- Offer Profile

- TIMES CHANGE – BUT QUALITY REMAINS!

We offer you technically mature solutions for the mixing of substrates from small plants (75kW) up to plant sizes in the MW range.

The consistent focus on the development and construction of agitators for agriculture and the biogas sector allows us a high vertical range of manufacture. This not only results in sophisticated products, but also enables us to respond to the individual needs of our customers at an early stage.

Biogas

-

Agitators for biogas technology

WE MAKE STIRRING BETTER !

The agitator is the most important component in biogas technology. It is the “heart” of an anerobic digestion plant.

Whether it is for the digester, secondary digester or the end storage tank – the right mixing technology must be able to deal with an extensive range of feedstocks. It must be able to stir fibre rich feedstocks with a high DM content. It must also be able to cope with waste from agriculture, general refuse and

industry.Whether you are constructing a new plant or repowering an existing one – Peters will plan the mixing system with you, so that it is perfectly suited to your needs and the demands of your feedstock.

Dosing System

ECO-DOS R

-

The digester feed has a key role to play in biogas plant performance. Our „ECO-DOS R“ solids feeder is available in four modular versions.

Thanks to its corrosion and acid-resistant interior lining it is extremely durable. It can operate forwards and backwards and is suitable for side or rear loading. It can be interfaced with the plant central control system via a PLC control. The „ECO-DOS R“ is also available with a weighing device.

This feeder has very low energy requirements.

Your benefits

- Modular structure

- Very low energy consumption

- Acid-resistant inner lining

- High corrosion resistance

- High-strength round steel chains ensure low wear

- Reversible operation possible

- Side and rear loading possible

- Special shaft breakers minimize bridging

- Modular configuration with various screw feeders and/or mixer

- PLC controller with various programs (auto or manual mode) available

- Interfacing with biogas plant controller possible

- Weighing system optional

Paddel Mixer

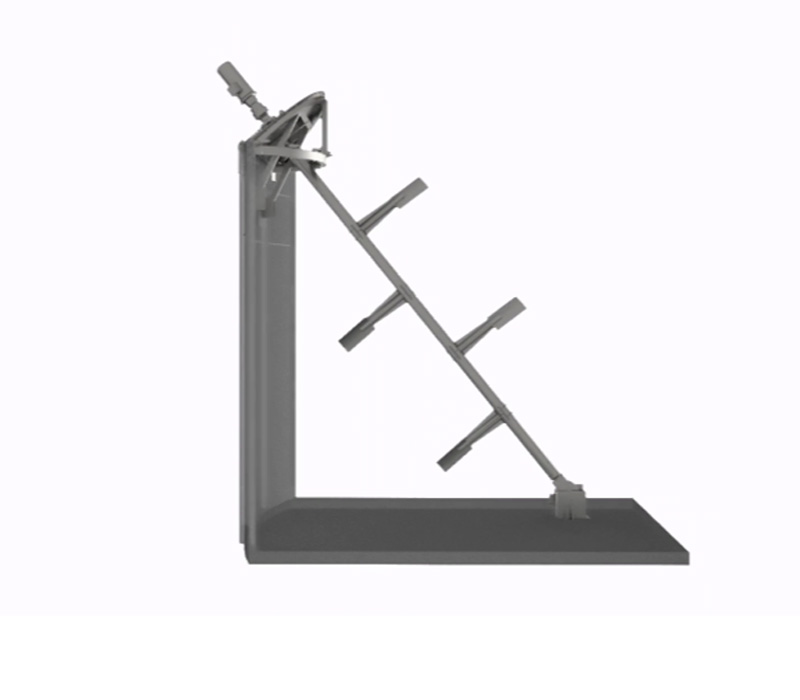

Paddle Mixer EXCENTRO V

-

THE VERTICAL EXCENTRO

The defining characteristic of Paddle mixers is that they mix slowly and evenly.

