- Offer Profile

-

With more than 85 years of experience, we are an expert in hydraulic power transmission and control. That is an obligation!

Five locations in Germany, Austria and Poland are united under the umbrella of the WEBER-HYDRAULIK Group. Together they stand for customized and reliable hydraulic solutions and innovative rescue technology. The aim of bundling our know-how is to be able to offer successful solutions in the demanding and challenging market of mobile and stationary hydraulics.

Our investment in research and development, the use of modern production technologies and the continuous training of our employees ensure rapid progress. Our many years of experience in the development of high-quality cylinders, control blocks, valves and power units form the core of our technology. As an internationally leading, innovative and future-oriented partner, we use this as the basis for implementing sophisticated, application-specific system solutions for our customers.

CYLINDERS

-

One of the core competences of WEBER-HYDRAULIK is the development of individual cylinders or the revision of existing cylinders for your special application or your installation space and the transfer to series production.

Each cylinder is subject to rigorous measurements prior to use in order to meet the highest quality standards.

For intelligent additional functions we equip our cylinders with sensors and systems for stroke measurement, pressure measurement, temperature measurement, force measurement and point measurement.

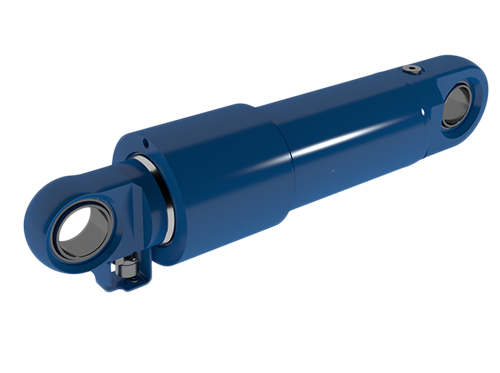

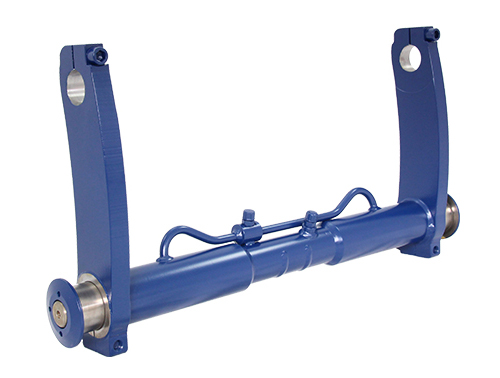

STEERING CYLINDER WITH CENTERING FUNCTION

-

This cylinder has been specially developed for mobile cranes with several actively steered rear axles. The steering of the rear axles significantly improves manoeuvring with these vehicles. A special requirement for the cylinder was that the steering centering cylinder should set the axle to run straight at a certain vehicle speed and in the case of a fault in the rear axle steering area. Legal security requirements also required a robust design with high reliability.

Advantages:

- The robust and reliable, exclusively hydraulic, active centre positioning without mechanical locking elements is almost wear-free.

- Check and pressure relief valves are located directly on the cylinder, minimizing the risk of pipe breakage and excessive external forces.

- Successfully tested on the endurance test system and meanwhile successfully used in series production for several years.

Nickel-chrome plating of the induction hardened piston rod with corrosion resistance 600h NSS R10′ (optionally with bellows)

Steels with notched bar impact values KV min. 27 J. at -40 °C transverse/longitudinal

TECHNICAL DATA:PISTON DIAMETER: 80 mm and 70 mm

HOLDING FORCE AT EXTERNAL PULL FORCE: 84.1 kN

HOLDING FORCE AT EXTERNAL PUSH FORCE: 80.8 kN

DRIVER'S CAB TILT CYLINDER (LOST MOTION)

-

Due to the design of most trucks, the engine is located directly underneath the driver’s cab. In order to guarantee the accessibility of the engine, a hydraulic system is used. The individually adjustable driver’s cab cylinder plays an important role here. Once activated, the cylinder retracts and initiates the tilting process of the driver’s cab. Once it reaches its end position, the cylinder holds the cab in a fixed position and thus ensures safe access to the engine compartment.

The WEBER-HYDRAULIK patented lost motion system ensures optimum comfort while driving. The cab tilt cylinder establishes a static connection between the chassis and the cab. During driving, however, the damping causes relative movements between these components. To compensate for these shocks, the cylinder must be freely movable while driving. The is possible with the lost motion system.

Advantages:

- Patented lost motion system for free movement of the cylinder during driving

- Robust and durable design

TECHNICAL DATA:NOMINAL PRESSURE FORCE: max. 60 kN

NOMINAL PULL FORCE: max. 40 kN

SUPPORTING CYLINDER WITH INTEGRATED FORCE MEASUREMENT

-

Up to now, the force at the supporting cylinders has often been determined indirectly via the pressure in the piston chamber. However, this is very inaccurate and measurement deviations of more than 20% are possible, especially under the influence of lateral forces. In order to ensure stability at all times, however, appropriate safety factors are required, which in turn lead to reduced load capacity utilisation. For this reason, WEBER-HYDRAULIK developed a new supporting cylinder for a customer, in which the force is measured directly at the spherical head of the cylinder. For this purpose, an innovative force transducer has been developed that is fully integrated into the piston rod. A large number of realizable analog or digital output signals also ensure the best possible compatibility with the user’s systems.

Advantages:

- Fully integrated force measurement

- High measuring accuracy even under difficult ground conditions

- Mechanical decoupling of the force transducer in the rest position to protect the sensor from external influences and shocks

- Improved machine utilization due to maximum exploitation of the load capacity

- Online monitoring of the supporting situation and the degree of utilization of the stability limit

- Protection of the measuring technology against lateral forces and vibrations during driving

TECHNICAL DATA:STROKE: 700 mm

ROD DIAMETER:160 mm

PISTON DIAMETER: 180 mm

SUSPENSION CYLINDER WITH INTEGRATED PISTON ACCUMULATOR

-

The suspension cylinder with integrated piston accumulator developed by WEBER-HYDRAULIK is used as a chain tensioner in crawler chassis. The harsh conditions of the application mean that the components would be exposed to extreme conditions and heavy wear. This applies in particular to external storage devices that have to be connected to the vehicle’s electrical wiring. For this reason, an accumulator integrated into the cylinder has been developed, which is thus protected from the harsh environmental conditions. In addition, the system is particularly light due to the omission of components.

Advantages:

- Weight reduction due to the elimination of components

- Cylinders can be delivered filled, which results in less assembly effort.

- Compact installation dimensions

- Long lifetime

TECHNICAL DATA:CYLINDER: EZ75

STROKE: 185 mm

NOMINAL PRESSURE: 210 bar

IMPLEMENTED OPTIONS:- Customized installation length and piston diameter

- Customized mounting with a ball joint at the top and bottom

- Load-dependent preload of the integrated piston accumulator

- Low friction compact seal

- Corrosion protection piston rod chrome plating / surface treatment and customized paint system

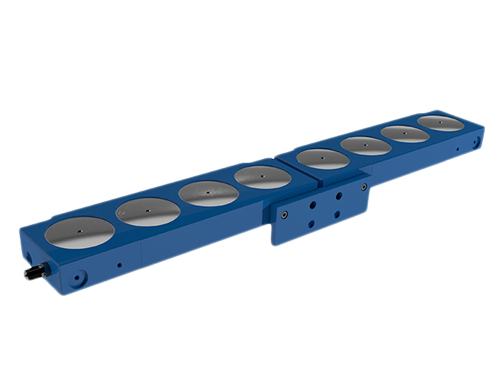

CROWN CYLINDER

-

The crown cylinder was specially developed for use in bending machines. During the bending process, the machine is subjected to extreme forces, which, among other things, cause deformation of the bending tool. The bending result is strongly affected by this so-called crowning and is therefore difficult to calculate.

The crown cylinder is used inside the machine to compensate for this deformation, it compensates the forces and thus guarantees an exact result.

Advantages:

- Patented lost motion system for free movement of the cylinder during driving

- Robust and durable design

TECHNICAL DATA:NOMINAL PRESSURE: 300 bar

TEST PRESSURE: 310 bar

PUSH FORCE AT PN PER CYLINDER: 259,8 kN

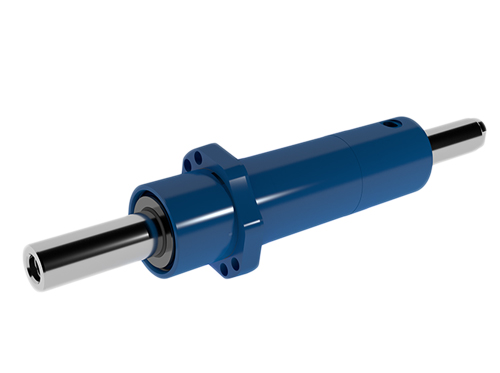

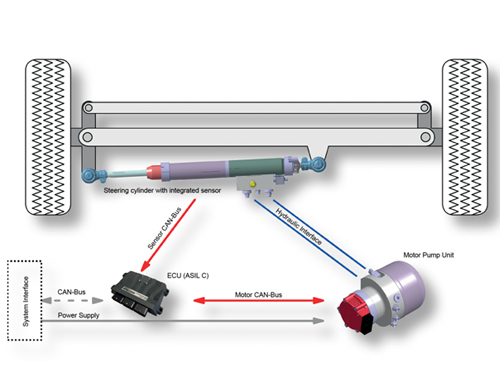

DOUBLE-ACTING STEERING CYLINDER WITH POSTION MEASUREMENT

-

WEBER-HYDRAULIK’s double acting steering cylinder is used in agricultural and construction machinery such as small loaders and backhoe loaders when using different steering modes such as crab steering and 4-wheel steering.

