- Offer Profile

-

Rely on HYDAC’s expertise in hydraulics, systems and fluid engineering. We are committed to providing all-inclusive solutions that span industrial sectors and are sustainable and above all customer-oriented. We are not theorists – with comprehensive understanding of the industry, we develop systems that will stand the test of time. For you and with you.

Founded in Saarland in 1963 as “Gesellschaft für Hydraulikzubehör” (Company for Hydraulics Accessories) and run as a family company, HYDAC has never stopped improving. HYDAC now has 50 international subsidiaries, roughly 500 sales and service partners, 14 product lines and around 10,000 employees worldwide.

Filter Technology

- Our filters and filter systems support oil and fluid maintenance and thus contribute to safe and economical plant operation. Efficient and safe filtration solutions for hydraulic and lubricating oil, water, fuel, KSS and other process fluids have been part of the product range for decades. The high-quality filtration products are always developed with customer focus and enable economical and reliable plant operation. HYDAC offers laboratory-based and proven technologies and innovations within a broad filter range for liquid and gaseous media. All filtration products are of very high quality and reliably increase the service life of components, systems and machines.

Inline filters

- Take a look at our range of inline filters and choose the right filter for your application. We are happy to provide advice across all sectors.

Block mounting filters

- Choose from our range of block mounting filters with filters up to 315 bar. We are happy to provide advice across all sectors.

Return line filters, tank-mounted

- Take a look at our range of return line filters and choose the right filter for your application. We are happy to provide advice across all sectors.

Suction line filters

- Take a look at our range of suction filters and choose the right filter for your application. We are happy to provide advice across all sectors.

Return line suction filters

- Take a look at our range of return line suction filters and choose the right filter for your application. We are happy to provide advice across all sectors.

Bypass filter

-

Hydraulic oil filters for the bypass flow have the task of filtering the operating fluid located in the hydraulic container in a separate circuit, of relieving the oil filters in the main flow and thus of increasing the availability of the system while simultaneously reducing the operating costs.

- Flow rates up to 5,600 l/min

- Pressure ranges up to 40 bar

- Reversible version for 24-hour operation

- Numerous connection options

Fluid conditioning systems

- HYDAC – your reliable partner for all questions relating to fluid management. We develop application-specific solutions for the treatment of operating fluids. Our customers benefit from extended service life of their fluids and increased component protection. Increasing the availability of your hydraulic and lubrication systems and reducing downtime are our main concerns.

Process filter, automatic back-flushing filter

-

Conservation of resourcesby using automatic back-flush filters: Filtration is usually one of the most important steps in multi-stage treatment processes, since it has a crucial impact on the operating efficiency of the main treatment and after-treatment processes further downstream. Through the use of our filters, system owners and the environment benefit equally from:

- Regenerable filter materials

- Improved service life for system components further downstream

- Low energy consumption

- Increased process reliability

- Guaranteed quality

Process filter, inline filter

-

HYDAC process inline filters provide effective filtration of all types of solid contamination. Numerous designs and filter materials ensure the best fit to the filtration task and the given process conditions:

- Temperatures up to 400 °C

- Pressures of up to 1000 bar

- Filtration ratings from 1 µm (absolute) to 10000 µm

- Flow rates up to 3600 m3/h

- Skid and system solutions as well as special customised solutions

Process filter, gas filter

-

CHALLENGE: Fluid or particulate contaminations of gas can significantly impair the service life of major components and plants. This results in costly maintenance interventions and even complete downtime. Typical problems caused by solid and fluid aerosols becoming deposited on components include:

- Erosion

- Deposits

- Fouling

- Corrosion

Diesel fuel filters

-

In order to meet the requirements for diesel fuels, it is not sufficient to treat diesel only immediately before use on the machine. The fuel must be filtered and dewatered at every station in the transport chain - from refinery production to the end user. Monitoring particulate contamination and water content is essential to comply with high quality requirements.

Innovative solution in solid design.

In addition to the on-board products for smaller diesel quantities on consumer devices, products for larger volume flows are also available. These are used during transport between different reservoirs, at petrol stations, and thus at the transition to the engine.

Breather filters/dryers

- Take a look at our range of breather filters and dryer filters and choose the right filter for your application.

Filter elements

- Every area of application in filtration requires an individual element design optimised for the respective use case. HYDAC offers innovative filter element technology that meets the increasing challenges in oil care and filtration. SUSTAINMICRON represents a new generation of element and a step forward in technological development that sets a new standard in element technology, providing an important contribution to sustainability.

Clogging indicators

- Take a look at our range and choose the perfect clogging indicator for your application.

Hydraulic accumulators

-

ROBUST AND VERSATILE: Wherever hydraulic tasks need to be performed, HYDAC hydraulic accumulators can help. They are versatile, make your machine more convenient to use, secure your hydraulic system and are used to increase the energy efficiency of hydraulic systems and for many other tasks.

HYDRAULICS ARE YOUR HOME: The know-how of our hydraulic specialists extends to all accumulator types, such as bladder accumulators, piston accumulators or diaphragm accumulators and metal bellows accumulators. We will gladly assist you in selecting the right design and in determining the suitable accumulator model. The extensive range of accessories makes proper installation, protection on the gas and fluid side, and maintenance easier.