This means that the bacteria in the mix is constantly fed, thus promoting the undisturbed anerobic breakdown of the biomass.

Paddle mixers are especially suited to challenging feedstocks and those with a high concentration of dry matter.

The paddles ensure that the digestate is mixed thoroughly, thus fully homogenising any floating or sinking layers. Our EXCENTRO V paddle mixer has already proven its high level of efficiency in numerous plants.

Technical details

- Rated output : from 5.5 to 15 kW

- Rated voltage : 400/690 V

- Frequency : 50 Hz

- Miscellaneous : frequency inversion possible 30-75 Hz

- Gear type : planetary or hollow shaft gearbox

- Lubrication : synthetic oil fill ISO VG 220

- Ingress protection rating : IP 55

- ATEX compliant motor : ATEX II 2G - Exd IIC T4

- ATEX compliant gearbox : ATEX II 2G T4

- Stirring paddles (replaceable) : 4, 6 or 8 paddle arms

- Main tube (thick-walled) : Ø 200 mm - Ø 267 mm

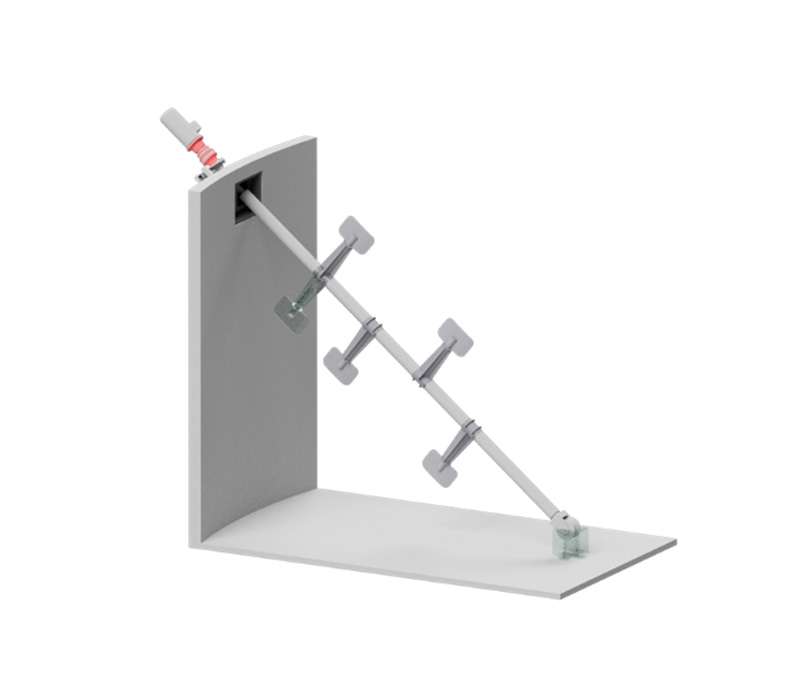

Paddle mixer EXCENTRO S

-

THE DIAGONAL EXCENTRO

Based on this sophisticated and highly reliable technology Peters have developed the EXCENTRO S paddle stirrer.

Just like its partner system, its special advantage is that all of the maintenance and replacement work on the EXCENTRO S can be carried out without emptying the digester.

Now this even applies to digesters with flexible gas storage instead of concrete covers. For operators this means the minimum amount of downtime for the plant.

The EXCENTRO S also has a gear reducer motor with an output of between 7.5 and 15 kW. High quality and robust materials guarantee smooth low-maintenance operation.The full diameter of the system is 3 m and the length is between 5 and 10 m. The EXCENTRO S not only ensures optimum efficiency in new plants, it can also be installed to upgrade existing plants.

