- Offer Profile

-

HEROSE provides safety around the world for the handling of technical gases, steams and liquids. With 140 years experience in the development, manufacture and sale of valves with a high level of innovation and modern production with certified quality management, our company is one of the world's leading manufacturers and suppliers of:

- Fittings and valves for cryogenic technology

- Fittings and valves for small-scale LNG applications

- Safety valves for general industrial applications

- Special fittings for oil-cooled transformers

- Industrial fittings based on DIN-EN standards

Valves for Cryogenic Services

-

Globe valves, control valves, check valves, gate valves, fillsystems as well as safety valves for Cryogenic Services

Valves for cryogenic liquefied industrial gases

When liquefied at cryogenic temperatures, the volume of industrial gases reduces by a factor of up to 600 and therefore enables economic solutions for transport and storage. Our know-how in the development and manufacture of cryogenic valves guarantees maximum process reliability in the handling of industrial gases.

Valves for cryogenic liquefied natural gas

Natural gas is liquefied at a temperature of -161°C and enables this versatile fuel to be supplied without depending on pipelines. We use our many years of experience in the field of industrial air gases to provided valves which are optimised for small-scale LNG applications.

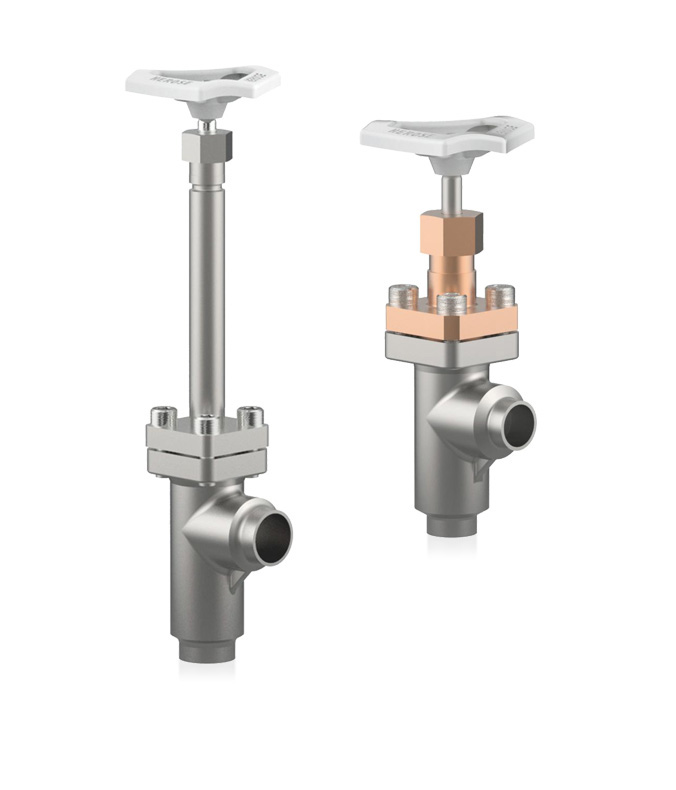

Cryogenic globe valve

-

Sizes: DN10 to DN200

Pressures: up to 50 bar

Temperatures: -255°C to +120°C

Connections: Butt weld, socket weld, welded stubs, thread, flange

Materials: Stainless steel, bronzeHEROSE cryogenic globe valves are available with a wide range of connections and material combinations. They can be equipped with additional functions, such as bellows seals for increased tightness requirements, or with a non-return function. With this combination, use of a separate valve can be eliminated. Cryogenic globe valves are available in sizes from DN10 to DN200 and secure pressures up to 50 bar, at operating temperatures of -255°C to +120°C.

Cryogenic angle valve

-

Sizes: DN15 to DN50

Pressures: up to 50 bar

Temperatures: -196°C to +120°C

Connections: Butt weld, socket weld, welded stubs

Materials: Stainless steelHEROSE cryogenic angle valves are available with weld connections in stainless steel. They can be equipped with additional functions, such as bellows seals for increased tightness requirements, or with a non-return function. With this combination, use of a separate valve can be eliminated. Cryogenic angle valves are available in sizes from DN15 to DN50 and secure pressures up to 50 bar, at operating temperatures of -196°C to +120°C.

Cryogenic gate valve

-

Sizes: DN25 to DN100

Pressures: up to 50 bar

Temperatures: -196°C to +120°C

Connections: Butt weld, socket weld

Materials: Stainless steelWith HEROSE cryogenic gate valves, the flow rate is three to five times higher than with globe valves of comparable size. This speeds up the filling of tanks and trailers and saves valuable time for the delivery of cryogenic liquefied gases.

The cryogenic gate valves are available in sizes from DN25 to DN100 and secure pressures up to 50 bar, at operating temperatures of -196°C to +120°C. The gate valves are manufactured in stainless steel.