The requirement for this cylinder was that for steering control, the alignment of the axle to the straight position should be recorded. For this purpose, the middle position of the piston rod of the double acting steering cylinder is measured. This is enabled by means of magnetic detection. An external magnetic field sensor detects the magnetic field of a permanent magnet integrated in the piston. The cylinder tube is made of austenitic steel and cannot be magnetized.Advantages:

- Robust cylinder design with few additional components for the realization of position detection with a very high reliability.

- The cylinder is pushed into the axle housing for mounting and bolted to the flange with the axle.

- The magnetic field sensor is plugged into the axle housing at the appropriate position and screwed in place.

TECHNICAL DATA:CYLINDER FORCE (PULL/PUSH): 56 kN

NOMINAL PRESSURE: 185 bar

USED STROKE RANGE: 2 x 90,5 mm

PRESS CYLINDER FOR GARBAGE COMPACTORS WITH INTEGRATED DAMPING

-

The compacting plant cylinder with integrated damping is used in the municipal sector for garbage trucks.

TECHNICAL DATA:PUSH FORCE 70MM AT PN: 53,1 kN

TEST PRESSURE: 180 bar

NOMINAL PRESSURE: 140 bar

IMPLEMENTED OPTIONS:- Cardanic mounting

- Integrated damping

WEBER-HYDRAULIK TELESCOPE CYLINDER

-

In addition to our customer-specific cylinder development, we also offer telescopic cylinders mainly as tilting cylinders for farm vehicles and 2 or 3-way tilting equipment.The listed telescopic cylinder types are executed in a plunger construction with the piston rod side seal. Suspension pins with a gimbal ring are mounted at the cylinder surface. The piston’s last stage of the 2-stage telescopic cylinders is provided with a bore. The piston’s last stage of the 3-6 stage telescopic cylinders is provided with a ball socket for welding or screw mounting. A time-tested snap ring design combined with low wear wipers/seals made of polyurethane ensure reliability and low lubricant film thickness.

Advantages:- Chromed extending pillar

- High nominal pressure

- Venting screw from piston diameter 75mm upwards

TECHNICAL DATA:LIFTING SPEED RANGE: up tp 0,1 m/s

TEMPERATURE RANGE: -10C to + 80C

NOMINAL PRESSURE: 200 bar bar

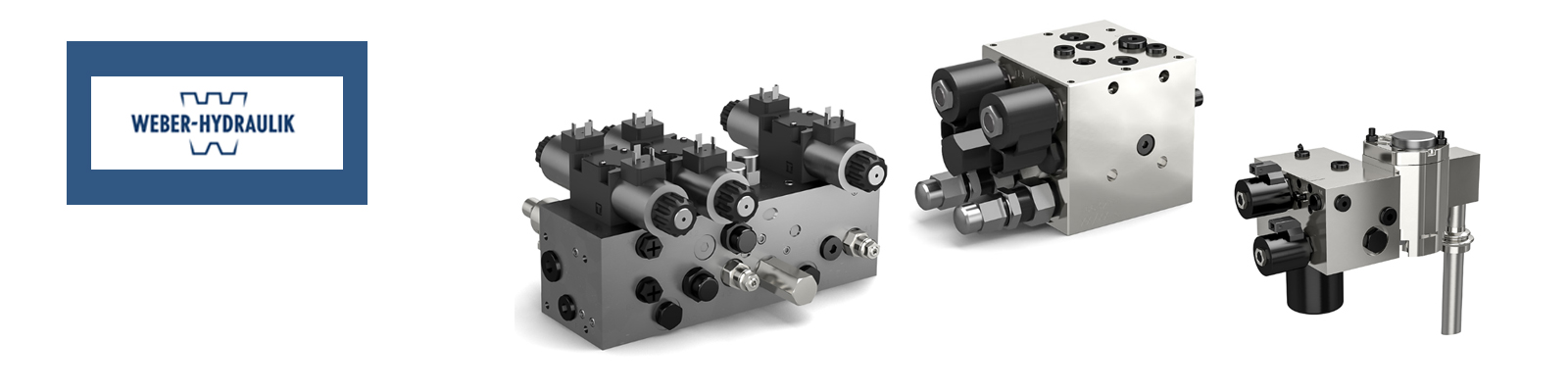

HYDRAULIC CONTROL SYSTEMS

-

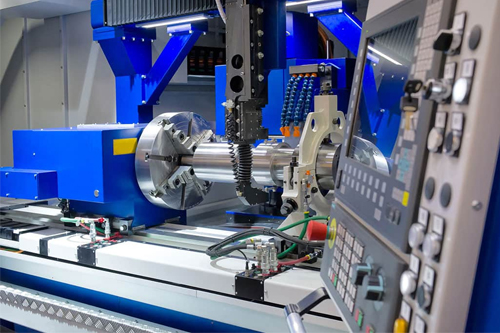

WEBER-HYDRAULIK is your partner for customized control systems. Together we develop a fast and cost efficient project planning. We accompany you with the product idea, the development of the prototypes and the SOP. Our sales and development team supports you in design and system integration.

To offer you the most efficient and highest quality valve solutions, we have access to all valve manufacturers available on the market in addition to our own proportional valve technology.

Our state-of-the-art machinery produces technologically sophisticated control blocks, from the smallest to the largest series. Quality is our top priority: Our quality management processes meet the highest standards and are constantly optimized at our assembly and testing facilities.

CONTROL BLOCK STEERING BY WIRE

-

In modern machines, the steering cylinders are controlled electrohydraulically. This makes it possible to map various steering characteristics and increase the driving comfort of the driver.

The integrated load sensing function in combination with a flow-optimized design ensures an energy-efficient system structure.

Advantages:

- Compact and flow-optimized design

- Proportional and sensitive steering control

- Load-Sensing integrated

- Minimized pressure losses

TECHNICAL DATA:MAXIMUM OPERATING PRESSURE: 210 bar

MAXIMUM VOLUME FLOW: 25 l/min

OPERATING TEMPERATURE: -25C to + 80C

MATERIAL CONTROL BLOCK: Aluminum

CONTROL BLOCK HYDRAULIC RELIEF OF ATTACHMENTS

-

Attachments on working machines usually have a high tare weight and thus provide a high negative load on the actuating cylinder.

The tare weight can be hydraulically counteracted by a relief function.

This ensures the adjustment accuracy of the attachment.

Advantages:

- Proportional control with pressure protection on all sides

- Load-independent volume control even with pulling loads

- Integrated swimming function

TECHNICAL DATA:MAXIMUM OPERATING PRESSURE: 250 bar

MAXIMUM VOLUME FLOW: 30 l/min

OPERATING TEMPERATURE: -25C to + 80C

MATERIAL CONTROL BLOCK: Aluminum

CONTROL BLOCK CYLINDER FUNCTION

-

The control of several hydraulic cylinders in mobile work machines is mapped via a central control block.

Proportional directional valves in combination with efficient lowering brake valves ensure a very well manageable control even with high loads.

The integrated Load-Sensing ensures a demand-oriented volume flow supply to the control block.

Advantages:

- Proportional control of three cylinder functions

- Load-Sensing integrated

- Integrated lowering brake valves for controlled lowering under high load

- Pressure protection on all sides

TECHNICAL DATA:MAXIMUM OPERATING PRESSURE: 250 bar

MAXIMUM VOLUME FLOW: 30 l/min

OPERATING TEMPERATURE: -25C to + 80C

MATERIA CONTROL BLOCKL: Aluminum

CONTROL BLOCK SWIVEL TRAVERSE FORK

-

The control of the swivel traverse fork is necessary to ensure accurate loading and unloading of the load carriers.

Monitoring interfering contours in the rack aisle enables narrow aisle equipment, for example, to avoid contacts and thus damage to the load.

Advantages:

- Proportional lifting and lowering of the auxiliary lift

- Automated parallel operation of swiveling and reaching

- Weight and cost savings due to aluminum control block.

TECHNICAL DATA:

MAXIMUM OPERATING PRESSURE: 150 bar

MAXIMUM VOLUME FLOW: 40 l/min

OPERATING TEMPERATURE: -25C to + 80C

MATERIAL: Aluminum

MAST MAIN CONTROL

-

This control block enables the control of all working functions of an order picker, i.e. lifting and lowering of the mast.

The compact control block was developed for direct pump mounting.

Advantages:

- Small installation space due to direct mounting of the hydraulic pump

- Integrated pressure filter in the control block

- Energy efficient due to energy recuperation when lowering the lift mast

- Weight and cost savings due to aluminum control block

TECHNICAL DATA:

MAXIMUM OPERATING PRESSURE: 210 bar

MAXIMUM VOLUME FLOW: 40 l/min

OPERATING TEMPERATURE: -25C to + 80C

MATERIAL: Aluminum

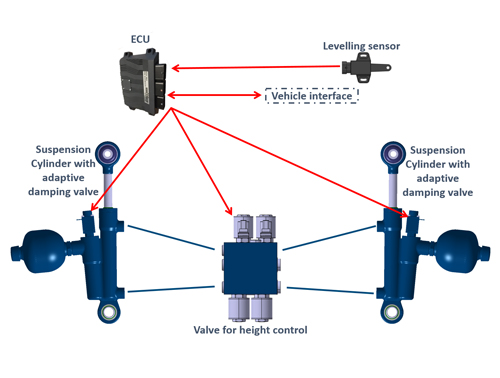

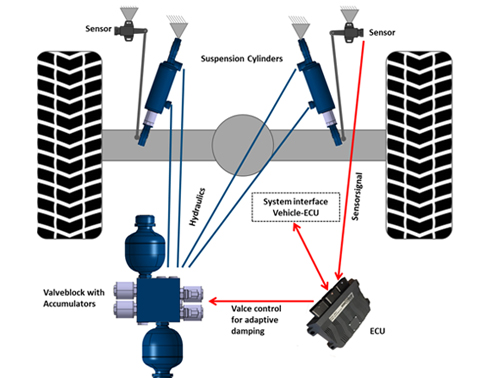

CONTROL BLOCK AXLE VALVE FUNCTION

-

While driving, mobile cranes are suspended by hydraulic cylinders to ensure driving comfort and safety. The required high hydraulic flow and pressure is directed through the axle valve to the suspension cylinders.

