- Offer Profile

- SMC has a range of 12,000 basic models and over 700,000 variations to respond to day-to-day automation needs. Our experts are always on hand to provide the necessary technical support and guidance. With european stock to give a quick response to our customer's requirements.

Sustainable management of CO2

-

SMC’s CO2 emission-reducing initiatives

Production process and product performance improvements with a focus on the environment

Over the past several years, SMC has continued to take on its social responsibility to seriously promote and support sustainability in order to minimize negative impacts to the environment.

SMC is always looking to develop newer and greener solutions with CO2 reduction as a top priority as a leader in the field of pneumatics. One of the key components of our comprehensive approach is the designing of compact and lightweight products. Smaller, lighter products require less raw materials to make and less time to process. In addition, the products themselves use less energy. All of these efforts contribute to reduced CO2 emissions.

SMC’s fully integrated technical, production, and sales departments are able to respond to the needs of our customers from around the world with a shared goal of finding new methods to effectively protect the environment. Actuators

Linear Actuators and Linear Acting Cylinders

Guided Actuators

Grippers & Escapements

Rotary Actuators

Rodless Pneumatic Cylinders and Rodless Actuators

Specialty Actuators

Actuator Accessories

Electric Actuators

Slider Types

Rod Types

Slide Tables

Electric Rotary Actuator - LER, LE2R

Grippers & EOAT for Collaborative Robots

Digital I/O Commanded Controllers / Drivers

Motor Controllers

Directional Control Valves

Pilot Operated 4/5 Port Solenoid Valves

Pilot Operated 3 Port Solenoid Valves

Direct Operated 3/4/5 Port Solenoid Valves

Safety Pressure Release Valves (ISO 13849)

Fieldbus System

Air Operated Valves

Mechanical Valves / Hand Valves

Accessories - Mufflers

NAMUR Valves: 3 Port / 5 port / Hygienic

Airline Equipment

Air Combination Units

Regulators

Filter-Regulators

Lubricators

Filters

Pressure Boosters and Tanks

Pressure Gauges

Air Dryers

Auto Drain Valve

Blow Guns / Nozzles

Silencers / Exhaust Cleaners

Fittings & Tubing

Fittings

Flow Control Equipment

Tubing

Manifolds

Quick Couplers

Check Valves

Accessories

Vacuum Products

Vacuum Pads

Vacuum Generators

Vacuum Filters

Vacuum Switches

Vacuum Regulators

Vacuum Saving Valve

Vacuum Gripper for Collaborative Robots

Other Vacuum Equipment

Fluid Control Equipment

Process Valves

Process Pumps

High Purity Products

Industrial Filters

Electro-Pneumatic Positioners

Water Equipment

Sensors & Switches

Static Control

Bar Ionizers

Nozzle Ionizers

Fan Ionizers

Desktop Duster Box

Sensors

Anti-Static Tubing & Fittings

Gun Ionizer

Temperature Control

Circulating Fluid Temperature Controller

Thermoelectric Bath

Temperature Control System for Chemical Liquids

IDH, Thermo-dryer

High Vacuum Products

Angle and In-line Valves

Slit Valves

Smooth Vent

XSA, Normally Closed, High Vacuum Solenoid Valve

Safety Related Products

VP500/700-X536, Single Residual Pressure Release Valve

Dual Residual Pressure Release Valve, 3 port Solenoid Valve, ISO13849-1

Dual Residual Pressure Release Valve with Soft Start-up Function, ISO13849-1

Dual Residual Pressure Release Valve, 3 port Solenoid Valve, ISO13849-1

VR51, Two Hand Control Valve

ATEX Products

Actuators

Directional Control Valves

Electric & Pneumatic Control Valves

Fluid Control Equipment

Sensors

ATEX Catalogue

Clean Room Products

Actuators

Compressed Air Preparation

Pneumatic Connection Technology

SRF

Solutions

-

What are the similarities between a car and a bar of chocolate?

None at all, and their production process even less.

So that is why we've got teams of experts around the world specialized in the characteristics of each industry: in their laws, regulations, standards or specific technology requirements.We are concerned about the specifics of your production process.

Automotive

-

Robustness, durability, strength, velocity; is this what your process demands?

Flexible and smart solutions for this very dynamic industry

If there is one industry that is reinventing itself that is the automotive, a renewal that affects both the automobile themselves and their production processes. Autonomous car, for example, are by now a reality; for the automotive industry the future is really the present.

Beyond our compliant solutions with standards such as CNOMO, DIN, ISO, VDMA, ATEX or NAAMS, we can provide you with our range of tested solutions that will endure harsh working conditions. Products that are strong and solid, as well as compact and light components for robotics applications.

More specifically, we are in position to give you support, both with our products and our team of experts, in all the steps of your production process: Body shop, Press shop, Power Train, Paint shop and Final assembly. Further down, you can discover our solutions for each of these processes.

