BRAND HYDRAULICS

- Offer Profile

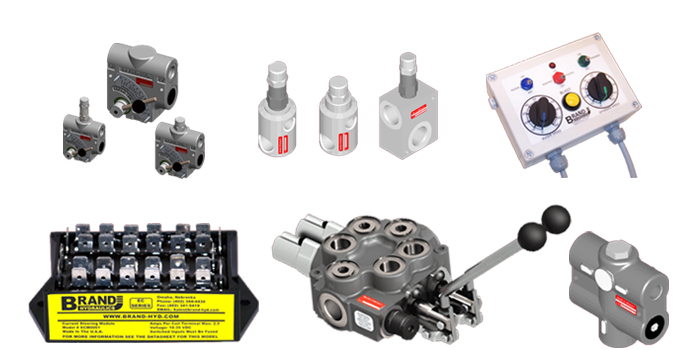

- Brand has designed,

manufactured, assembled and tested hydraulic valves for over fifty years. In

1997, Brand began to design and incorporate electronic controllers and

custom wiring harnesses into their product line.

Brand is strongly committed to the future of hydraulics and electro-hydraulic components and plans to continue developing hydraulic valves, electronic controllers and products which incorporate both (electro-hydraulics). Many of the products Brand provides are modified to specifically fit our customers’ applications and needs. Feel free to give our engineering department a call to learn more about special modifications to meet your needs.

Product Portfolio

Electronic Controllers

EC-12-01 -

Electronic control box- he Brand, electronic control box is designed to proportionally adjust the Brand EFC-Series valves and other proportional valves that meet the appropriate specifications. The controller’s design makes it suitable for use in harsh environments as well as protected installations. The box has extensive weather proofing features to help it stand up against everyday use in sun, rain, snow or anything else that Mother Nature can dish out.

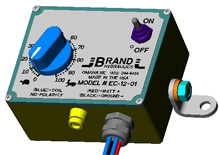

EC-12-02 -

Electronic panel mount- The Brand, electronic panel mount control is designed to proportionally adjust the Brand EFC-Series valves and other proportional valves that meet the appropriate solenoid specifications. The panel mount control is designed to mount behind a control panel in an industrial setting, behind the dash panel of mobile equipment, or in any other mounting location.

EC0004A -

Electronic interface card- The EC0004A has been designed to meet the various requirements of mobile and industrial hydraulic control applications. EC0004A cards are versatile, cost effective and easily integrated into new or pre-existing designs. Much of this is a result of the unique ability each card has to accept 4 different signals. The EC0004A can accept any of the following input types: Potentiometer, 0-10V, 0-5V, or 4-20mA. The card takes these signals and converts them into a PWM output suitable for a Brand EFC-Series valve or other proportional valves.

EC20100 -

Spreader control- The EC20100 is a compact, durable, and easy to operate control, built with high quality long life components that are designed for use in harsh environments. The EC20100 is a perfect compliment to the Brand EFC, LEFC, and SEFC flow controls. Other flow controls meeting the appropriate specifications may be used as well.

ECM0001 -

Current steering module- The ECM0001 was designed to simplify the wiring of Brand Series 36 and Series 38 stack valves. When a switch input is activated a corresponding work section coil terminal and the inlet coil output terminals become energized. The module is set up to run up to a 6-spool stack valve. Two ECM0001 modules can be daisy chained for control of up to 12 sections.

EC20200 -

Potentiometer control- Easy to use and versatile the EC20200 simplifies valve control and system design. It is built with high quality long life components that are designed for use in harsh environments. The EC20200 is a perfect compliment to the Brand EFC and LEFC flow controls. Other flow controls meeting the appropriate specifications may be used as well.

EC20300 -

Sealed interface control- The EC20300 has been designed to meet the various requirements of mobile and industrial hydraulic control applications. EC20300 controls are versatile, cost effective and easily integrated into new or pre-existing designs. Much of this is a result of the unique ability each card has to accept 4 different signals. The EC20300 can accept any of the following input types: Potentiometer, 0-10V, 0-5V, or 4-20mA. The control takes these signals and converts them into a PWM output suitable for a Brand EFC-Series valve or other proportional valves that meet the proper specifications.