While the mobile crane is being lifted, the wheels must be unloaded (often hovering above the ground) to allow the mobile crane to stand safely and reliably. The axle valve blocks the suspension cylinder from extending so the wheels do not touch the ground.

Advantages:

- Project planning, design and production from a single source

- High flexibility, fast decisions, short time to market

- Extensive expertise from many different applications and industries

TECHNICAL DATA:MAXIMUM OPERATING PRESSURE: 375 bar

MAXIMUM VOLUME FLOW: 300 l/min

OPERATING TEMPERATURE: -40C to + 80C

MATERIAL: Aluminum/ steel

VALVE CATALOG

PROPORTIONAL DIRECTIONAL VALVES

4/2 Proportional Directional Valve W42E-5PS03

-

The proportional directional valve W42E-5PS03 is a direct operated valve with maximum hydraulic performance in a compact size. It is used for the stepless adjustment of both the size and direction of volume flows.

The W42E-5PS03 essentially consists of a nitrocarburized body in which a hardened and honed steel sleeve is shrunk. The hardened and polished control piston runs in it. This construction ensures very low oil leakage values and extreme durability. There are three flow ranges available for adaptation to the respective application.

Characteristics:

- Proportional directional valve in a piston design

- Compact dimensions

- Flow rate direction and volume control

- Low leakage oil values

- Spring-centred piston

- Maintenance-free

- Different nominal flow ranges

Different Variants available.

4/2 Proportional Directional Valve W42E-1AS06

-

The proportional directional valve W42E-1AS06 is a direct operated valve with maximum hydraulic performance in a compact size. It is used for the stepless adjustment of both the size and direction of volume flows.

The control piston moves proportional to the solenoid current, thereby changing the respective opening cross-sections.

The proportional directional valve is available as a 4/2-way directional valve or as a 4/3-way directional valve.

There are various flow ranges available for adaptation to the respective application.Characteristics:

- Proportional directional spool valve

- Spring centred spool

- Controls volume and direction of flow rate

- Maintenance-free

- Rotatable and replaceable coils

- Available woth various volume flows

- 4/2-way and 4/3-way variants

4/3 Proportional Directional Valve W43E-1AS06

-

The proportional directional valve W43E-1AS06 is a direct operated valve with maximum hydraulic performance in a compact size. It is used for the stepless adjustment of both the size and direction of volume flows.

The control piston moves proportional to the solenoid current, thereby changing the respective opening cross-sections.

The proportional directional valve is available as a 4/2-way directional valve or as a 4/3-way directional valve.

There are various flow ranges available for adaptation to the respective application.Characteristics:

- Proportional directional spool valve

- Spring centred spool

- Controls volume and direction of flow rate

- Maintenance-free

- Rotatable and replaceable coils

- Available woth various volume flows

- 4/2-way and 4/3-way variants

PROPORTIONAL 2/2-WAY POPPET VALVE S22E-1V08

-

The proportional poppet valve S22E-1V08 is a pilot operated valve with maximum hydraulic performance in a compact size. It is used for volume flow control.

Characteristics:

- proportional poppet valve

- compact design

- leakage free closing

- volume flow control

- maintenance-free

- rotatable and replaceable solenoid coils

PROPORTIONAL PRESSURE RELIEF VALVES

Proportional Pressure Relief Valve EPDBD 05

-

The proportional pressure relief valve, size 05, is a direct operated valve in a differential cone construction that can be also used as a pilot valve for remote pressure adjustment. It allows pressures to be set proportionally to the solenoid current.

The direct operated proportional pressure relief valve size 05 is constructed according to the differential surface principle, which makes it particularly suitable for controlling relatively large pilot flow rates (e.g. of variable delivery pumps). It allows pressures to be set proportionally to the solenoid current. The valve opens as soon as the pressure applied to port P reaches the current setpoint value (solenoid current) thus allowing the medium to flow to port T. If the pressure drops again, the valve closes with low hysteresis.

Characteristics:

- proportional pressure relief valve in spool design

- according to the ATEX-directive for the use in potentially explosive atmospheres

- slip-in valve for cavity EEPDBD 05

- suitable as pilot valve

- low vibration

- maintenance-free

- Electric

TECHNICAL DATA:OPERATION: Direct operated

FLOW RATE: 12 l/min

SIZE: C-10-2 (7/8-14 UNF), In-line Body 1/4″, NG 6, Slip-in valve d = 16 mm, T-10A (M20x1,5)

MAX. OPERATING PRESSURE: 315 bar

Proportional Pressure Relief Valve EPDBDGA 05/06

-

The direct operated proportional pressure relief valve EPDBDGA-05/06 enables pressures to be set proportional to the solenoid current. The proportional pressure relief valve EPDBDGA-05/06 can be used directly to limit flow rates of up to 12 l/min or as a pilot valve for remote-controlled pressure relief or pressure control valves.

The valve opens as soon as the pressure applied to port P reaches the current setpoint value (solenoid current) thus allowing the medium to flow to port T. If the pressure drops again, the valve closes with low hysteresis.

The valve has a fast and precise control behaviour that remains stable even when vibration is present.

It is relatively insensitive to oil contamination. The control piston is hardened and polished.

The very robust valve is characterised by its very flat Δp/Q characteristic curve.

TECHNICAL DATA:FLOW RATE: 12 l/min

SIZE: NG 6S

MAX. OPERATING PRESSURE: 315 bar

ACTUATION: Electric

Proportional Pressure Relief Valve EPDB 08

-

The proportional pressure relief valve, size 08, is a pilot operated spool type valve. It allows pressures to be set proportionally to the solenoid current.

The valve opens as soon as the pressure applied to port 1 reaches the current setpoint value (solenoid current) thus allowing the medium to flow to port 2. At the same time it reduces the risk of a soar in pressure under unfavourable conditions (long hose lines, large dead volume, etc.).

All function-relevant parts are hardened and honed. To achieve an optimal resolution, there are numerous setpoint pressure areas available. The valve is available for the stepped bores T-10A and C-10-2. The valve is also available complete with various pipe casings. Furthermore, it is also available in a wide range of sandwich and top-mount bodies in the nominal size 6 (DIN 24340 A06) and 10 (DIN 24340 A10).

TECHNICAL DATA:OPERATION: Pilot operated

FLOW RATE: 80 l/min

SIZE: C-10-2 (7/8-14 UNF), NG 6, T-10A (M20x1,5)

MAX. OPERATING PRESSURE: 315 bar

ACTUATION: Electric

Proportional Pressure Relief Valve EPDBS 10

-

The proportional pressure relief valve, size 10, is a pilot operated valve in spool design. Pressures can be set proportional to the solenoid current.

A progressive increase of the opening cross-section is achieved thanks to an offset arrangement of the outlet holes. This results in a precise response over the entire flow range. At the same time it reduces the risk of a soar in pressure under unfavourable conditions (long hose lines, large dead volume, etc.).

All function-relevant parts are hardened and honed. To achieve an optimal resolution, there are numerous setpoint pressure areas available. The cartridge valve is available for the stepped bore T-3A. The valve is also available complete with various pipe casings and a wide range of sandwich and top-mounting plates in the nominal size NG 10 (DIN 24340 A10).

TECHNICAL DATA:

OPERATION: Pilot operatedFLOW RATE: 150 l/min

SIZE: NG 10, T-3A (1″-14 UNS)

MAX. OPERATING PRESSURE: 315 bar

ACTUATION: Electric

Pilot Operated Proportional Pressure Relief Valves With Large Nominal Size

-

Characteristics:

- Pilot-operated proportional pressure relief valves or pressure control valves with large nominal size

- Modular set-up out of proportional pilot valves and mechanical cartridge valves with cavities up to T-19A

- Pressure relief valves up to 760 l/min

- Suitable in-line bodies and subplates up to NG 25

- Varied combinations with different technical characteristics possible

TECHNICAL DATA:OPERATION: Pilot operated

FLOW RATE: 760 l/min

SIZE: NG 25, T-19A (M48x2)

MAX. OPERATING PRESSURE: 315 bar

ACTUATION: Electric

Proportional Pressure Sequence Valve EPDZA 06

-

The proportional pressure sequence valve EPDZA allows oil coming from channel P to flow from a defined, proportionally adjustable opening pressure to channel A.

If the pressure in channel P drops under the setpoint value, the valve closes with low hysteresis.

In contrast to pressure relief valves, with EPDZA the actual opening pressure in channel P remains constant, regardless of pressure variations in channel A (requirement P < A). The EPDZA consists of a remote-controlled mechanical pressure relief valve, which is piloted by a proportional pilot valve. The spring chamber of the pilot stage of the mechanical valve is relieved separately via channel T.If the pressure fluctuations in the T-channel are negligible, the control oil of the proportional pressure relief valve can be channelled to T (plug 1, see icon). Otherwise, it must drain to channel B (plug 2). The valve has a mechanical maximum pressure setting. Below this setting, the valve works proportionally.

FIELDS OF APPLICATION:

- The EPDZA is used for a more precise adjustment of consumer or system pressures, as it is independent of pressure fluctuations in the flowing oil.

- For clamping and braking functions, to ensure that a certain pressure is present before the oil can flow to further consumers.

TECHNICAL DATA:OPERATION: Pilot operated

FLOW RATE: 40 l/minSIZE: NG 6

MAX. OPERATING PRESSURE: 350 bar

ACTUATION: Electric

PROPORTIONAL PRESSURE CONTROL VALVES

Proportional Pressure Control Valve EPDRD3-04

-

The 3-way proportional pressure control valve EPDRD3 size 04, is a direct operated valve in spool design that is suitable as a pilot valve. It reduces an inlets’ pressure to a lower consumer pressure. The consumer pressure is proportionally adjustable to the solenoid current. The valve is particularly suitable for controlling relatively large pilot flow rates (e.g. of variable delivery pumps). However, due to the very small leakage oil values, it is also widely used in low-loss small hydraulic systems (e.g. clamping or braking systems).