Are you a Tier 1? Do you offer advanced processes in the supply chain?

The supplier industry, too, relies on our experience and benefits from our know-how as well as our customised solutions for all areas of the supply chain.

Our global teams of experts are fully trained to provide support in key areas such as Industry 4.0 or Machinery Safety. With the backup of 1,500 experienced engineers allocated in 5 technical centres (two of them in Europe: Germany & UK) ready to develop the customized solutions that are many times needed.

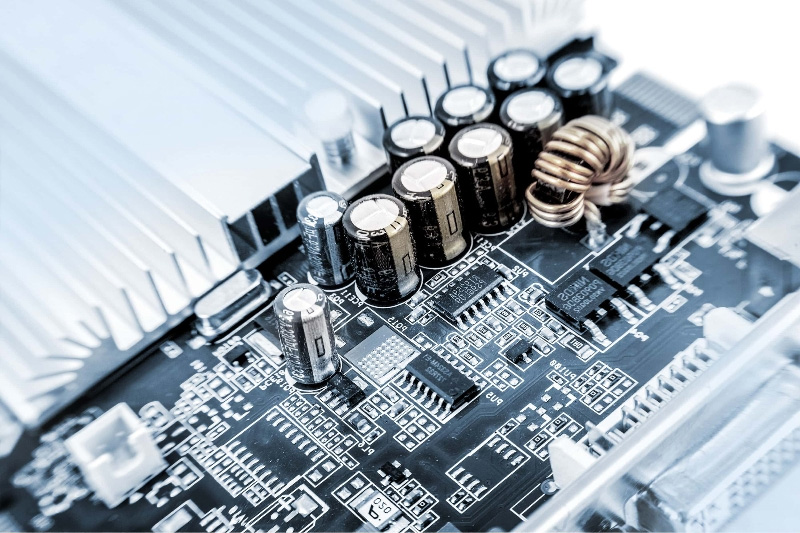

Electronics

-

Innovative & compact solutions for a Technology-driven industry

We've got the innovative solutions you need

Hardly any other industry is as marked by rapid progress and change as the electronic industry. Today's trends are the natural standards of tomorrow. Innovations secure market share and revolutionary achievements characterize a new generation of devices.

In order to meet the demands of this fast moving industry, we put at your disposal our extensive portfolio, with solutions for the different applications and process involved in the electronic industry. These are:

- High-purity applications

- Ultra-pure gas applications

- High vacuum applications

- Semiconductor transfer

- Positioning and motion control

- Assembly of printed circuit boards

- Cooling processes and temperature control

- Coating

- Media monitoring and control

- Control of static electricity.

- Further down you can see in detail these processes and our specific solutions for each of them.

Nevertheless, we know that standard models not always fulfill your necessities. For it, we count with 5 technical centers, 2 of them in Europe (UK & Germany) that assist in developing customized solutions.

Food

-

Understanding that hygienic standards & high speed are key for you

Be our partner because we know; because we can

The food industry is highly influenced by strict legal regulations. At the end of day, we all need guarantees on the food we consume. Therefore, these norms are a major issue for us when developing specific solutions for this industry. Not only in terms of materials that guarantee non-toxic final consumer products, but also in terms of the hygienic design, corrosion resistant of the materials to be used in the cleaning areas.

Solutions that go, on and on and on…as your process does

Besides the compliance to related food regulations, we also have solutions ready to fulfil the challenging requirements of continuous 24/7 operation. the gold standard for measuring manufacturing productivity. Long-life components to keep up with non-stop production processes.Identify the percentage of manufacturing time that is truly productive, with the OEE (Overall Equipment Effectiveness).

Our team of experts, distributed amongst 83 countries, boast the specific expertise to support all the above daily challenges with either standard or customised solutions that are supported by our five technical centres, two of them located in Europe.

Robotics

-

Compact, lightweight and energy efficient solutions to meet your needs

Your right arm

Robots and humans are forced to work hand in hand: industrial robots running more and more production plants, humans contributing their skills for strategic thinking, invention and detail.

With a close relationship with our customers – our inspiration – SMC products are used to find and create solutions that were not previously thought possible.

We consider, SMC can be “Your right arm” in Robotics, our international teams of Experts are ready to support you with your daily challenges and our local and European technical centres ready to develop any customised solution you might need.

Discover below our key solutions for robotics : innovative, compact, lightweight and enduring. Easy & Flexible.

Further down, do not miss how SMC solutions can specifically boost welding, painting and handling applications.

Life Science

-

Quality & specific materials to guarantee all of us well-being

Meet our Life Science team; they are full of answers

You need high-tech solutions, quality and long-life products and perhaps even miniature components.