Technical details

- Rated output : from 5.5 to 15 kW

- Rated voltage : 400/690 V

- Frequency : 50 Hz

- Miscellaneous : frequency inversion possible 30-75 Hz

- Gear type : planetary or hollow shaft gearbox

- Lubrication : synthetic oil fill ISO VG 220

- Ingress protection rating : IP 55

- ATEX compliant motor : ATEX II 2G - Exd IIC T4

- ATEX compliant gearbox : ATEX II 2G T4

- Stirring paddles (replaceable) : 4, 6 or 8 paddle arms

- Main tube (thick-walled) : Ø 200 mm - Ø 267 mm

Long-axis Agitator

Rod mixer Fermento

-

OUR POWERHOUSE

Our powerhouse the FERMENTO comes in six different performance classes from 7.5 kW to 22 kW.

It is installed into the side of the concrete lid, in a mounting frame which is embedded in the concrete. It can be easily de- and re-installed for maintenance work or retro-fitted into the digester. It is suitable for steel or concrete tanks.

The FERMENTO rod mixer is installed laterally and can be easily removed and re-inserted for maintenance. It is suitable for steel or concrete tanks and can be mounted in the wall or cover. For steel tanks there is a special support available. The mixer can be adjusted easily and efficiently via a manual, hydraulic or electric height control mechanism. Our FERMENTO rod mixer is available in different versions.

Technical details

- Rated output : 7,5kW-11kW-15kW-18,5kW-22kW

- Rated motor rotations : 1100 1/min. - 1460 1/min.

- Rated voltage : 400/690 V

- Frequency: 50 Hz

- Miscellaneous : suitable for frequency inversion 30-75 Hz

- Drive type: V-belt | Gear motors

Rod mixer Fermento XL

-

The Methabolix

Based on our decades of experience in the manufacture of agitators for agriculture and biogas plants, we have developed our "Methabolix" power package.

It can be installed laterally into the concrete wall, from above through the concrete ceiling or over the roof frame "Methabox". The installation can also be carried out with the tank filled.

As with all Peters agitator systems, maintenance or repair can be carried out conveniently, as the agitator can be removed without emptying the fermenter. The agitator Methabolix is not only an option for new plants, but also for the extension of existing plants.

Technical details

- Stirrer type: Methabolix

- Nominal power: 18.5 and 22 kW

- Frequency: 50 Hz

- Miscellaneous: Suitable for FU 30-75 Hz

- Gear type: planetary gear or hollow shaft gear

- Lubrication: synthetic oil filling ISO VG 220

- Protection class: IP 55

- ATEX marking Motor: ATEX II 2G - Exd IIC T4

- ATEX marking Gear unit: ATEX II 2G T4

- Segmented tube lengths: 2000mm - 4000mm - 6000mm - 8000mm

- Thick-walled outer tube: 7.4 mm stainless steel Ø168 mm

- The bearing of the agitator is located as a cartridge in the inner reinforcement tube

- Bearing arrangement on the agitator blade consisting of 2 tapered and spherical roller bearings

Service-Methabox

Mixers for Air-Supported Roofs

-

The Methabox® system is a built-in option for flexible gas storage, such as air-supported roofs and has been specially developed for flexible gas membranes.

Air-supported or foil roofs are often used as flexible biogas storage and gastight silo covers for biogas plants. These roofs are usually made of a PE film and an outer weather protection film made of PVC. The new Methabox system from Peters Mixer is easy to install into these air-supported roofs on biogas plants. The stainless steel frame is shaped so that the film can fit around it perfectly. At the same time the tarp between the two sheets is pulled taut, both for the double and single membranes. Thanks to the curves, stress points are avoided.

As with all stirring systems from Peters, maintenance and repairs can be carried out easily as the agitator (EXCENTRO) can be removed without draining the digester. The Methabox system is not just an option for new plants, but also for the expansion of existing plants.