Bladder accumulators

- Robust, autonomous, for high discharge speeds: select the right bladder accumulator for your hydraulic application.

Piston accumulators

- HYDAC piston accumulators can be customised with a chosen diameter and nominal volume. More details can be found here.

Diaphragm accumulators

- HYDAC diaphragm accumulators are designed as modules and thus provide the right pressure stages for your application: optimum dimensioning also reduces environmental impact.

Metal bellows accumulators

- While fluids are practically incompressible, this does not apply to gases. Hydraulic accumulators use these basic laws of physics to store hydraulic energy. Nitrogen is normally used as the compressible medium. The various types of hydraulic accumulator are categorised on the basis of the separation element that keeps the gas section separate from the fluid section in the pressure vessel. In the case of metal bellows accumulators, this is a metallic corrugated or diaphragm bellows.

Hydraulic dampers

- Hydraulic dampers reduce, in particular, pulsations, pressure spikes and noise. A small selection of our dampers and silencers is presented here.

Hydraulic accumulator accessories

- Overview of HYDAC accumulator accessories: Indispensable for correct maintenance, repair and professional installation of your hydraulic accumulator.

Valves

- HYDAC builds on decades of experience in valve technology and, through continuous development, achieves a high-quality and broad product range.

Whether directional spool valves, directional seat valves, pressure valves, flow valves or shut-off valves as screw-in, plug-in, manifold mounting, intermediate plate or pipeline valves - we have the ideal valve for your system.HYDAC valves - the right valve for every application!

Thanks to its extensive application-specific experience and modular system, HYDAC is always a reliable partner for customer-specific requirements. HYDAC offers you comprehensive support and global on-site expertise.

Directional valves

-

- 2 directions / 2 positions

- Directional poppet valve

- Normally closed

- Allows flow through one side

Pressure valves

-

- Release valve

- Poppet type

- Direct-acting

- Cartridge valve

Flow valves

-

- Throttle valve

- Direct-acting

- Cartridge valve

- e.g. DV5E

Shut-off valves

-

- Check valve

- Cartridge valve

- e.g. RV08A, RVM10120, RVF A

Proportional valves

- Proportional pressure relief valve

Logic valves

-

- Cone A

- Pressure function

Coaxial valves

- The compressed air with the spring produces a pre-charge force on the closing cone and this is pressed onto the valve seat. Hydraulic compressive force is exerted on the opposite side of the closing cone. If this is below the pre-set pre-load force, the valve is closed. If the hydraulic compressive force exceeds the pre-set pre-load force, then the closing cone is lifted away from the valve seat and operating fluid flows from pressure port P to tank port T. This has the effect of limiting the pressure at port P. The hydraulic energy used is converted to heat and the operating fluid is drained to tank.

Coils

- HYDAC solenoid coils are known for their high quality and performance in hydraulic systems.

Available in different sizes and connection types, they enable optimal design and flexible integration.

The robust construction guarantees durability and reliability under demanding environmental conditions. Ideal for users who value precision and quality. An extensive range with UL approval completes the offering.

Electrohydraulic systems

-

More efficient, safer, smarter: HYDAC is already developing tomorrow's components and systems for mobile work machines today. Because our engineers combine many years of expertise in electro-hydraulics with comprehensive application knowledge. In this way, we recognise the potential of your machine and develop your custom-fit application - from customer-specifics product to holistic industry solutions. As a competent development partner, we transparently accompany you in every phase of your project. Even after the series phase, you can count on HYDAC as your reliable contact partner.

Hydraulics paired with intelligent closed loop technology: in addition to standardised and pre-developed solutions, which we parametrise to your machine to save you time, our portfolio also includes individual complete systems for your vehicle. Tailored to your risk analysis, our solutions are certifiable and meet the highest functional safety requirements. Thanks to an efficient system design, verification by means of simulation models and on our test benches as well as in field and hall tests on site, you can always rely on the tried-and-true HYDAC quality.

Implement the technologies of the future together with HYDAC, increase your machine performance or rely on our compact systems with maximum flexibility. Find out more about our portfolio of construction machines, agricultural and forestry machines, municipal machines as well as lifting and material handling machines now.