To achieve optimal resolution, there are numerous pressure ranges available. The valve has a fast, accurate and low-vibration response. At just about 0.3 bar, the adjustable static minimum pressure is very low. Any functionally relevant components are hardened and polished or honed.The leakage values are extremely low.

The valve is buit in a compact design and is also available in a variety of in-line bodies and mounting plates in nominal size 4 (NG 4, ISO 4401) and nominal size 6 (NG 6, DIN 24340 A06).

Characteristics:- 3-way proportional pressure control valve in spool design

- operating pressure max.: 315 bar

- slip-in valve for cavity EPDRD3-04

- suitable as pilot valve

- compact design

- minimum oil leakage

- low vibration

- maintenance-free

- degressive version available

- also usable as 2-way proprotional pressure reducing valve (after consultation with WEBER-HYDRAULIK)

TECHNICAL DATA:OPERATION:Direct operated

FLOW RATE:4 l/min

SIZE: In-line Body 1/4″, NG 4, NG 6, Slip-in valve d = 16 mmMAX. OPERATING PRESSURE: 315 bar

ACTUATION:Electric

Other variants available. (EPDRD3-05)

The valve is also available in degressive versions.

Proportional Pressure Control Valve EPDR3-06

-

Oil keeps flowing from port P to A until the setpoint pressure is reached, then the valve closes. The valve only opens up again from P to A when the consumer pressure drops. If the setpoint pressure is exceeded on the consumer side, the pressure relief function of the valve is activated (three-way function). Oil will then flow from port A to T until the setpoint pressure is reached. The valve can also be used purely as a pressure reducer (2-way function). However, the third port (T) may not be closed.

The valve has a mechanical limitation of max regulating pressure, in case it is not allowed to exceed a certain value even if control electronics fail. Optimal adaptation to the requirements is possible through a variety of pressure ranges. The valve has a precise and reliable response and control behaviour.

The following should be noted:

the greater the difference between the inlet pressure and consumer pressure, the cleaner the oil must be (it is necessary to have filtration down to 3 µm).

TECHNICAL DATA:

OPERATION:Pilot operatedFLOW RATE:30 l/min

SIZE: NG 6MAX. OPERATING PRESSURE: 315 bar

ACTUATION:Electric

Other variants available.

(EPDR3-08)

Proportional Pressure Control Valve EPDRS3-10

-

The compact 3-way proportional pressure control valve EPDRS3 size 10, is a pilot operated valve in spool design which reduces an inlet pressure to a lower consumer pressure. The consumer pressure is proportionally adjustable to the solenoid current.

To achieve optimal resolution, there are numerous pressure ranges available. The valve has a fast, accurate and low-vibration response. Any functionally relevant components are hardened and polished. The valve is also available in a variety of sandwich- or in-line bodies and mounting plates. The valve is available in degressive versions.

Characteristics:

- 3-way proportional pressure control valve in spool design

- operating pressure max.: 315 bar

- screw-in valve for cavity T-2A

- low vibration

- maintenance-free

- degressive version available

- also usable as 2-way proprotional pressure reducing valve (after consultation with WEBER-HYDRAULIK ValveTech)

TECHNICAL DATA:OPERATION: Pilot operated

FLOW RATE:80 l/min

SIZE: NG 10, T-2A (1″-14 UNS)MAX. OPERATING PRESSURE: 315 bar

ACTUATION:Electric

Pilot Operated Propportional Pressure Control Valves With Large Nominal Size

-

Characteristics:

- 3-way proportional pressure control valve in spool design

- operating pressure max.: 315 bar

- screw-in valve for cavity T-2A

- low vibration

- maintenance-free

- degressive version available

- also usable as 2-way proprotional pressure reducing valve (after consultation with WEBER-HYDRAULIK ValveTech)

TECHNICAL DATA:OPERATION: Pilot operated

FLOW RATE: 320 l/min

SIZE: NG 25, T-19A (M48x2)MAX. OPERATING PRESSURE: 315 bar

ACTUATION:Electric

PROPORTIONAL THROTTLE VALVES

Proportional Throttle Valve PVDE2-11

-

Proportional throttle valves of the PVDE, PVDR and PVDES series adjust a flow rate steplessly depending on the electric control current and Δp.Proportional throttle valves of the PVDE, PVDR and PVDES series adjust a flow rate steplessly depending on the electric control current and Δp.

The PVD * proportional throttle valve is very versatile. Thus, for example, it can be used in combination with pressure compensators to create very high quality 2 and 3-way flow controllers (see series EPSR). When used in conjunction with Δp- regulated, variable displacement pumps it is possible to create energy-saving load-sensing controls.

Characteristics:

- proportional 2/2-way throttle valve

- normally open or normally closed models

- maintenance-free

- also available with EX-plug according to the ATEX-directive for the use in potentially explosive atmospheres

Available designs:- PVDE: Block-type slip-in valve (plug-in cartridge)

- PVDR: in pipe casing

- PVDES: screw-in cartridge with cavity T-13A

TECHNICAL DATA:OPERATION: Pilot operated

FLOW RATE: 3 l/min, 7 l/min, 11 l/min, 17 l/min, 21 l/min

SIZE: In-line Body 3/8″, NG 6, Slip-in valve d = 20 mm, T-13A (M20x1,5)MAX. OPERATING PRESSURE: 350 bar

ACTUATION: Electric

Different variants available.

(PVDES2-14, PVDES2-18)

PROPORTIONAL FLOW CONTROL VALVES

2-way Proportional Flow Control Valve EPSR2-11

-

The proportional flow control valve EPSR 11 controls a flow steplessly, depending on the drive electric current. The set flow rate remains constant even under changing pressure conditions (e.g. load pressure).

The EPSR 11 is available in both 2-way and 3-way designs. Within this size it is possible to choose between numerous nominal flow rates.

Characteristics:

- 2- or 3-way proportional flow control valve in in-line body, in sandwich body NG 6 or in mounting plate NG 6

- normally open or normally closed models

- available with or without check valve

- maintenance free

TECHNICAL DATA:

OPERATION: direct operated

FLOW RATE: 2 l/min, 5 l/min, 10 l/min, 15 l/min, 20 l/min

SIZE: In-line Body 3/8″, NG 6MAX. OPERATING PRESSURE: 350 bar

ACTUATION: Electric

Different variants available.

(EPSR3-11, EPSR2-14, EPSR3-14)

ELECTRONICS AND SENSORS

Proportional Chopper Amplifier SC-/ESC-/DSC-2000-U

-

The amplifiers can be used both in mobile applications as well as in stationary installations. The voltage range is therefore very broad and varies between 8 and 35 V DC. These amplifiers are very insensitive to undervoltage and voltage spikes, these amplifiers are very insensitive. They can be controlled via PLC or external potentiometers. Thanks to an optimal Imin and Imax setting it is possible to achieve a very good area dither frequency.

Special Features:

- Compensation of the temperature-dependent resistance change of the proportional solenoid

- Standard dither frequency of 140 Hz (PWM)

- Multiturn potentiometer to set Imin, Imax and ramp time

- 2 LEDs to control the power supply and the output state

- Maximum current setting of up to 2.6 A, i.e. for solenoid voltages of 12 V and 24 V

- Possibility of external control via variable voltage or current

Design:

- SC-2000-U: amplifier plug that can be plugged in directly to proportional solenoids.

- ESC-2000-U: single-amplifier block for one proportional solenoid. For mounting on 35 mm top-hat rail according to DIN EN 50022 or 50035.

- DSC-2000-U: double-amplifier block for two proportional solenoids, that can be used completely independent of each other. For mounting on 35 mm top-hat rail according to DIN EN 50022 or 50035.

Pressure Transmitter MODS

-

The MODS pressure transmitter with its stainless steel membrane and semiconductor thinfilm technology is very reliable and robust and therefore usable in most industrial applications, even in very harsh conditions.

The MODS is protected against overload and reverse voltage, and contains a limitation of power loss. It is resistant to pressure peaks. Thanks to the electronic calibration, the total error is very low. The fully welded, “dry” measuring cell has a high long-term stability and tightness. Since various signal-, thread- and connecting options are available, the pressure transmitter is applicable with all standard signals for industry, hydraulics and pneumatics.

Characteristics:

- robust

- compact

- pressure peak resistant

- overload protected

- with reverse voltage protection

- limitation of power loss

- electronic calibration

- stainless steel

- fully welded, “dry” measuring cell, therefore no internal transmission media

Applications:

- Industrial applications

- Hydraulics

- Pneumatics

- Marine application

- Railway application

- Industrial equipment and automation technology

Certifications:

- German Lloyd (GL) for marine applications

- CE-Directive 2014/30/EU

- CE-Directive 2014/68/EU

- Railway applications (DIN EN 50155)

DIRECTIONAL VALVES

2/2-way Poppet Valve MSVT-03

-

The 2/2-way MSVT poppet valves, are leakproof pilot operated cartridge valves.

The solenoid coils of 2/2-way MSVT poppet valve is easy to turn and exchange.

The valves are available as “normally open” (NO) and “normally closed” (NC). The normally closed versions are also available with manual override.Characteristics:

- screw-in poppet valve

- pilot operated

- pilot-to-open or pilot-to-close versions available

- maintanance-free

TECHNICAL DATA:

OPERATION: Pilot operatedFLOW RATE: 40 l/min

SIZE: 3/4-16 UNF

MAX. OPERATING PRESSURE: 350 bar

ACTUATION: Electric

Different variants available.

(MSVT-04, -07, -20, -21, -22)

2/2-way Miniature Pilot Poppet Valve SMSVP

-

The tightness of the 2/2-way miniature pilot poppet valve is guaranteed up to maximum pressures of 250 bar. The valve works very reliably even after long idle times.