Technical details

Methabox S:

Suitable for the installation of Excentro S, Fermento and Methabolix

Frame width : 3430 mm

Frame height : 1040 mm

Frame depth : 1390 mm

Weight : ca. 530 kg

All parts in connection with gas: stainless steel A4Methabox L:

Suitable for the installation of Excentro S, Fermento and Methabolix

Frame width : 4470 mm

Frame height : 1200 mm

Frame depth : 1600 mm

Weight : ca. 800 kg

All parts in connection with gas: stainless steel A4

Agriculture

-

Our mixers: TURN LIQUID MANURE INTO FERTILISER

Electric Slurry Mixer

-

Our powerful, low maintenance, easy to install SLE electric mixers (11kw, 15kw, 18.5kw, 22kw) achieve optimal mixing of the slurry through daily use. They also maximize yield when pumping out the slurry cellar and ensure uniform spreading of the manure. The drive unit is located outside the slurry in a sealed, fully galvanized housing, this means that it is completely protected from external weather conditions.

SLE electric mixer

-

Our powerful, low maintenance, easy to install SLE electric mixers (11kw, 15kw, 18.5kw, 22kw) achieve optimal mixing of the slurry through daily use. They also maximize yield when pumping out the slurry cellar and ensure uniform spreading of the manure. The drive unit is located outside the slurry in a sealed, fully galvanized housing, this means that it is completely protected from external weather conditions.

- Fully automatic controls with soft start

- Right-left functions and digitally programmable running time

- Can also be powered by a tractor

Technical details

- Tube length 4m - 6m

- Also available up to 8m

- Mixer available in V2A

- Shaft supported by 3 bearings:

> ball bearings (45 mm) at the tractor end

> intermediate bearing for stabilisation

> bronze bearing with triple sealing and VG680 oil bath lubrication - V2A stainless steel propeller (2 blades): double reinforcement (Ø 600 mm)

- User-friendly drive system for connection to tractor

- Galvanized and reinforced main tube coated with epoxy resin

- Counter-cutting blade on the ring propeller that contains straw

- Rotations: 800 rpm in short-term use, 540 rpm in normal use

with fully automatic or manual controls (soft-start, suction pressure, digitized controls) also suitable for exterior use.

SLE electric mixer - Wall mount

-

Slalom system: SLE electric mixer with wall mount

FLEXIBLE AND PRACTICAL

The wall-mounted SLE electro mixer guarantees a thoroughly regular mixing of the slurry in an open pit all year round. This can be equipped with a manual or hydraulic hight adjustment mechanism.

Your benefits

- Sturdy construction

- Available in full stainless steel

- Wide working radius

- Works efficiently in pits up to 6m deep

Technical details

- Tube length 4m - 6m

- Special length up to 8m available

- Mixer available in V2A

- Shaft with 4 bearings:

> Ball bearing (45 mm)

> Interim storage for stabilization

> triple sealed bronze bearing with bio oil bath VG680 - Stainless steel stirring blade (2 blades): double right (Ø: 600 mm)

- User friendly drive device for tractor operation

- Galvanized and right main pipe coated with epoxy resin

- Counter cutting knife on the ring wing for straw-containing liquid manure

- Electric motor in a lost, robust and galvanized housing

- With fully automatic or manual switching (soft start, suction-pressure, digital control)

SLE electric mixer - Telescopic Mount

-

Slalom system: SLE electric mixer with telescopic Mount

FLEXIBLE AND PRACTICAL

The telescopic hitch or front-loader hitch (available for a wide range of models) make the electric mixer suitable for use in open slurry pits, digesters or biogas plants.

Technical details

- Tube length 4m - 6m

- Special length up to 8m available

- Mixer available in V2A

- Shaft with 4 bearings:

> Ball bearing (45 mm) at the tractor side

> Interim storage for stabilization

> triple sealed bronze bearing with bio oil bath VG680 - Stainless steel stirring blade (2 blades): double right (Ø: 600 mm)

- User friendly drive device for tractor operation

- Galvanized and right main pipe coated with epoxy resin

- Counter cutting knife on the ring wing for straw-containing liquid manure

- Speed: 800 rpm in short time operation, 540 rpm in continuous operation

- Electric motor in a lost, robust and galvanized housing

- With fully automatic or manual switching (soft start, suction-pressure, digital control)