EC20400 -

Joystick control- The EC20400 is a compact weatherproof joystick control built with high quality long life components that are designed for use in harsh environments. The control comes loaded with user friendly features that provide versatility without sacrificing ease of use.

Flow Control

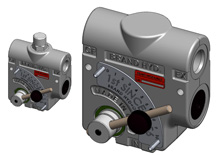

FC - Pressure compensated variable flow control

- 0-30 gpm (0-114 lpm)

The Brand, full range pressure compensating variable flow control is designed so that the orifice area varies as the lever is rotated. Fluid travels past the variable orifice, through the compensator spool and then out the controlled flow port. Therefore the flow out of the CF port is proportional to the orifice area which can vary from closed to open. The sum of the controlled flow and the excess flow equals the inlet flow and as the controlled flow increases the excess flow decreases.

FC - Pressure compensated variable flow control

- 0-90 gpm (0-341 lpm)

The Brand, full range pressure compensating variable flow control is designed so that the orifice area varies as the lever is rotated. Fluid travels past the variable orifice, by the compensator spool and then out the controlled flow port. Therefore the flow out of the CF port is proportional to the orifice area which can vary from closed to wide open. The sum of the controlled flow and the excess flow equals the inlet flow and as the controlled flow increases the excess flow decreases. Both outlet flows are pressure compensated with a spool that maintains a constant flow while adjusting for pressure.

Series 83 - Non-adjustable inline flow control

- The Brand, Series 83 is a two port, non-adjustable, pressure compensated, inline flow control, with free reverse flow. The amount of flow is determined by the diameter of the orifice in the compensator piston. The spring and piston are held in place when it is connected to an #8 SAE male fitting. This flow control is inexpensive and gives the customer the ability to change the flow rate by swapping the piston with another that has a different size orifice.

Series 84 - Non-adjustable fixed orifice

- The Brand, Series 84 is a two port, non–adjustable, inline, fixed orifice with free reverse flow. The flow is determined by the orifice diameter and fluid pressure. The orifice diameter must be specified by the customer when ordering (up to a diameter of 0.250” (6.35mm)). The orifice plate is held in place when it is connected to a #8 SAE male fitting. This restricted flow assembly is inexpensive and gives the customer the ability to change the orifice diameter by swapping the orifice plate with another that has a different orifice size.

EFC - Electronic pressure compensated variable flow control

- 0-30 gpm (0-114 lpm)

The Brand, electronically adjustable proportional pressure compensated flow control is an electronically controlled version of the original FC51 style flow control valve. The EFC performance as a flow control is very similar to the FC51 because they both use the same spring and compensator spool. Thus, the control flow port (CF) and the excess flow port (EX) remain usable and pressure compensated. The main advantage of the EFC over the FC51 is that the flow can be adjusted proportionally with a solenoid instead of manually. As the current to the solenoid increases the variable orifice moves proportionally similar to positioning the rotary side lever on the manual FC's.

LEFC - Electronic pressure compensated variable flow control

- 0-55 gpm (0-208 lpm)

The Brand, LEFC (large electronically adjustable proportional pressure compensated flow control) is an electronically controlled version of the original large FC51 style flow control valve. The LEFC performance as a flow control is very similar to the large FC51 because they both use the same spring and compensator spool. Thus, the control flow port (CF) and the excess flow port (EX) remain usable and pressure compensated.