The actuation of the valve is carried out via a pressure-tight wet pin solenoid.Good heat dissipation is even produced at 100% duty cycle. The valve is available in a “normally closed”(NC) position. It is direct operated and seals at both sides. Optional solenoids with manual override are also possible.

TECHNICAL DATA:OPERATION: Direct operated

FLOW RATE: 2 l/min

SIZE: M18x1,5

MAX. OPERATING PRESSURE: 250 bar

ACTUATION: Electric

Sandwich Body 2/2- Double Poppet Valve ZMSV2

-

The sandwich body 2/2-way double poppet valves can close channel A and B tightly, regardless of the load pressure. Function “normally closed”.

The switching process is slightly damped, which avoids decompression strokes. The minimum switching pressure (pressure difference between channel P and T) should be at least 28 bar. Sandwich plates are available in the nominal sizes 6 and 10 (also with X and Y channel).Available Versions:

- ZMSV2-06: sandwich plate NS 6 (DIN 24340 A06, CETOP/ISO 3)

- ZMSV2-10: sandwich plate NS 10 (DIN 24340 A10, CETOP/ISO 5)

- ZMSV2-10Y: sandwich plate NS 10(DIN 24340 A06, CETOP/ISO 5) with X and Y channels

TECHNICAL DATA:OPERATION: Pilot operated

FLOW RATE: 40 l/min, 80 l/minSIZE: NG 10, NG 6

MAX. OPERATING PRESSURE: 250 bar

ACTUATION: Electric

3/2-way Miniature Pilot Poppet Valve SMSV6

-

The tightness of the 3/2-way miniature pilot poppet valve is guaranteed up to maximum pressures of 250 bar. The valve works very reliably even after long idle times.

The actuation of the valve is carried out by a pressure-tight wet pin solenoid.Good heat dissipation is even produced at 100% duty cycle. The valve is available in a “normally closed”(NC) position. It is direct operated and seals at both sides.

Optional solenoids with manual override are also possible.

TECHNICAL DATA:

OPERATION: direct operatedFLOW RATE: 2 l/min

SIZE: M18x1,5

MAX. OPERATING PRESSURE: 250 bar

ACTUATION: Electric

3/2-way Miniature Compact Poppet Valve MSV3/2

-

The tightness of the valve is guaranteed up to maximum pressures of 315 bar. The valves switch very reliably even after long idle times. The actuation of the valves occurs via a pressure-tight solenoid tube.

The solenoid coils are easy to screw and interchangeable. The valve offers good heat dissipation, even at 100% duty cycle.Available Casing Types:

- Pipe casing 3/8”

- Mounting plate NG 06 (DIN 24340 A06, CETOP/ISO 3)

TECHNICAL DATA:OPERATION: Direct operated

FLOW RATE: 20 l/min

SIZE: In-line Body 3/8″, M20x1,5, NG 6

MAX. OPERATING PRESSURE: 315 bar

ACTUATION: Electric

Hot Oil Shuttle W33H-1X06

-

The hot oil shuttle valve W33H-1X06 is a direct operated flush valve.

As soon as the switching pressure of 10 bar is reached, the flush valve allows the medium to flow from port 1 or 2 to the tank in port 3. The hot oil shuttle is highly suitable for cooling in closed circuits. Due to its robust design, it is particularly durable and can withstand the highest demands.

Characteristics:

- directional flush vavle in spool design

- available in in-line body G3/8″ or mounting plate NG 10

- robust and durable

- minimum oil leakage

- maintenance-free

TECHNICAL DATA:OPERATION: Direct operated

FLOW RATE: 40 l/minSIZE: NCS06/4, In-line Body 3/8″, NG 10

MAX. OPERATING PRESSURE: 420 bar

ACTUATION: Hydraulic

4/3 Directional Valve W43S-5PS03

-

The pistons are hardened and polished, and the housing is made of hydraulic cast. The fit clearance was reduced to just a few µm, thus ensuring excellent oil leakage values.

Characteristics:

- on/off directional spool valve

- miniature edition

- 2-way- or 3-way-version available

- spring centred spool

- maintenance-free

TECHNICAL DATA:

OPERATION: Direct operatedFLOW RATE: 8 l/min

SIZE: NG 3

MAX. OPERATING PRESSURE: 315 bar

ACTUATION: Electric

Different variants available.

(4/3 directional valve W43S-5PS03)

4/2 Directional Valve W42S-A1AS06

-

The directional valves W42S-A1AS06 and W43S-A1AS06 are directional valves with maximum hydraulic performance in a compact size. They are used for the adjustment of the direction of volume flows.

Characteristics:

- directional valve in a piston design

- Flow rate direction control

- Spring centred piston

- Maintenance-free

- Coils are easy to exchange and turn

- 4/2-way and 4/3-way variants

TECHNICAL DATA:OPERATION: Direct operated

FLOW RATE: ß0 l/min

SIZE: NG 6

MAX. OPERATING PRESSURE: 350 bar

ACTUATION: Electric

Different variants available.

(4/3 directional valve W43S-A1AS06)

Shuttle Valve FTRW-2,5

-

The shuttle valve is a compact screw-in logic valve.

Characteristics:

- screw-in shuttle valve

- sizes G1/8″ or G1/4″ available

- compact design

- maintenance-free

TECHNICAL DATA:OPERATION: Direct operated

FLOW RATE: 8 l/minSIZE: G 1/8″

MAX. OPERATING PRESSURE: 315 bar

ACTUATION: HydraulicDifferent variants available.

(FTRW-5)

PRESSURE VALVES

Counterbalance Valve SBH-X106

-

Counterbalance valves regulate the release of oil in hydraulic cylinders to allow for the controlled lowering of pulling loads. The compact design dispenses with an integrated check valve, allowing return to the pump through a filter, which is particularly suitable for closed systems. In combination with a pipe housing or intermediate plate, the counterbalance brake is also available with check valves. ? CUSTOMER BENEFITS ? Our counterbalance valves have been developed according to automotive standards and are produced according to the corresponding specifications. The counterbalance valve is designed for at least 10 million cycles. Thanks to the ZnNi coating of all exposed parts, it is corrosion-resistant and offers a long service life.

Characteristics:

- Counterbalance valve without check valve

- Cartridge valve

- Enables controlled release of loads

- Robust and durable

- Seat-tight

- Maintenance-free

TECHNICAL DATA:FLOW RATE: 30 l/min

MAX. OPERATING PRESSURE: 280 bar

ACTUATION: Hydraulic

Pressure Relief Valve DBG1

-

Characteristics:

- screw-in pressure relief valve

- low-vibration

- maintenance-free

TECHNICAL DATA:OPERATION: Direct operated

FLOW RATE: 17 l/min

SIZE: 3/4-16 UNF

MAX. OPERATING PRESSURE: 370 bar

ACTUATION: Hydraulic

Different variants available.

(DBG4)

Pressure Discharge Valve ZMSVD2

-

The pressure discharge valve ZMSVD2 enables the simple removal of residual pressures in the A and B channels from vertical linking. Channels A and B can be relieved separately to the tank (T-channel) by two 2/2-way poppet valves. By using compact modular valves, the hight-induced pressure increase is low.

TECHNICAL DATA:OPERATION: Direct operated

FLOW RATE: 30 l/minSIZE: NG 10, NG 16, NG 6

MAX. OPERATING PRESSURE: 315 bar

ACTUATION: Electric

High/Low On/Off Valve ZHD/ND

-

The High/low pressure switching valve ZHD/ND allows you to choose between two pressure levels for the outgoing P channel:

- High pressure (HD) = supply pressure in the P channel

- Low pressure (ND) = set pressure of the 3-way pressure control valve

Switching is done electrically via a 2/2-way poppet valve. The low pressure is given when the poppet valve is open, allowing the pilot oil of the pressure control valve to flow into the tank (T channel). Oil flows into the outgoing P channel until the setpoint pressure is reached, which then closes the pressure control valve. As soon as the pressure goes below the setpoint pressure, the valve opens up again. By selecting high pressure, the pressure regulator is put out of function, which allows oil to flow with little resistance through the Sandwich plate. As standard, the poppet valve is set to the neutral position “normally open”, but it is also available as “normally closed”.

TECHNICAL DATA:

OPERATION: direct operatedFLOW RATE: 40 l/min, 80 l/min

SIZE: NG 10, NG 6

MAX. OPERATING PRESSURE: 315 bar

ACTUATION: Electric

Accumulator Charging Valve SLV

-

The accumulator charging valve SLV is a switching valve with a pressure-dependent switching point. The switching pressure is taken from port B (accumulator). If the switching pressure is reached, the valve opens the connection from port P to T, the pump runs without pressure. Once the pressure in port B has fallen to the reset point, the valve closes the connection from P to T, the accumulator is then recharged.

The reset pressure depends on the type, for example, approximately 15% below the setpoint switching pressure (= reset pressure hysteresis).

The SLV is available with a top-mount body in the nominal sizes 06 (SLV 6) and 10 (SLV 10). The adjustment can be made in our factory. An adjustment protection is optionally available. Devices with integrated check valves are also available, if the accumulator is directly connected to the mounting plate.

TECHNICAL DATA:OPERATION: Direct operated

FLOW RATE: 30 l/min, 60 l/min

SIZE: NG 10, NG 6

MAX. OPERATING PRESSURE: 315 bar

ACTUATION: Hydraulic

Pressure Relief Valve DBT1

-

The pressure relief valve DBT1 is a direct operated valve.

The valve opens as soon as the pressure applied to port 1 (P) reaches the current setpoint value (solenoid current) thus allowing the medium to flow to port 2 (T). If the pressure drops again, the valve closes with low hysteresis. The valves have a fast, precise and stable response behaviour. They are relatively unaffected by oil contamination. All important parts are hardened and polished.