Cryogenic fill cluster

-

Sizes: DN25 to DN40

Pressures: up to 50 bar

Temperatures: -196°C to +120°C

Connections: Butt weld, socket weld, welded stubs, thread, flange

Materials: Stainless steel, bronzeA combination of individual HEROSE valves with different functions will be pre-assembled at the factory to form a system. This reduces the joining and welding work on site and saves time and costs for installation on vacuum insulated vessels. Cryogenic fill cluster are available in sizes DN25 and DN40 and secure pressures up to 50 bar, at operating temperatures of -196°C to +120°C. The fill clusters are manufactured in stainless steel and bronze.

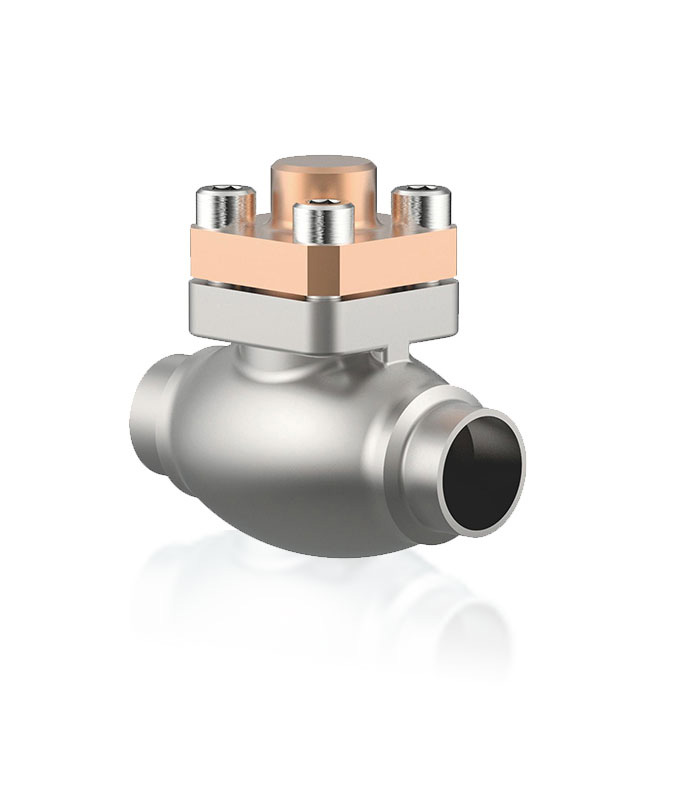

Cryogenic ball valve

-

Sizes: DN8 to DN150

Pressures: up to 50 bar

Temperatures: -196°C to +120°C

Connections: Butt weld, socket weld, thread, flange

Materials: Stainless steelHEROSE cryogenic ball valves have a larger flow diameter than comparable shut-off valves. They provide faster opening and closing times and are suitable for tank applications, as well as for cryogenic pumps, pipelines or low pressure trailers.

Cryogenic ball valves are available in sizes from DN8 to DN150 and secure pressures up to 50 bar, at operating temperatures of -196°C to +120°C. The cryogenic ball valves are manufactured in stainless steel.

Cryogenic actuated valve

-

Sizes: DN10 to DN200

Pressures: up to 50 bar

Temperatures: -196°C to +120°C

Connections: Butt weld, socket weld, thread, flange

Materials: Stainless steel, bronzeIf required, HEROSE pneumatically actuated globe valves can be equipped with an additional hand wheel, with which the valve can be opened or closed manually in case of loss of pressure. Optional seawater-resistant materials are available, which are ideally suitable for offshore use. The actuated valves are available in sizes from DN10 to DN200 and secure pressures up to 50 bar, at operating temperatures of -196°C to +120°C. The actuated valves are manufactured in stainless steel and bronze.

Cryogenic pressure regulator

-

Sizes: DN20

Pressures: up to 38 bar

Temperatures: -196°C to +200°C

Connections: Thread

Materials: Stainless steelThe HEROSE pressure regulator combines three functions: pressure build-up, economiser and safety function. Fewer valves and piping are required, which also saves costs. With combined pressure regulators, cryogenic liquefied technical gases such as nitrogen, oxygen or argon can be economically stored at constant pressure during operation.

The combined pressure regulator is available in DN20 and secure pressures up to 38 bar, at operating temperatures of -196°C to +200°C. The pressure regulator is manufactured in stainless with flow rates of 1,2 m3/h and 3,2 m3/h.