Dividers and Combiners

BG - Non-adjustable constant volume priority divider

- 0-30 gpm (0-114 lpm)

The Brand, non-adjustable priority flow divider comes in three basic models BG5, BGR5 and BGC5. The BG series receive a single stream of fluid and divides it into two separate output streams. The priority port will maintain the same flow even with an increase or decrease in the input flow. The priority port size is 3/8” NPT for 0-8 gpm (0-30.2 lpm), 1/2” NPT for 8-16 gpm (30.2-60.5 lpm) and 3/4” NPT for 16-30 gpm (60.5-113.4 lpm)

BG4 - Non-adjustable constant volume priority divider

- 30-45 gpm (114-170 lpm)

The Brand, BG4 non-adjustable priority flow divider receives a single stream of fluid and divides it into a priority stream and an excess stream. The priority flow port maintains the same flow even with an increase or decrease in the input flow. Both outlet flows are pressure compensating and the sum of said flows equals the inlet flow. Flow can only pass through the valve in one direction, inlet to outlet. Accuracy is normally better than ± 5%. The priority flow setting must be specified when ordering. Pressure drop through the valve will range from 33 to 50 psi (2.3 to 3.4 bar) depending on the flow and pressure in the system.

FG - Adjustable constant volume priority divider

- The Brand, adjustable priority flow divider comes in two

basic models FG52 and FG54. The FG series receives a single stream of fluid

and divides it into two separate output streams. The priority flow is

adjustable from 0.2 to 12 gpm (.8 to 45.4 lpm) with minimal pressure drop.

The priority port will maintain the same flow setting even with an increase

or decrease in the input flow.

B - Non-adjustable proportional flow dividers

- 0-30 gpm

(0-114 lpm)

The Brand, non-adjustable, proportional flow divider comes in three basic models B50, B100 and B100AB. The B series receives a single stream of fluid and divides it into two output streams. The ratio of division to the two outlets will remain constant even though the work being done by one of the streams is much greater than the work being done by the other. The ratio of the outlet flows, remains constant even when the input flow increases or decreases. The ratio of the outlet flows may be varied from equal flow (50:50) all the way up to a 95:5 ratio.

B - Non adjustable proportional flow dividers

- 45 and 120 gpm (170-454 lpm)

The Brand, non-adjustable, proportional flow divider comes in two basic models BX50, and B100. The B series receives a single stream of fluid and divides it into two output streams. The ratio of division to the two outlets will remain constant even though the work being done by one of the streams is much greater than the work being done by the other. The ratio of the outlet flows, remains constant even when the input flow increases or decreases. The ratio of the outlet flows may be varied from equal flow (50:50) all the way up to an 85:15 ratio.

FP - Adjustable proportional flow dividers

- The Brand, adjustable proportional flow divider comes in three basic models FP53, FP55 and FP56. The FP series receives a single stream of fluid and divides it into two streams. The customer has the ability to adjust one (FP53 or FP55) or both (FP56) outlet flows. The initial flow settings will not fluctuate even though the work being done by one of the streams is much greater than the work being done by the other. The ratio of the outlet streams remains constant even when the inlet flow increases or decreases.

B300 - Non-adjustable proportional combiner

- The Brand, B300 non-adjustable proportional combiner takes two streams of flow and combines them into one stream and it also offers free reverse flow from each outlet port. Flow can travel in reverse through the outlet port and is non-metered when it goes in reverse. The non-metered flow travels through the outlet, up the center of the valve, past both ball checks and then out the inlet port. This valve gives the customer the ability to synchronize two single acting cylinders when lowering two different gravity loads. It also gives the customer the ability to synchronize two double acting cylinders by plumbing a B300 at the inlet of both cylinders and another B300 at the outlet of both cylinders.

4-Way Directional Control Valves

LV-Loader Directional Control

- 0-10 gpm (0-38 lpm)

The Brand LV22, loader directional control valve, is a superbly designed two spool monoblock valve suitable for Front End Loaders. The LV22 offers two parallel, tandem center 4-way work sections available with two of the following spool actions: float, regenerative or spring-to-center. The valve is also field convertible to closed center or power beyond with the appropriate cartridge.