And whether you are a small organization or a big multinational, we put at your disposal:

- Materials to deal with all sorts of fluids; even the most aggressive ones

- Fluid handling systems

- Quiet temperature control equipment

- Acrylic products for high purity applications

- Specialist pumps, and

- Miniature valves.

Mining

-

Reliable, efficient & powerful solutions for harsh working conditions

We provide you with the strong and enduring solutions you need

An industry as important as the Mining industry could benefit greatly from pneumatics and automation.

The extraction and processing involves very harsh and extreme working conditions; if one industry demands strong, reliable and quality products it is yours.

Many times, because staff health and safety are at stake. To achieve the peace of mind you need, we are here to offer you:

- A wide range of solid solutions: heavy duty actuators, ISO cylinders, positioners.

- Custom-made solutions: special cylinders adapted to your own working requirements or control cabinets to fit your specific needs.

- Materials that withstand high temperatures and durable components.

Packaging

-

We support you in every step of your process

Filled with solutions for you

Packaging was born to deliver goods from producer to consumer. However, nowadays packaging functions go far beyond containing, protecting and preserving.

The current customer-centric arena, assisted by multiple technological innovations, has introduced communication, promotion and differentiation within its core functionalities.

These new requirements, together with cost-efficiency, light solutions, demand and the ever-present sustainability, have made us, the suppliers, adapt and evolve together with our customers’ new needs.

Nevertheless, our core commitment to the packaging industry has remained unchanged.

Thermo-forming, Filling, Sealing, Shrink Wrapping, Case Erecting, Conveying, Case packing, Palletising. These are some of the parts of your process.

These are our solutions for them, and the benefits for you:

- Temperature control equipment – Improve performance & reliability

- Products & Materials compliant with your process – Ensure product & process hygienic conditions

- Static electricity removal solutions – Guarantee final product quality

- High-speed guarantors – Keep up your productivity

- Smart Flexibility – Achieve the Smart Flexibility your customers demand

- Environmentally-resistant products – Operate smoothly in micro-powder environments.

Machinery safety

-

Creating confidence with confidence. SMC is an innovative, reliable and strong partner for pneumatic and electrical automation technology. We accompany our customers throughout the entire life cycle of their plant and, for all relevant safety issues, we have competent and professional solutions at your disposal.

From individually designed machines to highly complex systems, we not only meet all the requirements for flexibility and productivity, but also for smooth user and operational safety.

To also ensure this in your company, we offer innovative and tailor-made safety solutions and ISO 13849-compliant safety components. Achieving the highest possible risk minimisation and protecting machine operators is the focus here.

The success of the whole lies in the detail For all questions about your safety technology, we rely on personal commitment. We have a large customer care team throughout Europe and a wide distribution network. For you this means: Our competent team is directly in your area and is available for you by way of personal contact.

Energy efficiency

-

Transform energy into a boost for your competitiveness

Energise your efficiency

In our 24/7 economy and as Governments, industries and consumers battle with our thirst for ever increasing supplies of energy, SMC has always been fully committed to assist customers in reducing their bills and of course, in making its modest contribution to global sustainability.

We now want to share our 5 cornerstones of energy efficiency with you that will help you to embrace good energy policies for your business in a very intuitive and simple way.

IO-Link

-

Enjoy IO-Link advantages with SMC. Your one supplier for your automation needs

SMC your one-stop-shop for all your automation needs

Hot on the heels of Lean Manufacturing the focus has once again changed.

With the goal to improve manufacturing performance, using more automated operations and the use of data analytics, Smart Manufacturing (SM) is today’s Holy Grail. This technology-driven approach, using internet connected machinery to monitor the production process, has seen the development of smart machine components.

SMC IO-Link sensors, IO-Link master and IO Link actuators are just some of our smart products that can help improve your productivity and reduce your costs.

For more information on our smart factory solutions check out our latest products on our website today.

New technology enables sensors and actuators to become smarter but…

What is IO-Link really?

IO-Link (IEC61131-9) is an open standard serial communication protocol that allows the bidirectional exchange of data from sensors and devices that support IO-Link and are connected to a master. The IO-Link master can transmit this data over various networks, fieldbuses, or backplane buses, making the data accessible for immediate action or long-term analysis via an industrial information system (PLC, HMI, etc.). Each IO-Link device has an IODD (IO Device Description) file that describes it and its IO-Link capabilities.

Did you know that...

IO-Link is not another fieldbus. It is a point-to-point communication between a compatible IO-Link Master and a field device. Because IO-Link is an open standard, Master devices are available for virtually any fieldbus or automation system (PLC).

Industry 4.0

-

SMC’s Smart Flexibility helps you to build the flexible machines that will materialise the adaptability, speed and customisation the markets are demanding

SMC’s approach on Industry 4.0 - Smart Flexibility

From mass production to mass customisation, does it sound familiar?