Cryogenic check valve

-

Sizes: DN10 to DN200

Pressures: up to 50 bar

Temperatures: -196°C to +120°C

Connections: Butt weld, socket weld, welded stubs, thread, flange

Materials: Stainless steel, bronzeA check valve is used to secure against undesired return flows in pipelines, as it allows the flow of gases or liquids only in one direction. In the cryogenic area specially designed check valves are required, which are up to the requirements of temperatures well below freezing point. Cryogenic check valves are available in sizes from DN10 to DN200 and secure pressures up to 50 bar, at operating temperatures of -196°C to +120°C. The check valves are manufactured in stainless steel and bronze.

Cryogenic strainer

-

Sizes: DN10 to DN200

Pressures: up to 50 bar

Temperatures: -196°C to +120°C

Connections: Butt weld, socket weld, welded stubs, thread, flange

Materials: Stainless steel, bronzeFiltration of the medium ensures compliance with the specified level of purity for downstream processes. For this various screens and filters with different mesh sizes are available. Cryogenic strainers are available in sizes from DN10 to DN200 and secure pressures up to 50 bar, at operating temperatures of -196°C to +120°C. The strainer are manufactured in stainless steel and bronze.

Cryogenic safety valve

-

Sizes: DN6 to DN50

Pressures: 0,2 up to 250 bar

Temperatures: -270°C to +400°C

Connections: Thread, flange

Materials: Stainless steel, brass, bronzeHEROSE cryogenic safety valves are certified to global certifications for CN, TR CU and ASME. Thus they can be used worldwide, regardless of where the system is installed later. Cryogenic safety valves are available in sizes from DN6 to DN50 and secure pressures up to 550 bar, at operating temperatures of -270°C to +400°C. The safety valves are manufactured primarily in stainless steel but also in bronze and brass.

Cryogenic overflow valve

-

Sizes: DN6 to DN50

Pressures: 0,5 up to 36 bar

Temperatures: -196°C to +185°C

Connections: Thread

Materials: Stainless steel, bronzeThe cryogenic overflow valves secure pressures up to 36 bar, at operating temperatures of -196°C to +185°C. The overflow valves are manufactured in stainless steel and bronce.

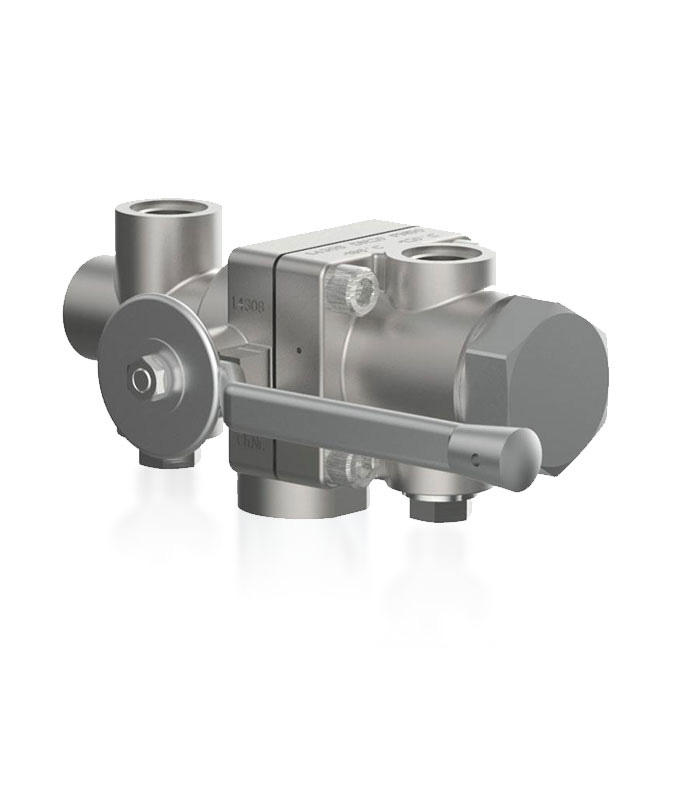

Cryogenic changeover valve

-

Sizes: DN6 to DN50

Pressures: 0,2 up to 250 bar

Temperatures: -270°C to +400°C

Connections: Thread, flange

Materials: Stainless steel, brass, bronzeIn contrast to a standard ball valve on a changeover valve at least two safety valves are designed to protect the application (for example, a liquid gas tank) against impermissible overpressure.

A changeover valve has usually two outputs but one input only and serves to connect two safety valves with a pressure device. Changeover valves can be found in the area of air gases, vapours and in cryogenics at cryogenic liquefied gases such as Nitrogen. Cange-over valves are available in sizes from DN6 to DN50 and secure pressures up to 250 bar, at operating temperatures of -270°C to +400°C. The changeover valves are manufactured primarily in stainless steel but also in bronze and brass.