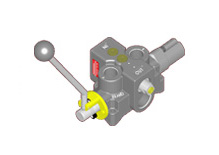

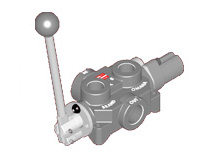

SDCF - 4-way directional control w/ pressure compensation

- 0-18 gpm (0-68 lpm)

The Brand, SDCF combines the features of a four-way directional control valve, a full range pressure compensated by-pass type flow control valve, and an adjustable pilot operated pressure relief valve all in one compact package. This valve reduces the number of fittings, plumbing and potential leakage points in hydraulic circuits. The manual handle allows the customer to meter the flow out of either port. Flow to the work port is directly proportional to the movement of the lever.

AO - 4-way directional control

- 0-18 gpm (0-68 lpm)

The Brand, 4-way directional control valve is designed to be durable and dependable. The manually shifted handle provides metered flow to either port. Port flow is directly proportional to the movement of the lever. The tank port must go directly back to tank.

LS - 4-way directional control w/ hydr. kick out

- The Brand, LS 4-way directional control valve is designed primarily for log splitters. The manual adjustable handle provides fine metering to either port. Port flow is directly proportional to the movement of the lever. The tank port must be plumbed directly back to tank.

LA – Mono-block directional control w/ auto-cycle hydr. kick out

- The Brand autocycle valve will cycle a double acting cylinder from retracted to fully extended and then back to fully retracted using two spools. The first spool can be used to manually extend and retract cylinder while the second spool only retracts the cylinder. Pushing both levers forward starts the autocycle process. The first hydraulic detent can be adjusted up to 2000 PSI (103 bar) and the second detent should always be set 500 PSI (34 bar) above the first detent setting. The valve is also field convertible to closed center and power beyond.

HPV4 - 4-way directional control

- 0-5 gpm (0-19 lpm)

The Brand, HPV4 directional control valves are small and compact. The HPV4’s were designed primarily for use with hand pumps and other low flow applications where size weight and appearance are important. Three-position detent (D) holds the spool in neutral or either active position. Closed center (standard) blocks all ports when in neutral. Tandem center (T4) sends oil from P to T when in the neutral position. The T4 spool should not be used for flows of 4 gpm and greater because the pressure drop increases significantly.

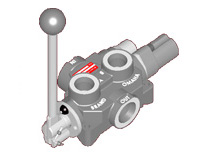

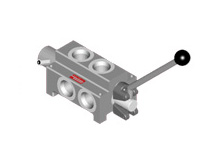

DC Series - 4-way directional control w/ or without flow control

- 0-45 gpm (0-170 lpm)

The Brand, DCF directional flow control valve combines the features of a four-way directional control valve, a full range pressure compensated by-pass type flow control valve, and a pilot operated pressure relief valve, all in one compact package. This valve reduces the number of fittings, plumbing and potential leakage points in hydraulic circuits. The manual handle provides fine metering to either port. Flow to the work port is directly proportional to the movement of the lever. Flow out of each work port is constant regardless of load changes, this allows the customer to maintain smooth and constant movement of a cylinder or motor.

TS - Mono block directional control

- The Brand, mono block directional control valve is available in one (TS1), two (TS2) and three (TS3) spool configurations. This valve was designed for applications in which one valve is required to operate separate circuits independently. The TS offers parallel, tandem center 4-way, open center 4-way(motor spool), and tandem 3-way spools. The valve is also field convertible to closed center and power beyond.

MS - Manual selector

- The Brand, MS two-position manual selector valves are available in two different sizes MS75 and MS16SAE. The MS16SAE allows up to 45 gpm (170 lpm) out of either port and has a manual handle for effortless shifting of the spool. The MS75 allows up to 30 gpm (113 lpm) out of either port and has a “T” grip handle for effortless push/pull shifting of the spool. The inlet is orificed to ports A and B when the spool is being shifted from port A to port B or vise versa.

DS - 6-way double selector, electric, pilot and manual operation

- 0-26 gpm (0-98 lpm)

The Brand Double Selector DS is a 6-way two position double selector valve. We offer this valve with four different operators: electric, pilot, manual lever and manual knob. This valve is typically used to divert flow between two separate circuits. The standard selector spool (open cross-over) allows operation of two double action cylinders or two reversible motors with one 4-way directional control valve. It also allows operation of four single action cylinders with one 4-way directional control valve. When the coil is de-energized top ports C and D are connected to B and F respectively. When the coil is energized top ports C and D are connected to A and E respectively.