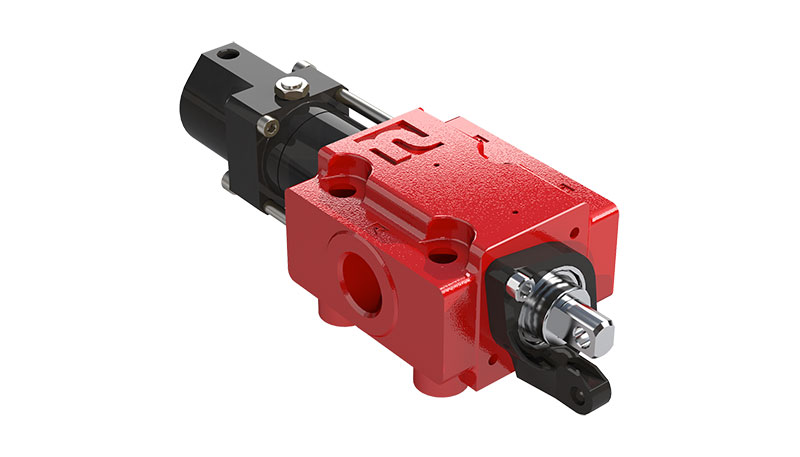

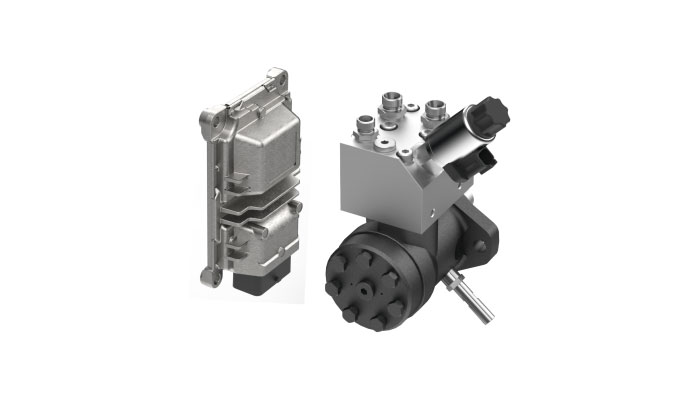

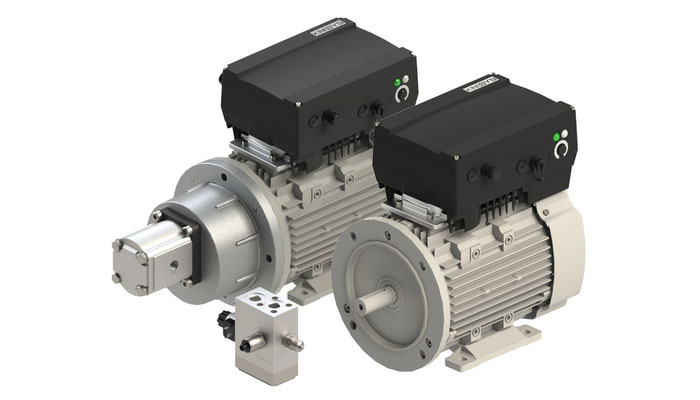

HYDAC Rotary Drive Control

-

Tried-and-tested hydraulics combined with intelligent control technology

Rotary Drive Control is a clever type of speed control for your mobile machine. This is because electro-hydraulic systems require high precision, especially in the case of increased environmental protection or when there are new regulations. Wherever there is a need for speed-controlled functions combined with high power densities, the Rotary Drive Control operates with extreme precision and dynamic performance thanks to the electronic control. For the best performance of your mobile machine – even with pressure fluctuations.

Boom Control

-

Modular solutions for crop protection: precision farming with HYDAC systems

The prerequisite for a good harvest and secure yields in agriculture is successful crop protection. Agricultural machinery such as field sprayers and hoeing equipment play a central role here. Their hydraulic functions need to be able to be precisely controlled to ensure good quality work. With HYDAC Implement Control and HYDAC Ground Control, we offer you the right system solution for every machine function. Find out more here.

Hydropneumatic suspension

-

Hydropneumatic suspension systems: increasing your machine's driving performance

Hydropneumatic suspension systems from HYDAC help to compensate for uneven surfaces, reduce vibration loads on drivers and vehicle components and increase driving stability. Adapted to your mobile machine, our suspensions significantly improve driving safety and driving performance. Learn more about the different suspensions systems and their advantages now!

Electro-hydraulic additional steering

-

The new type of electro-hydraulic additional steering

Increase the flexibility of your vehicle fleet with ADSteer Profi - the autonomous subsystem for electro-hydraulic additional steering, which calculates the target angle of the steering axes in a non-contact manner. Get to know our unique solution now!

Sensors

- The area of sensors covers products for measuring pressure, temperature, level, flow rate, position, linear position, angle, Inclination, contamination and oil condition, and also cameras. In addition to products for standard applications, the product portfolio also covers special applications such as potentially explosive atmospheres or applications with increased functional safety.

Pressure sensors

-

Electronic pressure sensors are used for recording pressures in fluid technology systems. Functionality and form of execution are determined by the respective utilisation conditions. To fulfil these requirements, HYDAC offers an extensive range of miniature pressure transmitters including custom multiple pressure switches.

Electronic pressure measuring transmitters collect pressure data and convert these into a proportional output signal. Electronic pressure switches record the measured variable for pressure, process it and output a switching signal in accordance with the presetting.

Temperature sensors

-

For measuring and evaluating temperatures, HYDAC supplies temperature transmitters and temperature switches for installation in pressure lines or for tank installation.

Temperature transmitters measure the temperature and convert it into a proportional output signal. Electronic temperature switches measure the temperature, process it and output a switch signal in accordance with the presetting.

Level sensors

-

In industry, level sensors are used for the most diverse tasks. In the main, sensors which are based on capacitive, magnetostrictive or ultrasonic measurement are used.