Characteristics:

- screw-in pressure relief valve

- available in in-line body or sandwich body

- compact design

- maintenance-free

TECHNICAL DATA:OPERATION: Direct operated

FLOW RATE: 25 l/minSIZE: 3/4-16 UNF, In-line Body 3/8″

MAX. OPERATING PRESSURE: 350 bar

ACTUATION: HydraulicDifferent variants available.

(DBT2, DBT3)

Pressure Relief Valve DB12-FT

-

Characteristics:

- screw-in pressure relief valve

- available with preset pressure and plumbed

- low-vibration

- maintenance-free

TECHNICAL DATA:

OPERATION: Direct operatedFLOW RATE: 100 l/min

SIZE: M27x2

MAX. OPERATING PRESSURE: 350 bar

ACTUATION: Hydraulic

Pressure Relief Valve EBD

-

The pressure relief valve EDB is a direct operated valve with anti-caviation/check function. Max. operating pressure 420 bar, max. volume flow 60 l/min.

Characteristics:

- pressure relief valve with anti-caviation/check function

- slip-in valve EDB or

- cartridge valve T-10A or T-13A

- or in in-line body or double slip-in valve in in-line body

- compact desgin

- low leakage

- maintenance-free

TECHNICAL DATA:

OPERATION: Direct operatedFLOW RATE: 60 l/min

SIZE: In-line Body 1/2″, In-line Body 3/8″, M16x1,5, M18x1,5, T-10A (M20x1,5), T-13A (M20x1,5)

MAX. OPERATING PRESSURE: 420 bar

ACTUATION: Hydraulic

Different variants available.

(4/3 directional valve W43S-5PS03)

FLOW VALVES

Throttle Valve STD

-

The throttle valve STD is an extremely compact and cost-effective screw-in valve for the manual limitation of volume flows in both flow directions.

Characteristics:

- screw-in throttle valve

- pressure setting range up to 350 bar

- throttling in both directions

- for manual limitation of volume flow

- cinq coated steel

- compact design

- maintenance-free

TECHNICAL DATA:

OPERATION: direct operatedSIZE: M10x1

MAX. OPERATING PRESSURE: 350 bar

Throttle Valve STE

-

The throttle valve STE is an extremely compact and cost-effective screw-in valve for the manual limitation of volume flows in both flow directions.

Characteristics:

- screw-in throttle valve

- for manual limitation of volume flows

- compact design

- maintenance-free

TECHNICAL DATA:

OPERATION: Direct operated

SIZE: G 3/8″

MAX. OPERATING PRESSURE: 315 bar

Throttle Valve STO

-

The throttle valve STO is an extremely compact and cost-effective screw-in valve for the manual limitation of volume flows in both flow directions.

Characteristics:

- screw-in throttle valve

- for manual limitation of volume flows

- compact design

- maintenance-free

TECHNICAL DATA:OPERATION: Direct operated

SIZE: 3/4-16 UNF

MAX. OPERATING PRESSURE: 315 bar

Flow Control Valve VCL-14

-

The valve VCL is a screw-in valve for assembly directly into the thread. It limits a flow rate in the working direction to the indicated nominal value.

The size of the flow rate is specified with a drilling in the hardened and polished piston. By the principle orifice drilling is the valve relatively viscosity independent. The dispersion of valves of same nominal value with same Δp is very small. In the opposite direction the medium flows free through the orifice drilling. For tubing or assembly on cylinders there are various bodies available.

Characteristics:

- screw-in flow control valve

- various sizes available

- compact design

- load compensated

- maintenance-free

TECHNICAL DATA:

OPERATION: direct operatedSIZE: G 1/4"

MAX. OPERATING PRESSURE: 210 bar

ACTUATION: Hydraulic

Different variants available.

(VCL-38, -12)

Flow Control Valve VCD-14

-

Characteristics:

- 2-way screw-in flow control valve

- operating pressure up to 315 bar

- adjustable

- various sizes

- manifolds available

TECHNICAL DATA:OPERATION: Direct operated

FLOW RATE: 10 l/min

SIZE: G 1/4"

MAX. OPERATING PRESSURE: 315 bar

ACTUATION: Hydraulic

Different variants available.

(VCD-38, -12, -34)

Flow Control Valve VCM

-

The flow control valve VCM is a compact screw-in valve that limits a flow rate in working direction to the indicated nominal value. It is available for various nominal flow values.

Characteristics:

- screw-in flow control valve

- available for various volume flows

- compact design

- maintenance-free

TECHNICAL DATA:OPERATION: Direct operated

FLOW RATE: 0,85 l/min, 1,5 l/min, 2,5 l/min, 3 l/min, 4,2 l/min, 6 l/min, 7,5 l/min, 9 l/minSIZE: 3/4-16 UNF

MAX. OPERATING PRESSURE: 315 bar

ACTUATION: Hydraulic

3-Way Flow Control Valve SR3

-

TECHNICAL DATA:

OPERATION: direct operatedFLOW RATE: 60 l/min

SIZE: In-line Body 1/2″

MAX. OPERATING PRESSURE: 250 bar

ACTUATION: Hydraulic

CHECK VALVES

Plugg-In Check Valves RVH-5F10, RVH-4F14 and RVH-2F22

-

There is no hydraulic system that does not also have check valves installed. A non-return valve ensures that the oil flow can only flow in one direction and that the return flow is tightly shut off. Our non-return valves offer nominal volume flows of 20l/min, 50l/min and 120l/min and can be mounted in core hole drillings for G1/4, G3/8 and G3/4.

The variants with a nominal volume flow of 50l/min and 120l/min can be inserted in both directions and meet automotive specifications in terms of development, production and assembly. The pressure drop is significantly lower than with conventional check valves and with a minimum opening pressure of just < 0.1 bar, they are suitable for use as suction valves. Thanks to the snap ring assembly of our check valves, they provide a secure hold in the event of temperature fluctuations, vibrations and structural stress. The assembly is carried out reliably with the help of an electronically monitored assembly tool, which enables time-saving and traceable assembly. In addition, primary contamination from thread abrasion or O-ring damage is minimised.

Characteristics:

- Plug-in check valve

- Various sizes available

- Compact dimensions

- Maintenance-free

- Vibration-resistant

- Lower pressure loss than conventional check valves

TECHNICAL DATA:

MEDIUM TEMPERATURE: -22°F to +212°F (NBR seal), -40°F to +230°F (PU seal)AMBIENT TEMPERATURE: 22°F to +212°F (NBR seal), -40°F to +230°F (PU seal)

FLOW DIRECTION: From 1 to 2

MAX. OPERATING PRESSURE: Aluminum: 210 bar, Steel: 350 bar

Component Coupling Check Valve KK-M14X1, 5

-

The very compact component coupling check valve KK-M14x1,5 is suitable for universal needs, particularly in jig manufacturing.

The reliable component coupling check valve KK-M14x1,5 locks up oil channels as soon as these are beeing separated from each other.

Characteristics:

- operating pressure max.: 315 bar

- for use in jig manufacturing and others

- blocks oil cannel of components when sepperated

- compact design

- flow direction from either side

- hardened and honed parts

- minimum oil leakage

- maintenance-free

TECHNICAL DATA:OPERATION: Direct operated

FLOW RATE: 20 l/min

SIZE: M14x1,5

MAX. OPERATING PRESSURE: 315 bar

Check Valve RBR-14

-

The check valve is a compact and maintenance-free valve.

Characteristics:

- screw-in ball-type check valve

- various sizes available

- compact design

- maintenance-free

TECHNICAL DATA:OPERATION: Direct operated

FLOW RATE: 20 l/minSIZE: G 1/4″

MAX. OPERATING PRESSURE: 350 bar

ACTUATION: HydraulicDifferent variants available.

(RBR-38, -12)

Check Valve RHR-14

-

The RHR type ball check valve is a very compact cartridge valve with a hemispherical closing surface.

The RHR type ball check valve has a large opening cross-section, thus resulting in low pressure loss. It closes in the direction it is screwed in.

Characteristics:

- screw-in check valve

- various sizes available

- compact design

- maintenance-free

TECHNICAL DATA:

OPERATION: Direct operatedFLOW RATE: 20 l/min

OPENING PRESSURE: 0,2 bar

SIZE: G 1/4"

MAX. OPERATING PRESSURE: 350 bar

ACTUATION: Hydraulic

Different variants available.

(RHR-38, -12, -34)

Check Valve RKR-14

-

The check valve is reciprocally mountable and available in various sizes.

Characteristics:

- screw-in check valve

- reciprocally mountable

- various sizes available

- compact design

- maintenance-free

TECHNICAL DATA:OPERATION: Direct operated

FLOW RATE: 20 l/min

OPENING PRESSURE: 2,3 bar

SIZE: G 1/4"

MAX. OPERATING PRESSURE: 350 bar

ACTUATION: Hydraulic

Different variants available.

(RKR-38, -12, -34)

Double Check Valve DRV

-

The valve consists of 2 check valves in one body.

Characteristics:

- double check valve in poppet style

- pressure range up to 350 bar

- available in in-line body

TECHNICAL DATA:OPERATION: Direct operated

FLOW RATE: 50 l/minOPENING PRESSURE: 0,5 bar, 2 bar, 3 bar, 10 bar, 15 ba

SIZE: G 1/2″, In-line Body 1/2″

MAX. OPERATING PRESSURE: 350 bar

ACTUATION: Hydraulic

Shuttle Valve FTRW-2,5

-

The shuttle valve is a compact screw-in logic valve.

Characteristics:

- screw-in shuttle valve

- sizes G1/8″ or G1/4″ available

- compact design

- maintenance-free

TECHNICAL DATA:

OPERATION: direct operatedFLOW RATE: 8 l/min

SIZE: G 1/8"

MAX. OPERATING PRESSURE: 315 bar

ACTUATION: Hydraulic

Different variants available.

