Hydroll

Videos

Loading the player ...

- Offer Profile

- Hydroll – The Piston

Accumulator Company

Hydroll is the only company in the world purely specialized in the design and production of high-quality piston accumulators. The latest piston accumulator technology combined with top-notch know-how and an in-depth understanding of the challenges that our customers face in their applications, makes Hydroll the optimum international technology partner in piston accumulators.

Product Portfolio

Can you afford NOT to choose piston accumulator

- Two of the most commonly used hydraulic accumulators

are the bladder accumulator and the piston accumulator. A third type of

accumulator, the membrane/diaphragm accumulator, is typically used for small

(gas) volumes.

Each type of accumulator has advantages and limitations that must be considered. When choosing your accumulators, you should take into consideration such factors as response time, system speed, mounting orientation, fluid type, pressure, temperature, diagnostic characteristics, maintenance and service intervals as well as costs for servicing and downtime.

Main application for accumulators in hydraulic systems:- Energy storage

- Damping of pump pulsations

- Shock absorber

- Flow stabilizer

- Emergency or safety back up in hydraulic system

- Primary power source for low volume systems

- Oil flow rate: High

- Compression ratio (max. pressure to pre-charge pressure): 10:1

- Horizontal mounting position: Yes

- Size optimization for system requirements: Yes

- Space requirement: Small

- Sensoring (e.g. pressure and piston position monitoring): Yes

- Temperature tolerance (low): - 45°C

- Extra gas tank connection: Yes

- Dual functionality (dual piston or gas chamber): Yes

- Gas permeation (loss off pre-charge pressure): Very low

- Service interval: Long

- Response time: Medium

- Tolerance for dirt: Low

- Pre-charge lost in case of failure: Gradual

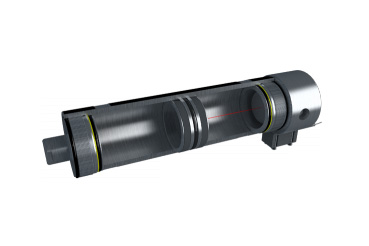

Piston Accumulators

- Hydroll offers three individual product families, which

are all designed to perform in the toughest conditions. Our accumulators are

easy to optimize for all application requirements providing optimum

functionality and efficiency.

A wide range of available working pressures and optional equipment enables our solutions to meet even the most demanding needs of customers.

Pressure equipment directives- CE approved to European standard PED 97/23/EC

- SELO – Pressure Vessels A1

HPS – Single action

- Hydroll’s hydropneumatic piston accumulators (HPS) are divided into three product lines. All HPS products consist of a one-piece threaded end flange fitted with O-ring and back up seal assembly. The piston is fitted with a central two-part seal and a two guide ring assembly.

HPS 10

- 50-180mm ID

- 250, 350, 415, 500, 650 bar max working pressure

- 0,1-40 L volume

- WInd turbines

- Solar panels

- Mobile equipment boom suspencion

- Emergency storage

- Industrial hydraulics

- Suitable for heavy duty static and dynamic load applications and harsh weather conditions

- Excellent gas sealing properties

- Easy to install optional sensors or piston position monitoring equipment

- Optimized structure

- Wide range of size and working pressures

HPS 11

- 180mm-250 ID

- 250, 350, 415 bar max working pressure

- 8-80 L volume

- Emergency storage

- Suitable for heavy duty static and dynamic load applications and harsh weather conditions

- Excellent gas sealing properties

- Easy to install optional sensors or piston position monitoring equipment

- Suitable for large diameters and volumes

HPS 14

- 50 mm ID

- 250, 320 bar max working pressures

- 0,1-1 L volume

- Break system back up

- Boom suspension

- Compensator for pump pulsations

- Cost-efficient non-repairable accumulator

- Suitable for heavy duty static and dynamic load applications and harsh weather conditions

- Excellent gas sealing properties

- Installation into any position

HPD – double action / HDC – double chamber

HPD – double action

- 50-80 mm ID

- 250 bar max working pressures

- 0,4-3 l. volume

Example application:- Boom suspensions

- Loaders

- Tractor front loaders

- Forest harvesters heads

- Proven and robust design

- Space-saving structure combining two accumulators into one

- Excellent dampening features

- Installation to into any position

HDC – double chamber

- 80-125 mm ID

- 250 bar max working pressures

- 2 x 1 – 2 x3,5 l. volume

Example application:- Axle suspension

- Proven and robust design

- Space saving structure combining two accumulators into one

Accumulator Stations

Accumulator Stations

- Accumulator stations with frame, piping, accumulators with necessary valves and safety devices enable our customer to get plug-and-play modules for their assembly process. Hydroll accumulator stations provide easy-to-install solutions tailored to our customer needs.