Tractor-driven Agitator

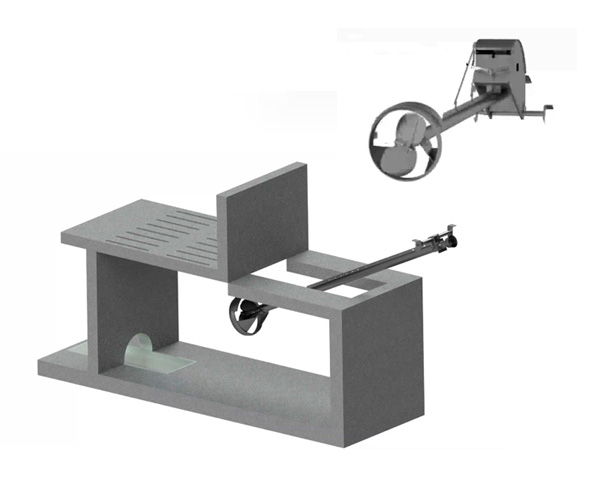

Stationary Mixer

-

Slalom system: SLT tractor mixer

OUR CLASSIC MODEL – PERMANENTLY INSTALLEDThe SLT slalom mixer for tractor drive is particularly suitable for small circuits (100 m).

The agitator is permanently installed and can be fitted with a bi-directional or angular gearbox as required. A retrofit to electric drive with gears is also possible.

The special shape of the stainless steel Peters propeller and the adjustable counter blade ensure optimal chopping and homogenisation of slurry that contains strawTechnical details

- Tube length 4m - 6m

- Also available up to 8m

- Mixer available in V2A

- Shaft supported by 3 bearings:

> ball bearings (45 mm) at the tractor end

> intermediate bearing for stabilisation

> bronze bearing with triple sealing and VG680 oil bath lubrication - V2A stainless steel propeller (2 blades): double reinforcement (Ø 600 mm)

- User-friendly drive system for connection to tractor

- Galvanized and reinforced main tube coated with epoxy resin

- Counter-cutting blade on the ring propeller that contains straw

- Rotations: 800 rpm in short-term use, 540 rpm in normal use

Electric drive can be retrofitted at any time on request!

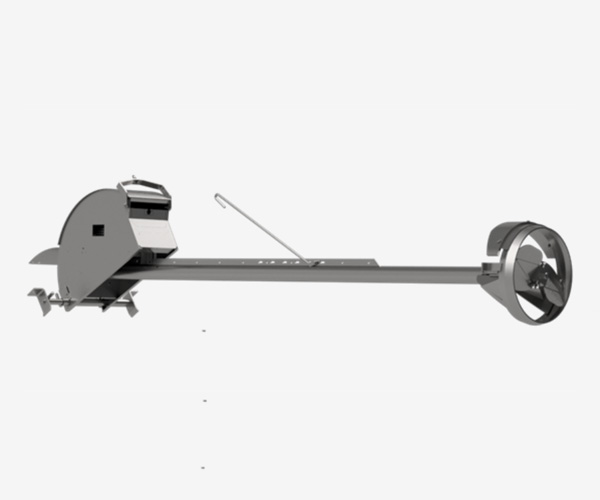

Three-point STD

-

THE MOBILE MIXER

Our powerful, low-maintanence STD mixer, with a three-point hitching system and hydraulic cylinder is especially suitable for smaller spaces. Due to its characteristic mobility and flexibility it has a whole host of applications.

The STD is available with a variety of mixing tanks. A switching mechanism (suction input/pressure output) or an electric motor for automatic stirring are also available for the STD.