(FTRW-5)

Hose Burst Valve RBS1-14

-

The hose burst valve RBS1-14 prevents sudden pressure decreases due to tubing or hose breaks.

Characteristics:

- operating pressure 350 bar

- easy installation

- set volumen flow

- various sizes

- material: steel

- compact design

- maintenance-free

TECHNICAL DATA:OPERATION: Direct operated

FLOW RATE: 25 l/min

SIZE: G 1/4"

MAX. OPERATING PRESSURE: 350 bar

ACTUATION: Hydraulic

Different variants available.

(RBS1-38, -12, -34, RBS1-M18)

Hydraulic Motor Anti Cavitation Valve HNV

-

The bypass anti cavitation valve HNV ensures cavitation protection for Danfoss OMM and similar motors.

The bypass anti cavitation valve HNV guarantees cavitaion protection for orbital engines. The HNV includes two hollow bolts G 3/8″, which ensures an easy and space -saving installation.

Characteristics:

- cavitation protection for Danfoss OMM and similar motors

- hydraulic motor bypass valve in subplate

- the check valve ensures a backflow of oil in case of motor overrun

- space-saving installation possible

- maintenance-free

TECHNICAL DATA:OPERATION: Direct operated

FLOW RATE: 10 l/minSIZE: Hollow Bolt 3/8"

MAX. OPERATING PRESSURE: 210 bar

ACTUATION: Hydraulic

SPECIAL VALVES

Pressure Discharge Valve ZMSVD2

-

The pressure discharge valve ZMSVD2 enables the simple removal of residual pressures in the A and B channels from vertical linking. Channels A and B can be relieved separately to the tank (T-channel) by two 2/2-way poppet valves. By using compact modular valves, the hight-induced pressure increase is low.

TECHNICAL DATA:OPERATION: Direct operated

FLOW RATE: 30 l/minSIZE: NG 10, NG 16, NG 6

MAX. OPERATING PRESSURE: 315 bar

ACTUATION: Electric

Rapid Traverse/Creep Valve ZMSR

-

It is possible to choose between a load-compensated two-way flow control valve and a throttle valve. The flow control valves have a sharp edged aperture (triangle notch) and are therefore largely independent of viscosity. They have a pressure balanced adjustment spindle and are easy to adjust, even at high pressure.

The solenoid operated poppet valve can either be a ‘normally closed’ model or a ‘normally open’ model. The ZMSRP2 (standard) limits the inflow of oil in P, the ZMSRT2 limits the outflow of oil in T.

TECHNICAL DATA:OPERATION: Direct operated

FLOW RATE: 30 l/min

NOMINAL VOLTAGE: 12V DC, 24V DC

SIZE: NG 6

MAX. OPERATING PRESSURE: 250 bar

ACTUATION: Electric

High/Low On/Off Valve ZHD/ND

-

The High/low pressure switching valve ZHD/ND allows you to choose between two pressure levels for the outgoing P channel:

- High pressure (HD) = supply pressure in the P channel

- Low pressure (ND) = set pressure of the 3-way pressure control valve

Switching is done electrically via a 2/2-way poppet valve. The low pressure is given when the poppet valve is open, allowing the pilot oil of the pressure control valve to flow into the tank (T channel). Oil flows into the outgoing P channel until the setpoint pressure is reached, which then closes the pressure control valve. As soon as the pressure goes below the setpoint pressure, the valve opens up again. By selecting high pressure, the pressure regulator is put out of function, which allows oil to flow with little resistance through the Sandwich plate. As standard, the poppet valve is set to the neutral position “normally open”, but it is also available as “normally closed”.

TECHNICAL DATA:

OPERATION: direct operatedFLOW RATE: 40 l/min, 80 l/min

SIZE: NG 10, NG 6

MAX. OPERATING PRESSURE: 315 bar

ACTUATION: Electric

Accumulator Charging Valve SLV

-

The accumulator charging valve SLV is a switching valve with a pressure-dependent switching point. The switching pressure is taken from port B (accumulator). If the switching pressure is reached, the valve opens the connection from port P to T, the pump runs without pressure. Once the pressure in port B has fallen to the reset point, the valve closes the connection from P to T, the accumulator is then recharged.

The reset pressure depends on the type, for example, approximately 15% below the setpoint switching pressure (= reset pressure hysteresis).

The SLV is available with a top-mount body in the nominal sizes 06 (SLV 6) and 10 (SLV 10). The adjustment can be made in our factory. An adjustment protection is optionally available. Devices with integrated check valves are also available, if the accumulator is directly connected to the mounting plate.

TECHNICAL DATA:OPERATION: Direct operated

FLOW RATE: 30 l/min, 60 l/min

SIZE: NG 10, NG 6

MAX. OPERATING PRESSURE: 315 bar

ACTUATION: Hydraulic

Hydraulic Accumulator Safety Block HSB-06

-

The hydraulic accumulator safety block HSB-06 is used for the prescribed protection and relief of hydraulic systems with pressure accumulators.It is possible to have a nominal size 06 installation without piping work by vertically linking them with a mounting plate. It is easy to add other functions, such as (throttle) check valves, by using standard sandwich plates. The internal connection of channels A, B and P offers additional connectivity options, including but not limited to accumulator, consumer or testing connections.The directly operated pressure relief valve has achieved the type examination and can be supplied as pre-set.

There are various options available:

Manual (with drain plug) or electric (solenoid operated poppet valve) pressure relief and a Minimess® connection in P.Safety notes for type-tested safety valves according to Pressure Equipment Directive 97/23/EC available.

- In the factory, the specified response pressure is adjusted with a flow rate of 2 l/min

- The specified maximum allowable flow rate is valid for applications with no discharge counterpressure

(connection “T”) - The removal of the seal on the valve will invalidate the approval according to the PED!

- Basically, the requirements of the Pressure Equipment Directives have to be observed!

TECHNICAL DATA:OPERATION: Direct operated

FLOW RATE: 40 l/minNOMINAL VOLTAGE: 24V DC

SIZE: NG 6

MAX. OPERATING PRESSURE: 350 bar

ACTUATION: Hydraulic

MANIFOLDS AND ACCESSORIES

Connecting Plates and Manifolds

-

There are different empty manifolds for various cavities. Other manifolds may be provided up on request.

TECHNICAL DATA:MAX. OPERATING PRESSURE: 315 bar

Hollow Bolt Body HSS

-

Characteristics:

- hollow bolt body for counterbalance valves or pilot to open check valves

- space-saving installation possible

- dead space is minimized

- available in many variations

- available with already mounted valves

- turnable

- hollow bolt can be mounted from both sides

- maintenance-free

TECHNICAL DATA:SIZE: Hollow Bolt 1/4″, Hollow Bolt 3/4″, Hollow Bolt 3/8″, Hollow Bolt M18x1,5

MAX. OPERATING PRESSURE: 315 bar

Pressure Transmitter MODS

-

The MODS pressure transmitter with its stainless steel membrane and semiconductor thinfilm technology is very reliable and robust and therefore usable in most industrial applications, even in very harsh conditions.

The MODS is protected against overload and reverse voltage, and contains a limitation of power loss. It is resistant to pressure peaks. Thanks to the electronic calibration, the total error is very low. The fully welded, “dry” measuring cell has a high long-term stability and tightness. Since various signal-, thread- and connecting options are available, the pressure transmitter is applicable with all standard signals for industry, hydraulics and pneumatics.

Characteristics:

- robust

- compact

- pressure peak resistant

- overload protected

- with reverse voltage protection

- limitation of power loss

- electronic calibration

- stainless steel

- fully welded, “dry” measuring cell, therefore no internal transmission media

Applications:

- Industrial applications

- Hydraulics

- Pneumatics

- Marine application

- Railway application

- Industrial equipment and automation technology

Certifications:

- German Lloyd (GL) for marine applications

- CE-Directive 2014/30/EU

- CE-Directive 2014/68/EU

- Railway applications (DIN EN 50155)

Line Mount Bodies, Tools

-

TECHNICAL DATA:

MAX. OPERATING PRESSURE: 350 bar

WEBER RESCUE SYSTEMS

-

As an internationally leading, innovative manufacturer of high-quality hydraulic and pneumatic rescue equipment & systems, WEBER RESCUE SYSTEMS also offers solutions in numerous other areas in addition to products for technical rescue (THL).

For example, we also offer digital solutions, and our customers also include the military, industry, recycling companies and the police. During a personal product presentation on site or during a technical consultation, you can experience for yourself what lies behind the experience of our products.

Fire and Rescue

-

Innovative and efficient rescue systems for fire brigades and rescue forces that are constantly being further developed.

New vehicle technologies and materials, along with continuously optimised safety systems in vehicles is improving the protection of the occupants. However, this is always presenting new challenges for the emergency services. WEBER RESCUE SYSTEMS has always reacted to this trend with innovative and powerful rescue systems that are continuously being developed and further improved. We have the right extrication equipment and tools for practically any usage scenario and a comprehensive portfolio of accessories completes the range.

Fire Services and Equipment:

- Hydraulic Rescue Systems

- Pneumatic Rescue Systems

- Additional Equipment

- CASH-SYSTEM

Digital Solutions

-

Whether product-related, as training or for real use - digital solutions offer opportunities for improvement and innovation.

The RETTERWelt connects digital solutions with the fire service and vica verse. Whether product-related, as exercise support or for real operations. For example, to optimise the efficiency of processes with RETTERAlarm, further training through e-learning in the RETTERAcademy or simply a more reliable database for improved decision-making.

Solutions:

- Smart Alarming

- Product-Specific Digital Solutions

- Digital Solutions for Operational & Training Support

- E-Learning for Aid Organisations

Tactical

-

Tactical Tools for Special Operations

Special operations require special equipment. Our range in the TACTICAL segment offers a wide spectrum of equipment for police, military and special operations teams. From multi-purpose combi tools to hydraulic door openers and breaking tools such as the Halligantool.