Optional equipment

Arctic package

- Hydroll has vast experience in the design and production

of accumulators for arctic conditions in a wide range of applications. With

uncompromising development and rigorous testing Hydroll has developed

reliable and cost effective arctic accumulator solutions.

Available arctic packages:- -25 °C to + 80 °C (Standard)

- -40 °C to + 80 °C (Arctic package I)

Piston position monitoring

- Hydroll piston accumulators are available with different

systems for piston position monitoring in the accumulator.

- Rod measuring system

- Wire measuring system

- Limit switches

Pressure monitoring

- REAL TIME PRE-CHARGE PRESSURE MONITORING

Real time diagnostics are becoming an increasingly important feature. Hydroll piston accumulators can be equipped with simple and extremely reliable real time pre-charge monitoring. This is one of the key advantages of piston accumulator technology over bladder accumulators.

This feature consists of a piston stopper in the gas side of the cylinder and a pressure transmitter for pre-charge pressure. During operation pre-charge pressure in compared to pressure in the hydraulic system. If the pressure difference exceeds the set limit (i.e. the piston is touching the end stopper) it is an indication of the fact that the pre-charge is below the required level and enables a service crew to react before any damage is caused to the entire system.

This feature is recommended for use when accumulators are acting as critical safety back up (e.g. wind turbines) or as critical components in energy production (e.g. wave energy rigs or hybrid systems).

Engineering services and tools

Engineering services and tools

- 1. Application analyses

- In-depth analyses of application specific requirements for accumulator solutions

- Feedback and recommendations for optimized solutions

- Accumulator sizing is carried out together with the customer

- Prototype

- 0-series

- Serial production and continuous support

Accessories

Clamps

- Hydroll clamps are used to mount all types of

accumulators safely and simply into position. A suitable clamp has been

designed for every accumulator type.

A clamp’s task is:- To keep the accumulator in position

- To carry the weight of the accumulator

Seal kits

- Seal kits should be selected according to the accumulator

type. A seal kit includes:

- Piston seal

- Piston guide ring

- O-ring seals

- Support rings

Valves

- Our standard gas valve is named HGV1620. It functions

well in Hydroll accumulators and can be used in connection with the charging

kit. Hydroll Oy supplies both standard and special gas valves on request.

Technical data – Material

Coupling body and metal cap made of steel 1.0718 or in option Stainless steel 1.4571.

Sealing

Internal primary- and secondary sealing as well as sealing for screw-in threads are made of NBR. Option in FKM (Viton), high temperature up to +200°C.

Vibration

NBR and/or FKM (Viton) O-ring to prevent cap loosening due to vibration.

Temperature ranges

Hydroll’s stardard valve is HGV 1620 with plastic cap. Temperature range is -25°C to +100°C.

Valves for special conditions are HGV 1620 ARCTIC and HGV 1620 SST. Body and metal cap is made of stainless steel 1.4571. Temperature range is -45°C to +100°C, for a short time, can be also used up to +120°C. If sealing made of FKM (Viton), high temperature is up to +200°C.

Screw-in thread

A large range of threads are available. Thread 1/4 is standard.

Media application

Suitable for Nitrogen (N2) piston accumulator hydraulic- and other oils on mineral oil basis.

Charging unit

- The HPCK charging kit is required to check the pre-

charge pressure of an accumulator. The HPCK charging kit can be used with

all Hydroll piston accumulators and it suits to HGV 1620 gas valve with M16

x 2 mm thread.

DESCRIPTION

1. Connector to nitrogen gas bottle

2. Valve body, meter & gas release valve

3. 5 m hose with end connectors Gas valve adapter M16 X 2

4. Straight reducing coupling

Applications

- Hydroll supplies piston accumulator technology to customers in a wide range of very different industries. The one thing that these customer industries and end use environments have in common is the high demands that are set on accumulators by the demanding and often remote and extreme operating environments. Our products and solutions offer efficiency and functionality as well as operational safety and reliability to meet and exceed the needs and expectations of our customers.

Mobile Equipment

- Safety, ergonomics, reliability, productivity and

efficiency are some of the most important features of any mobile equipment

in today’s mining sites, construction sites, farmland or forests.

Having these features in mind, Hydroll accumulators have been developed over the past 15 years to meet the toughest needs to provide reliable functionality with long service intervals in the toughest conditions.

Hydroll mobile equipment accumulator solutions have proven their operations in extreme conditions from Siberia to Chile and from Australia to North America.

Boom Suspension

- Active or passive boom suspension or ride control is a

shock absorber for the bucket or boom. While tramming the material should

stay in place, which means a smoother ride for the operator and less stress

for the machine.