HYDAC ELECTRONIC has level sensors for each of these measurement principles in its product range. Electronic level switches record the fluid level and output one or more switching signals in accordance with the presetting. As an option, the fluid level can also be permanently output as an analogue signal (4 .. 20 mA or 0 .. 10 V).

Linear position sensors

- HYDAC offers an extensive range of sensors for position recording for that purpose. Electronic position sensors are designed for recording linear positions such as those of cylinders and valves and for recording distances.

Our extensive range, which includes everything from inductive switches and basic add-on sensors to fully-integrated and customer-specific transducers, comprises robust solutions for both mobile as well as stationary applications.

Angle sensors

- Electronic angle sensors are used to measure angular position and speed of rotary movement and to position and control both mobile and stationary machine segments.

HYDAC angle sensors are designed for the most demanding requirements when it comes to robustness and reliability. For the mechanical integration, HYDAC is on hand to help you as an experienced consultant.

Inclination sensors

- Many applications depend on inclination angle measurements in order for machines and equipment to work properly and for managing processes.

Cameras

- HYDAC digital cameras were specially developed to extend the field of vision and for use in customised vision and detection solutions under demanding ambient conditions.

With their compact and robust design, our cameras are perfect for use in a wide variety of applications. They feature reliability across a wide temperature range and are used in commercial vehicles and mobile machines and in industry.

Flow transmitters

-

HYDAC offers various volume flow transmitters and flow switches for measuring the flow rate in machines and systems.

The flow rate transducers of the EVS 3000 series work according to the turbine principle – recording the speed of an impeller rotating in the media flow. Depending on the version, additional connection openings for pressure and/or temperature transmitters are available.

The flow switches / flow transducers of the HFS 2000 / HFT 2000 series are based on a position-independent float measuring principle.

Fluid monitoring sensors

-

HYDAC offers an extensive range of fluid sensors to measure

- Solid particle contamination

- Metallic particles or

- Fluid contamination (water).

Measurement, display & analysis technology

- HYDAC measurement, display and analysis technology provides controlled safety thanks to concrete diagnosis.

Fluid level gauges and sensors

- High-quality and robust fluid level gauges for checking levels in your container visually. Choose from world’s largest product portfolio with great number of sizes from 076 to 1000 mm and seal variants. High media-resistance, UV-resistance, pressure fluid temperatures from -50°C to +160°C and extensive accessories and contrast panes in custom designs complete the product portfolio. Please ask us for help in finding the right product for your application.

Component analysis devices

- The demands on the life expectancy of individual components and assemblies are increasing in the automotive and supplier industries, in transmission and engine construction, in mobile hydraulics and in the manufacture of hydraulic and lubrication system components. The technical cleanliness of electronic components is also becoming increasingly relevant. This is largely determined by their technical cleanliness. The determination is carried out in accordance with ISO 16232 and VDA 19 guidelines. In addition, the analysis of the particles allows conclusions to be drawn about the possible source of contamination.

Portable data recorders

-

Our measuring instruments and data recorders were developed for use in the laboratory and for commissioning, service and maintenance.

Analogue and digital sensors for a wide range of measured variables can be attached.

An extensive selection of matching accessories for various measurement tasks round off the portfolio.

- HMG 500

Mobile, easy-to-handle low-cost portable data recorder for simple measurement tasks. - HMG 510

Mobile, easy-to-handle low-cost portable data recorder for simple measurement tasks and

for displaying the measured values of condition monitoring sensors. - HMG 2500

Mobile portable data recorder for recording, processing and saving measured data. - HMG 4000

Powerful portable high-end data recorder for recording, processing and saving measured data.

- HMG 500

Contamination measuring instruments

-

HYDAC offers a comprehensive range of easy-to-use contamination measurement systems for implementing modern maintenance strategies. Whether solid particles or liquid contamination, for sporadic monitoring or as a fixed installation, in rough field use or in the laboratory.

The right tool for every application:

- Portable contamination measuring devices (for recording solid contamination and water saturation)

- Stationary contamination measuring devices (for recording solid contamination and water saturation)

Pressure display units

- Multi-station gauge isolators are designed to check different pressures in a hydraulic system. There are models with a built-in pressure gauge for different pressure ranges or models to which a separate pressure gauge can be connected. If it is necessary for the system pressure to be retained during the measuring process, the leakage-free model must be used.

Installed in control panel

- The universal display unit HDA 5500 offers the opportunity for visualisation and further processing of the signals from our sensors.

The device is designed for front-panel installation with standard 92 x 45 mm cutout.

Mounting and connection technology

- When you need to fasten cylinders, accumulators, exhaust systems, tanks, batteries, containers, heat exchangers, thermal management elements and their supply lines (such as pipes, hoses and cables) securely, the product range of HYDAC mounting technology HY-ROS (HYDAC piping clamps) has the right solution for almost any application. We have standard parts in stock and develop custom easy-to-install solutions.

Mounting elements for pipes, hoses and cables

- Mounting supply lines (pipes, hoses and cables) is quick, clean and tidy with HY-ROS mounting clamps, which are available in all sizes directly from stock.

