant is engineered for maximum efficiency, automation, and environmental impact. The modular systems convert local feedstocks such as wood chips, green waste, or agricultural residues into EBC-certified biochar, locking away CO₂ permanently and creating measurable climate benefits.

Carbon Twister F500 Pro

- For professional production of biochar at high throughput and high heat output.

F500 PRO

-

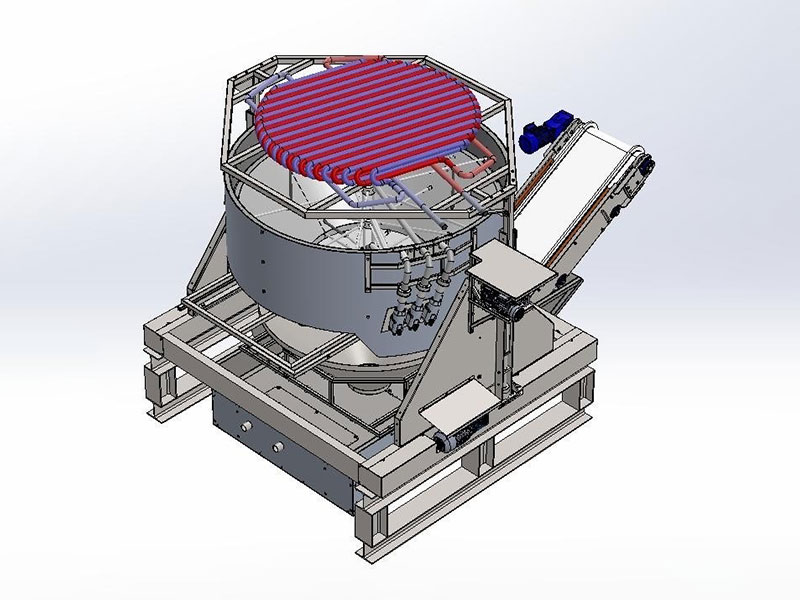

Fully automated, with heat exchanger, for high throughput

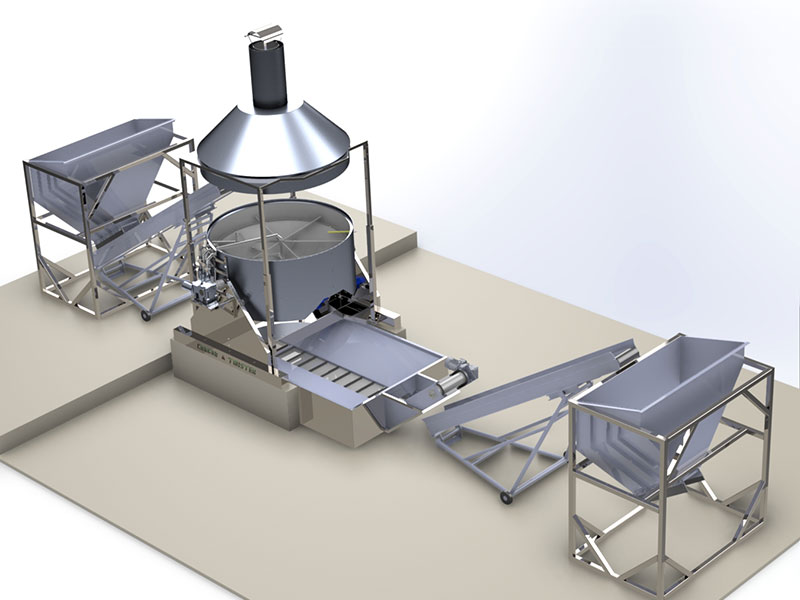

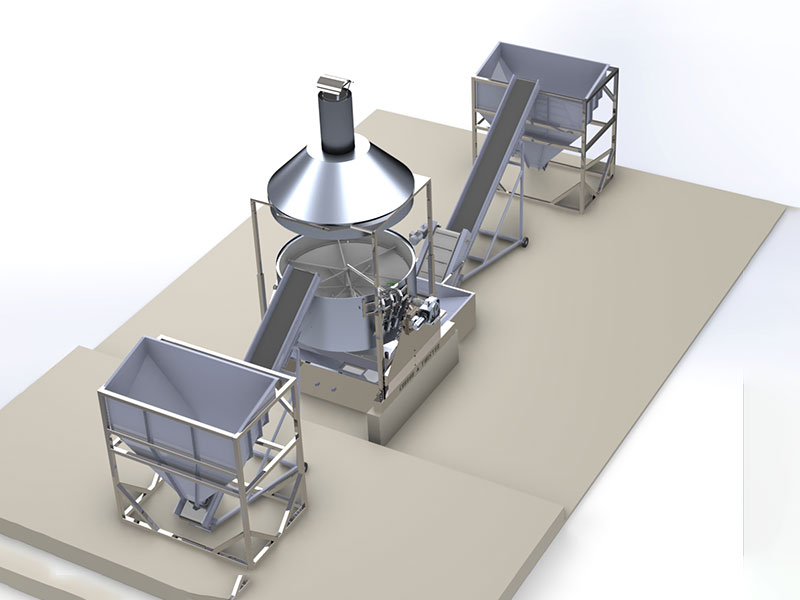

The F500 Pro operates fully automatically, is equipped with a heat exchanger to use the process heat and is optimised for high throughput. It is the "big brother" of the F250 Pro and has a higher throughput in direct comparison. As a result, more process heat is available for heat use. In contrast to the F500 Basic, it is fully automated, equipped with a heat exchanger, has a hood and includes all additional components such as a bunker and a bath.