- Safety – Improved wheel contact with the ground

- Productivity – The load is “floating” (not influenced by terrain)

- Ergonomics – Operator comfort

- Reliability – Less stress on the structures

Example applications- Wheel loaders

- Forest harvesters

- Tractor front loaders

- Tele-handlers

- Wheel excavators

- Mining Equipment

Axle Suspension

- Reliable and smooth suspension for variable loads is

built with single or double piston accumulators. Piston accumulators, due to

their reliability, ability to withstand higher pressure peaks and freedom in

installation are high performance solutions for heavy machinery in the most

demanding operating environment.

Hydroll HPS or space saving and innovative HDC accumulators can be optimized to your system requirements.

Example applications- Earth moving trucks

- Mining trucks

- Military vehicles

- Agricultural trailers

Energy Storage In Hybrid systems

- Piston accumulators have been proven to be the superior

solution in hybrid systems. Hydroll’s groundbreaking piston accumulator

technology enables clear reductions in energy expenditure. In boom lowering

motions for example, most of the potential energy is first stored in the

accumulators and then recovered in the next lifting motions.

In hybrid systems Hydroll piston accumulators, which have been designed in close cooperation with our customers, act as active energy storage.

With high flow rates, reliability, efficiency and long service intervals Hydroll piston accumulators are the optimal choice in hybrid systems.

Example applications- Material handlers

- Forest equipment

- Cranes

- Wheel loader

- Excavators

Emergency Back Up

- As an emergency back up, the piston accumulator’s

function is to store energy, which is available regardless of fluctuations

in hydraulic pressure and provides for continued fail-safe application in

the event of a loss of hydraulic power.

Piston accumulators are a long-life solution in which the failure mode is gradual, making them superior alternatives for diaphragm and bladder accumulators, which fail catastrophically.

Example applications- Breaking system

- Steering system

- Transmission

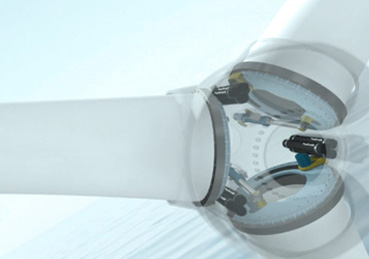

Renewable Energy

- Our piston accumulator solution are truly proven

solutions as in just over a decade Hydroll has gained the position of

leading piston accumulator provider for the wind turbine industry, with over

120 000 piston accumulators in over 10 000 on and offshore turbines.

Hydroll has also been involved in the development of piston accumulator solutions for solar and tidal energy applications for many years. Development is carried out in close cooperation with our customers.

Wind Energy

- WIND TURBINE HYDRAULIC PITCH CONTROL SYSTEM AND BRAKES

Hydraulic pitch control constantly adjusts the angle of the blades to the wind to optimize the wind turbine’s energy production. Also hydraulic pitch systems act as a main brake in extreme weather or wind conditions protecting the high value turbine.

Piston accumulators are in a vital role in hydraulic pitch systems. Typically they perform three functions:- Damping pulsations from the pump and the proportional valve

- During emergency stops accumulators supply extra oil/energy to the cylinders that pitches the blades to a safe position

- Manual decompression is used during service

- Multiple times lower gas permeation

- Superior reliability

- Failure of piston accumulator is not sudden

- High and low temperature tolerances

- Ability to withstand centrifugal forces

- Easy to install real time pressure monitoring diagnostics

Solar Energy

- SOLAR PANEL MOVEMENT

In concentrated photovoltaic (CPV) systems tracking the sun all day is key for system efficiency. In remote locations high reliability with minimum maintenance is one of the key demands for hydraulic systems. Proven Hydroll accumulators are built for this purpose. Hydroll has recently developed a high pressure accumulator to better serve the needs of our customers in the solar sector.

Wave & Tidal Energy

- Wave and tidal energy production

Hydroll, closely together with its customers, has developed accumulator solutions to help to utilize the huge potential of wave and tidal energy in the ocean. Hydroll accumulators are in a crucial role in energy production in Wave and Tidal energy.

Marine And Offshore

- Hydroll accumulators serve Marine and Offshore

customers in a broad variety of functions. Our accumulators are designed to

perform even in the toughest conditions, including arctic conditions, for

extensive periods of time. The products are tailored to meet your

requirements.

- Hydroll accumulators meet a range of approvals (see Type approvals)

- Special coatings available on demand

- Arctic package -40 °C (see Arctic Package)

- Heave compensation in cranes

- Brake release in winch systems

- Emergency back up for lifeboats

- Energy intensifier

- Damping element

Industry and Projects

- In industrial hydraulics accumulators are used in a wide variety of

functions. Hydroll’s comprehensive accumulator offering can support even the

most demanding needs in the markets.

- Molding machines

- Press machines

- Paper machines

- Hydro power plant

- Offshore rigs, vessels and cranes

- Damping element

- Smoothing of pump pulsations

- Energy storage in hybrid system

- Energy storage to support pumps

- Back up energy storage