Band straps

- Clamping bands are used to fasten large-size components with all kinds of shapes (round or rectangular), for example air containers, plastic containers, steel and plastic tanks, type I–IV tanks, as well as all kinds of accumulators and much more.

Accumulator mounting elements

- Find the perfect fastening system for your hydraulic accumulators, clamps, support bases or entire accumulator fastening sets from HYDAC.

Ball valves

- HYDAC ball valves and fittings open and secure multiple channels.

Ball valves

- Shut off and redirect your media securely with HYDAC ball valves.

From the 2-way ball valve to complete ball-valve function systems, automated and position-monitored, we offer custom solutions for almost all application areas. Our expertise ranges from the requirements analysis and development to the finished product. Get in touch – we will gladly assist you with your project from the outset.Additional options:

- Pneumatic, electric or hydraulic actuators

- Position monitoring, from analogue to IO-Link

- Mounting solutions

- Settings secured by detent mechanism, safety lever or lock

Shut-off valves

-

Long life and continuous accuracy can be achieved if pressure gauges are only pressurised for the time it takes to read the pressure. For the rest of the time the gauge isolator isolates the pressure gauge and the gauge is automatically vented to the tank. This then protects the gauge from possible pressure surges from the system.

This is possible with the HYDAC Single Station Gauge Isolator.

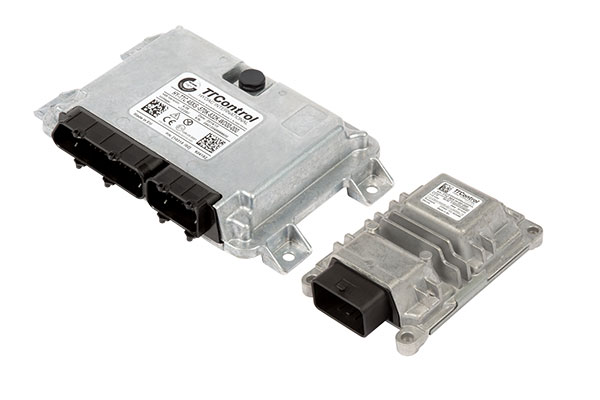

Electronic control technology

- Always on the right track with mobile control technology from HYDAC/TTControl. With the hardware and software products specially developed for use in working machines, you can realise control tasks for simple for highly complex machine applications in central or decentralised machine architectures. We have the right product for any field of application, taking into account the constantly increasing requirements for safety, functionality, efficiency, reliability and connectivity both inside and outside the machine.

Controllers

-

Controllers for mobile machines and applications

HYDAC’s controller platform for mobile machines offers an extensive and powerful product range for realising and automating individual work and drive functions, including complete machine control.

- Powerful CPU platforms and modern electronics architectures

- Extensive and flexibly configurable inputs/outputs and interfaces

- Certified for many relevant safety standards in the mobile sector

- Scalable hardware platform and uniform development environment

- Extensive options for developing the application software (C, Qt, CODESYS, MATLAB Simulink)

- HYDAC software development platform MATCH for mobile automation

Displays

-

HYDAC is meeting the different requirements with respect to machine operation and monitoring by means of a wide array of visualisation solutions.

- Many different display solutions (from simple display to transreflective colour displays)

- Various display sizes and formats

- Versions with fixed function keys and with and without touchscreen are available

- Connection of several cameras possible

- Various communication interfaces: Ethernet; CAN; RS232; LIN

- Programmable using CoDeSys® or C/C++

- Extensive software libraries are available for programming support

- Expansion package for Tele-Service

I/O modules

-

Extension modules for general applications

The versions of the I/O expansion modules provide additional varied PWM outputs with internal current measurement and an integrated PID control device, alongside numerous powerful switch outputs. These permit proportional controls to be implemented very simply. The detection of digital switch and analogue current/voltage signals is possible using digital and analogue inputs which can be parametrised differently.

Electrohydraulics

- Regardless of whether you want to control a proportional valve, regulate a pressure or synchronise a cylinder movement: Find the right control unit for your application quickly and easily.

Telematics and connectivity

- Communication does not come to an end at the mechanical limits of a vehicle. To be able to provide modern, service-orientated services, it is vital for a connection to be established with the outside world. Communication between vehicles is just as important as the ability to exchange information with a centre.

A product range with corresponding interfaces is available for internal machine communication and external communication of digital data.

Software

- The challenges involved in developing mobile machinery are complex: the level of automation is increasing, and digitization is opening up new possibilities. At the same time, the requirements for functional safety are also growing. To support you constructively as a machine manufacturer, we have developed tailored products and technologies for safety-relevant controllers: uniform IT solutions for mobile machinery in which functional safety is implemented consistently from the outset.

Thermal Management

Air coolers

- Air cooling is a convenient method of dissipating heat loss from industrial and mobile systems.

The medium to be cooled – usually oil or a water-glycol mixture – flows through a heat exchanger. A fan draws in ambient air and feeds it through the cooling element. The difference in temperature causes a heat exchange to take place, whereby the cooler air absorbs the heat from the medium and releases it back into the atmosphere.

This allows the medium to be cooled down to a few degrees Celsius above ambient temperature.