Technical details- Standard total length 5 m

- Available in customised lengths

- Thick-walled, galvanised external tube (115 mm)

- Three-point hitch system

- Two-way hydraulic cylinder to control the insertion angle

- Guard ring (Ø: 650 mm)

- Mixer available in V2A stainless steel

- Bronze bearing with quadruple sealing and oil bath lubrication

- V2A stainless steel propeller (2 blades) - double reinforcement (Ø: 600 mm)

- User-friendly drive system for connection to tractor

- V2A counter blade on the ring propeller

- Tractor power: 50 - 100 hp

- Rotations: 540 rpm in normal use

- Retrofit with bi-directional gearbox possible

- Retrofit with electric motor possible

Lagoonmix LA6

-

OUR TOUGH AND AGILE MIXE

The V2A stainless steel mixing paddles and counter blades in the LA6 make short work of shredding straw in sediment layers.

The specially developed bearing seal with oil bath lubrication is perfect for medium to large open pits and lagoons. Electric drive of up to 22 kW is also available.The STS version makes it easy to swing the mixer into pits with a small opening (80 x 80cm). Also available with a hydraulic swivel arm and bi-directional gearbox.

Technical details

- Standard length 6m

- Thick-walled, galvanised external tube (115 mm)

- Three-point hitch system

- Hydraulic cylinder (double-action) to control the insertion angle

- Guard ring (Ø: 650 mm)

- Shaft supported by 3 bearings: ball bearing (45 mm) at the tractor end

- Intermediate bearing for stabilisation, and bronze bearing with triple sealing and oil bath lubrication VG680

- Completely galvanised frame, reinforced with two side tubes

- Support feet included as standard

- V2A stainless steel propeller (2 blades), also available with 3 baldes (with suck or push action): double reinforced (Ø: 600 mm)

- V2A Counter blade on the ring propeller

- Tractor power: min. 80 hp

- Rotations: 800 rpm in short-term use, 540 rpm in normal use

Optional extras

- Bi-directional gearbox

- Hydraulic swivel arm

Jumbomix JU7

-

The Jumbomix is a fully hot-dip galvanized slurry agitator equipped with a high-performance pressure propeller made of reinforced stainless steel as standard. It is the ideal choice for large open pits.

As it is particularly robust and designed for high-performance stirring it needs tractor

power of at least 120 bhp. The agitator blades are specially designed to easily shred and stir large quantities of slurry. A counter blade made of stainless steel finely chops straw and other fibers in the mix.All wear and tear parts can be ordered as kitsand can be replaced quickly and easily.

Using extensions the frame can be extendedup to 13m.

Technical details- Shaft supported by 4 bearings (Ø 50 mm)

- Ball bearings at the tractor end

- 2 intermediate bearings for stabilisation

- Bearing reinforced by 2 conical tapered roller bearings and

a spherical roller bearing in oil bath on the agitator blades - Fully hot-dip galvanized frame construction

- Hochleistungs- Edelstahlrührflügel verstärkt (Ø625 mm)

- Reinforced high-performance stainless-steel agitator blades

(Ø 650 mm) - Stainless steel counter blades on the ring propeller

- Stable three-point hitch system

- Two-way hydraulic cylinder to control the insertion angle,

also available with two cylinders - Thick-walled main tube: Ø 127 mm

- Tooth splined shaft: 6-1¾“

- Support feet included as standard

- Doppelwirkender Hydraulikzylinder regelt den Einführwinkel optional mit zwei Zylindern lieferbar

- Standard lengths: 6m, 7 m, 8m

- Total weight: about 450 kg

- Rotations:

1000 rpm in short-term use, 750 rpm in normal use - Tractor power: min. 120 bhp

Frame Extension

- EXTENSION TO 3m, 4m AND 5m

A Jumbo mixer JU7 with a frame extension is perfect for reaching over a wall or mound.

The frame extension with quick-coupling for the lower link is available in three lengths: 3m, 4m and 5m. These can be fitted to a Tractor mixer to create a machine that is up to 13m long. It can also be fitted with a double cylinder.