The most important key data of the F500 PRO at a glance:- Firing capacity: 500 kW

- Filling volume: 2.2 m³

- Raw material: 5,860 m³/year

- Raw material 30% dry matter: 2,770 t/year

- Raw material 80% dry matter: 1,745 t/year

- Biochar 100% dry matter: 212 t/year

- Biochar 80% dry matter: 265 t/year

- Heat exchanger: 240 kW

- Automatic process control

- Monitoring via app

- Motorised drives

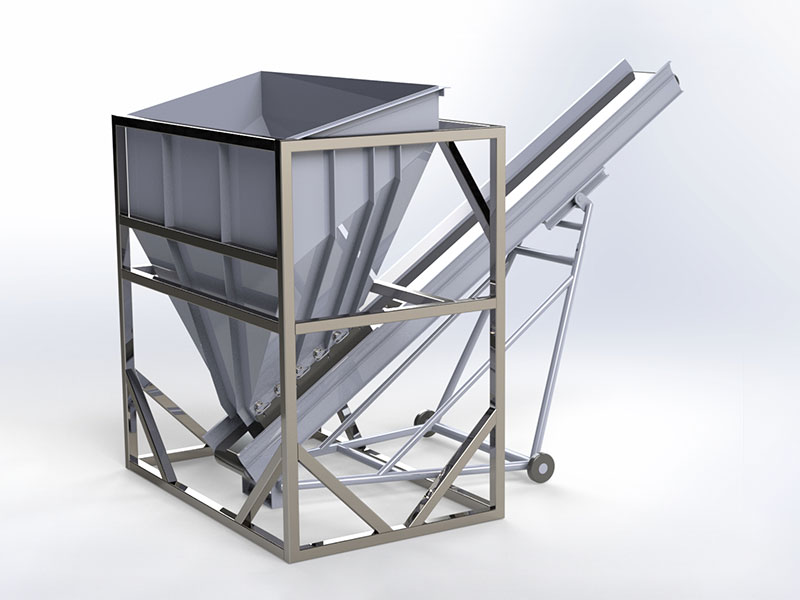

- Raw material bunker

- Hood

- Quench bath

- Conveyor belts

- Electric ignition

Carbon Twister F500 Basic

F500 Basic

-

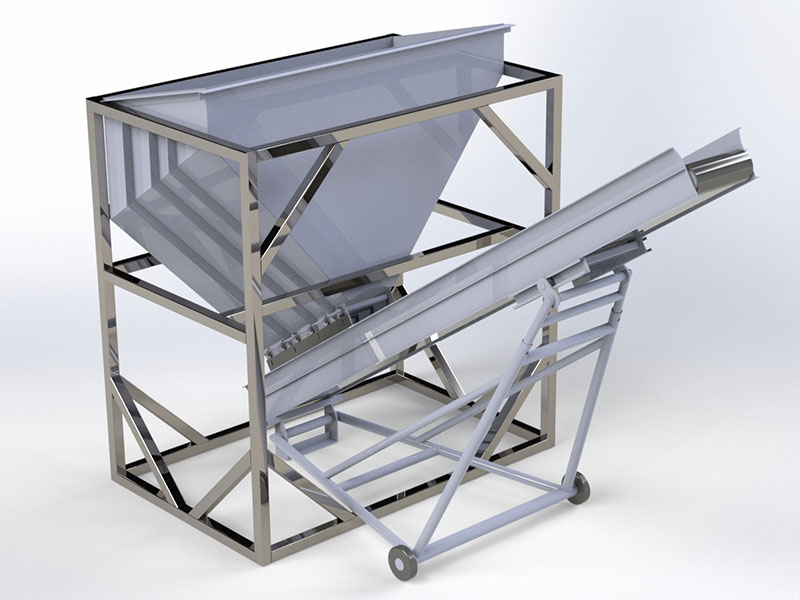

Manual operation, without hood, with optional heat exchanger

The F500 Basic is operated manually, open at the top (without hood) and can be optionally equipped with a heat exchanger to use the process heat. The throughput rates depend on how efficiently you integrate the manual interventions into your daily routine. The fully automated version of the F500 Basic, which is equipped with a heat exchanger as standard, is the F500 Pro.