At HYDAC you will find the right air cooling unit to suit your needs, from standard to large coolers for use in the energy sector or even custom-made coolers for mobile machinery.

Fluid cooling

- Liquid cooling is an effective and cost-effective method for cooling high output densities. Cooling below ambient temperature is also possible, depending on the temperature of the cold water used. Plate heat exchangers used either as an intermediate circuit or as a separating circuit help protect the system components from contamination and corrosion due to poor quality cold water.

HYDAC can offer you highly specialised solutions, such as fluid cold plates for cooling electrical components, as well as highly efficient screwed and brazed plate heat exchangers.

Cooling systems

- Greater safety through cool system solutions.

The heat produced by internal losses in the main spindle, drives, control cabinets, cooling lubricants and hydraulics can be dissipated very effectively by means of liquid cooling.

HYDAC has a wide range of cooling systems including air cooling, water cooling or compressor cooling to provide you with the optimum cooling solution that meets your requirements in terms of installation space, noise levels, control accuracy or maintenance requirements.

Cooling for mobile applications

- HYDAC cooling for mobile applications.

Pumps

- Pumps convey fluids and can get things moving in your system!

HYDAC supplies a broad spectrum of pumps for a large number of hydraulic applications and systems. Our pumps are used in many industries worldwide. HYDAC supplies fixed and variable displacement pumps with various designs and setting ranges. They range from 0.25cm³/rev. to 560cm³/rev. with setting ranges of up to 400 bar.

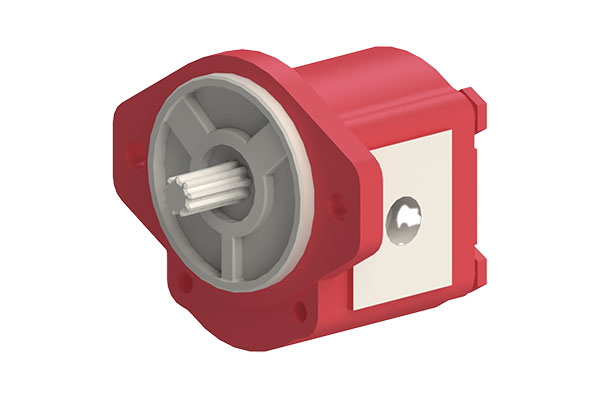

External gear pumps

Internal gear pumps

Vane pumps

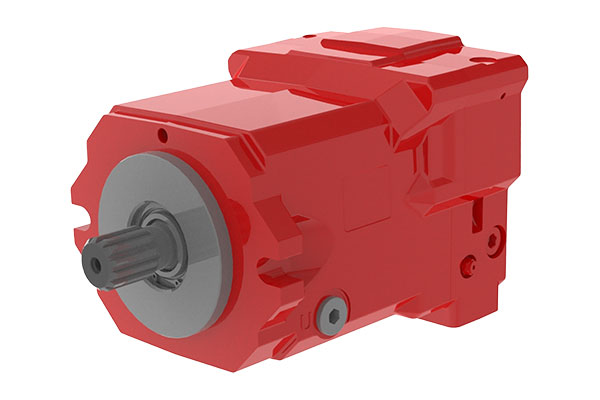

Axial piston pumps

Bell Housing

Hydraulic motors

Valve manifolds

- Discover our wide product portfolio of tried-and-tested control blocks for mobile work machines. Whether agricultural machinery, municipal machinery, construction machinery or material handling, we offer the right solution for a wide range of work functions, from the main control to the fan control to lifting and lowering blocks. Further details on the different hydraulic blocks can be found here.

Selector valves

- Our HYDAC changeover valves are available in various designs. The MWV 6/2-12 6/2-way valve is particularly suitable for front loaders, telehandlers and attachments. For example, it enables the control of two different hydraulic cylinders with one main control valve. The RV 713, on the other hand, is used for tipping devices and removable superstructures.

Electrohydraulic systems

- More efficient, safer, smarter: HYDAC is already developing tomorrow's components and systems for mobile work machines today. Because our engineers combine many years of expertise in electro-hydraulics with comprehensive application knowledge. In this way, we recognise the potential of your machine and develop your custom-fit application - from customer-specifics product to holistic industry solutions. As a competent development partner, we transparently accompany you in every phase of your project. Even after the series phase, you can count on HYDAC as your reliable contact partner.

HYDAC Rotary Drive Control

-

Tried-and-tested hydraulics combined with intelligent control technology

Rotary Drive Control is a clever type of speed control for your mobile machine. This is because electro-hydraulic systems require high precision, especially in the case of increased environmental protection or when there are new regulations. Wherever there is a need for speed-controlled functions combined with high power densities, the Rotary Drive Control operates with extreme precision and dynamic performance thanks to the electronic control. For the best performance of your mobile machine – even with pressure fluctuations.

Boom control

- The prerequisite for a good harvest and secure yields in agriculture is successful crop protection. Agricultural machinery such as field sprayers and hoeing equipment play a central role here. Their hydraulic functions need to be able to be precisely controlled to ensure good quality work. With HYDAC Implement Control and HYDAC Ground Control, we offer you the right system solution for every machine function. Find out more here.