MS6 - 6-way manual selector

- The Brand, MS6 series valve comes standard with two-position detent and manual handle. The MS6 offers a selector spool or a series-parallel spool. Both ports on the top of the valve serve as the inlet and outlet while the ports on the sides are plumbed into two separate circuits. The MS6 allows up to 45 gpm flow.

MB – Monoblock Directional Control

- 0-10 gpm (0-38 lpm)

The Brand MB, monoblock directional control valve, is a superbly designed monoblock spool valve suitable for applications requiring one valve to perform up to three separate functions. The MB valve is available in one (MB21), two (MB22) or three (MB23) spool configurations. The valve is also field convertible to closed center or power beyond with the appropriate cartridge.

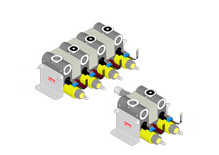

Stackable 4-Way Directional Control Valves

Series 20 - 4-way manual sectional directional control

- 0-6 gpm (0-23 lpm)

The Brand, Series 20 Sectional Directional Control Valves are assembled to meet our customer’s requirements for up to six individual applications per assembly (consult factory for more sections). Brand Hydraulics does not charge anything extra for this process and assembly is priced solely on the overall sum of the prices of its components.

Series 21 – 4-way electrical sectional directional control

- 0-6 gpm (0-22.7 lpm)

The Brand, Series 21 Direct Acting Solenoid Operated Stackable Directional Control Valves are assembled to meet our customer’s requirements for up to six individual applications per assembly. Brand Hydraulics does not charge anything extra for this process, an assembly is priced solely on the overall sum of the prices of its components.

Series 34 - 4-way sectional directional control

- The Brand, Series 34 Sectional Directional Control Valves are assembled to meet our customer’s requirements for up to twelve individual applications per assembly. Brand Hydraulics does not charge anything extra for this process and assembly is priced solely on the overall sum of the prices of its components.

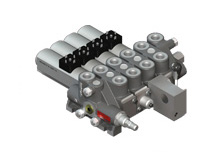

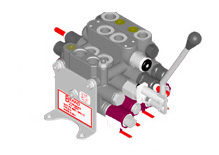

Series 36 - 4-way electrical sectional directional control

- 0-12 gpm (0-45 lpm)

The Series 36 is available with electric unloading in the inlet section. The flow goes directly to tank in the neutral condition. Neutral flow does not pass through the spool sections; therefore, the neutral pressure drop to tank remains low and constant regardless of the number of spool sections.

Series 38 - 4-way electrical sectional directional control

- 0-24 gpm (0-91 lpm)

The Series 38 is available with electric unloading in the inlet section. The flow goes directly to tank in the neutral condition. Neutral flow does not pass through the spool sections; therefore, the neutral pressure drop to tank remains low and constant regardless of the number of spool sections.

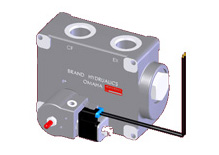

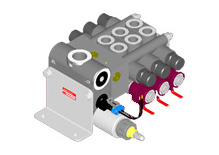

36EFC - Series 36-38 and EFC valve package

- he Brand, 36EFC provides the functionality of Brand’s Series 36-38 stack valve combined with the precise flow control of our EFC valve. This allows users to proportionally control the input flow to the stack valve in one complete package. For example, a motor’s speed on a winch can be controlled in forward and reverse. The 36EFC may also electrically control the rate at which a cylinder extends or retracts. Please refer to EFC, series 36 and series 38 literature for information on work sections, valve capabilities and work section model codes.