- Firing capacity: 500 kW

- Filling volume: 2.2 m³

- Raw material: 2,900 m³/year

- Raw material 30% dry matter: 1,380 t/year

- Raw material 80% dry matter: 870 t/year

- Biochar 100% dry matter: 105 t/year

- Biochar 80% dry matter: 132 t/year

- Heat exchanger: 25 kW

- Automatic process control

- Monitoring via app

- Motorised drives

- Raw material bunker

- Hood

- Quench bath

- Conveyor belts

- Electric ignition

Carbon Twister F250 Pro

F250 PRO

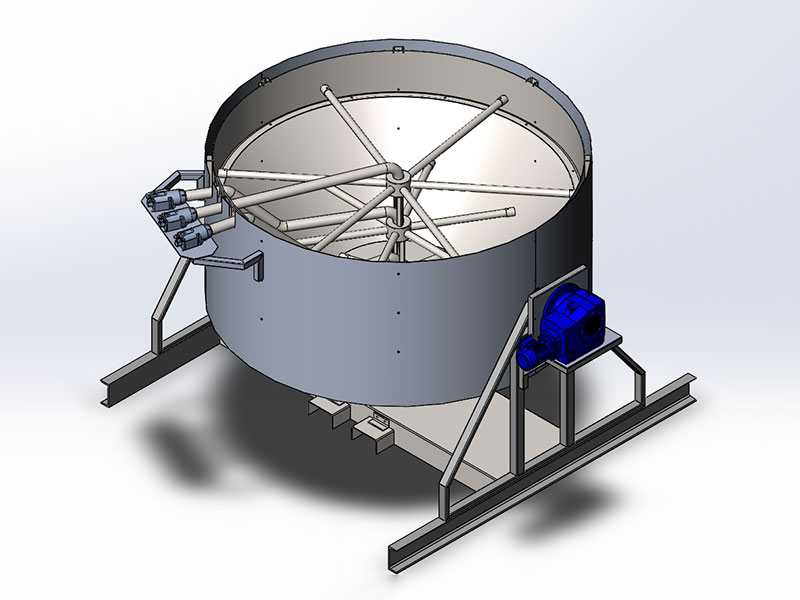

- Fully automated, with heat exchanger, for medium throughput

The F250 Pro operates fully automatically, is equipped with a heat exchanger to use the process heat and is optimised for medium throughput with medium heat output. It is the "little brother" of the F500 Pro and has a lower throughput in direct comparison.

Industries

-

Wood chips, digestate, branch cuttings, shells, husks, grasses, stalks, sewage sludge and more

The list of raw materials that are suitable for pyrolysis in the Carbon Twister is long. As long as a few boundary conditions are observed, almost any dry, organic raw material can be used.

Varietal purity not required

Mixed materials as well as single-variety raw materials can be processed in the reactor. This does not affect the pyrolysis process itself. Materials with a lower density will tend to ash a little more than dense materials, a fact that may have some effect on the carbon content in the biochar.

Agriculture

-

There is a wide range of possible applications for biochar in agriculture.

- Spreading on arable land to increase yields and combat drought

- Feed additive to improve animal health

- Mixed into slurry to reduce odour emissions

Forestry

- When planting trees, it is important to have a good nutrient soil at your disposal. Tree substrates can significantly enhance the soil and thus lead to better growth. The biochar in these substrates serves as a nutrient and water reservoir. Many success stories have already been reported. In Sweden, for example, substrates based on biochar are used in inner-city tree planting.

Composting Plants

- Peat-free compost, Terra Preta, substrates

Composting plants usually have a wide range of products at their disposal, which they sell mainly regionally, but sometimes also supraregionally.

Municipalities, local communities, garden centres as well as hobby gardeners are increasingly looking for sustainable alternatives to conventional products that are as effective as or even superior to them. These include:

- Peat-free compost

- Terra Preta

Peat-free compost with added biochar is a sustainable option, especially for municipalities.

Biogas Plants

- Biochar produced from digestate can be used in the same way as biochar produced from any other organic raw material. Either on the own farm by spreading it on the fields. Or by refining it into other end products or by selling it. Digestate from biogas plants is ideally suited for the production of biochar. In a trial project spanning several years, we have optimised our plant in such a way that it produces high-quality biochar from pure digestate without the addition of other raw materials. The biochar produced by our plant from digestate meets the required EBC laboratory limits.

Municipalities

- Upgraded compost and Terra Preta

In the municipal sector, those who handle the raw material are often also those who handle the end products.

High-quality compost and Terra Preta are becoming increasingly popular. This is where biochar comes into play as an active component.

Construction

-

Applications:

- Building construction

- Concrete and asphalt in road construction