Hydropneumatic suspension

- Hydropneumatic suspension systems from HYDAC help to compensate for uneven surfaces, reduce vibration loads on drivers and vehicle components and increase driving stability. Adapted to your mobile machine, our suspensions significantly improve driving safety and driving performance. Learn more about the different suspensions systems and their advantages now!

Electrohydraulic steering

-

The new type of electro-hydraulic additional steering

Increase the flexibility of your vehicle fleet with ADSteer Profi - the autonomous subsystem for electro-hydraulic additional steering, which calculates the target angle of the steering axes in a non-contact manner. Get to know our unique solution now!

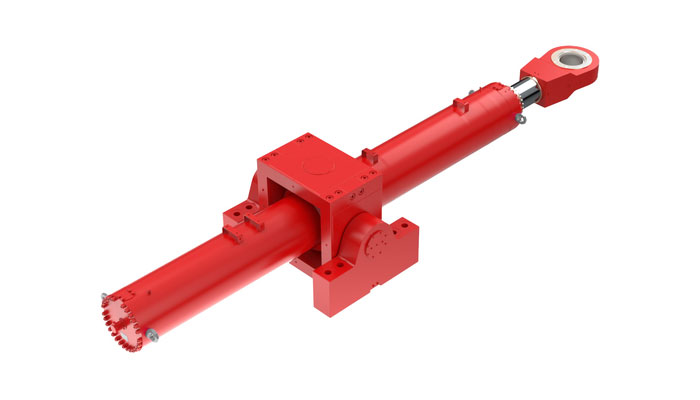

Cylinders

-

Cylinders are an important driving element in machine engineering. The application fields are highly diverse. Stationary, from special-purpose machine construction and bridge-raising cylinders to safety actuation functions in the power plant. Mobile, from crane-telescoping units to agricultural applications. Often under extreme conditions, high strains and long downtimes.

We set these requirements for ourselves and can draw on extensive experience and a wide range of products from hydraulic cylinders and electric cylinders. The customer-specific challenges are taken into account under the aspects of energy efficiency, weight optimisation, lifespan, maintenance and the overall economic viability of a system.

The combination of HYDAC hydraulic power units and KineSys drive solutions enables us to offer complete system solutions. On top of this, sensor systems can be integrated or attached to send information on the linear position, pressure or force to the controller. Combined with the controller and the corresponding drive system, the cylinders can be operated with open-loop or closed-loop control. A global service rounds out the extensive product range.

Hydraulic cylinders

-

Permanent surveillance of all processes. From design to mounting, control of single parts as well as the final products, the measuring surveillance, contamination control of all hydraulic oils used. Our top goal:

- High quality

- constant improvement of our quality

- permanent observation of our production and control of the goods produced Quality concerns our whole efficiency on all levels of our company:

- determination of our customers needs on schedule and specification conform delivery of the products

- installation

- repair

Electric cylinders

-

HYDAC electric cylinders (HEZ) are also known as electromechanical linear actuators. They consist of a nut-spindle drive that is driven by an electric motor. Electric cylinders only require electrical energy, which means they can be used very flexibly and decentrally.

They do not contain any hydraulic oils, only lubricants. Our electric cylinders are available with adjustment forces from 1 kN to 500 kN and stroke lengths of up to 5 metres. There are various designs and series that differ in terms of the connection between the motor and the threaded spindle as well as the area of application. Our product range also covers all areas of application. From simple adjustment functions with occasional movement to highly dynamic work functions in continuous operation. Electric cylinders are maintenance-free for their entire life.

Variable-speed drive solutions

- Variable-speed drive solutions control the drive motor so that kinetic energy is provided according to requirements.

The drive controller with its three-phase motor is the core of variable-speed drive solutions. This controller either powers a hydraulic system or the spindle drive of an electromechanical cylinder.

This technology makes extensive customisation of traditional hydraulic systems possible and, through this, achieve efficiency, such as: Reduced power and cooling requirements, lower tank and oil volumes, less material and lower weight.

Be it electromechanical cylinders or hydraulic systems: Variable-speed drives make it possible to network drive systems and make control tasks, commissioning and troubleshooting significantly easier.

Drive controller

- Our drive controllers in the HFI (HYDAC Frequency Inverter) series control the speed or torque of three-phase motors.

We use our drive controllers to implement drive solutions for hydraulic and electromechanical systems. Our drive solutions include simple component sets as well as complete drive system solutions. Be it electromechanical cylinders or hydraulic systems: Our drive controllers are the missing link. They make it possible to network drive systems, reduce the number of components and the space required, minimise complexity and create efficiency.

Our drive controllers differ in terms of how they are mounted and how they are used.

Drive kits - component sets

- The DVA kit and HFI-MM kit are drive component sets that make it easy to switch to speed-controlled hydraulic pumps.

The HFI-MM kit includes an asynchronous motor with a modular drive controller. It provides a simple interface for operating a hydraulic pump at a variable speed. The motor and drive controller are already in alignment, both mechanically and in terms of parametrisation. The user is responsible for the layout of the operating points and the hydraulic pump connection.