Industry Valves

-

Safety valves for gases, vapours and fluids; DIN EN valves made of stainless steel, gunmetal and brass

Valves for industrial applications

In order to prevent the uncontrolled rise in pressure in pressure vessels or pressurized pipelines, a safety valve is inserted. The safety valve is designed so that it opens at a given maximum pressure, thereby relieving the line or the container. Safety valves find their use in almost all areas of the pressure vessel and pipeline construction. In cryogenics as a spring-loaded safety valve for example.

Ultimate safety is the aim of our development and production. This is especially when the safety of people is at stake. Because of this, we test the reliability of our products in especially extreme situations.

Free discharge safety valve

-

Sizes: DN8 to DN50

Pressures: up to 43 bar

Temperatures: -40°C to +200°C

Connections: Thread

Materials: Stainless steel, brassThe free discharge safety valves have proved themselves thousands of times in daily use and their carefully matched design and materials offer optimum value for money. The valves are ideal for applications in which compressed air may be released into the atmosphere without problems. The free discharge safety valves are available in sizes from DN8 to DN50 and secure pressures up to 43 bar, at operating temperatures of -40°C to +200°C. The free discharge safety valves are manufactured in stainless steel and brass.

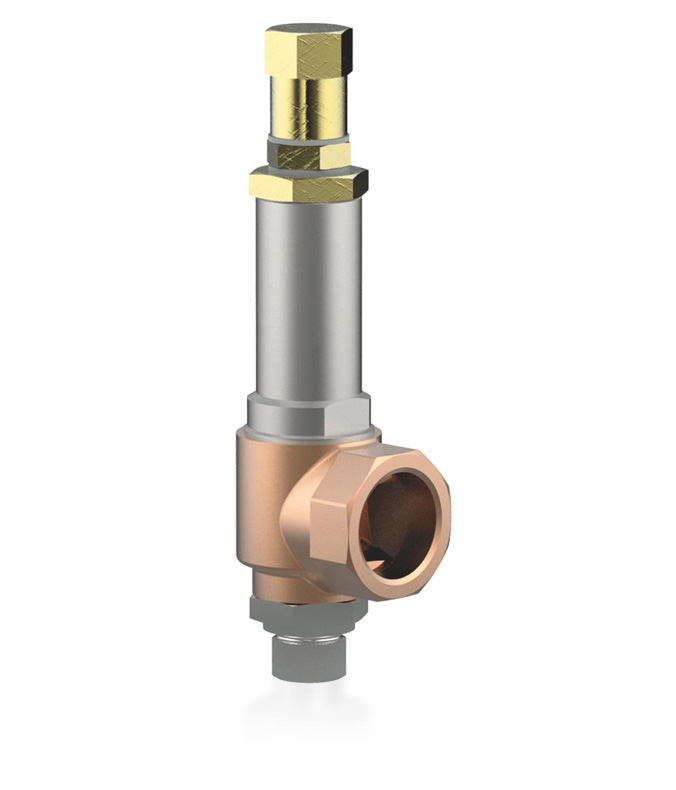

Angle type safety valve

-

Sizes: DN10 to DN50

Pressures: up to 250 bar

Temperatures: -270°C to +400°C

Connections: Thread, flange, Tri-Clamp

Materials: Stainless steel, bronze, brassHEROSE supplies angle type safety valves, which are approved for vapours, gases and liquids. The angle safety valve can therefore be used for various aggregate states. In addition, it is also available as a version with a flange, NPT or Tri-Clamp connection for the inlet and outlet and also with a soft sealed disc. The angle type safety valves are available in sizes from DN10 to DN50 and secure pressures up to 550 bar, at operating temperatures of -270°C to +400°C. The angle safety valves are manufactured in stainless steel, bronze and brass.

Safety valve for liquid, granular and powdery goods

-

Sizes: DN25 to DN50

Pressures: up to 6 bar

Temperatures: -40°C to +200°C

Connections: Thread

Materials: Stainless steel, brassAll components of the valvefor liquid, granular and powdery goods are protected against dirt and designed for a long service life. Because of this, these HEROSE safety valves are ideally suited for silo operations, where granular or powdered materials need to be reliably transported. The safety valves are available in sizes from DN25 to DN50 and secure pressures up to 6 bar, at operating temperatures of -40°C to +200°C. The safety valves are usually manufactured in stainless steel or brass.

DIN EN standard valve

-

Sizes: DN8 to DN50

Pressures: up to 40 bar

Temperatures: -40°C to +200°C

Connections: Thread

Materials: Stainless steel, brassHEROSE has a wide range of standard valves in its range, which offer especially good value for money. These include shut-off valves, gate valves, pressure reducers and strainer, as well as check valves for various industrial applications.

The DIN EN standard valves are available in sizes from DN8 to DN50 and secure pressures up to 40 bar, at operating temperatures of +200°C to -40°C. The DIN EN standard valves are manufactured in stainless steel, bronze and brass.