Tractor-driven Agitator S

STS Combimix

-

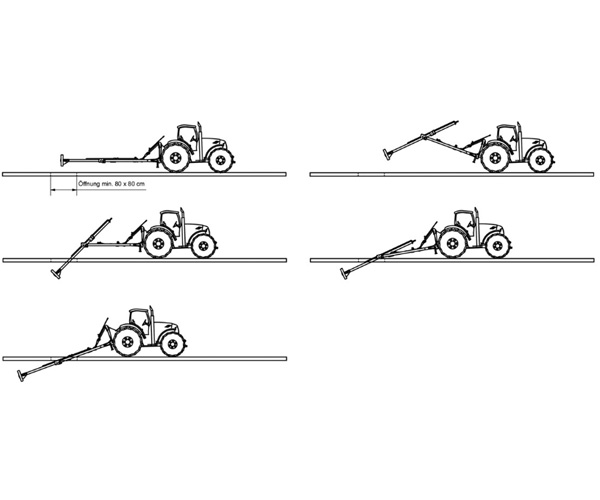

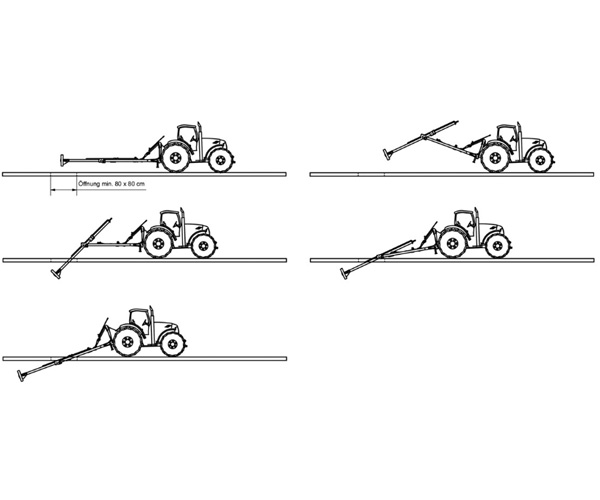

SPECIALIST FOR SPECIAL APPLICATIONS

The agitator type STS Combimix is ideal to be inserted into small pit openings (80 x 80cm) thanks to its pivoting device.

The agitator is optionally available with hydraulic swivel device and change-over gear.

Technical details

- Standard length 6m

- Thick-walled, galvanised external tube (115 mm)

- Three-point hitch system

- Hydraulic cylinder (double-action) to control the insertion angle

- Guard ring (Ø: 650 mm)

- Shaft supported by 3 bearings: ball bearing (45 mm) at the tractor end

- Intermediate bearing for stabilisation, and bronze bearing with triple sealing and oil bath lubrication VG680

- Completely galvanised frame, reinforced with two side tubes

- Support feet included as standard

- V2A stainless steel propeller (2 blades), also available with 3 baldes (with suck or push action): double reinforced (Ø: 600 mm)