- Dooropening

- Cutting

- Lifting and Pulling Loads

- Vehicle Opening

HYDRAULIC BOTTLE JACKS

- Hydraulic bottle jacks, including the so-called “WEBER-Heber”, are the pioneer products of WEBER-HYDRAULIK and have proven themselves since then over decades. WEBER-HYDRAULIK bottle jacks are constantly being developed and optimized and can be found in the original equipment of trucks as well as in many garages and private garages. All listed jacks are available in OEM quality.

Standard Models

-

- High lifting height

- Adjustable extension spindle

- capacity of 2,000 kg - 100,000 kg

*inclusive carton and pump lever

Different variants available.

Telescopic Models

-

- Extra high lifting height with two pistons

- Adjustable extension, spindle on selected models

- capacity of 3,000 kg - 12,000 kg

*inclusive carton and pump lever

Different variants available.

Special Models

-

- capacity of 35,000 kg - 12,000 kg

*inclusive carton and pump lever

Different variants available.

GARAGE EQUIPMENT

-

WEBER-HYDRAULIK’s extensive garage programme offers high-quality hydraulic lifting tools such as axle stands, hydraulic trolley jacks, air hydraulic jacks and folding cranes. They are part of the basic equipment of every garage and make daily work much easier.

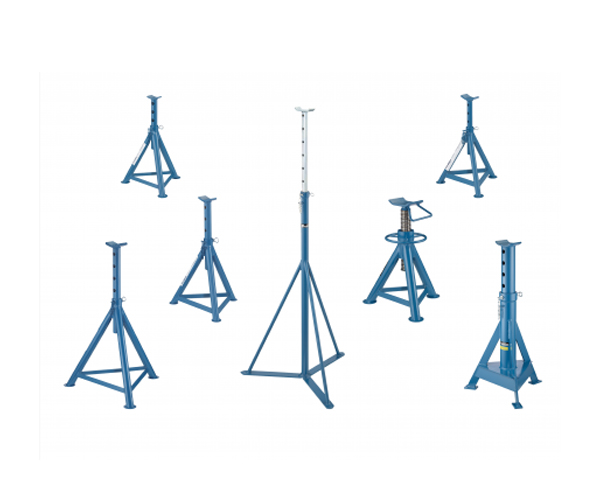

AXLE STANDS

-

- Capacity range from 1,500 kg-16,000 kg

- Axle stands are basic equipment for every garage

- According to the accident prevention regulations, every vehicle must be supported by stands

- Solid construction, high stability and long life

- Suitable for the use in cars, trucks and agricultural workshops as well as in the industrial sector

Different variants available.

Hydraulic Trolley Jacks from 2T - 10T

-

- All models feature a foot operated quick-approach pedal

- The L.C.S. control system provides an automatic, safe and smooth control of lowering

- Hydraulic manoeuvring jacks in the 2,000 – 10,000 kg range

Different variants available.

Air Hydraulic Jacks

-

- Air-hydraulic lifters with up to 3 stages and a capacity of 25,000 – 65,000 kg

- All jacks are fitted with a safety overload valve

- The pneumatic hose can be disconnected and used for other purposes

- Supplied with one 100 mm extension

- The L.C.S. control system provides an automatic, safe and smooth control of lowering

- Recommended air pressure: 7-10 bar – Required air flow 270 l/min.

Different variants available.

APPLICATIONS

Agriculture

-

Robust and comfortable in any terrain.

Rough operating conditions demand the highest degree of robustness and reliability from our systems and components. In addition, the ever-increasing complexity of vehicles as well as the increasing demands on comfort and functionality require a constant further development of our technical solutions. Target-oriented engineering and state-of-the-art production processes guarantee cost-effective serial components and systems tailored to the respective agricultural application.

- Tractors

- Bailing presses

- teleloaders

- Ploughs

- Attachment

- Self-propelled field sprayers

- Pulled sprayers

- Harvesters

- Forage Harvesters

- Frontloaders

- Forestry Harvesters

- Combines

- Trailer

Cranes

-

Stability and safety.

Mobile cranes are equipped with a wide range of different hydraulic components for their various operating functions. The challenge for us is the application-oriented development of complex cylinder solutions – some of which are equipped with additional functions such as electronic position and force measurement or position switches or various valves and control elements. For example, hydraulic support cylinders ensure the stability of massive cranes and turntable ladders. Hydraulically suspended axles and hydraulic steering cylinders with integrated mechanical locking mechanism ensure reliability, comfort and maximum mobility under all conceivable operating conditions.

- Mobile Cranes

- Crawler Cranes

Municipal

-

Reliable in all weather conditions.

Municipal vehicles have particularly complex requirements for the quality, flexibility and reliability of the components and systems they contain. Rough environmental conditions (salt, rain, extreme temperatures), a multitude of possible movements as well as the requirement to be able to control all functions simply and well dosed, play a decisive role in the construction of corresponding hydraulic systems. Many years of engineering know-how “made in Germany” and state-of-the-art manufacturing processes enable us to meet all of these requirements at the highest level and to supply products that prove their worth every day in tough practical use.

- Recycling Vehicles

- Spreaders

- Sweepers

- Snowploughs

- Mowers

- Equipment Carriers

Material Handling

-

Increasing productivity with WEBER-HYDRAULIK.

Industrial trucks and their attachments are equipped with a large number of cylinders and hydraulic components. For example, due to their high power density, combustion engine or electromotive powered forklifts are equipped with a hydraulic system that controls the working functions and the movement of the load handling equipment. In addition, this creates optimum conditions for the hydraulic steering system and energy recovery of the lifting and braking energy. Highest quality and compliance with legal regulations are essential for all installed components. In order to ensure the high demands on load capacity and lifetime, all elements are thoroughly tested on specially developed test facilities. The use of state-of-the-art manufacturing and engineering processes ensures that our specially developed series components and complete systems meet these requirements at all times.

- Picker

- Pallet Truck

- Reach Truck

- Very narrow aisle truck

- Counterbalance Forklift

Machinery

-

Tremendous forces with Highest Precision.

The wide range of applications for hydraulic systems in industry and mechanical engineering usually requires customer-specific developments that are optimally suited to the respective challenges. Hydraulic presses as well as punching machines must be able to generate and control enormous forces safely and guarantee smooth, wear-free running at high operating speeds in the long term. For the locking of bell-type furnaces special swivel clamping cylinders are used, which in addition to the axial movement enable up to 90° swivel stroke.

Hydraulic power packs used in presses and forming machines are always precisely adapted to the available space in terms of shape and size. Due to the direct mounting of the required manifolds, even sophisticated controls can be realized in a compact design.

- Press Brakes

- Laser Cutting Machines

- Recycling

- Hydraulic Presses

- CNC Machines

- Injection Moulding Machines

Construction

-

Maximum Performance with WEBER-HYDRAULIK.

Construction machinery and all its sensitive individual components are often subjected to extreme loads in the field. In the case of working cylinders, an application-specific design is therefore essential, taking all relevant factors into account. Increasing demands for stability, comfort and flexibility also require the continuous development of optimized solutions. By means of goal-oriented engineering and state-of-the-art manufacturing processes WEBER-HYDRAULIK produces cost-effective, custom-made serial components and complete systems for use in construction machinery.

- Wheel Loader

- Drilling Rig

- Road Roller

- Dumper

- Excavator

- Blacktop Paver

- Crawler

- Grader

- Concrete Pump

- Quick Coupler

- Walking Excavators

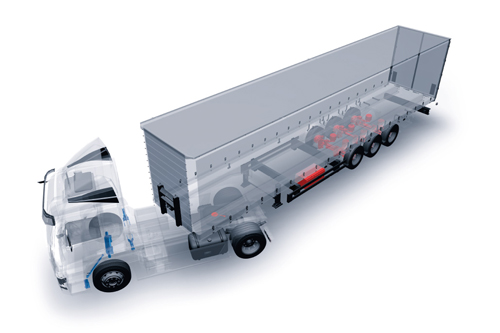

Truck Systems

-

Highest Integration into the customers vehicle.

Unlimited availability and reliability are essential characteristics of commercial vehicles with a view to constantly increasing cost pressure in the transport industry. With our high-quality components and systems we can make a decisive contribution to this. For example, our hydraulic cab tilting systems for trucks with underfloor engines enable quick and uncomplicated access to the engine block in the event of a problem. Hydraulic tail lifts with special cylinder solutions also simplify loading of the vehicle and hydraulic steering cylinders reduce steering forces, particularly in the case of heavy multi-axle vehicles. Hydraulic bottle jacks for repairing a tyre defect are always part of the prescribed equipment for all vehicles.

Trailer Systems

-

As Individual as every application.

Manufacturers of special vehicles for heavy-duty and special transports can offer their customers custom-fit transport solutions with the help of WEBER-HYDRAULIK. The design and layout of the hydraulic cylinders are always based on customer requirements. WEBER-HYDRAULIK offers a wide range of products: in addition to the basic functions of steering, suspension and damping, a hydraulic load securing system, for example, ensures safe transport even with sensitive loads such as concrete or glass slabs. Locking cylinders prevent the load carriers from sagging, among other things. Unlocking cylinders allow the length of the trailer to be adjusted. To meet the increased requirements for corrosion resistance and protection, our hydraulic cylinders are finished with special coatings. This also makes our products reliable in terms of function and robustness.

- Low Loader

- Tipper Truck

- Car Transporter

- SPMT (self-propelled modular transporter)

Rescue Systems

-

The world is our market.

Many of our customers have a global presence and require our support directly at their sites. These include fire departments and technical relief organizations, the military and police, and industrial and recycling companies. In order to be able to operate successfully close to the customer and to develop local markets, extensive services must increasingly be provided directly on site. With activities on five continents, WEBER RESCUE SYSTEMS is already represented in important international markets.

- Fire & Rescue

- Digital Solutions

- Tactical

Tactical

-

Tactical tools for special operations.