This is the main concern of the Industry 4.0, Factory of the Future, Smart Factory or Digitalisation, you name it. It is no longer to mass produce, but to do it in a personalised, cost-effective, speed and sustainable way.

Against the backdrop of rapid changes in expectations and preferences, in the accepted time to market, a sphere where loyalty has become rather slippery; where technologies are developing much faster than our understanding of them, we feel we need to grab something, and that something is Flexibility.

Through a close partnership with you, SMC’s Smart Flexibility is based on making your machines Industry 4.0-proof, in order to equip them with the necessary flexibility that markets are calling for. Smart Flexibility combines what works best; expertise in automation and the passion of working shoulder-to-shoulder with you.

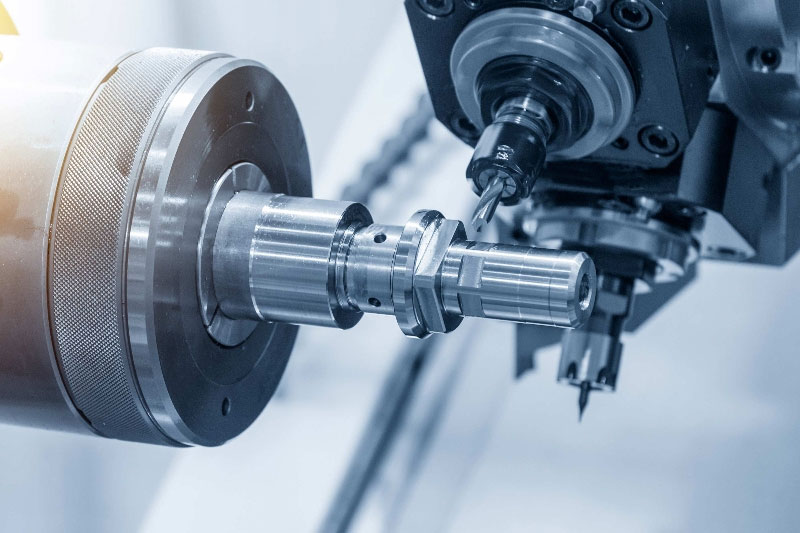

Machine Tool industry

-

Complete solutions for ongoing challenges

Machine tools are an integral part of the manufacturing process and indispensable to the industry, particularly for those reliant on interchangeable components. The category includes a wide range of equipment - lathes, presses, milling machines, laser cutters, shapers – and makes up a significant proportion of all manufacturing devices. Machine tools are therefore a key component of the global market. Europe produces 35% of the machine tools in the world (European Association of the Machine Tool Industries CECIMO, 18 June 2019). This is a substantial figure that cannot be ignored.

Nowadays, the main challenge for machine tool companies is to train mechanical, electronic and electrical engineers in the smart and flexible manufacturing processes that result in more productive lines with shorter cycle times. SMC’s global presence allows us to be close to our customers, understanding their needs and developing products that adapt to the challenges they face, taking into account the latest industry trends such as reducing weight and consumption, and increasing precision.

At SMC we make your machines more competitive thanks to our wide range of industrial automation products, from air treatment to laser equipment. Discover some of our solutions below.

Tyre industry

-

SMC, your support on the road to excellence

Who hasn’t ever drawn a car? Artistic skills aside, surely three elements were definitely in your drawing: windows, chassis and wheels. Nobody can argue that automobiles need wheels, and this principle is so basic that it makes tyres a fundamental pillar of the automobile industry.

To achieve high competitiveness, without relinquishing on the best quality, SMC offers you the best allies to guarantee that the tyre production process performs to its full potential.

Air treatment

-

Quality compressed air for efficient pneumatics

For engineers, compressed air is such an important resource that it is often cited as the fourth utility in industry – after electricity, water and gas. Studies estimate that ten per cent of all industrial energy is used just to compress air.

By following along, you can be confident in designing and building an air purification system that exactly matches the needs of the task at hand with no frills.

If you are looking to start your journey, or expand your knowledge on this topic, you can take a look at our expert report about compressed air quality. Otherwise, if you are willing to design the most suitable air treatment system for your process, then our air treatment guide is the best tool for you.

Industrial maintenance

-

Keep going!

There is no production process that can achieve optimum productivity without taking care of a good maintenance programme, but probably this information isn’t new for you. Since industrial maintenance became popular in the 20th century, most production lines and factories have been designing and implementing maintenance actions for their processes.

Nevertheless, industrial maintenance is a culture of its own, that not only consists of repairing machines, but implies that the whole production team (technicians, engineers, leaders, etc.) is trained in the continuous improvement of the maintenance strategy in order to reduce costs, eliminate waste and build a more efficient process.

If you’re willing to know which style suits you best, or how you can improve your programme, take a look at our solutions for industrial maintenance, and keep your production going.