- V2A Counter blade on the ring propeller

- Tractor power: min. 80 hp

- Rotations: 800 rpm in short-term use, 540 rpm in normal use

Optional extras

- Bi-directional gearbox

- Hydraulic swivel arm

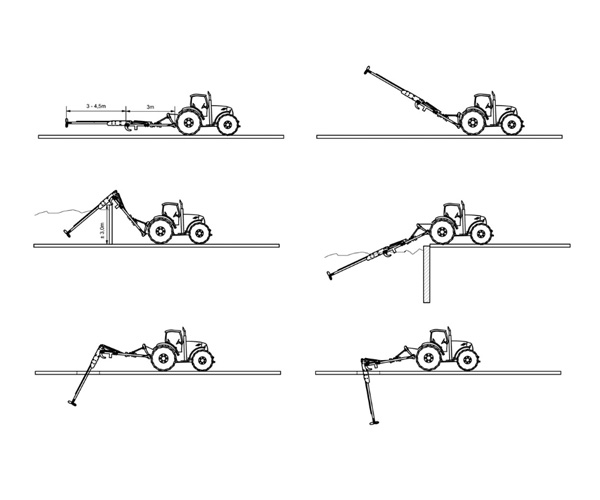

SPS Combimix

-

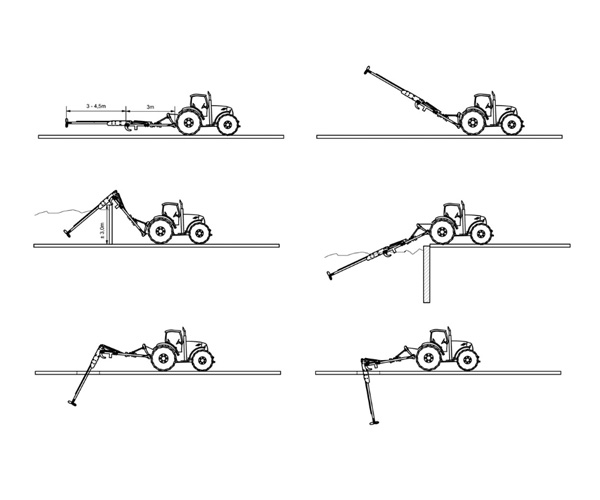

PERFECT FOR TRICKY SITUATIONS

The SPS Combimix is the ideal agitator for mixing slurry in raised tanks or difficult to access slurry pits.

Thanks to the combination of two double-acting cylinders and a t-gearbox this mixer can be used in different positions.

Technical details- Shaft supported by 3 bearings (Ø 50 mm), ball bearings (45mm) at the tractor end Intermediate bearing for stabilisation and bronze bearing with quadruple sealing and oil bath lubrication

- Three-point hitch system

- Two double-acting hydraulic cylinders

- Throttle to control the cylinder extension speed

- T gearbox

- Wide angle cardan shaft

- Safety bolts, linked to a guide rail

- Stainless steel propeller (2 blades) - double reinforcement (Ø: 600 mm)

- Support feet included as standard

- Counter blade on the ring propeller

- Standard tube length 3 – 4.5m Frame length 3m (total length 6 – 7.5m)

- Rotations: 800 rpm in short-term use, 540 rpm in normal use

SPX Combimix

-

SPX WITH THE MECANICAL SWIVEL ARM

The unique kinematics on this mixer make it possible to swivel up to 170° without having to get off the tractor or reclamp the cardan shaft.

The SPX Combimix is suitable for use in a raised slurry tank or in slurry pits that are difficult to access.

The combination of a double-acting hydraulic cylinder and a swivel gearbox that was specially designed for this mixer make it possible to use it in many different positions.

The mixer can be easily controlled from the tractor. This particularly robust machine is a powerful mixer and needs to be fitted to a tractor with at least 150 bhp. The swivel gearbox is protected from overload by a slip clutch.

Thanks to the specially developed stirring blades, the mixer can stir and chop very large quantites of slurry. A stainless steel counter blade keeps the rotor blades clean.

Technical details

- Shaft supported by 4 bearings (Ø 53 mm)

> Ball bearings at the tractor end

> Two intermediate bearings for stabilisation

> Bearing reinforced by 2 conical tapered roller bearings and a spherical roller bearing in oil bath on the agitator blades - Fully hot-dip galvanized frame construction

- Reinforced high-performance stainless-steel agitator blades (Ø 650 mm)

- Stainless steel counter blades on the ring propeller

- Secure three-point hitch system

- Double-acting hydraulic cylinders control the angle of insertion

- Thick-walled main tube: Ø 127 mm

- Tooth splined shaft: 1¾“

- Support feet included as standard

- Standard length: 7 m

- Total weight around 1200 kg

- Rotations: 1000 rpm in short-term use, 750 rpm in continuous use

- Tractor power: at least 150 bhp

- Shaft supported by 4 bearings (Ø 53 mm)