The DVA kit also includes the hydraulic pump connection. We are responsible for making sure the right decision is made when combining motor output, motor type and hydraulic pump, documentation and functional testing. This ensures that the necessary hydraulic operating points are reliably achieved.

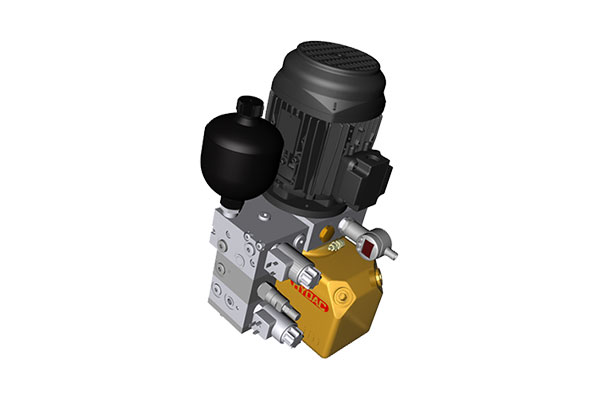

Units & systems

- Utilising the experience gained from numerous international projects, our industry and product specialists quickly arrive at the most economical solution, however new and challenging the problem may be. It is of no consequence whether it concerns the custom development and manufacture of stationary or mobile systems, or the implementation of series solutions. Be they customised one-off products or inexpensive and versatile series products, at HYDAC you can find a cost-effective solution for almost any industry.

Compact power unit

- Compact power units from HYDAC.

Stacking systems

-

Your partner for expertise in innovative hydraulics solutions in machine tools and other applications

The HL Stacking System is an intelligent control logic and forms the hydraulic intellect of your machine. It contains all the relevant controls for auxiliary functions in tools or other machines - structured as a modular system. In combination with our frequency-controlled Compact Unit CO3, this is the perfect complete solution for your machine.

Service instruments

- In a world where efficiency and reliability are paramount, our hydraulic service units offer the perfect solution for your industrial requirements. Our service units guarantee optimum performance and maximum flexibility.

Hydraulic tools

- Whether hydroment presses, quick-stroke units, hydroment or stationary or mobile riveting systems - as your expert in systems technology, we support you in the development, design and construction of hydroment tools in accordance with MRL 2006/42/EC.

Tank sets

-

As a provider of system solutions, HYDAC supplies all the accessories that are needed for the function, enhancement, retrofitting, equipping, optimisation and maintenance and rapid and conclusive installation of fluid power systems.

Scope of delivery:

- Tank (alum.)

- Feet for the tank (alum.)

- End cap seal

- End cap prepared for return line filter, breather filter and bell housing

- Return line filter RF

- Breather filter BFP

- Complete screw set for mounting all supplied components

Available sizes from 6.5 l to 70 l.

Hydraulic trainer

- The Hydraulic Trainer was designed for training and education purposes. It consists of components from the HYDAC product line, each one an industry model. The device features a coordinated overall concept, including a variety of training tasks.

It comes with a choice of the following packages:- Hydraulic package

- Electro-hydraulic package

- Proportional technology package

- Measurement technology package

- Digital package

Oil seperation units

- The OLSW series of our oil separator units were specially developed for offline use. They make it possible to remove unbound foreign oils and free mineral oils effectively from aqueous cleaning fluids. Using this series will enable you to protect your hydraulic systems from premature wear while reducing your consumption of operating media.

Nitrogen charging units

- Our nitrogen charging unit programme (N2 Server) encompasses mobile – portable and wheeled – and also stationary device types. They are used for the loading of accumulators, for supplementing the gas charging pressure and/or for the charging accumulator stations.

Actuators

- Hydraulic actuators combine the advantages of electricity and hydraulics. Consisting of a hydraulic power unit, work cylinder and position control, they provide precise positioning at high adjustment speeds and actuating forces.

Gas extraction

- Our Gas Separation Units GSU are special air separation systems that generate nitrogen from a compressed air supply, achieving N2 concentrations of up to 99.5%.

Electromobility

- In order not to pollute the environment with exhaust fumes, combustion engines are not used. Instead, an electro-hydraulic drive unit is used, which is connected to the local power supply.

High pressure hydraulics components

- BIERI high pressure hydraulics components include pumps as axial or radial units and valves of all types, suitable for pressures of up to 1000 bar and displacement volumes of up to 62.7 cm3/rev. or flow rates up to 32 l/min, and the corresponding accessories.

Pumps

- The BIERI line of pumps consists of axial piston pumps, radial piston pumps, pump combinations (combination of high-pressure radial piston pumps with low-pressure gear pump or radial piston design), multi-outlet radial piston pumps and ATEX-certified radial piston pumps. BIERI pumps are suitable for a wide range of pressures and delivery rates.

Valves

- The Bieri valve range includes linear-position, pressure, flow and check valves, suitable for pressures of up to 1000 bar and flow rates of up to 63 l/min, and the corresponding accessories.

Pressure and level switches

- BIERI pressure and level switches are robust valves, suitable for pressures of up to 1000 bar.

Software Platform Match