SEFC - Stackable electric flow control

- 0-30 gpm (0-114

lpm)

The Brand, SEFC allows the customer to stack EFC’s in series or parallel. Relief sections are also available for hydraulic circuit protection. Advantages of stacking EFC’s are reducing leakage points, fewer hoses and smaller packages. Please contact the Brand Engineering Department to help define the best way to stack your electric flow controls. One of the best applications for this valve is the salt or sand spreader. For this application, stack two EFC’s and one relief section.

Relief Valves

RL - Adjustable hydraulic relief

- The Brand, adjustable relief valve is precision built, dependable and low priced. Both the RL and RLC are of the ball spring type, which is the most dependable type of relief valve. The ball will not jam, lock, or seize and will always open. The advantage of the RLC over the RL option is that cracking pressure at low and high flow is virtually the same. The RLC is also more stable when flow is traveling past the ball and spring.

POR75 - Adjustable pilot operated relief

- The Brand, adjustable pilot operated relief valve maintains the same cracking pressure at low and high flows. As the pressure setting is exceeded a poppet type relief opens and allows a small pilot supply of fluid to escape a chamber at the end of the main spool. The escape of pilot supply causes the main spool to shift and thus opens a passageway which allows the main volume of pressurized fluid to escape to tank without passing over the poppet type relief. The higher the pump output the farther the spool shifts over to enlarge the opening to tank.

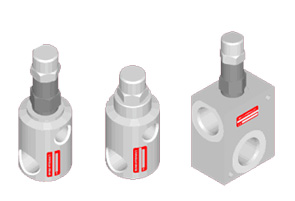

Pilot Operated Checks

PC - Pilot check valve

- The Brand, pilot check valve is precision built, dependable and low priced. In one direction oil opens a check valve and passes through the valve and into a cylinder. As the check valve closes the oil is positively trapped in the cylinder with a check ball valve. Applying pilot pressure to the pilot port of this valve moves a piston stem against the ball to push the check ball off its seat thus allowing the oil to leave the cylinder. The PC is intended to be a positive safety check, it is not intended to be a metering or counter balance valve. The pilot piston ratio is 4 to 1, this means that it only requires 1/4 as much pressure on the pilot piston as is being trapped in the cylinder by the check ball.

POC76 - Pilot operated check valve or counter balance valve

- The Brand, pilot check valve will permit free flow in one direction and will check flow in the opposite direction. Applying pilot pressure to the pilot port of this valve moves the main spool, causing it to shift and unblock the flow. Pilot pressure must be 50 psi (3.4 bar) or greater. The POC76-3/4 is normally connected to the bottom of a cylinder holding a heavy load. This valve will prevent the load from free falling if a hose or pipe breaks. The valve meters the flow at the same rate in both directions which prevents cavitation and run-a-way. Metering the flow can be accomplished by varying the pilot pressure. The POC76-3/4 is available in production quantities of 100 and greater, unless in stock.

SHV - Shuttle valve

- The Brand, shuttle valve has two inlet ports and one outlet port. The purpose of the shuttle valve is to accept flow from the inlet with the higher pressure and to route it to the outlet, while keeping the inlet flows isolated from one another. We manufacture shuttle valves in two sizes SHV50C and SHV25. The SHV50C has 1/2" NPT ports, capable of 0-15 gpm (0-57 lpm) and a peak pressure drop of 15 psi (1.0 bar). SHV25 has 1/4" NPT ports, capable of 0-5 gpm (0-19 lpm) and a peak pressure drop of 50 psi (3.4 bar).

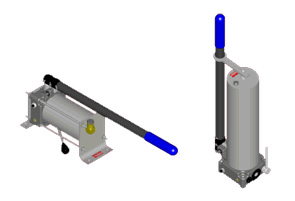

Hand Operated Hydraulic Pumps

HP - Hand operated hydraulic pumps

- The Brand, hand operated hydraulic pump comes in three basic models HP121DA, HP61DA and HP22SA. Each one of these models comes with a relief that can be adjusted manually to suit the customer’s requirements. Brand has also redesigned the outlet check seat for zero leakage. The zero leak seat was created by utilizing an o’ring seal to replace the steel ball seal. The NT (no tank) option does not have a tank, pressure relief and release valve.